Waste type pulverizer and the rubber powder preparing process therewith

A technology for crushing equipment and waste tires, applied in recycling technology, grain processing, plastic recycling, etc., can solve the problems of high price of liquid nitrogen, uneconomical, high energy consumption, etc., achieve good rubber powder fineness, improve the use of The effect of long life and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

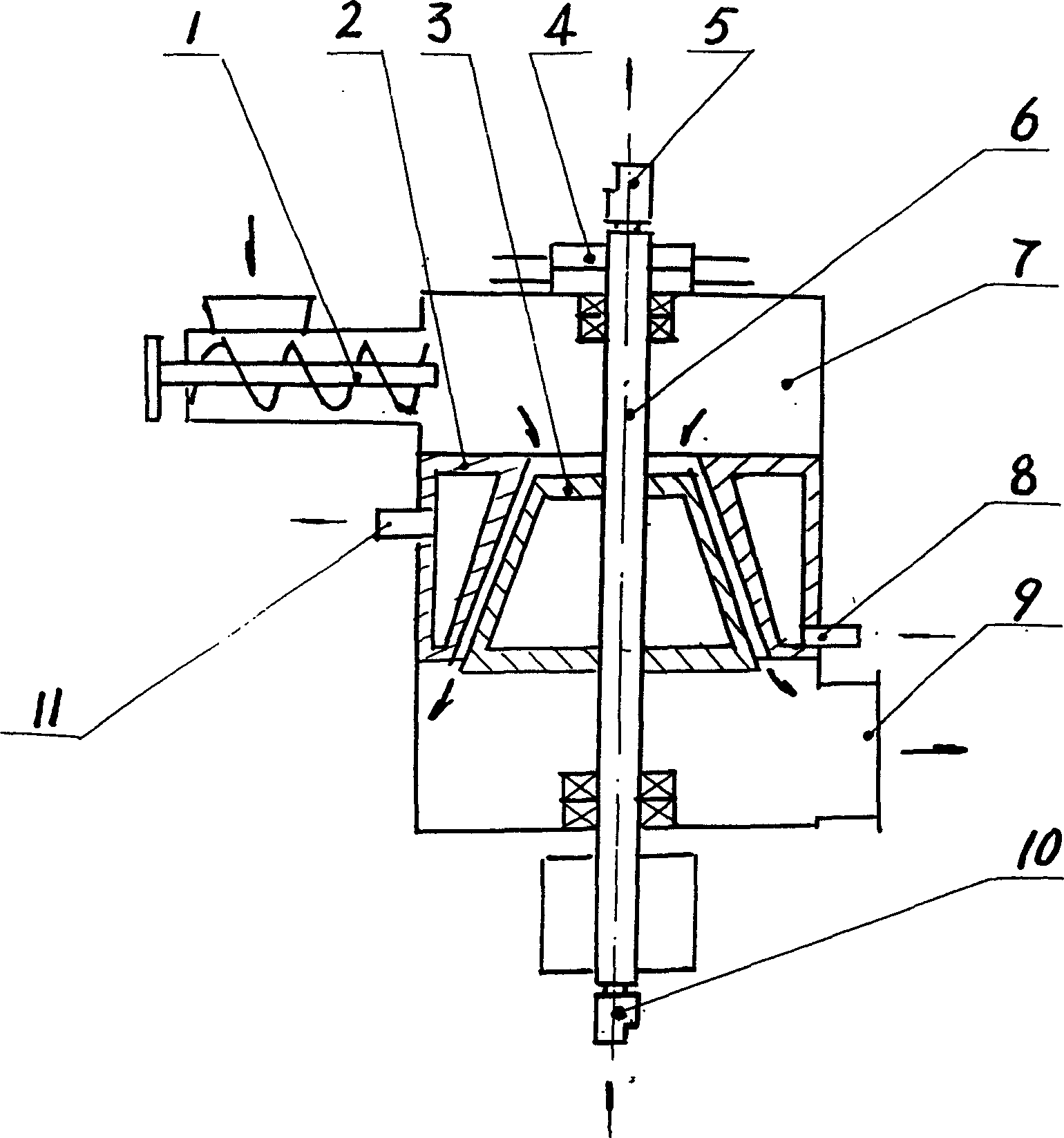

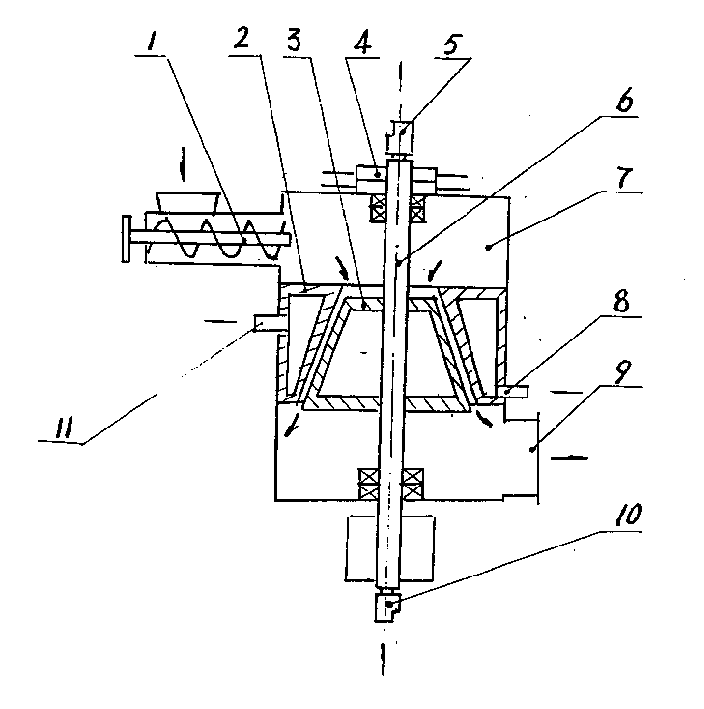

[0008] The implementation process of the present invention will be further described below in conjunction with the block flow chart and the structure diagram of the special pulverizer for waste tire rubber fine powder: the processed waste tires are first cut into two parts, an outer ring and an inner ring, by an inner ring cutting machine (1), and the inner ring Divided into two parts by the inner ring separator, the rubber ring and the steel traveler, the rubber ring and the outer ring enter the whole tire crusher (2) and are broken into rubber blocks I (the steel traveler is collected) smaller than 50×50mm. The rubber block I goes through the rubber steel wire separator (3) to further carry out the iron remover (about 80% of the steel wire of the outer ring is removed) to obtain the rubber block II smaller than 18×18×5mm, and then goes through the special rubber (4) crushing equipment for professional Fine crushing, the pulverized rubber blocks are pushed from the material pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com