Anti-propylene mask and preparation method thereof

A mask and propylene technology, applied in the field of health and safety protection, can solve the problems of unsuitable human safety protection, inconvenient use, large equipment, etc., and achieve the effects of stable elimination effect, protection of propylene poisoning, and prevention of accidents caused by static electricity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

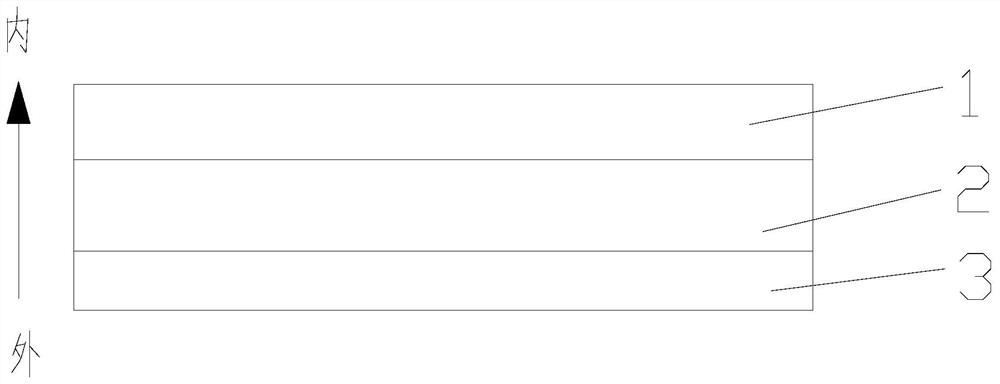

Image

Examples

Embodiment 1

[0040]Embodiment 1 Preparation of fullerene / nano-titanium dioxide spunbond layer

[0041] This example provides a fullerene / nano-titanium dioxide spunbond layer, which is made by spinning the modified resin material into a fiber web by the spunbond method. In terms of parts by mass, the raw material of the modified resin material includes carboxyl 5 parts of fullerene derivatives, 15 parts of nano-titanium dioxide, 79.925 parts of polyethylene terephthalate (PET), 0.0525 parts of lubricant, and 0.0225 parts of coupling agent.

[0042] Its preparation method is:

[0043] (1) Weigh carboxylated fullerene derivatives and nano-titanium dioxide according to the formula; then put the carboxylated fullerene derivatives and nano-titanium dioxide into absolute ethanol (mass fraction is 3%). Form a mixed solution under ultrasonic conditions; then put the obtained mixed solution in a reaction kettle at 100°C for 12 hours; cool to obtain a reaction mixed solution;

[0044] (2) The react...

Embodiment 2

[0049] Embodiment 2 Preparation of fullerene / nano-titanium dioxide spunbond layer

[0050] This example provides a fullerene / nano-titanium dioxide spunbond layer, which is made by spinning the modified resin material into a fiber web by the spunbond method. In terms of parts by mass, the raw material of the modified resin material includes carboxyl 7 parts of fullerene derivatives, 20 parts of nano-titanium dioxide, 72.9 parts of polyethylene terephthalate (PET), 0.07 parts of lubricant, and 0.03 parts of coupling agent.

[0051] Its preparation method is:

[0052] (1) Weigh the carboxylated fullerene derivative and nano-titanium dioxide according to the formula; then put the carboxylated fullerene derivative and nano-titanium dioxide into absolute ethanol (3% by mass fraction) , form a mixed solution under ultrasonic conditions; then put the obtained mixed solution in a reaction kettle at 100° C. for 12 hours; cool to obtain a reaction mixed solution;

[0053] (2) The react...

Embodiment 3

[0058] Example 3 Preparation of fullerene / nano-titanium dioxide spunbond layer

[0059] This example provides a fullerene / nano-titanium dioxide spunbond layer, which is made by spinning the modified resin material into a fiber web by the spunbond method. In terms of parts by mass, the raw material of the modified resin material includes carboxyl 8 parts of fullerene derivatives, 24 parts of nano-titanium dioxide, 67.88 parts of polyethylene terephthalate (PET), 0.084 parts of lubricant, and 0.036 parts of coupling agent.

[0060] Its preparation method is:

[0061] (1) Weigh the carboxylated fullerene derivative and nano-titanium dioxide according to the formula; then put the carboxylated fullerene derivative and nano-titanium dioxide into absolute ethanol (3% by mass fraction) , form a mixed solution under ultrasonic conditions; then put the obtained mixed solution in a reaction kettle at 100° C. for 12 hours; cool to obtain a reaction mixed solution;

[0062] (2) The react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com