Modified road asphalt and preparation method thereof

A road asphalt and modification technology, applied in building components, building insulation materials, buildings, etc., can solve the problems of poor high temperature resistance, high SBS seepage, poor waterproofness, etc., and achieve enhanced heat storage performance and temperature resistance. , Prevent road cracking and enhance the effect of firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

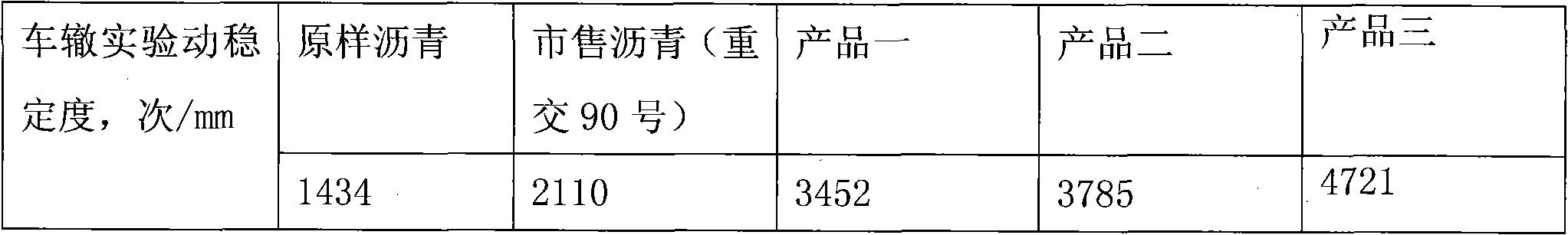

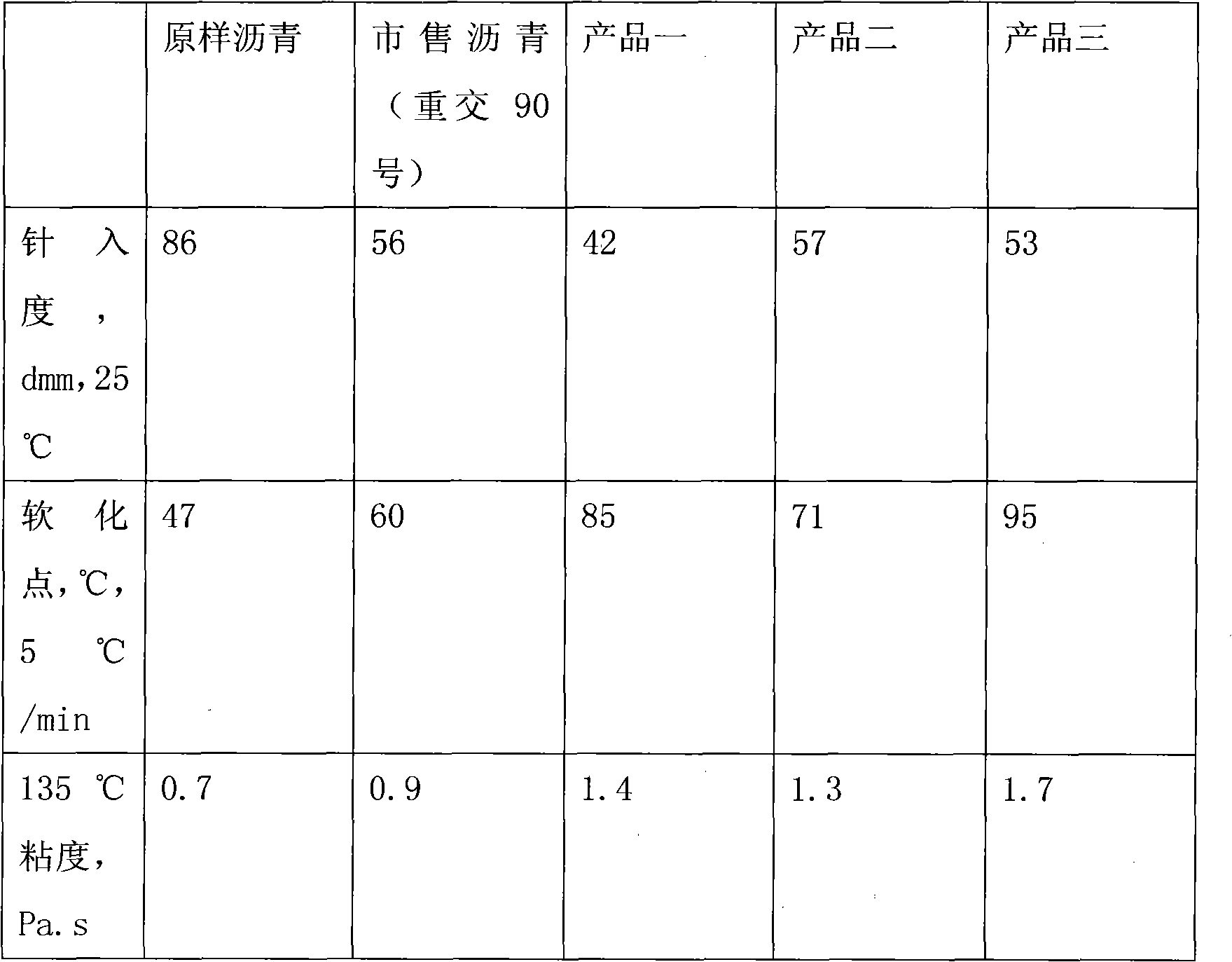

[0014] In the reaction tank, first heat 80kg of asphalt to 110°C until it is dissolved and flowable, then add 15kg of SBS, 1kg of waste tire rubber powder and 3.5kg of polyethylene glycol into the asphalt, stir and mix for 2 hours, after uniform mixing, add Sulfur 0.5kg, continue to stir, after above-mentioned mixed material mixes evenly, stop stirring, place 2 hours at 150 ℃, make cross-linking reaction complete, then cool down, obtain the modified road asphalt product 1 of the present invention.

Embodiment 2

[0016] In the reaction tank, first heat 85kg of asphalt to 130°C until it is dissolved and flowable, then add 10kg of SBS, 0.5kg of waste tire rubber powder and 4kg of polyethylene glycol into the asphalt, stir and mix for 2 hours, after uniform mixing, add Sulfur 0.5kg, continue to stir, after above-mentioned mixed material mixes evenly, stop stirring, place 2 hours at 150 ℃, make cross-linking reaction complete, then cool, obtain the modified road asphalt product 2 of the present invention.

Embodiment 3

[0018] In the reaction tank, first heat 83kg of asphalt to 130°C until it is dissolved and flowable, then add 11kg of SBS, 0.5kg of waste tire rubber powder and 3.8kg of polyethylene glycol into the asphalt, stir and mix for 2 hours, and after uniform mixing, Add 0.2 kg of sulfur and continue stirring. After the mixture is uniformly mixed, stop stirring and place it at 150° C. for 2 hours to complete the cross-linking reaction, then cool to obtain the modified road asphalt product 3 of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com