Nuclear waste gas all-oxidation combustion treatment device

A treatment device and waste gas technology, applied in the direction of gas fuel burners, burners, combustion types, etc., can solve the conditions that the tail gas does not have direct discharge, cannot realize the precise control of the flame temperature and waste gas residence time, and cannot adapt to nuclear waste gas Incineration requirements and other issues to achieve the effect of improving treatment efficiency and prolonging burning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

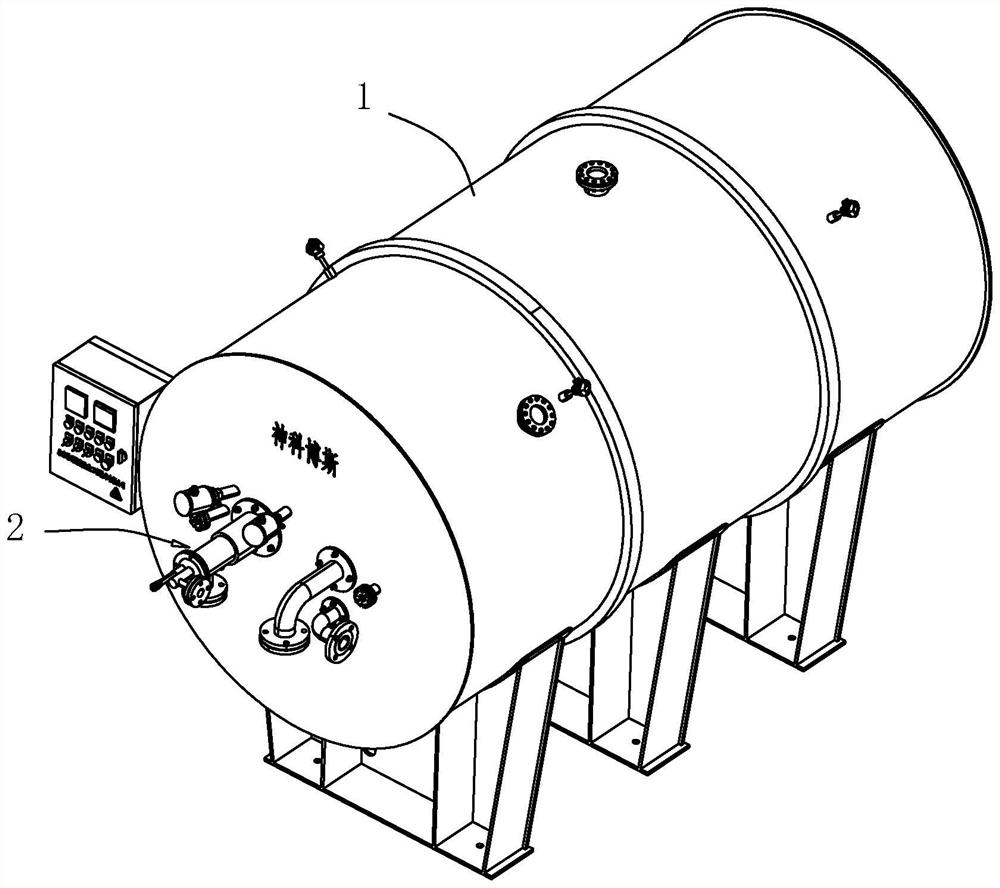

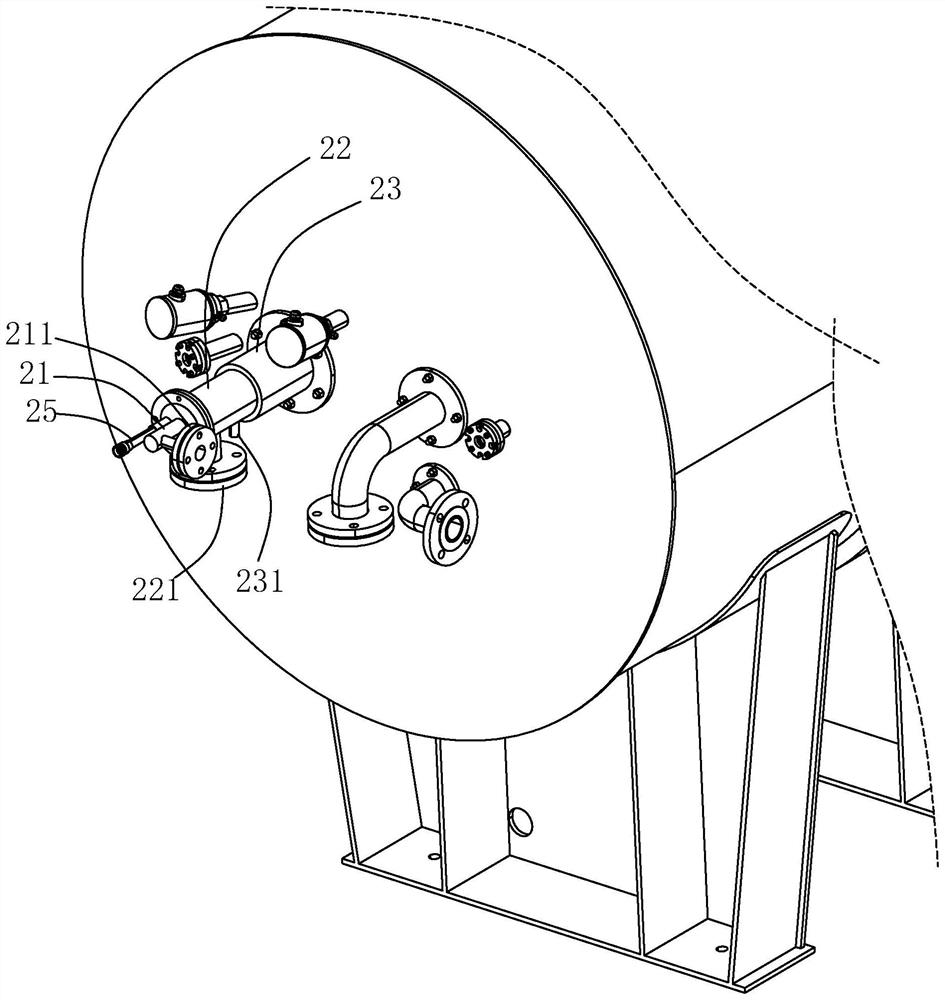

[0035] Embodiment 1: A nuclear waste gas total oxidation combustion treatment device, such as figure 1 As shown, it includes an incinerator 1 and an ultra-low nitrogen strong swirl high-speed burner 2 installed at one end of the incinerator 1 .

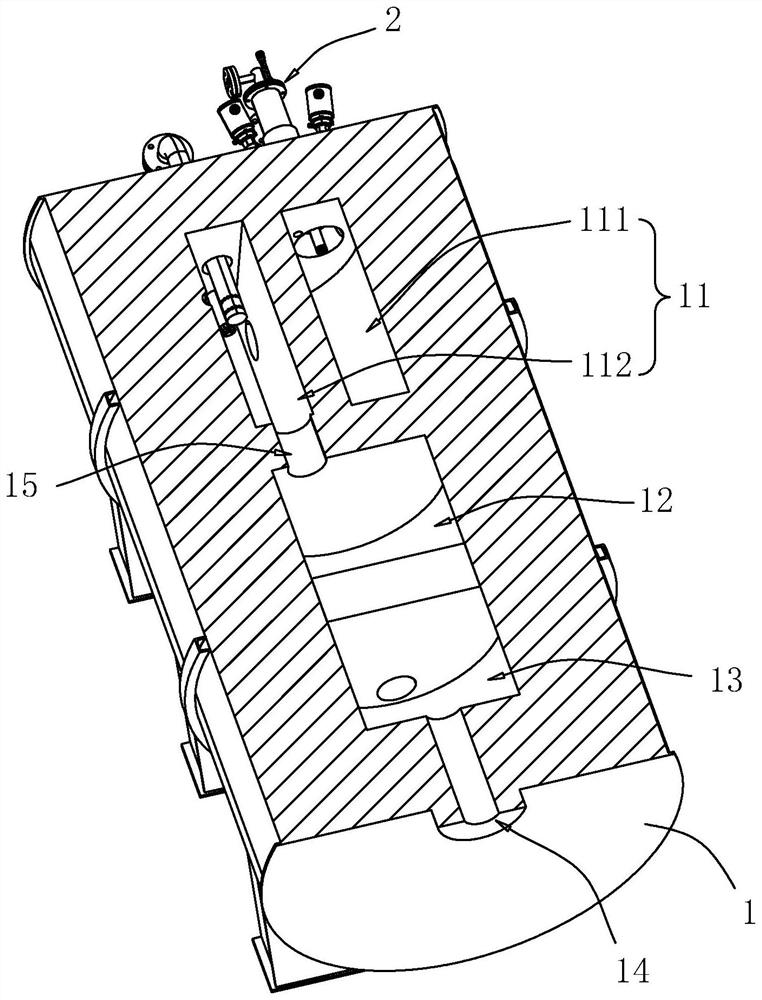

[0036] Such as figure 2 As shown, the incinerator 1 includes a front-stage combustion chamber 11, a middle-stage combustion chamber 12, and a final-stage combustion chamber 13, which are located on one side of the ultra-low nitrogen strong swirl high-speed burner 2 and are distributed sequentially toward the other end of the incinerator 1. The outer wall of the incinerator 1 There is also an exhaust port 14 communicating with the final combustion chamber 13 on the top. Wherein, the front combustion chamber 11 includes a primary flame combustion chamber 111 and a secondary mixing combustion chamber 112 . The primary flame combustion chamber 111 , the secondary mixing combustion chamber 112 , the middle combustion chamber 12 , and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com