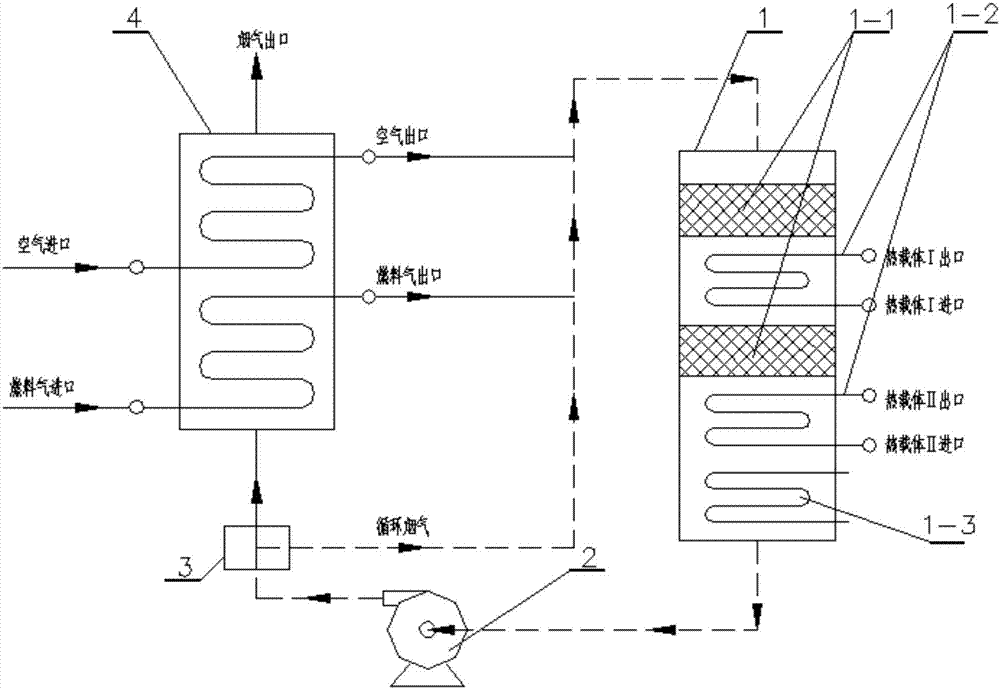

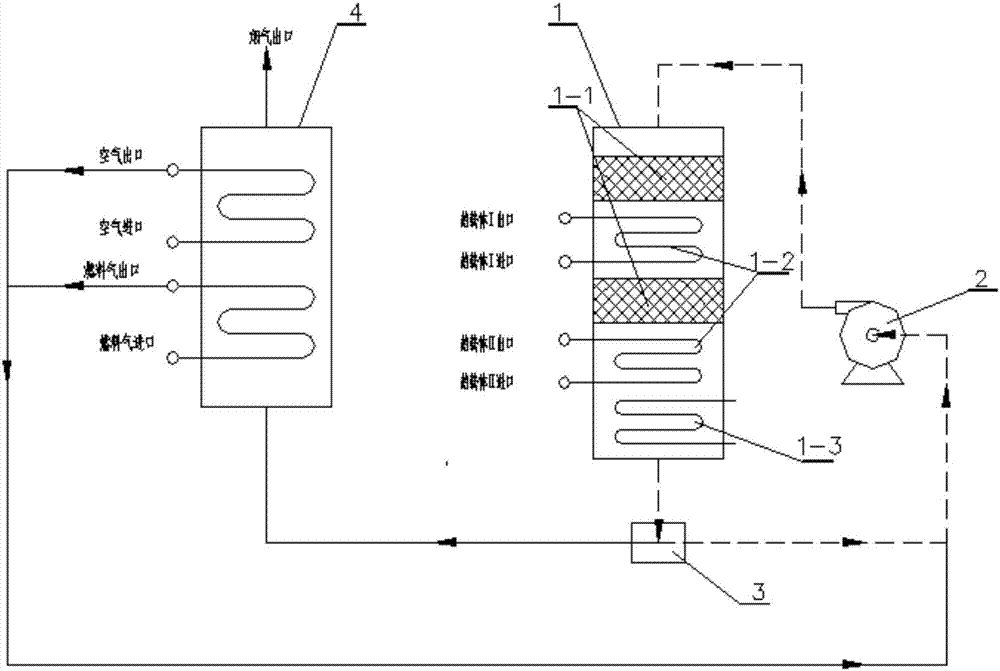

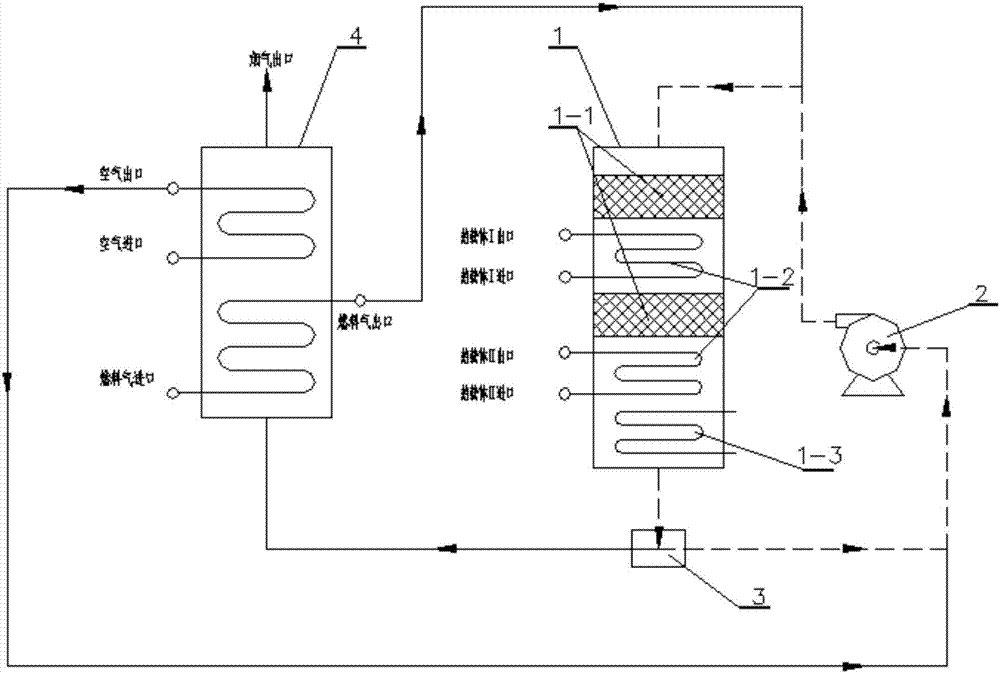

Catalytic combustion heating system and heating technology

A catalytic combustion and heating system technology, applied in the direction of combustion method, combustion type, lighting and heating equipment, etc., can solve the problems of increased floor area and large floor area of heat transfer oil system, so as to improve the utilization rate of heat energy, Ease of heat recovery and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 100Nm 3 / h Methanol Steam Reforming Hydrogen Production Heat Transfer Oil Heating System

[0036] 100Nm 3 / h Methanol steam hydrogen production in the raw material methanol and desalted water vaporization superheating and conversion reaction requires heat, the total heat required is 103kw, the heating carrier is No. 320 heat transfer oil, the temperature of the heat transfer oil entering and leaving the methanol hydrogen production device is 270 °C and 260 °C respectively ℃. In the process of hydrogen purification, tail gas emission is 57Nm3 / h tail gas (hydrogen yield 85%), and the gas composition is H 2 : 30.6%, CO: 1.7%, CO 2 : 67.1%, CH 4 : 0.4% and saturated water. With increasingly stringent environmental protection requirements, the tail gas must be treated before being discharged.

[0037] The methanol water steam reforming heat conduction oil heat supply system adopting the technology of the present invention uses methanol as the supplementary fuel and Pt / ...

Embodiment 2

[0041] 1200Nm 3 / h Methanol Steam Reforming Hydrogen Production Heat Transfer Oil Heating System

[0042] 1200Nm 3 / h methanol and desalted water vaporization superheating and conversion reaction of raw material methanol and water vapor hydrogen production require heat, the total heat required is 1212kw, the heating carrier is No. 320 heat transfer oil, and the temperature of the heat transfer oil entering and exiting the methanol hydrogen production device is 270°C and 260°C . Tail gas emission during hydrogen purification process is 647Nm 3 / h tail gas (hydrogen yield 87%), the gas composition is H 2 : 27.7%, CO: 1.8%, CO 2 : 69.8%, CH 4 : 0.4% and saturated water.

[0043] The methanol water vapor reforming heat conduction oil heat supply system adopting the technology of the present invention uses methanol as the supplementary fuel and Pd / Al as the catalyst 2 o 3 The catalyst and catalyst carrier adopt ceramic honeycomb blocks, which can reduce the resistance drop ...

Embodiment 3

[0047] 10t / h medium pressure steam heating system

[0048] Exhaust gas from a chemical plant is about 3500Nm 3 / h, the gas composition is H 2 : 31%, CO: 3.5%, CH 4 : 12.5%, CO 2 :30% :N 2 : 21%, C 2+ : 2%, generally enters the flare system and empties after combustion. And the public works medium pressure steam of factory area is short of all the time, the medium pressure steam that adopts the system of the present invention intends to produce 10t / h is used as the public works supplementary steam of factory area. The catalyst is Pd / Al 2 o 3 The catalyst and catalyst carrier adopt honeycomb block shape, which can reduce the resistance drop of the system and save the power consumption of the circulation device. Due to the exhaust gas has a certain back pressure, the system adopts figure 1 In the process shown, the heat exchange coil adopts two layers, the high temperature side is the steam generation coil, and the bottom is the boiler feed water preheating coil. Since ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com