Preparation method of two-dimensional flaky porous composite oxide and application of two-dimensional flaky porous composite oxide in control of chlorine-containing volatile organic pollutants

A composite oxide and sheet-like technology, applied in the field of air pollution control, can solve the problems of large energy consumption, achieve high stability and chlorine resistance, excellent oxidation ability of chlorine-containing volatile organic compounds and dechlorination ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

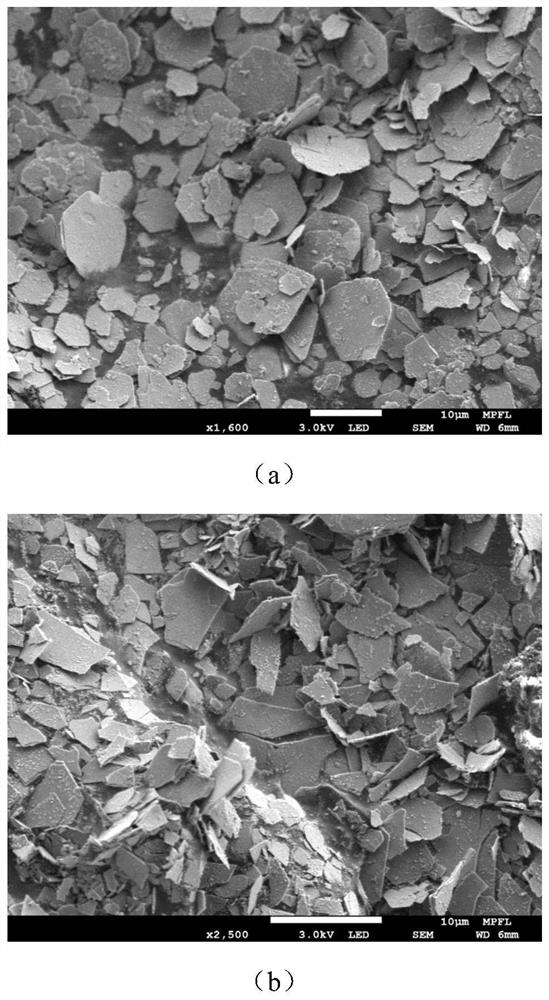

[0037]Example 1 A bifunctional multi-effect cobalt zinc oxide was prepared by the in situ crystallization method.

[0038]0.045 mol of dimethylimidazole was completely dissolved in 100 mL of anhydrous methanol, and stirred at 500 rpm to stir for 10 min, forming a colorless clear and transparent solution A; 0.045 mol of hexahydrate is completely dissolved in 100 mL of anhydrous methanol The mixture was stirred at 500 rpm for 20 min, and a colorless clear and clear solution B was formed. The B solution was gradually added to A. The mixture was mixed and stirred at 600 rpm to stir up to 200RMP stir until the solution exhibits white. The white solution was then allowed to stand 48 h, and the mixture was filtered, washed three times with anhydrous ethanol and deionized water, and dried under 60 ° C; 0.2 g of the prepared white powder was ground into thin powder, and 30 ml of deion In the water, the solution was ultrasound using an ultrasonic instrument until the white powder is completely u...

Embodiment 2

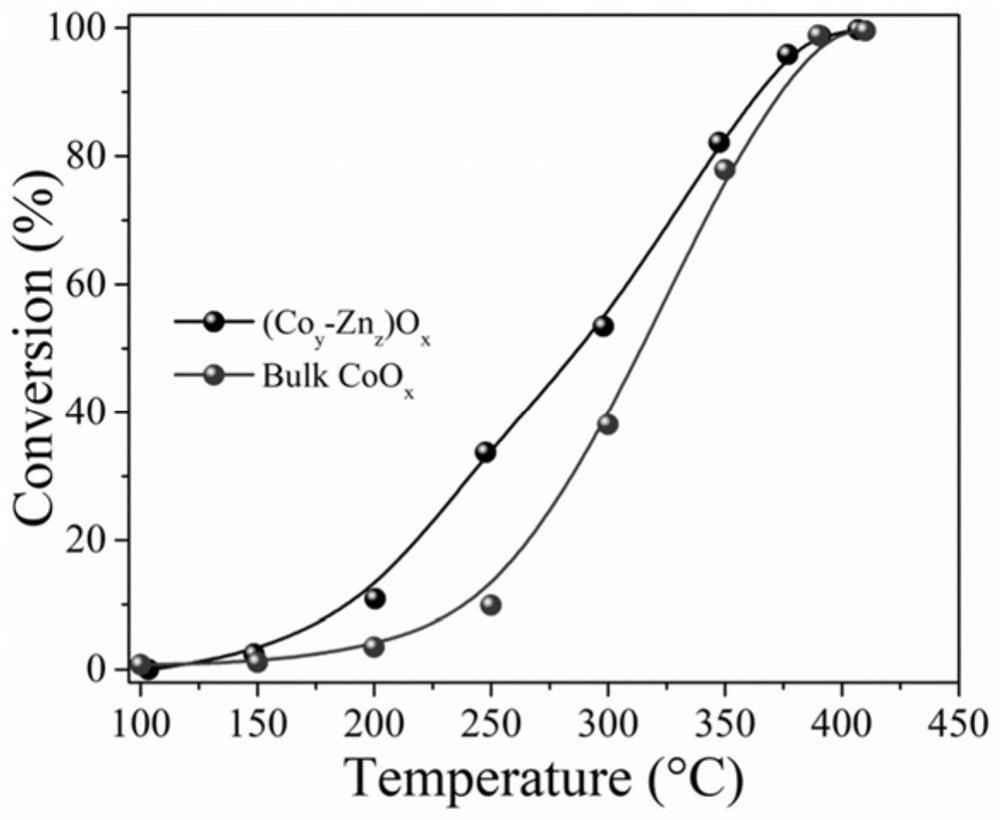

[0039]Example 2 Catalytic Test and Evaluation of Catalyzed 1,2-Dichloroethane by Cobalt Zinc Composite Metal Catalytic Material

[0040]Take the solid powder tables obtained in Example 1, a sieve (40-60 mesh), and accurately weigh 0.5 g of sieved catalytic material at 1,2-dichloroethane as a probe gas, reactant The concentration was controlled at 1000 ppm, the reaction vacancy was 36000 ml / g · h, and the oxygen concentration was 21%, and the catalyst was tested at different temperatures (100 ° C, 150 ° C, 200 ° C, 250 ° C, 300 ° C, 350 ° C, 380 ° C and The catalytic reaction activity of 400 ° C was 400 ° C, and the reaction product was monitored by gas chromatography.

Embodiment 3

[0041]Example 3 Catalytic Test of Catalytic Degradation of 1,2-Dichloroethane Catalyzed

[0042]Take the solid powder table obtained in Example 1, exemplify the sieve (40-60 mesh), accurately weigh 0.5 g of sieved catalytic material and placed in a fixed bed of the evaluation device, with 1,2-dichloroethism The alkane is a probe gas, the concentration of the reactants is controlled at 1000 ppm, and the reaction is air speed is 36000 h.-1The oxygen concentration is 21%, the catalytic reaction activity of the continuous test catalyst at 370 ° C, and the reaction product is analyzed by gas chromatography.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com