Industrial preparation method of antler gum granules

A deer antler glue and antler technology, which is applied in the direction of medical preparations containing active ingredients, pharmaceutical formulas, food ingredients, etc., can solve the problems of unqualified product quality, quality change of antler glue, long process time, etc., and achieve improved filtration Efficiency, save concentration time, high adaptability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

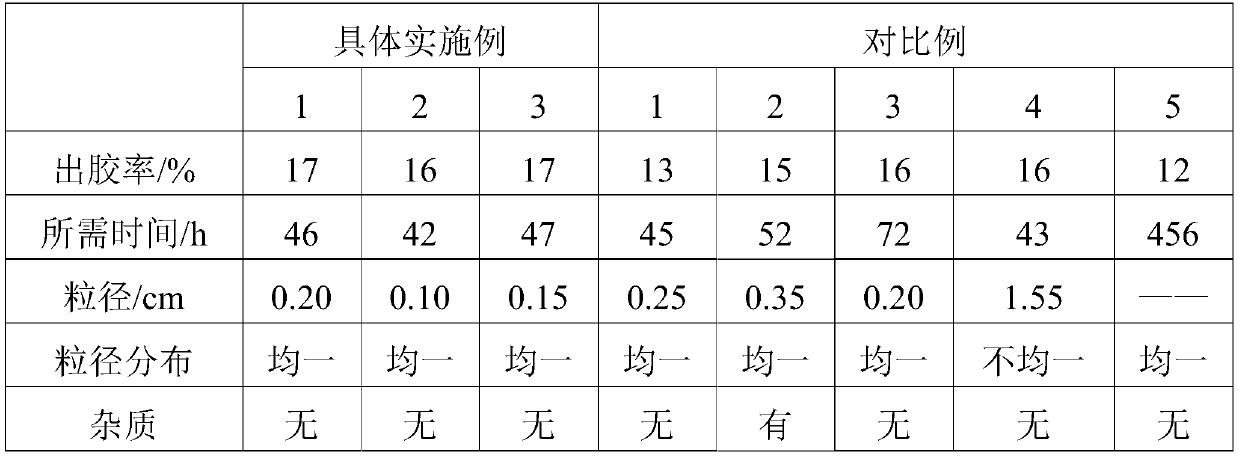

Examples

specific Embodiment 1

[0022] (1) cleaning the antler surface of the sika deer and sawing it into a block structure with a length of 1 to 3 cm, and then using a pulverizer to crush the antler of the block structure into a granular structure with a diameter of 0.2 to 0.5 cm;

[0023] (2) Steam the antlers with granular structure obtained through the above steps for 60 minutes at high temperature and high pressure, wherein the temperature of steaming antlers is 110°C, and the pressure of steaming antlers is 0.1 MPa;

[0024] (3) Add purified water 3 times the weight of the antlers to the antlers treated by the above steps, mix them evenly, and grind them repeatedly three times to obtain antler water slurry, boil the antler water slurry at 120°C for 2 hours, and then Use 80 mesh, 120 mesh and 200 mesh sieves to filter and remove impurities to obtain an antler gum extract;

[0025] (4) The deer horn gum extract obtained in the above steps is concentrated in vacuum, and the vacuum concentration is stoppe...

specific Embodiment 2

[0029] (1) cleaning the antler surface of the red deer and sawing it into a block structure with a length of 1-3 cm, and then using a pulverizer to crush the antlers of the block structure into a granular structure with a diameter of 0.2-0.5 cm;

[0030] (2) Steam the antlers with a granular structure obtained through the above steps for 45 minutes under high temperature and high pressure, wherein the temperature for steaming the antlers is 130° C., and the pressure for steaming the antlers is 0.12 MPa;

[0031](3) Add purified water 3.5 times the weight of the antlers to the antlers treated by the above steps, mix them evenly, and grind them repeatedly three times to obtain antler water slurry, boil the antler water slurry at 125°C for 3 hours, and then Use 80 mesh, 150 mesh and 200 mesh sieves to filter and remove impurities to obtain an antler gum extract;

[0032] (4) The deer horn gum extract obtained in the above steps is concentrated in vacuum, and the vacuum concentrat...

specific Embodiment 3

[0036] (1) cleaning the antler surface of the red deer and sawing it into a block structure with a length of 1-3 cm, and then using a pulverizer to crush the antlers of the block structure into a granular structure with a diameter of 0.2-0.5 cm;

[0037] (2) Steam the antlers with a granular structure obtained through the above steps for 120 minutes at high temperature and high pressure, wherein the temperature for steaming the antlers is 120° C., and the pressure for steaming the antlers is 0.12 MPa;

[0038] (3) Add purified water 4 times the weight of the antlers to the antlers treated by the above steps, mix them evenly, and grind them repeatedly three times to obtain antler water slurry, boil the antler water slurry at 130°C for 3 hours, and then Use 80 mesh, 120 mesh, 150 mesh and 200 mesh sieves to filter and remove impurities to obtain antler gum extract;

[0039] (4) The deer horn gum extract obtained in the above steps is concentrated in vacuum, and the vacuum concen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com