Automatic waste tire dicing production line

A waste tire and production line technology, applied in tires, recycling technology, other household appliances, etc., can solve the problems of no waste tire automatic cutting production line, inconvenient cutting, cutting operation, low work efficiency, etc., to achieve flat cutting The effect of good effect, low cost and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

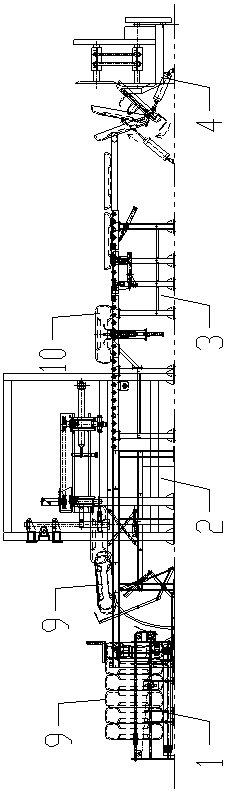

[0085] see Figure 1-12 , the present invention relates to an automatic cutting production line for waste tires, which includes a tire feeding device 1, an automatic tire cutting device 2, an automatic tire turning device 3, a tire strip cutting machine 4, a tire cutting machine 5, and a ring conveyor belt 6. Rubber block conveyor belt 7 and mouth ring frame 8.

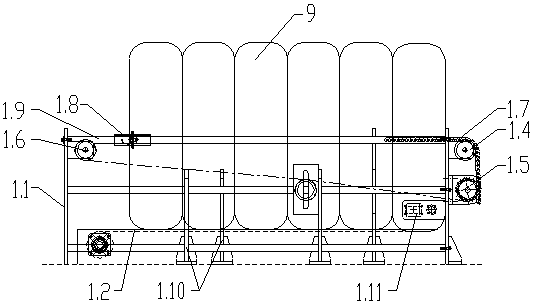

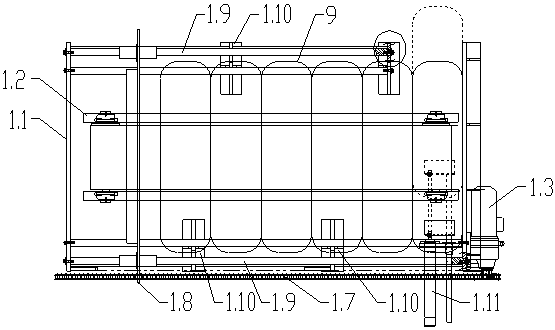

[0086] The tire feeding device 1 includes a feeding frame 1.1, a guide rail 1.2, a motor 1.3, a driving wheel 1.4, a first driven wheel 1.5, a second driven wheel 1.6, a first limiting plate 1.8, a slideway 1.9, and a side baffle 1.10 and propulsion means 1.11.

[0087] The guide rail 1.2 is arranged on the bottom of the feeding frame 1.1, the waste tire 9 is placed on the guide rail 1.2, two slideways 1.9 are arranged on the top of the feeding frame 1.1, the motor 1.3, the driving wheel 1.4, the first driven wheel 1.5 and the second The second driven wheel 1.6 is installed on the feeding frame 1.1, the driving whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com