Bituminous pavement crack maintenance and repair device

A technology for asphalt pavement and equipment, which is applied in the field of asphalt pavement crack maintenance and repair equipment, can solve the problems of inconvenient storage of asphalt concrete raw materials, inconvenient cleaning of foundation pit sandstone, and inflexible operation, so as to improve cleaning efficiency and repair effect, Easy to move and operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

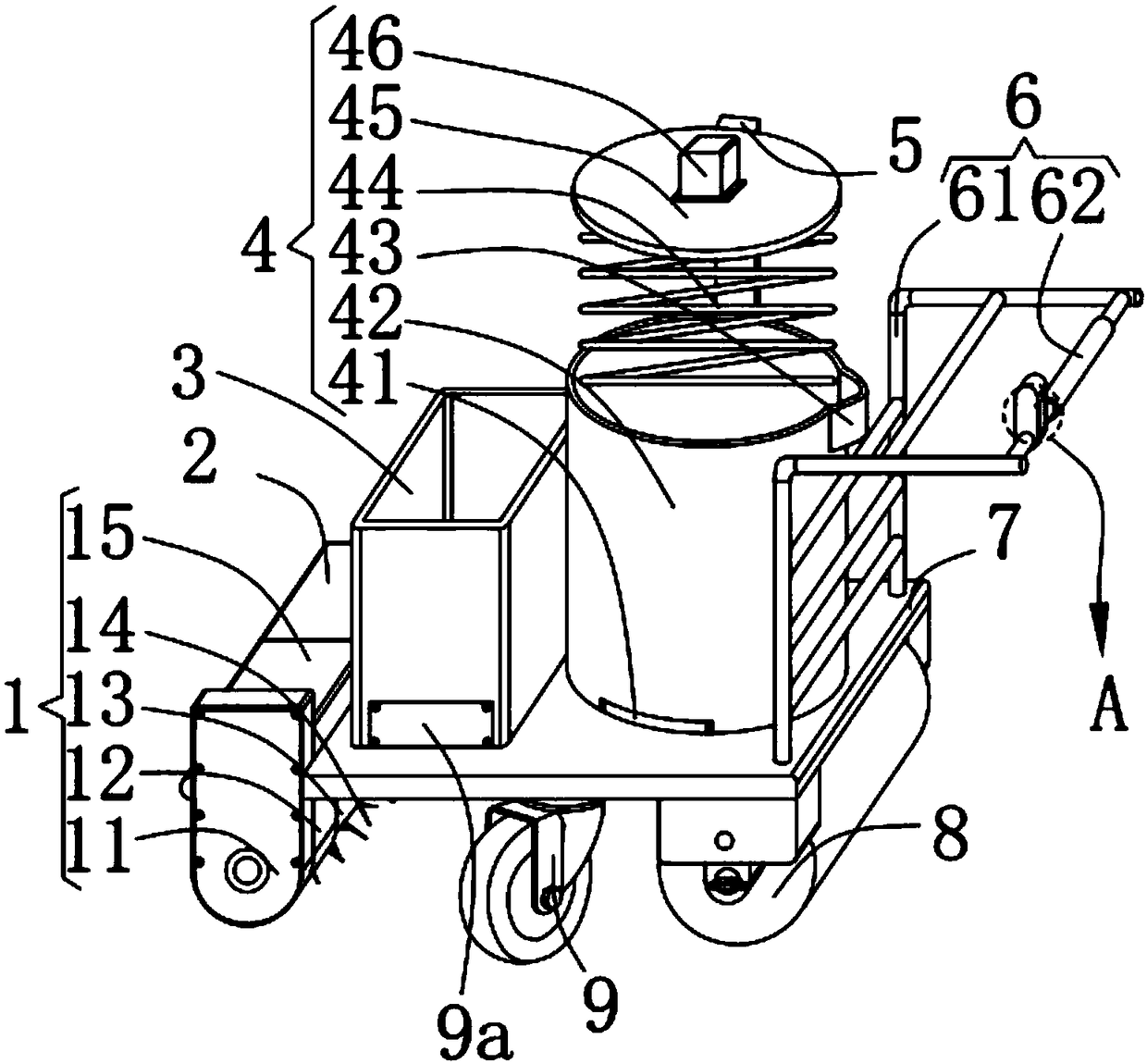

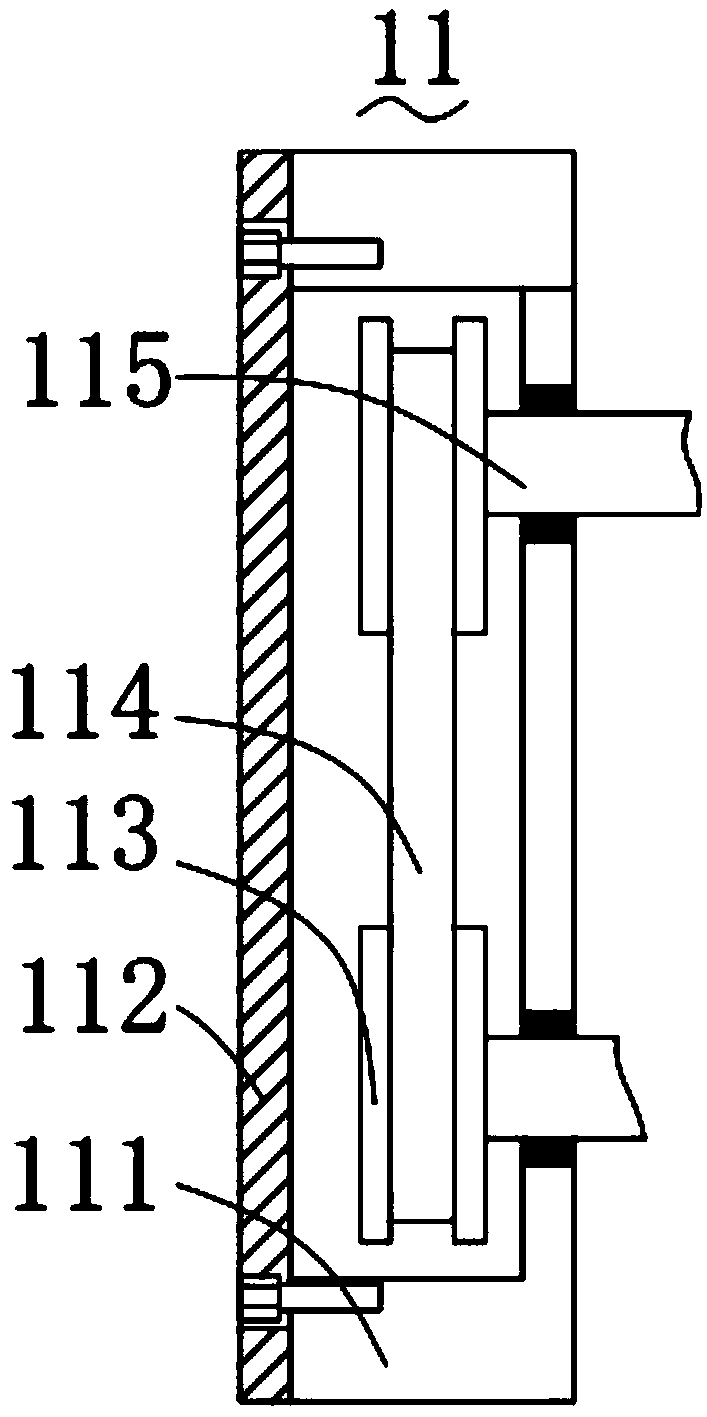

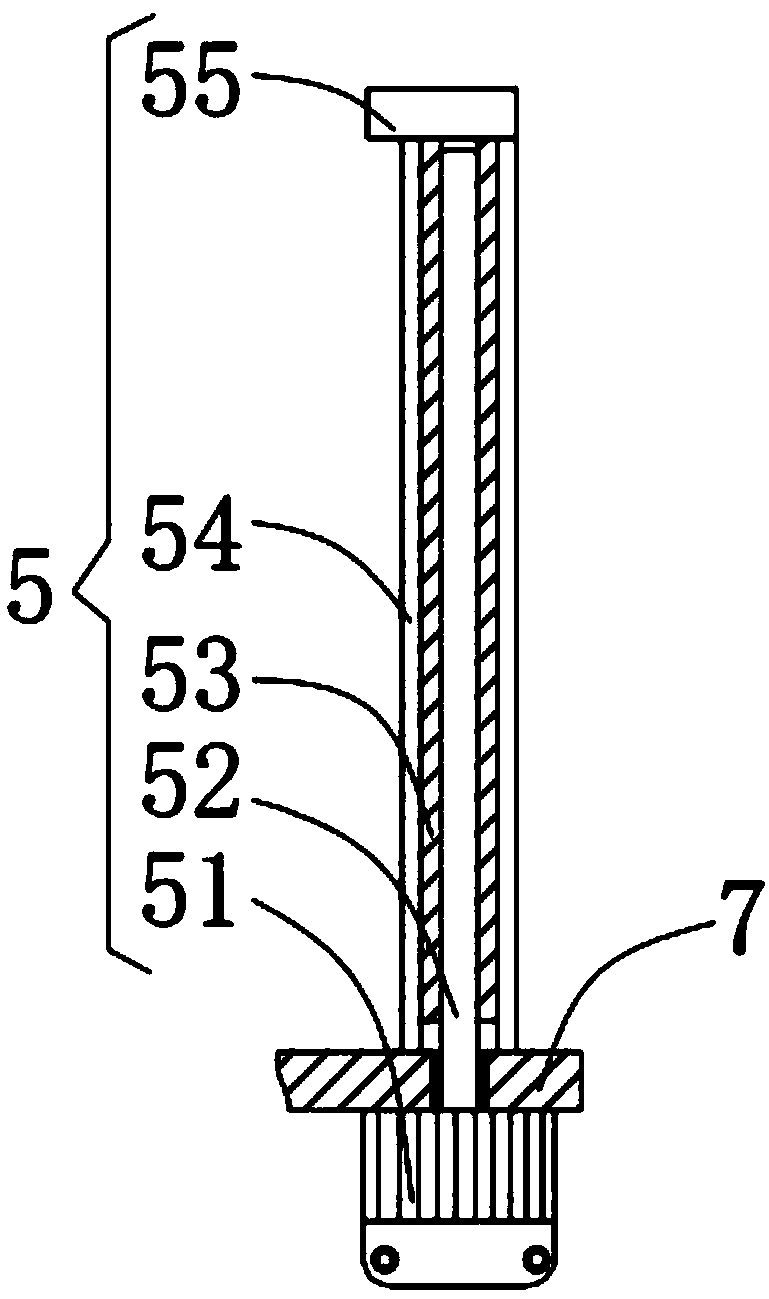

[0037] Such as figure 1 and Figure 4 As shown, an asphalt pavement crack maintenance and repair equipment according to Embodiment 1 of the present invention includes a grinding structure 1, a battery 2, a waste collection box 3, a stirring structure 4, a driving structure 5, a pulling structure 6, and a bottom plate 7 , a rolling structure 8, a universal wheel 9, a fan 9a and a junction box 9b; the bottom end of the bottom plate 7 is provided with the universal wheel 9, and one end of the bottom plate 7 is provided with the grinding structure 1, and The milling structure 1 and the storage battery 2 are arranged at the same end of the bottom plate 7; the top of the bottom plate 7 is provided with the waste collection box 3, and the waste collection box 3 and the stirring structure 4 are arranged at The same side of the base plate 7, and the fan 9a is arranged between the waste collection box 3 and the base plate 7; one end of the drive structure 5 is connected to the base pla...

Embodiment 2

[0047] Such as figure 1 and Figure 4 As shown, an asphalt pavement crack maintenance and repair equipment according to the second embodiment of the present invention includes a grinding structure 1, a storage battery 2, a waste collection box 3, a stirring structure 4, a driving structure 5, a pulling structure 6, and a bottom plate 7 , a rolling structure 8, a universal wheel 9, a fan 9a and a junction box 9b; the bottom end of the bottom plate 7 is provided with the universal wheel 9, and one end of the bottom plate 7 is provided with the grinding structure 1, and The milling structure 1 and the storage battery 2 are arranged at the same end of the bottom plate 7; the top of the bottom plate 7 is provided with the waste collection box 3, and the waste collection box 3 and the stirring structure 4 are arranged at The same side of the base plate 7, and the fan 9a is arranged between the waste collection box 3 and the base plate 7; one end of the drive structure 5 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com