Pt/Al2O3 catalyst and application thereof in room-temperature catalytic oxidation of formaldehyde

A catalyst, room temperature technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of high required temperature, inconvenient use, inability to eliminate formaldehyde, etc., achieving good stability, low environmental cost, The effect of good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

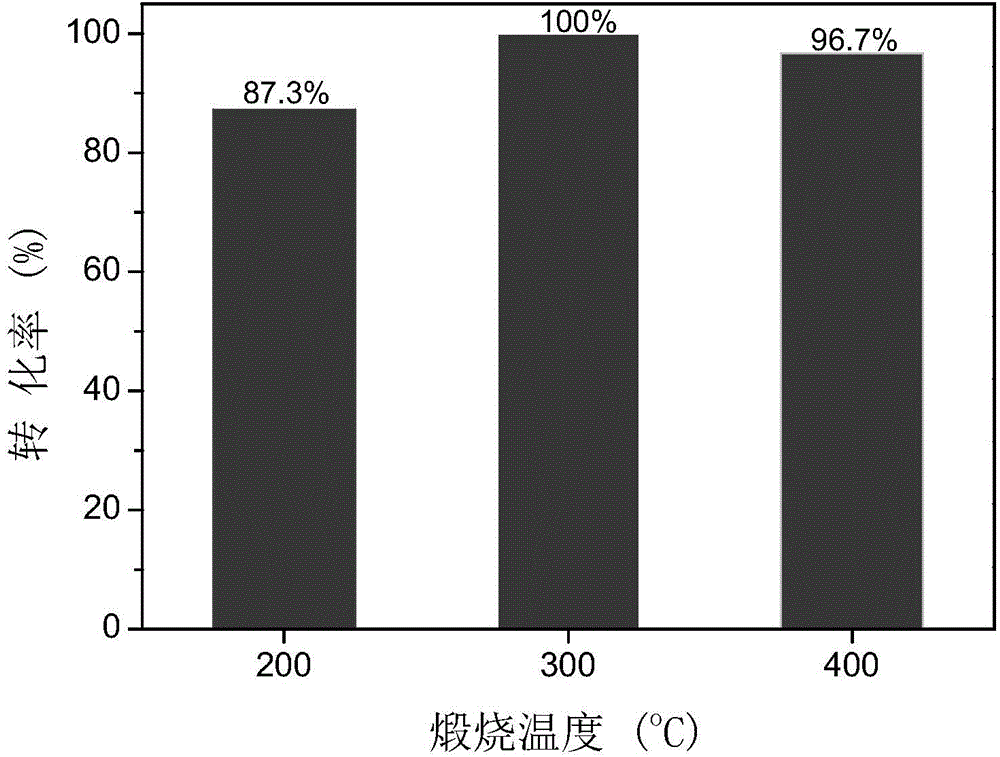

[0026] Prebody 28mg Pt 2 (dba) 3 Add 100ml of propylene carbonate, and react in a stainless steel reactor at a hydrogen pressure of 3.0MPa and room temperature (25°C) for 2 hours to obtain a reaction solution, namely 100ml of a Pt nanoparticle solution; 1.0g of Al 2 o 3 The carrier was added to the obtained Pt nanoparticle solution, stirred overnight under the action of electromagnetic force stirring, filtered, and the filter cake was roasted at 200 ° C for 2 hours to obtain 1% Pt / Al 2 o 3 catalyst.

Embodiment 2

[0028] Prebody 28mg Pt 2 (dba) 3 Add 100ml of propylene carbonate, and react in a stainless steel reactor at a hydrogen pressure of 3.0MPa and room temperature (25°C) for 2 hours to obtain a reaction solution, namely 100ml of a Pt nanoparticle solution; 1.0g of Al 2 o 3 The carrier was added to the obtained Pt nanoparticle solution, stirred overnight under the action of electromagnetic force stirring, filtered, and the filter cake was calcined at 300°C for 2 hours to obtain 1%Pt / Al 2 o 3 catalyst.

Embodiment 3

[0030] Prebody 28mg Pt 2 (dba) 3 Add 100ml of propylene carbonate, and react in a stainless steel reactor at a hydrogen pressure of 3.0MPa and room temperature (25°C) for 2 hours to obtain a reaction solution, namely 100ml of a Pt nanoparticle solution; 1.0g of Al 2 o 3The carrier was added to the obtained Pt nanoparticle solution, stirred overnight under the action of electromagnetic force stirring, filtered, and the filter cake was calcined at 400°C for 2 hours to obtain 1%Pt / Al 2 o 3 catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com