A kind of high-performance Brunei gum bacterial strain and application thereof

A Brunei gum, high-performance technology, applied in bacteria, microorganisms, biochemical equipment and methods, etc., can solve the problems of backward quality, no large scale, etc., to achieve high glue yield, short growth cycle, comprehensive performance excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Obtaining high-performance Brunei gum strains

[0026] 1. Activation of the original strain: The original strain is Sphingomonas Species (ATCC31555), which is purchased from Jiangnan University. The strain can also be purchased commercially; the original strain is a freeze-dried powder, which is sterile In the operating table, it was transferred to the slant culture medium by aseptic operation technology, and cultured at 30℃ for 72 hours; the formula of the slant culture medium: sucrose 1%, soy peptone 2%, yeast extract 0.5%, agar 2%, the rest was distilled water , PH control: 7.0-7.2;

[0027] 2. The state after cultivating the inclined plane: the moss is yellow, thin, and the surface is moist. After further cultivation, the color becomes darker and the surface is dry;

[0028] 3. Slope re-cultivation: The slant culture after 72h is transferred to the slant again for secondary cultivation, the culture temperature is 30℃, and the time is 72h;

[0029] 4. The state of the incli...

Embodiment 2

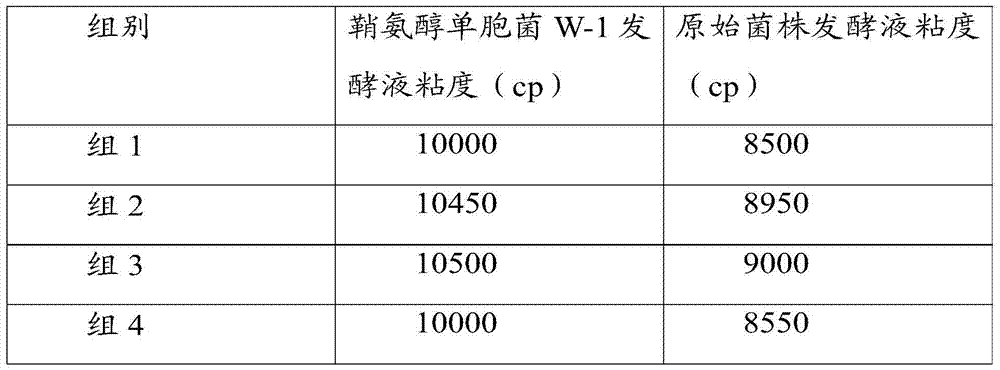

[0040] The original strain and Sphingomonas W-1 were cultured in shake flasks, and the culture conditions and culture medium were the same as in Example 1;

[0041] Group 1: Shake flask culture for 30 hours to obtain the original strain and Sphingomonas W-1 bacterial solution, calculate the concentration of the bacteria, inoculate the same amount of inoculation to the fermentation medium for fermentation culture, the fermentation culture uses a shaker culture, temperature The temperature is 30℃, the rotation speed is: 150 rpm, the fermentation culture is 70h; the fermentation medium: glucose 20g / L, ammonium nitrate 0.5g / L, yeast powder 0.4g / L, KH 2 PO 4 4g / L, K 2 HPO 4 3g / L, FeSO 4 0.0025g / L, 1ml / L of integrated trace element solution, pH 7.0, sterilized at 121°C for 20 minutes; among them, the integrated trace element solution contains 0.5% magnesium sulfate, 0.1% manganese sulfate, and 0.25% zinc sulfate;

[0042] Group 2: Shake flask culture for 30 hours to obtain the original st...

Embodiment 3

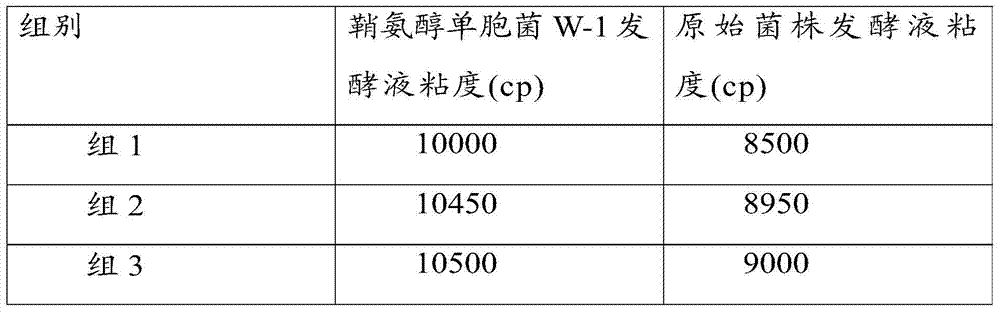

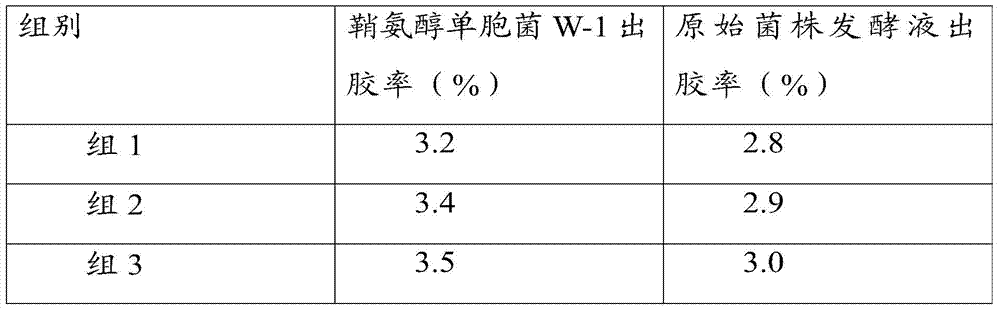

[0050] The original strain and Sphingomonas W-1 were cultured in shake flasks, and the culture conditions and culture medium were the same as in Example 1;

[0051] Group 1: Shake flask culture for 30 hours to obtain the original strain and Sphingomonas W-1 bacterial liquid, calculate the bacterial concentration, inoculate the same amount of inoculation into the fermentation medium for fermentation culture, and use the fermentation tank for fermentation culture at a temperature of 30℃, fermentation culture for 70h; fermentation medium: glucose 20g / L, ammonium nitrate 0.5g / L, yeast powder 0.4g / L, KH 2 PO 4 4g / L, K 2 HPO 4 3g / L, FeSO40.0025g / L, 1ml / L of integrated trace element solution, pH 7.0, sterilized at 121°C for 20 minutes; among them, the integrated trace element solution contains 0.5% magnesium sulfate, 0.1% manganese sulfate, and 0.25% zinc sulfate. , The dissolved oxygen in the fermentation process is 10%;

[0052] Group 2: Shake flask culture for 30 hours to obtain the or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com