CO low-temperature catalytic oxidation catalyst, and preparation method and application thereof

An oxidation catalyst, low temperature catalysis technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as fuel cell performance degradation and achieve good stability , the preparation method is simple, and the effect of improving the catalytic oxidation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

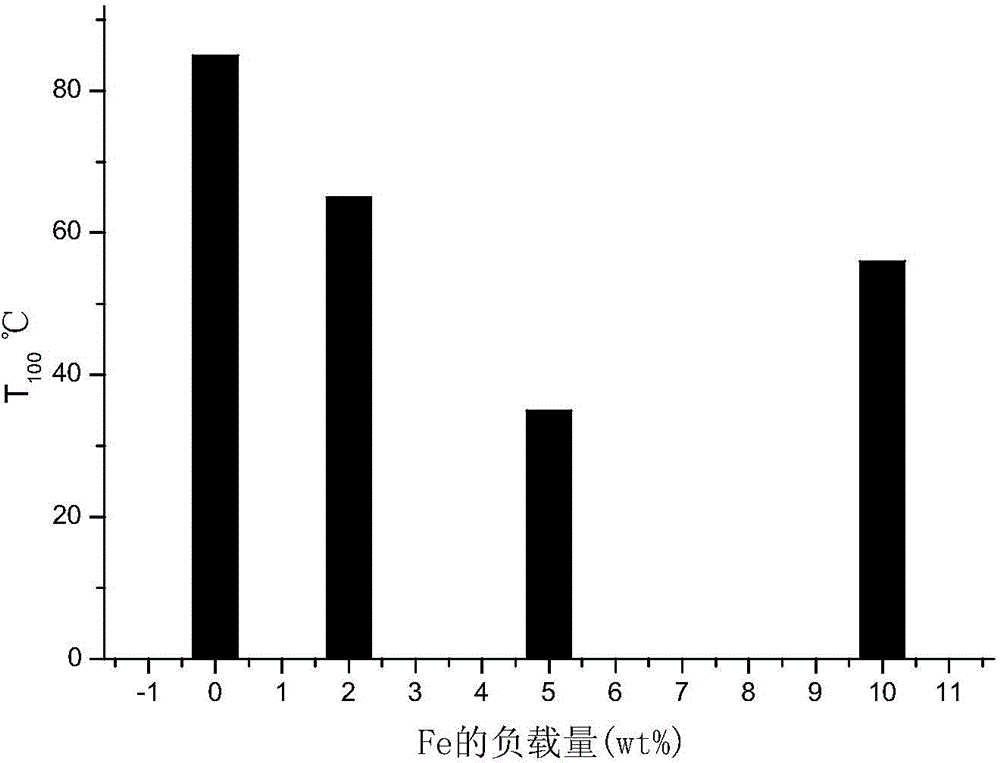

[0028] Add 0.26g of ferric nitrate to 60mL of TEG to form a mixed solution, then heat the mixed solution to 250°C under the protection of an inert gas, and cool naturally to obtain a solution containing Fe. 3 o 4 TEG solution of nanoparticles; 3 o 4 Add 0.026g chloroplatinic acid to the TEG solution of nanoparticles, stir for 2h, pass H 2 Reduction for 1h to obtain Pt-Fe 3 o 4 The solution of combination type nanoparticle; The Pt-Fe 3 o 4 A solution of combined nanoparticles with 1 g TiO 2 Mixing, magnetic stirring makes Pt-Fe 3 o 4 Combined nanoparticles are completely adsorbed on TiO 2 surface, filtered, washed, dried, and calcined at 250°C for 2 hours to obtain Pt-Fe 3 o 4 / TiO 2 The catalyst is the CO low-temperature catalytic oxidation catalyst.

Embodiment 2

[0030] Add 0.26g of ferric nitrate to 60mL of TEG to form a mixed solution, then heat the mixed solution to 250°C under the protection of an inert gas, and cool naturally to obtain a solution containing Fe. 3 o 4 TEG solution of nanoparticles; 3 o 4 Add 0.052 g of chloroplatinic acid to the TEG solution of nanoparticles, stir for 2 h, pass through H 2 Reduction for 1h to obtain Pt-Fe 3 o 4 The solution of combination type nanoparticle; The Pt-Fe 3 o 4 A solution of combined nanoparticles with 1 g TiO 2 Mixing, magnetic stirring makes Pt-Fe 3 o 4 Combined nanoparticles are completely adsorbed on TiO 2 surface, filtered, washed, dried, and calcined at 250°C for 2 hours to obtain Pt-Fe 3 o 4 / TiO 2 The catalyst is the CO low-temperature catalytic oxidation catalyst.

Embodiment 3

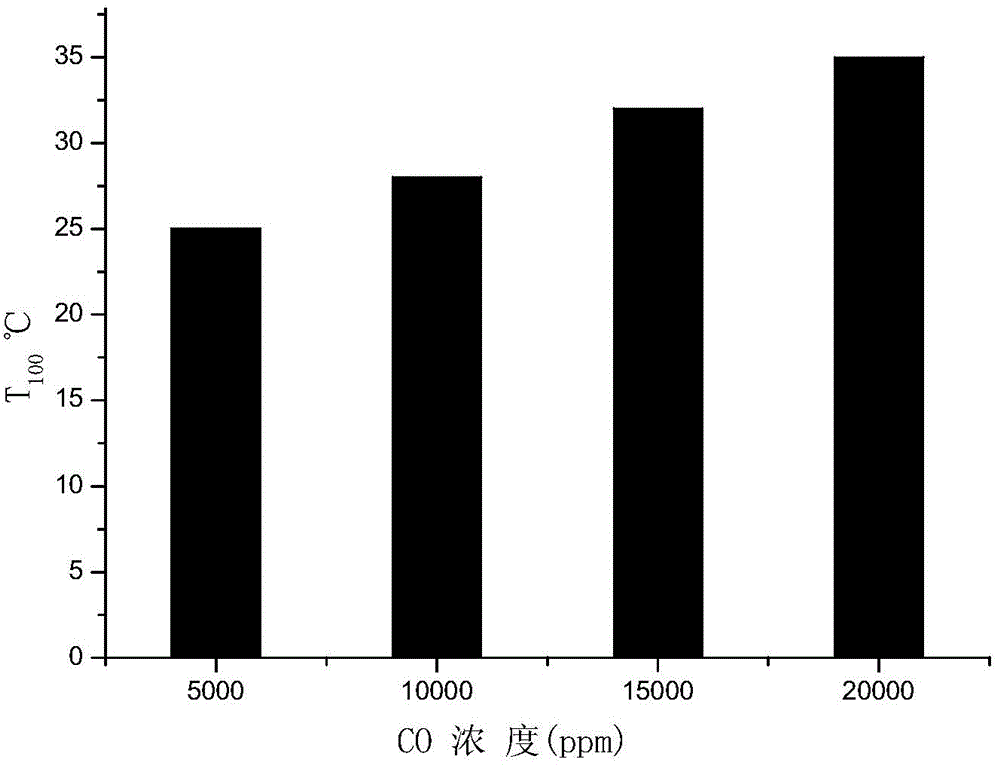

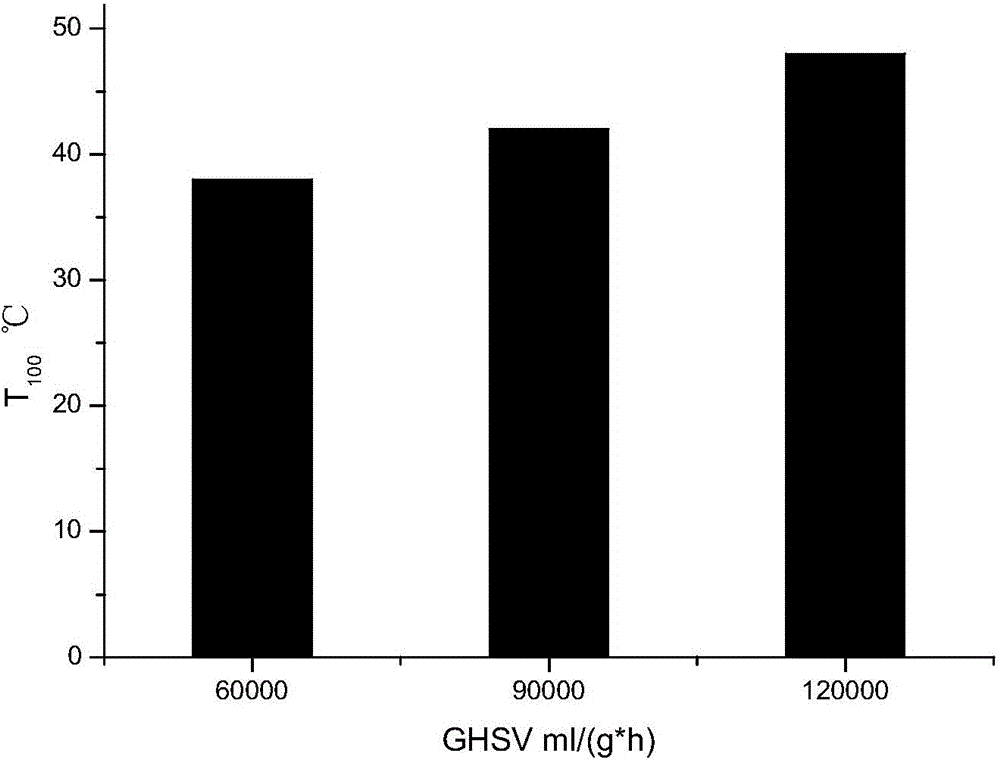

[0035] Take by weighing the Pt-Fe that 0.1g embodiment 2 makes 3 o 4 / TiO 2 The catalyst is placed in a U-shaped quartz tube reactor with an inner diameter of 8 mm, and the gas flow rate is adjusted so that CO:O 2 :N 2 =1:40:160 (volume ratio), wherein the volume concentration of CO is 5000ppm, the reaction space velocity (GHSV) is 60000mL / (g h), the reaction temperature is 25°C, and the CO concentration and products are determined by a CO detector.

[0036] The reaction results showed that the conversion of CO was 100% after passing through the catalyst system at 25 °C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com