Production method of gelatin

A production method and gelatin technology, applied in fermentation and other directions, can solve the problems of low glue rate, large capital occupancy rate, and large floor space, so as to ensure product quality and yield, save land and investment, and capital occupancy rate. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

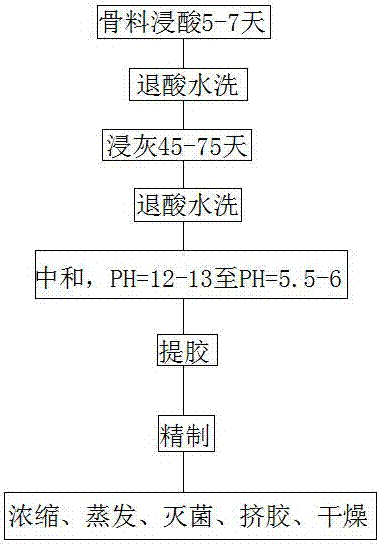

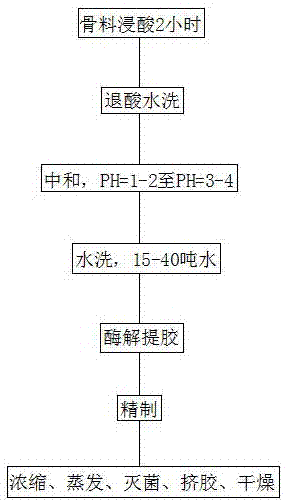

Method used

Image

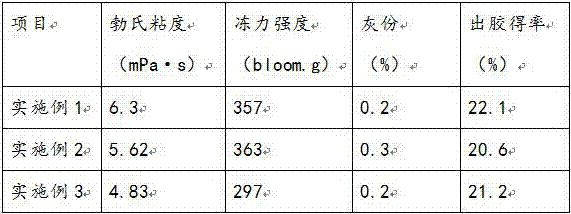

Examples

Embodiment 1

[0030] A kind of production method of gelatin, raw material is the bone meal of 20-40 mesh, and dilute hydrochloric acid concentration is 4.9wt%, and its specific production steps are:

[0031] Step 1, pickling treatment

[0032] Step 1-1. Weigh and prepare dilute hydrochloric acid at 12-19°C according to the weight ratio of bone meal: dilute hydrochloric acid of 1:6.5, and put the dilute hydrochloric acid into a pickling tank with stirring;

[0033] Step 1-2, start stirring, add a certain amount of bone meal at a constant speed at a speed of 80r / min, and control the feeding time at 0.5h. After feeding, keep it at a speed of 80r / min for 15 minutes to ensure that the bone meal and dilute hydrochloric acid are evenly mixed. After mixing, reduce the stirring speed to 15r / min and keep it for 1h;

[0034] Step 1-3, the mixture treated in step 1-2 is pumped into a plate and frame filter for solid-liquid separation, and the separated weak acid is sent to the calcium phosphate proces...

Embodiment 2

[0048] A kind of production method of gelatin, raw material is the bone meal of 40-100 mesh, dilute hydrochloric acid concentration is 5.01wt%, and its specific production steps are:

[0049] Step 1, pickling treatment

[0050]Step 1-1. Weigh and prepare dilute hydrochloric acid at 12-19°C according to the weight ratio of bone meal: dilute hydrochloric acid of 1:7, and put the dilute hydrochloric acid into a pickling tank with stirring;

[0051] Step 1-2, start stirring, add a certain amount of bone meal at a constant speed at a speed of 80r / min, and control the feeding time at 0.5h. After feeding, keep it at a speed of 80r / min for 15 minutes to ensure that the bone meal and dilute hydrochloric acid are evenly mixed. After mixing, reduce the stirring speed to 15r / min and keep it for 1h;

[0052] Step 1-3, the mixture treated in step 1-2 is pumped into a plate and frame filter for solid-liquid separation, and the separated weak acid is sent to the calcium phosphate process sec...

Embodiment 3

[0066] A kind of production method of gelatin, raw material is the bone meal of 100-200 mesh, and dilute hydrochloric acid concentration is 5.03wt%, and its specific production steps are:

[0067] Step 1, pickling treatment

[0068] Step 1-1. Weigh and prepare dilute hydrochloric acid at 12-19°C according to the weight ratio of bone meal: dilute hydrochloric acid of 1:7.5, and put the dilute hydrochloric acid into a pickling tank with stirring;

[0069] Step 1-2, start stirring, add a certain amount of bone meal at a constant speed at a speed of 80r / min, and control the feeding time at 0.5h. After feeding, keep it at a speed of 80r / min for 15 minutes to ensure that the bone meal and dilute hydrochloric acid are evenly mixed. After mixing, reduce the stirring speed to 15r / min and keep it for 1h;

[0070] Step 1-3, the mixture treated in step 1-2 is pumped into a plate and frame filter for solid-liquid separation, and the separated weak acid is sent to the calcium phosphate pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com