Method for preparing carbon black by electrocracking waste and old tyre

A waste tire and arc cracking technology, which is used in the preparation of liquid hydrocarbon mixtures, fibrous fillers, petroleum industry, etc., can solve the problems of small specific surface area of carbon black, low utilization value, pollution, etc. The effect of high and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

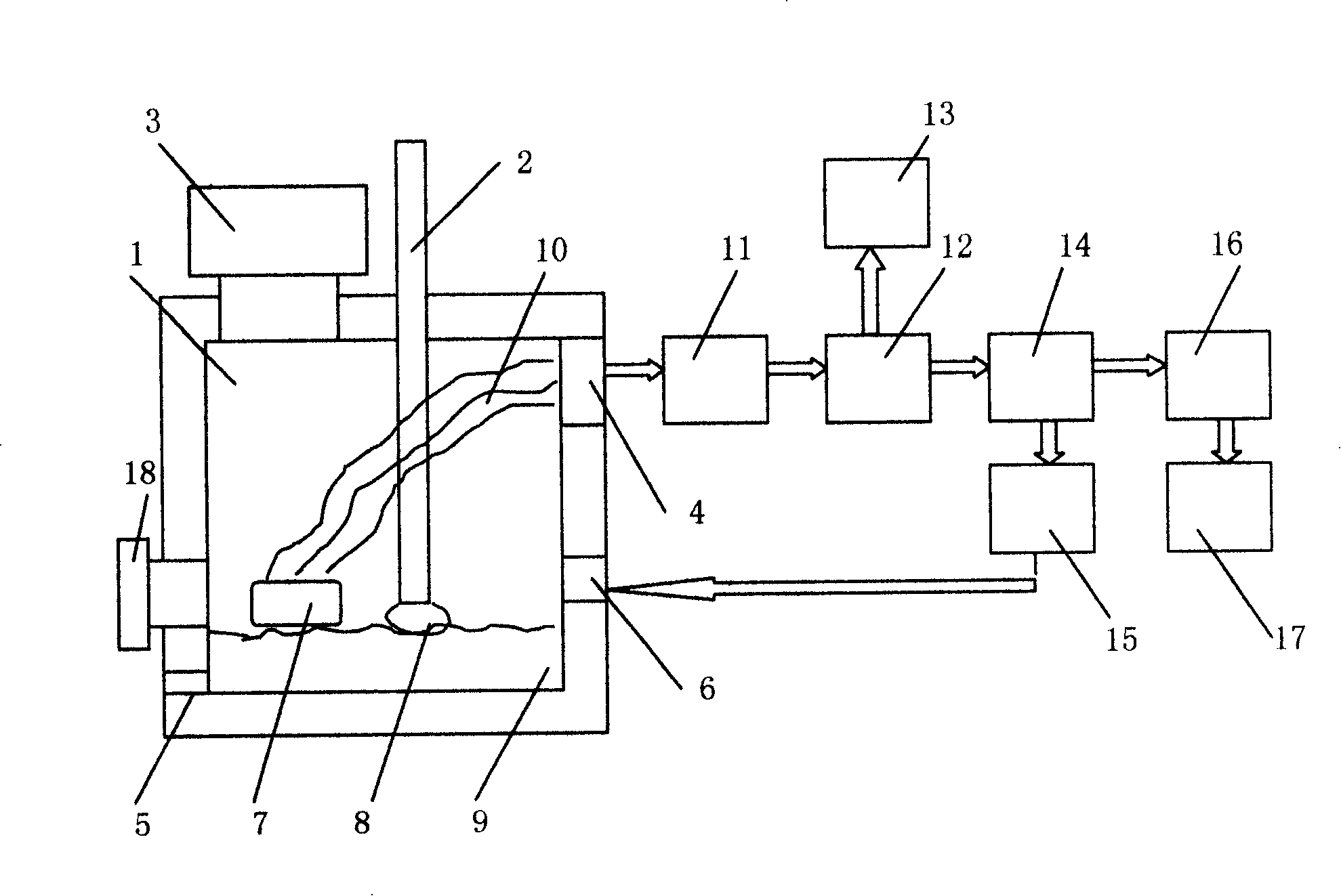

[0008] (1) airtight holding furnace in the electric arc cracking furnace is made up of (2) electrode, (18) oxygen control device, (4) gas outlet, (5) tap hole, (6) residual oil return port. 〔7〕The tire enters the 〔1〕 airtight holding furnace through the 〔3〕 tire entrance, and the electrode〔2〕 generates an 〔8〕 high-temperature electric arc to suddenly raise the temperature of the 〔7〕 tire, wherein the steel wire is melted into 〔9〕 molten steel, and 〔9〕 molten steel Recycling along the (5) tapping port; (7) tires are vaporized after pyrolysis to generate (10) gas containing carbon black, carbon monoxide and hydrogen, and the (10) gas enters the (11) temperature regulating device through the (4) gas outlet , (12) dedusting device reclaims (13) finished carbon black; (10) gas is separated from (15) residual oil through (14) deoiling device, and (15) residual oil returns along (6) residual oil return port 〔1〕The airtight holding furnace is used for cyclic cracking; 〔10〕 gas is desu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com