Hydrodynamic ultrasonic cavitation and advanced oxidation coupled degradation device for sulfide wastewater

An advanced oxidation and sulfide technology, which is applied in the fields of water/sewage multi-stage treatment, special compound water treatment, water/sewage treatment, etc. , the problem of unclear hydraulic cavitation device, etc., to achieve the effect of efficient and environmentally friendly degradation process, large processing capacity, and improved cavitation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

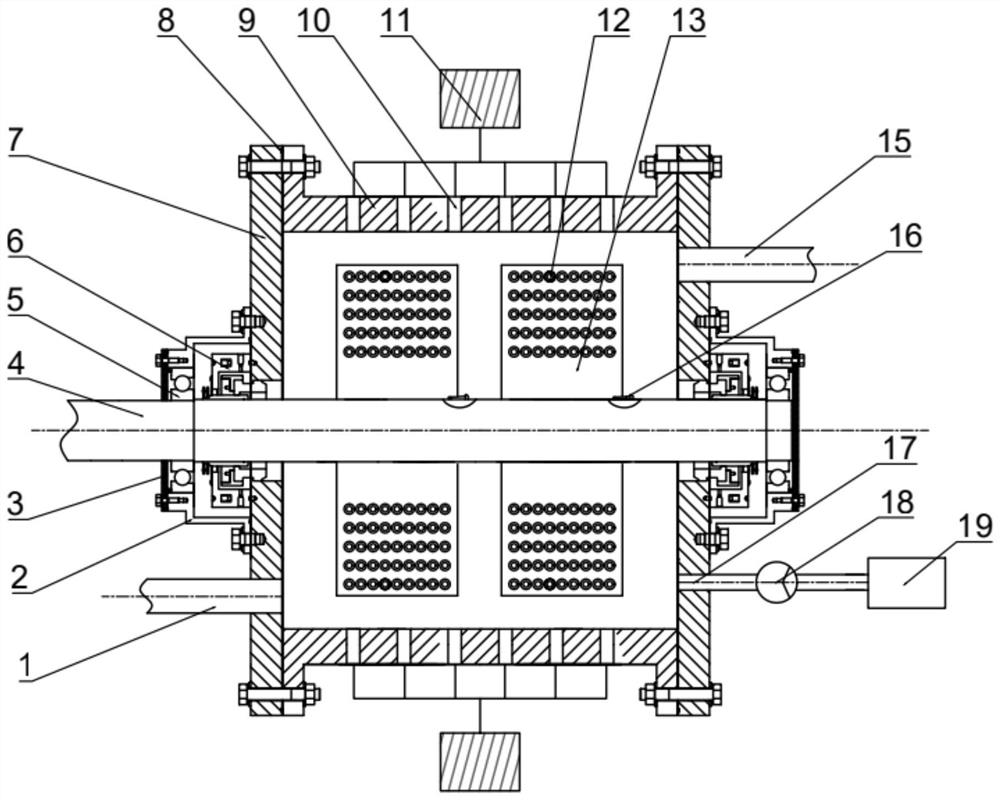

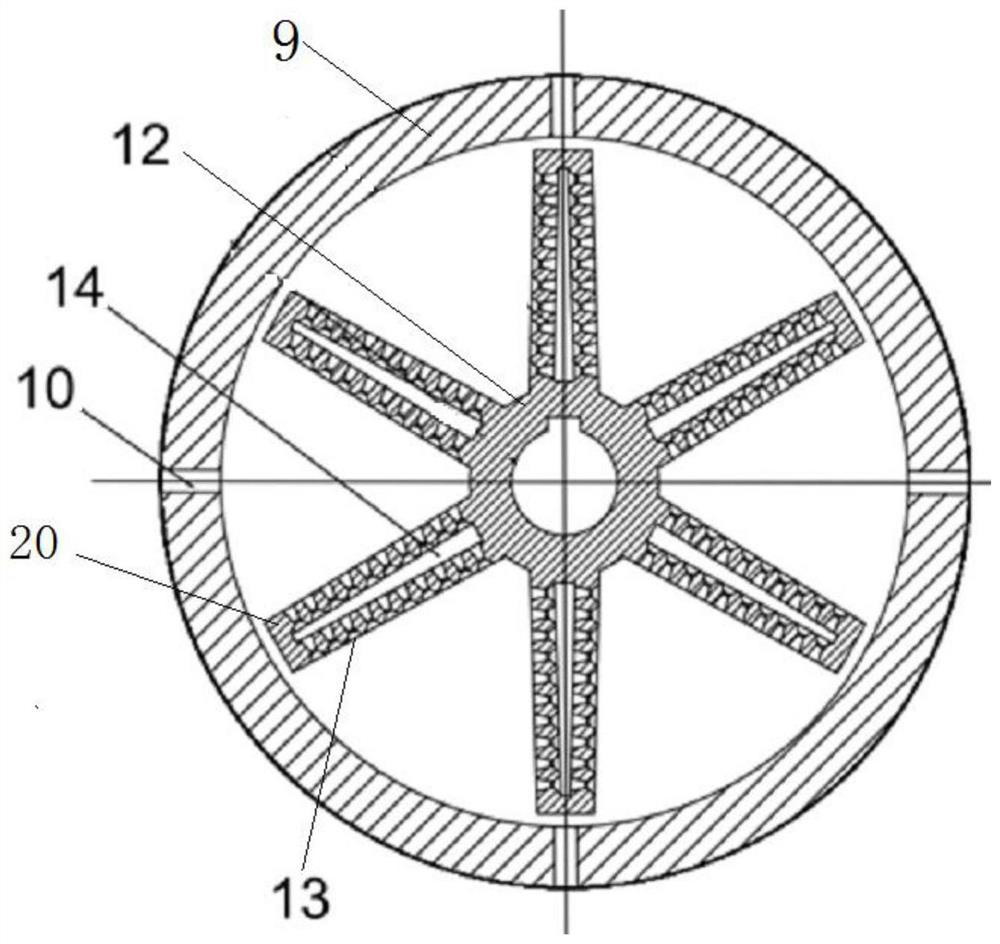

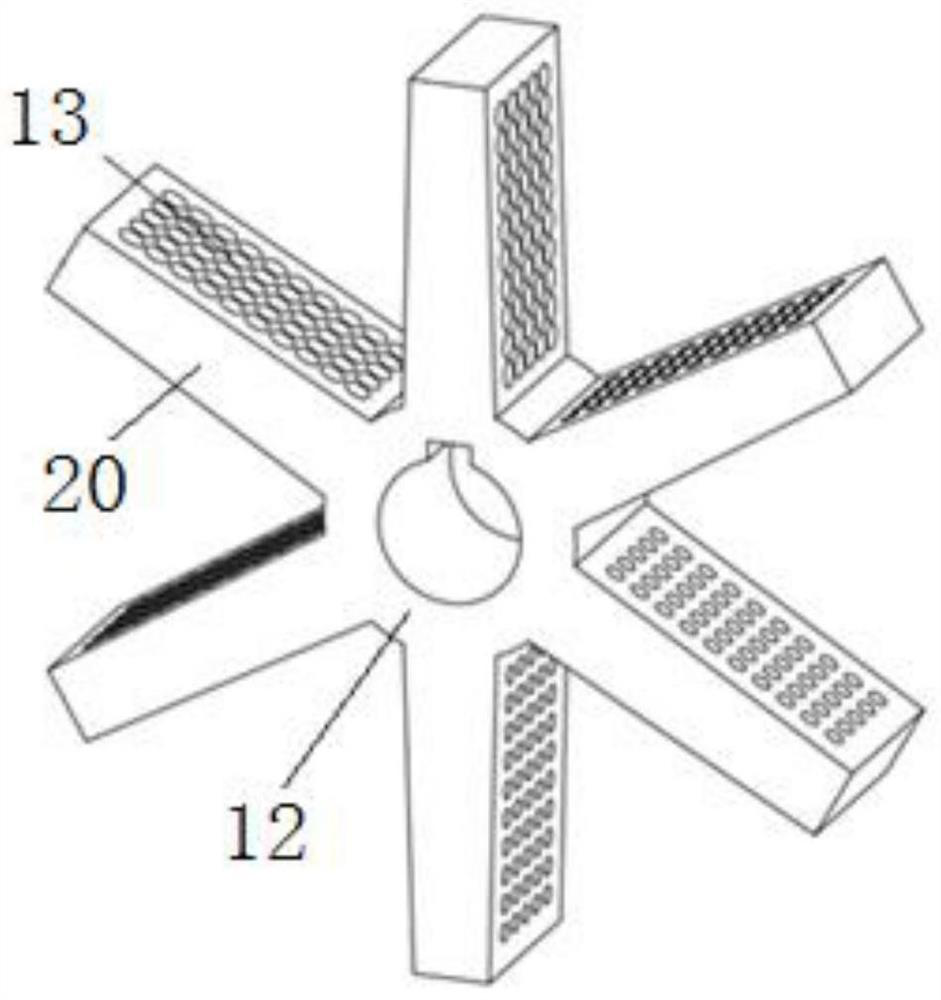

[0052] The hydraulic ultrasonic cavitation and advanced oxidation coupled degradation device for sulfide wastewater of the present invention, such as figure 1 and figure 2 As shown, it includes a stator 9, a rotor 12, a rotating shaft 4, an ultrasonic transducer 10 and an oxidant injection device, and the stator 9 is connected to the oxidant injection device. The oxidant injection device includes an oxidant delivery pipe 17, an oxidant pump 18 and an ozone generator 19 (oxidant tank) connected in sequence.

[0053] The stator 9 is a cavity sealed cylinder, the inner diameter of the stator is 300-600 mm, the width of the stator is 200-500 mm, and the wall thickness is 15-30 mm. Both ends of the stator are connected to the stator end cover 7 by bolts, and there is a sealing washer 8 at the connection, so that a sealed cavity is formed inside the stator 9 . An angular contact ball bearing 5 is arranged inside the stator end cover 7, and a sealing cover 2 is arranged outside. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com