Patents

Literature

64results about How to "For subsequent cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

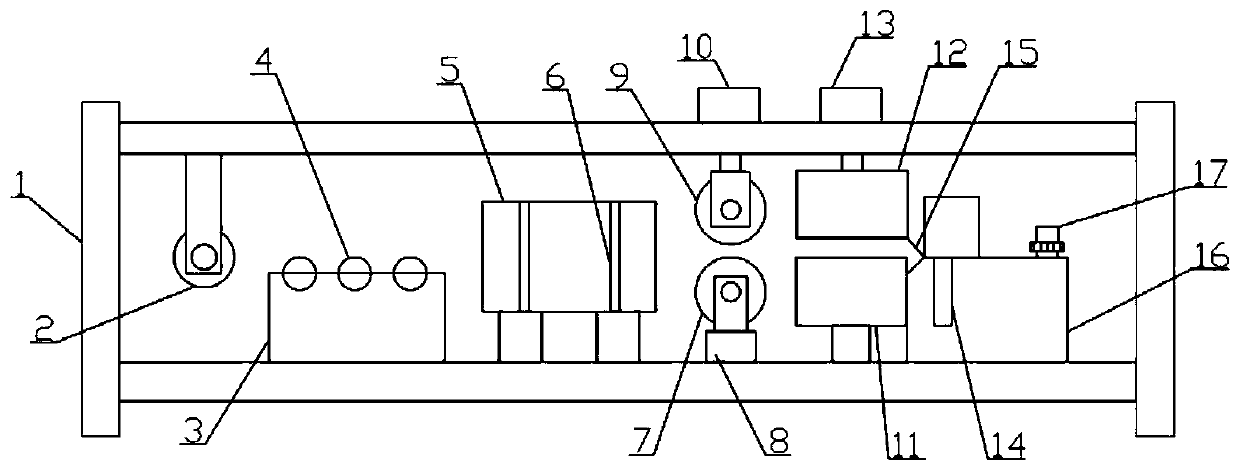

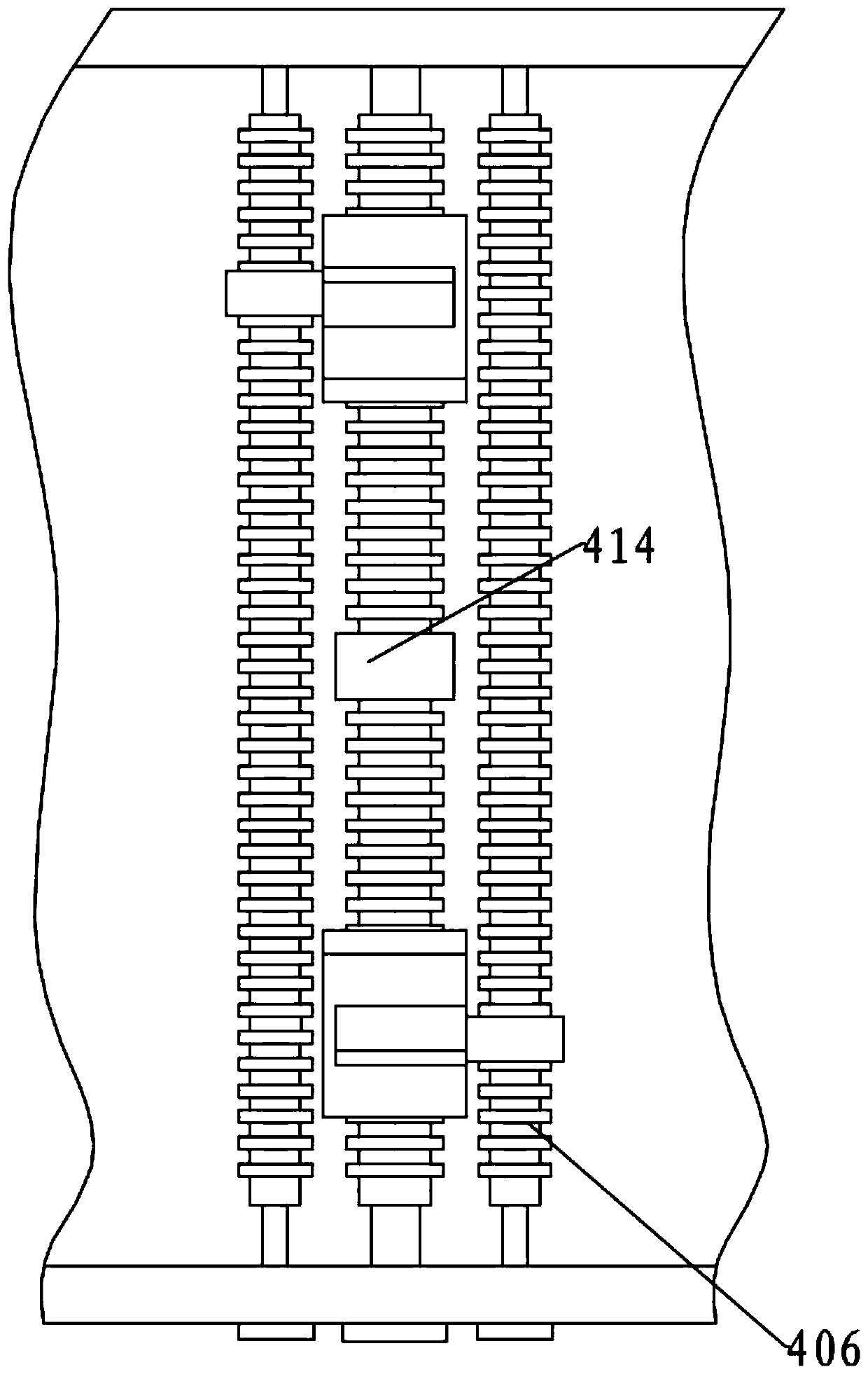

Extrusion-type straw smashing device

The invention discloses an extrusion-type straw smashing device. The device includes a shell, the left side of the shell is communicated with a feeding pipe, the communicated portion between the feeding pipe and the shell is provided with a communicating port, and the portion, at the right side of the communicating port, of the interior of the shell is provided with a cutting box; the right side of the cutting box is communicated with a smashing box. Through multiple groups of extrusion rollers which are arranged gradually close to one another, straw is extruded and conveyed by the extrusion rollers to provide convenience for follow-up cutting and smashing; by arranging cutting wheels and smashing cutters, straw strips are cut in a block shape by the cutting wheels to provide convenience for follow-up smashing, and the smashing efficiency is improved; by arranging an extruding plate to extrude the straw during smashing, the straw can be fully in contact with the smashing cutters, smashing can be achieved more thoroughly, and the smashing effect is improved; by arranging impact beads for beating a screening plate, the screening efficiency is ensured.

Owner:储君

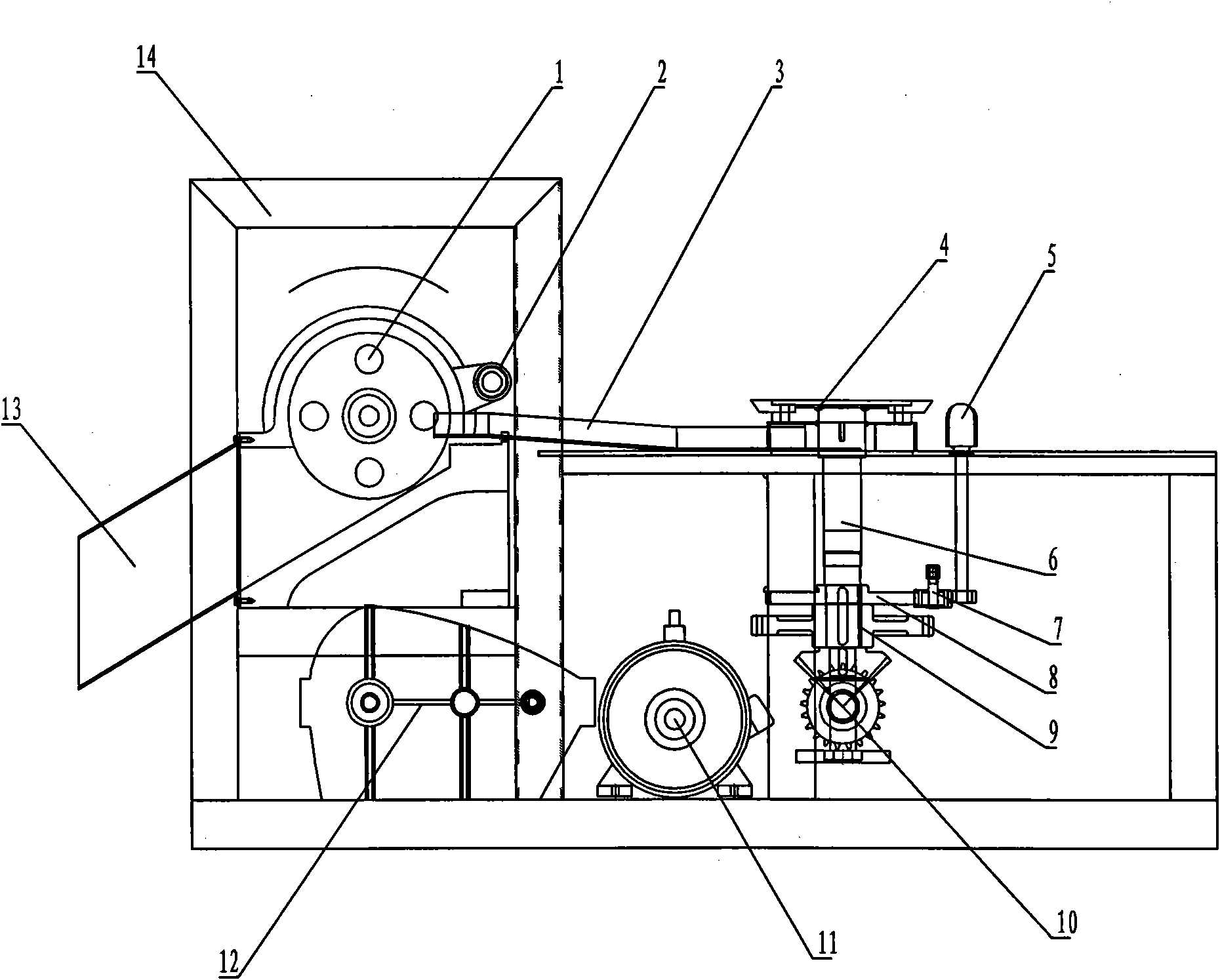

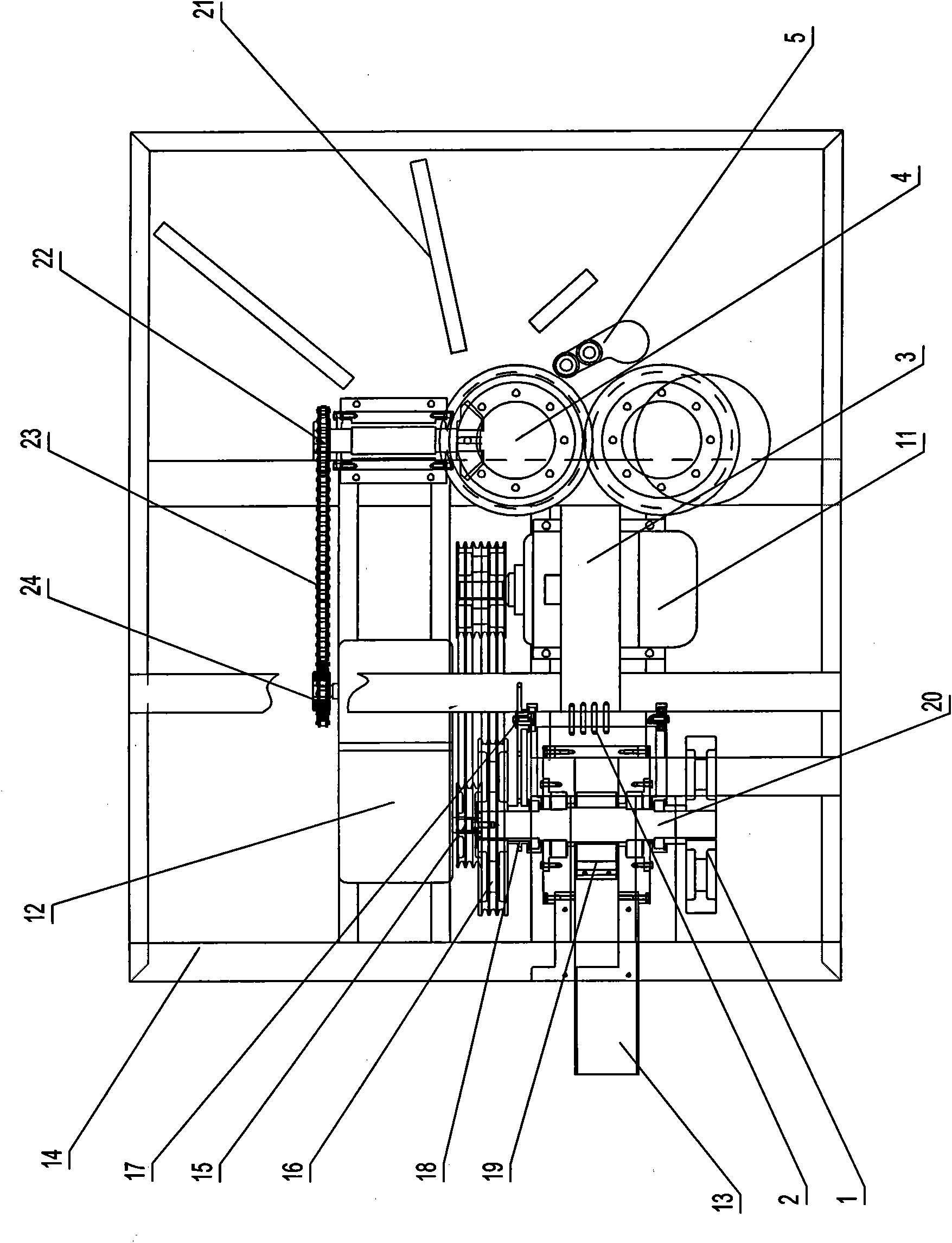

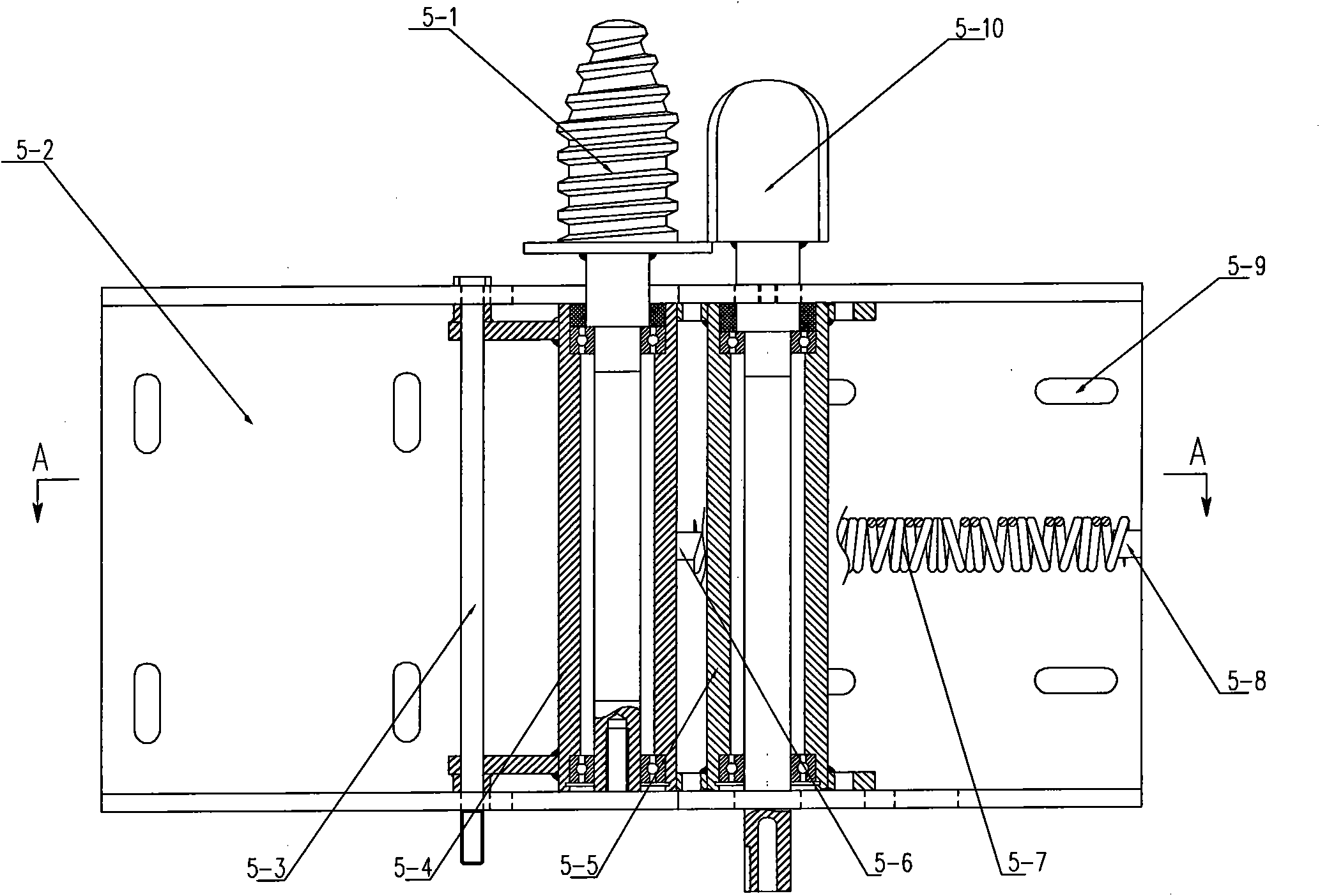

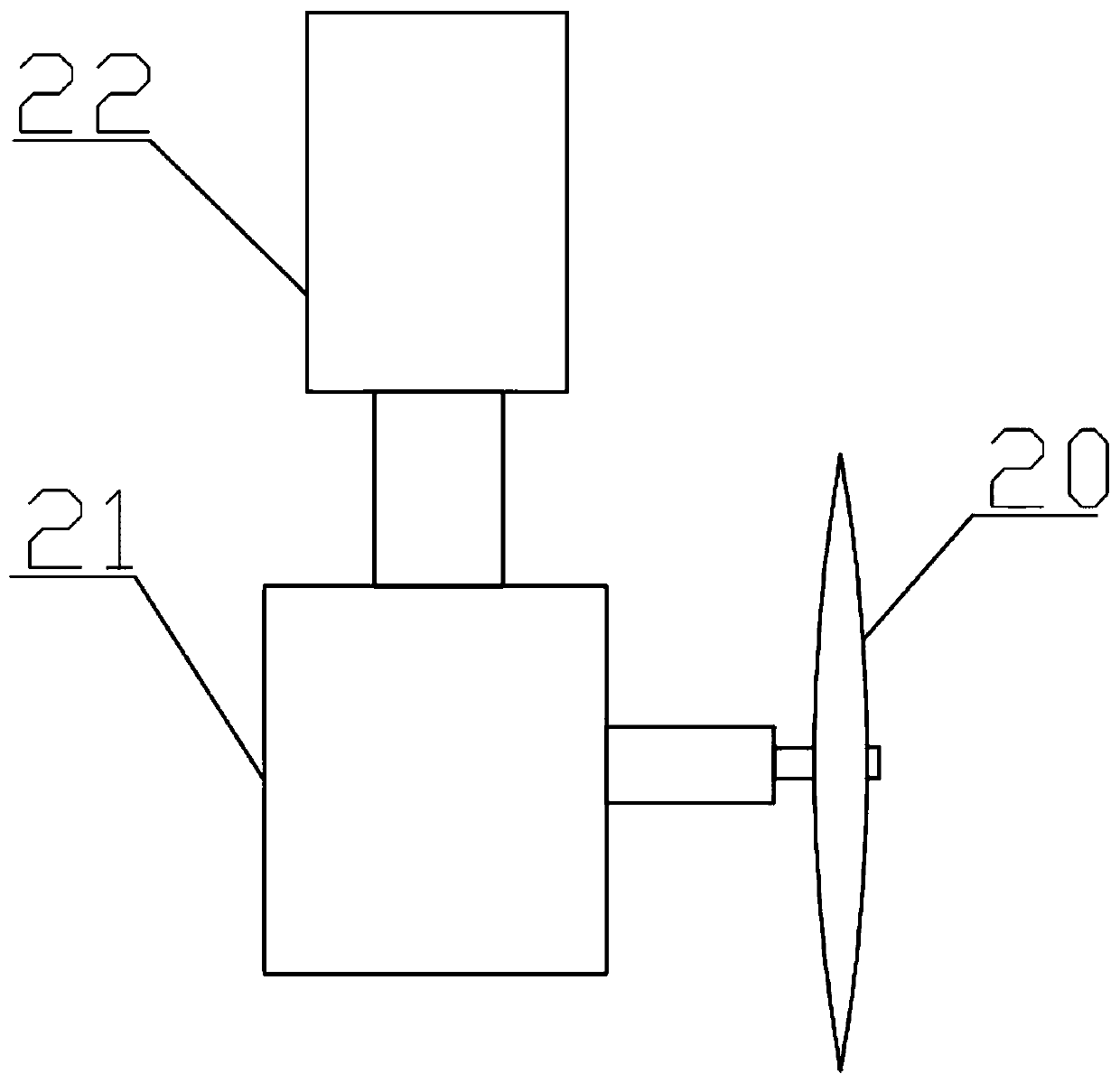

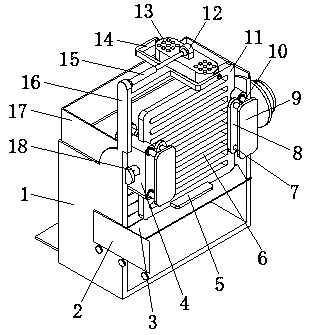

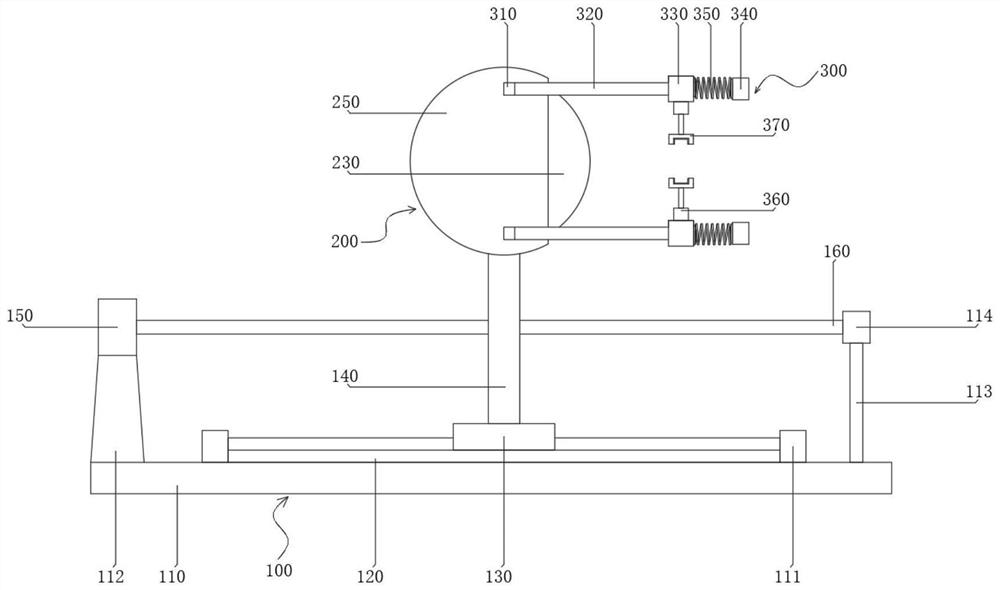

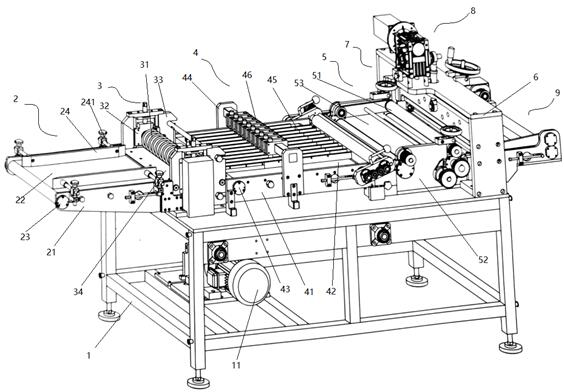

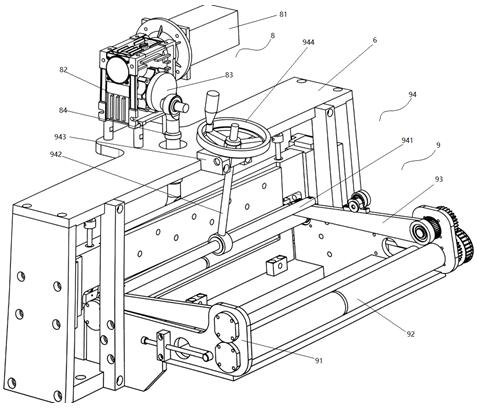

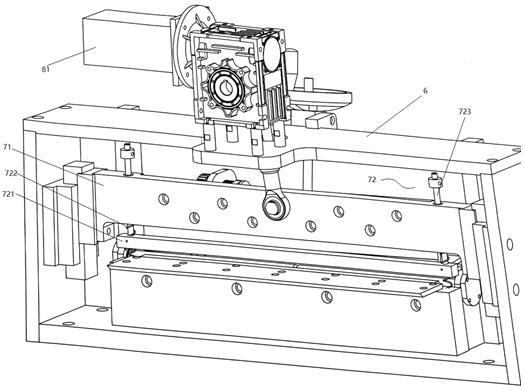

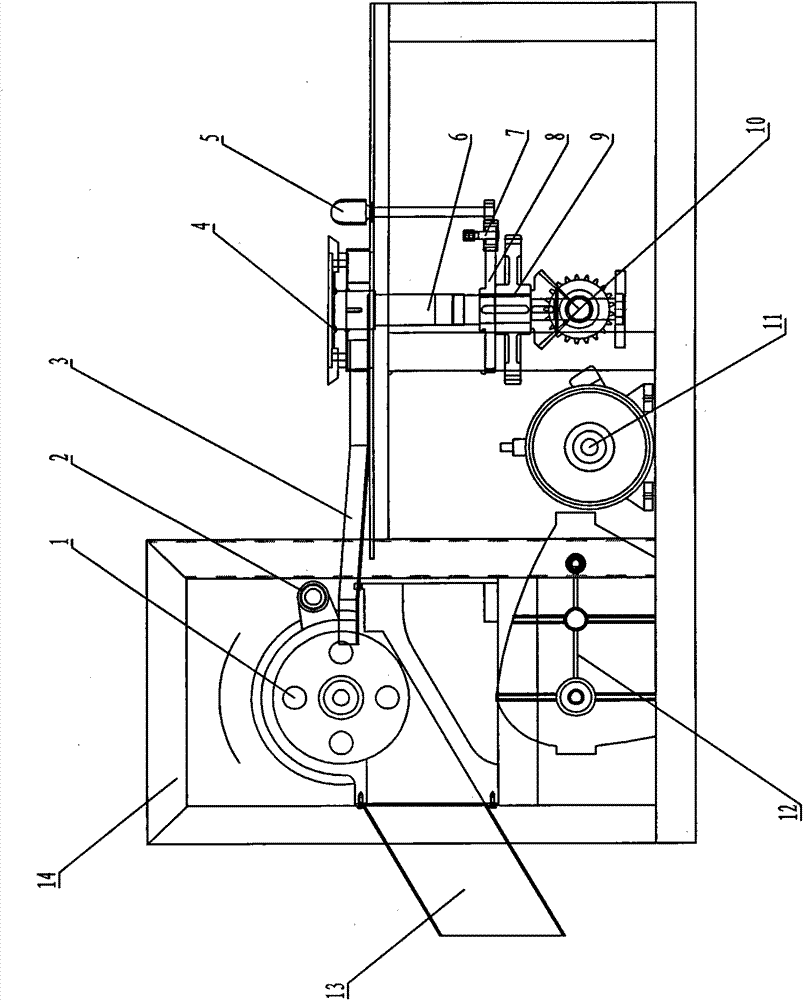

Waste rubber tire horizontal composite dicer

InactiveCN101850583AEasy feedingRealize feeding automationPlastic recyclingMetal working apparatusGear wheelWaste rubber

The invention relates to a waste rubber tire horizontal composite dicer which comprises a frame, a power source, a transmission gear, a slitter, a dicing device and a tire feeding device, wherein the slitter and the dicing device are installed on the upper part of the frame; the power source and the transmission gear are installed on the bottom of the frame; the tire feeding device is installed near the slitter; the slitter comprises an upper horizontal cutter head and a lower cutter head which contact the working surface; the shafts of the two cutter heads form a mesh transmission through various gears which match each other; the lower end of the shaft of one cutter head is connected with the power source through the transmission gear; the dicing device comprises a dicing shaft, a dicingcutter and an inertia wheel, the dicing shaft is installed on the frame, the dicing cutter and the inertia wheel are installed on the dicing shaft, and the dicing main shaft is connected with the power source through the transmission gear; and a guide chute is arranged between the slitter and the dicing device. The dicer provides convenience for feeding waste tires, can realize automatic feeding,and maximally reduces manual work.

Owner:HENAN ZHONGYING RUBBER TECH

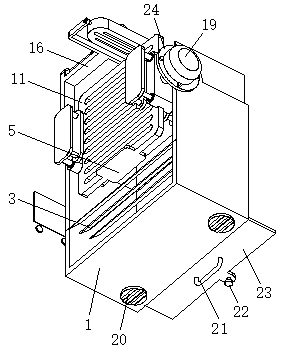

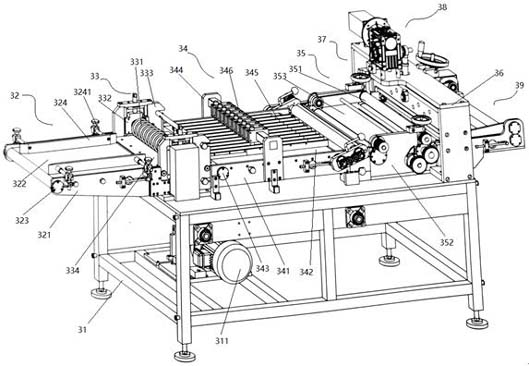

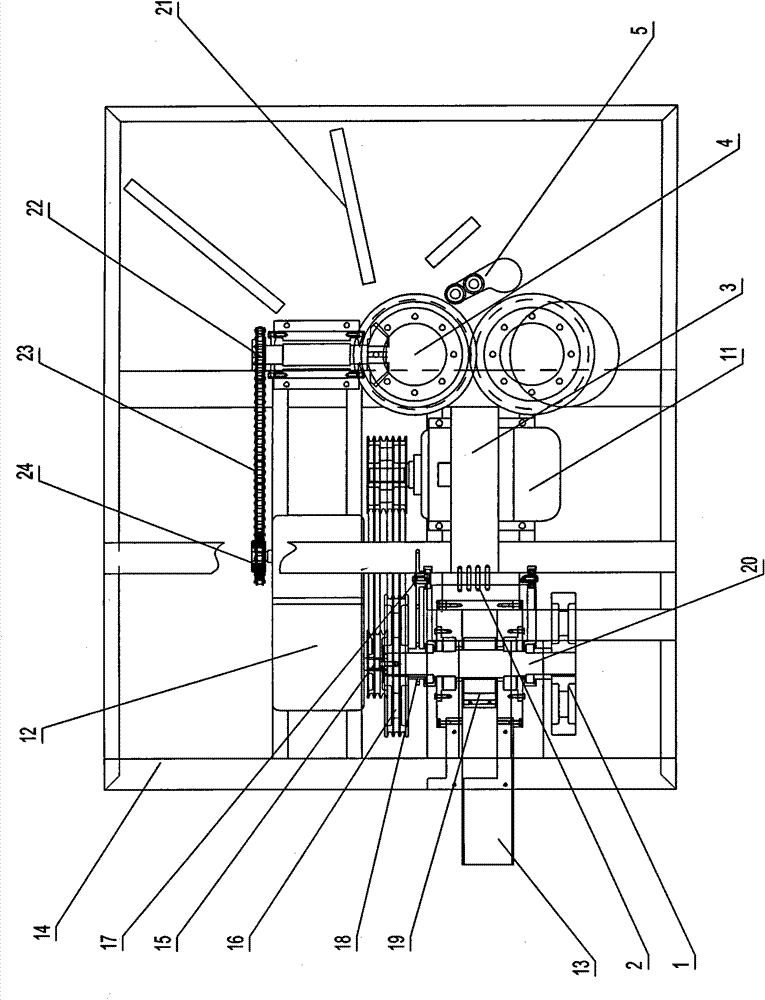

Rolling cutter for conical non-woven fabric gauze mask ear bands and method

ActiveCN111411505AImprove flatnessAvoid wrinklesSevering textilesStructural engineeringNonwoven fabric

The invention discloses a rolling cutter for conical non-woven fabric gauze mask ear bands and a method, and belongs to the technical field of conical gauze mask ear band cutting. The rolling cutter comprises a support. A working table plate is fixed to the upper side of the support. A conveying belt is arranged in the middle of the working table plate. A winding device, a guide device and a rolling cutting device are installed above the working table plate. The guide device is arranged at the side end of the winding device, and the rolling cutting device is arranged at the side end of the guide device. The rolling cutting device comprises a frame plate, a rolling roll, an air cylinder, moving plates and a connecting shaft rod. The moving plates are arranged below the two sides of the frame plate. According to the rolling cutter for the conical non-woven fabric gauze mask ear bands and the method in the invention, the flatness of materials is improved, the materials can be shaped, wrinkling is prevented, subsequent cutting can be facilitated, the length between two blades can be adjusted as required, ear band threads of different lengths can be cut conveniently, the rolling cutteris suitable for different gauze mask threads, and cutting efficiency is improved; and bothway cutting is conducted, the cutting speed is increased and production benefits are also increased.

Owner:MAANSHAN HENGLIDA MACHINE BLADE

Cloth breaking machine in textile field

InactiveCN108301180AEasy to flattenEasy to collectMechanical cleaningPressure cleaningEngineeringMechanical engineering

The invention discloses a cloth breaking machine used in textile field. The machine comprises a first support plate, an electric push rod, a baffle plate, a cutting bed, a guide rail, a pressure roller, a lifting mechanism, a raw material support bracket, a lower brush, a lower guide roller, second support plates, a filter screen and a suction draught fan, the second support plates are mounted onone ends of two sides of the cutting bed, the two second support plates are connected though the raw material support bracket, the raw material support bracket and the second support plates are connected through the bearings, the bottom of an upper guide roller is evenly provided with an upper brush, the lower guide roller is fixed directly below the upper guide roller through bolts, the lower brush is evenly disposed on the top of the lower guide roller, a collecting groove is formed in top of the cutting bed and directly located below the lower guiding roller, the inner wall of the bottom ofthe collecting groove is fixed to the suction draught fan through the bolts, and both sides of the inner wall of the collecting groove are connected by the filter screen; the cloth breaking machine conveniently adjusts the height of the pressure roller to flatten fabrics of different thicknesses and meanwhile has the function of dust removal.

Owner:CHANGXING BAOFU WEAVING

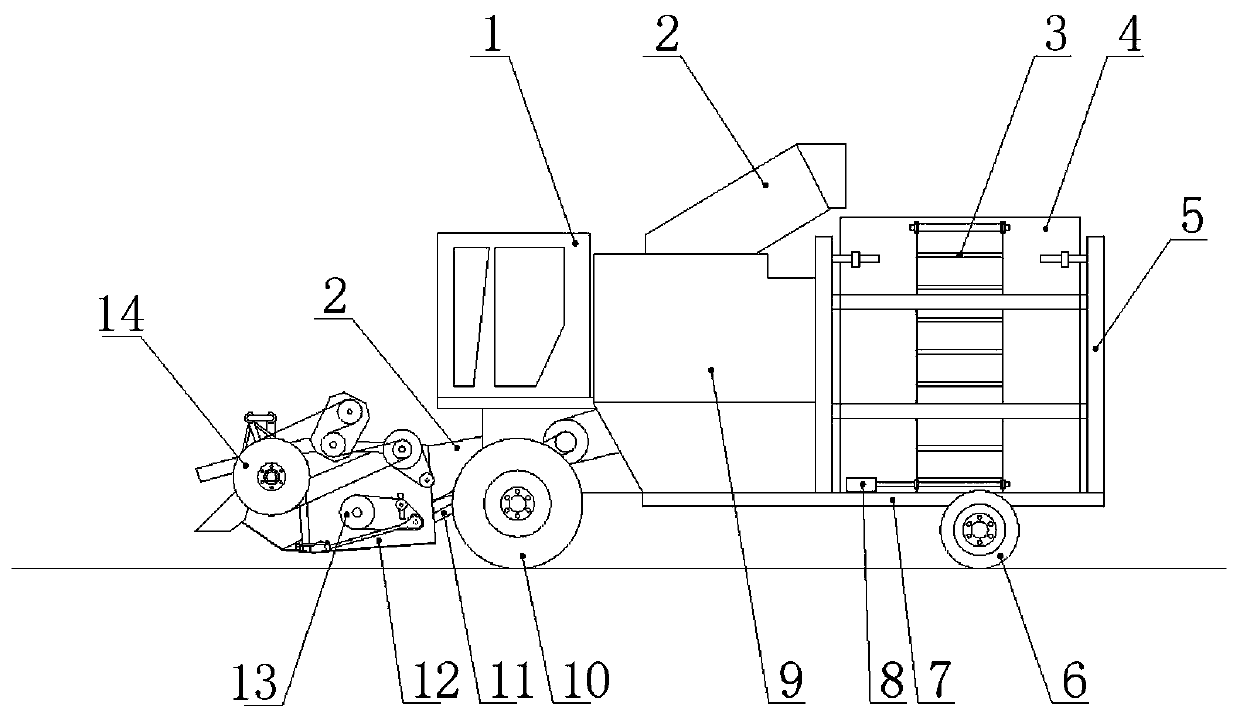

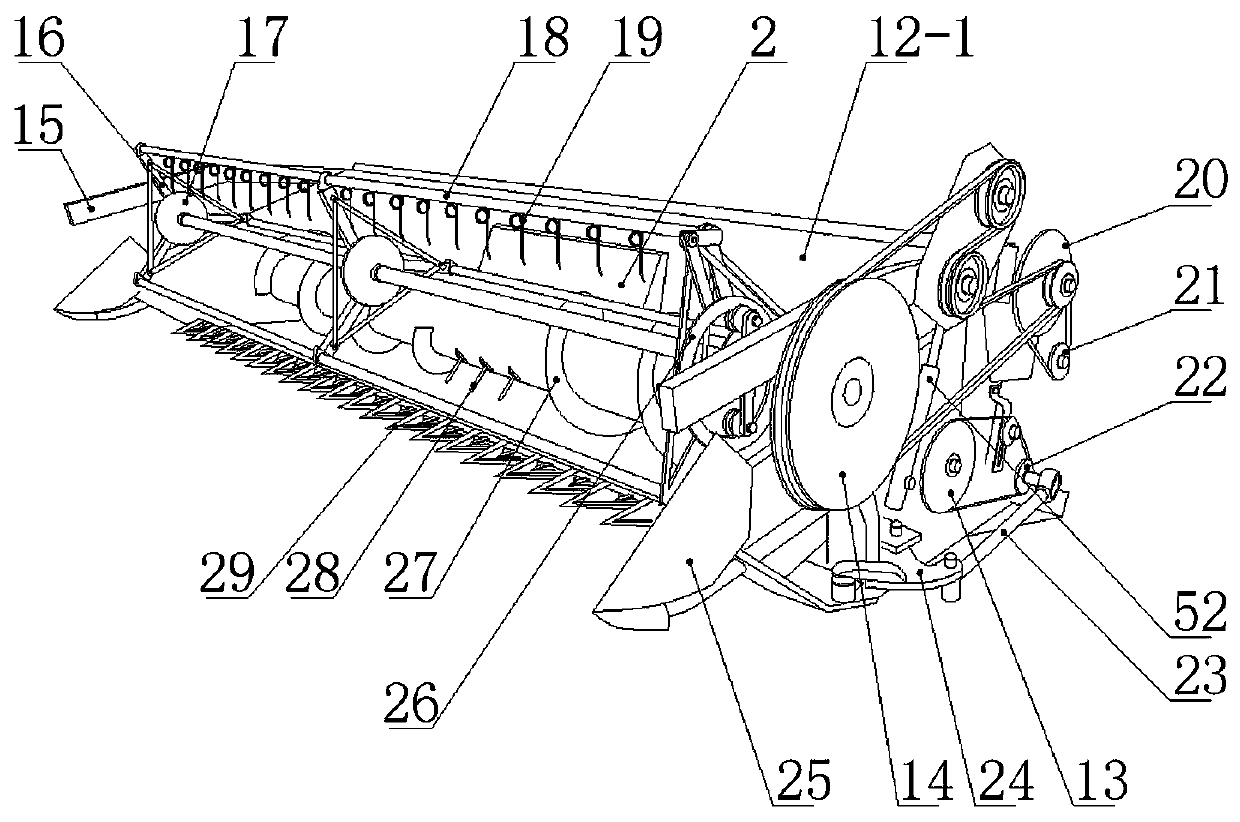

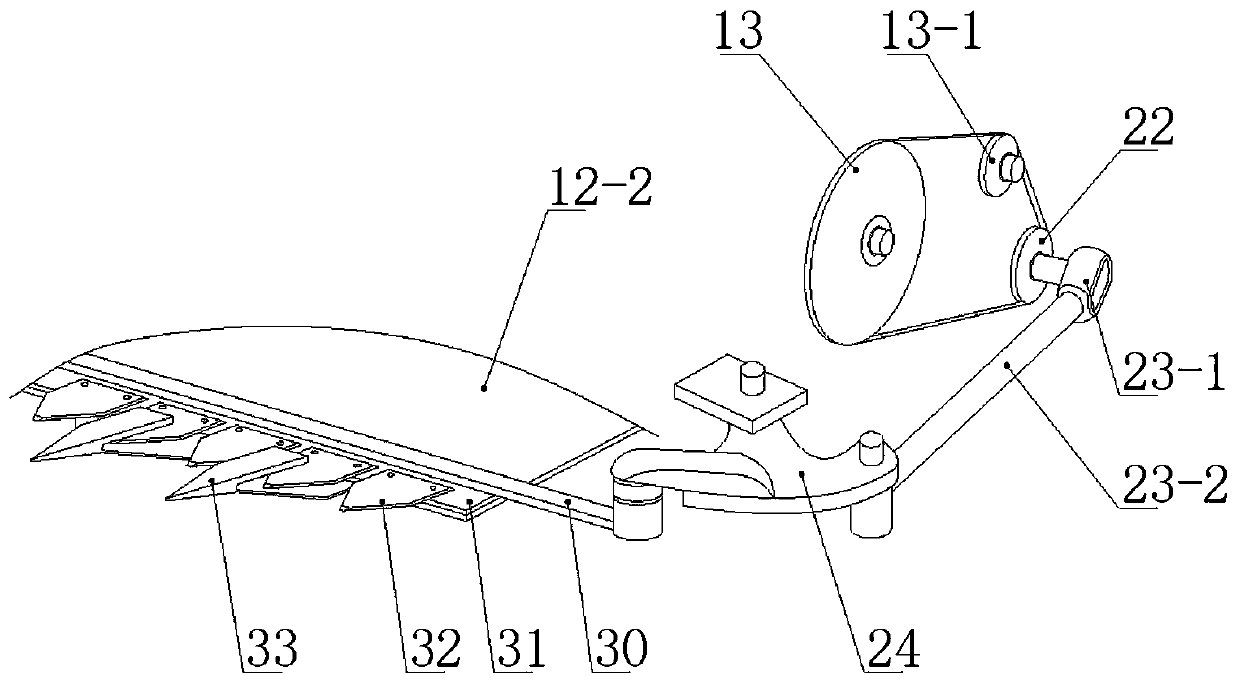

Lavender harvester

PendingCN110393080AStubble neatlyConducive to growth and unityMowersAgricultural lifting devicesEngineeringChassis

The invention relates to a lavender harvester. The lavender harvester comprises a chassis provided with front walking wheels and rear walking wheels, a turnover collecting hopper is arranged on the rear side of the chassis, a power cabin is arranged on the portion, on the front side of the collecting hopper, on the chassis, and a channel allowing a conveying channel to penetrate through is reserved in the power cabin. A platform higher than the chassis is fixed to the front side of the chassis, and a cab is arranged on the platform. The front end of the chassis is hinged to the lower side of aharvesting hopper located on the front side of the chassis through a first hydraulic arm, and a reel frame and a packing auger are arranged in the harvesting hopper from front to back; the front endof a bottom plate of the harvesting hopper is fixedly provided with crop holding teeth and is provided with cutting teeth; a collecting opening is formed in the portion, on the rear side of the packing auger, on the rear wall of the harvesting hopper and is communicated with the conveying channel; the conveying channel is started at the collecting opening, penetrates into the power cabin through the lower part of the cab and penetrates out of the upper end face of the rear side of the power cabin, and a discharging hole of the conveying channel is located above the collecting hopper. Harvesting and collecting of lavender crops are integrated, the adaptability is high, the structure is simple, the stability is good, the practicability is high, and production requirements are met.

Owner:冉军

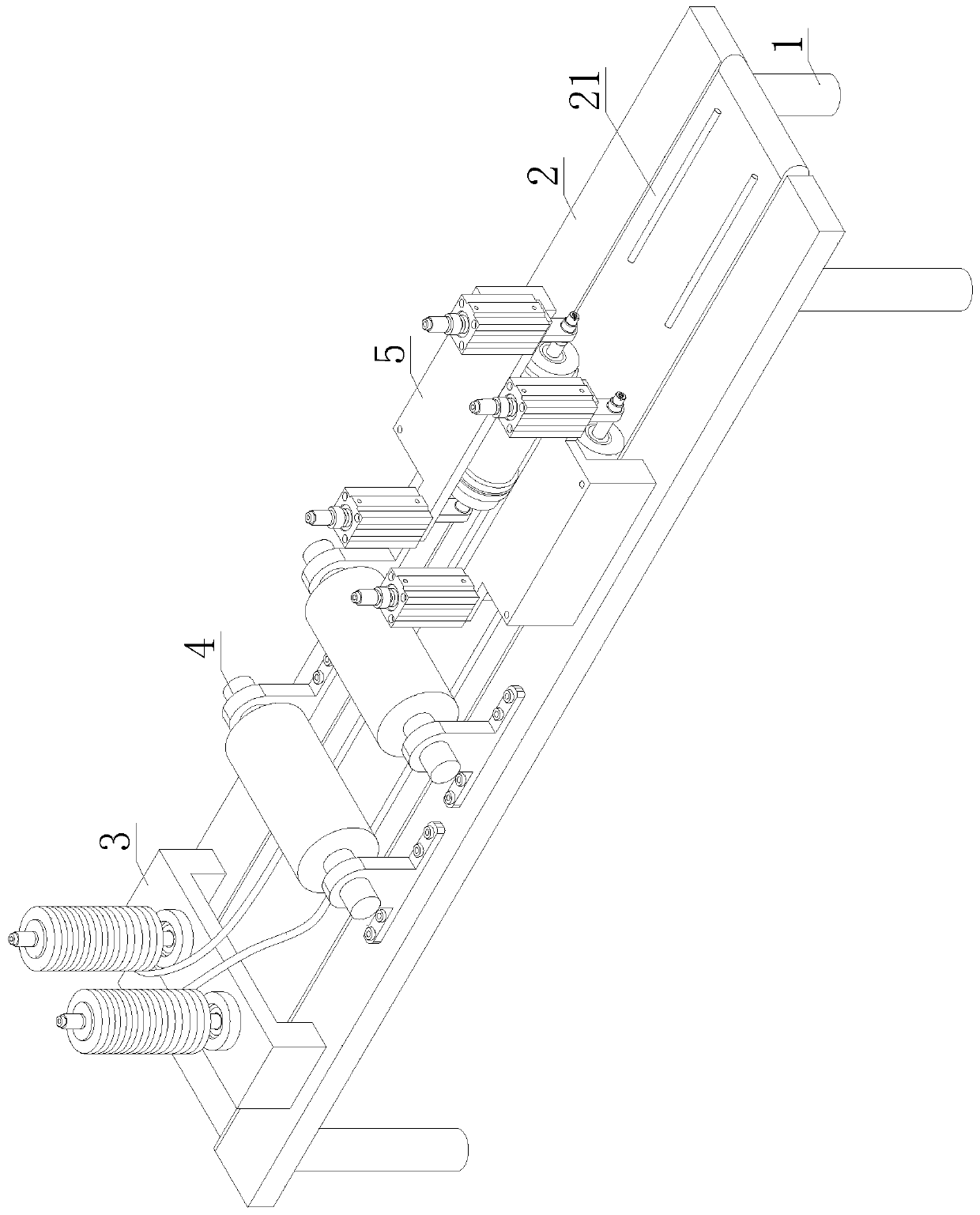

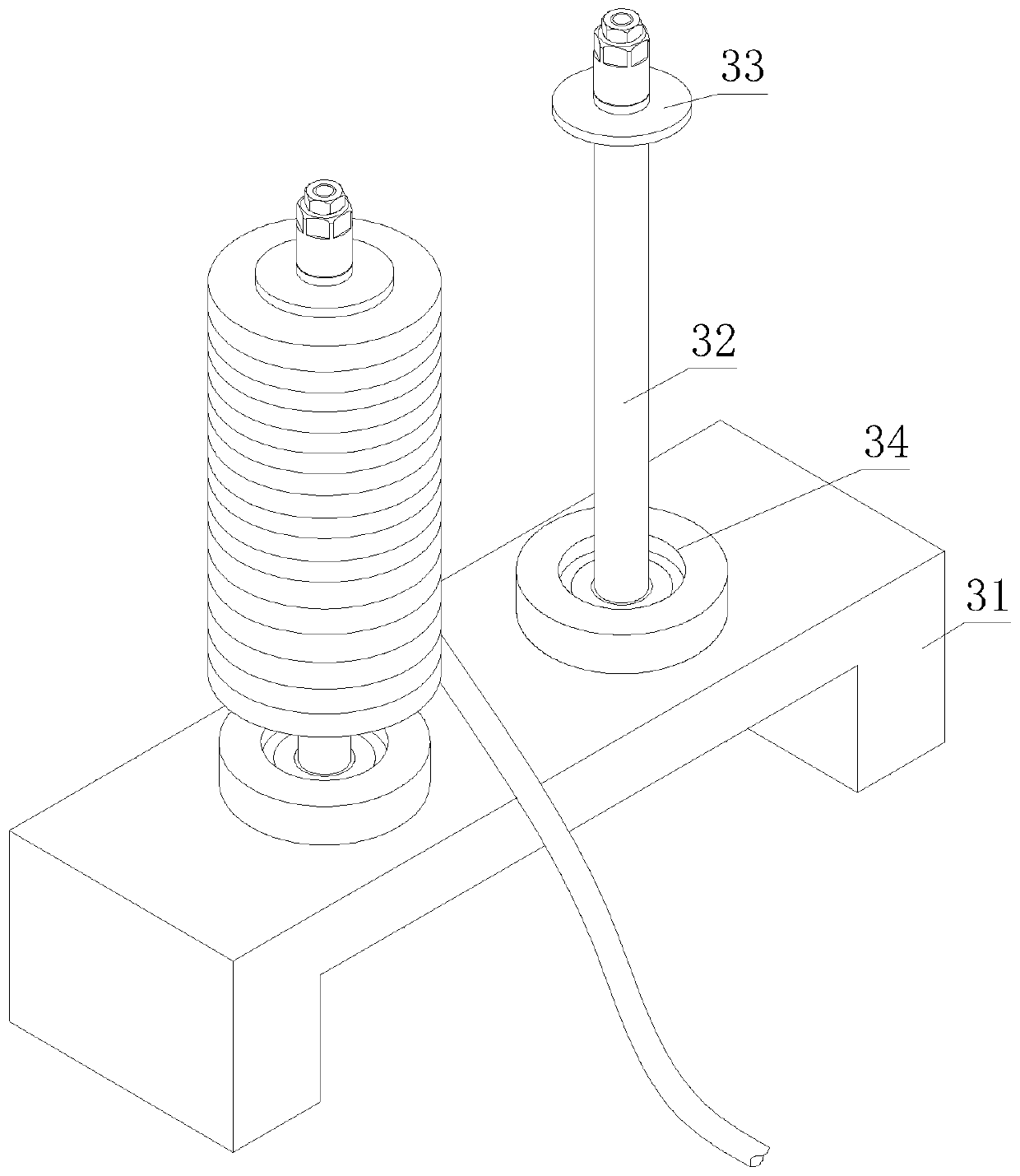

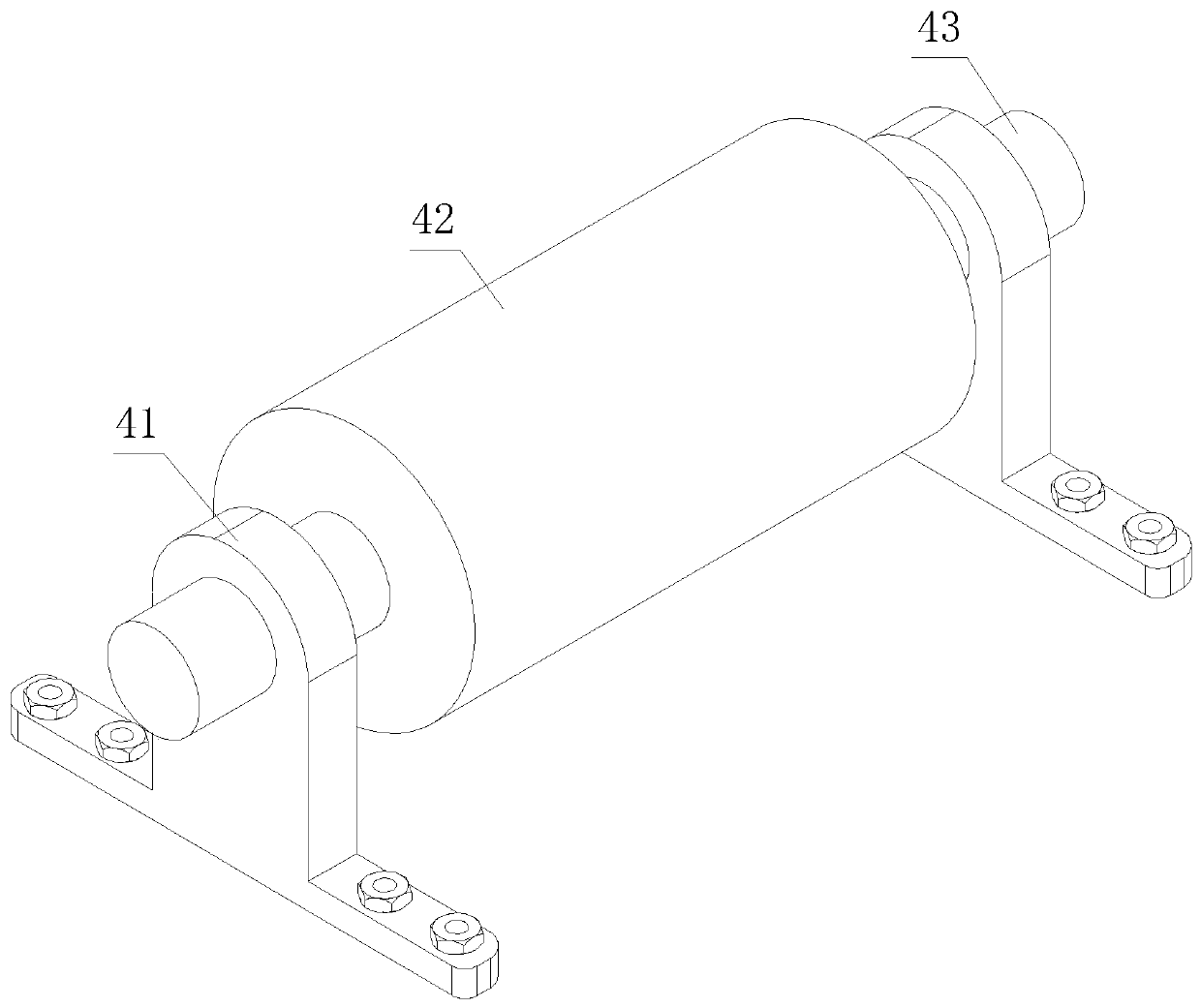

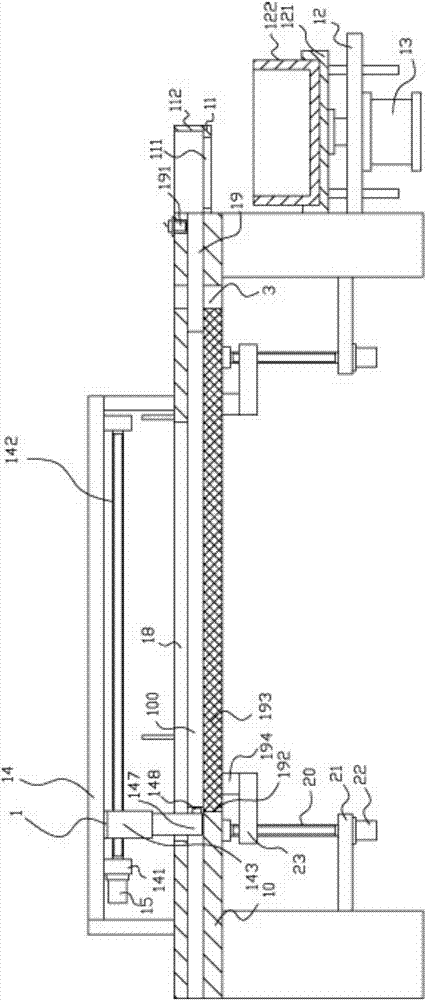

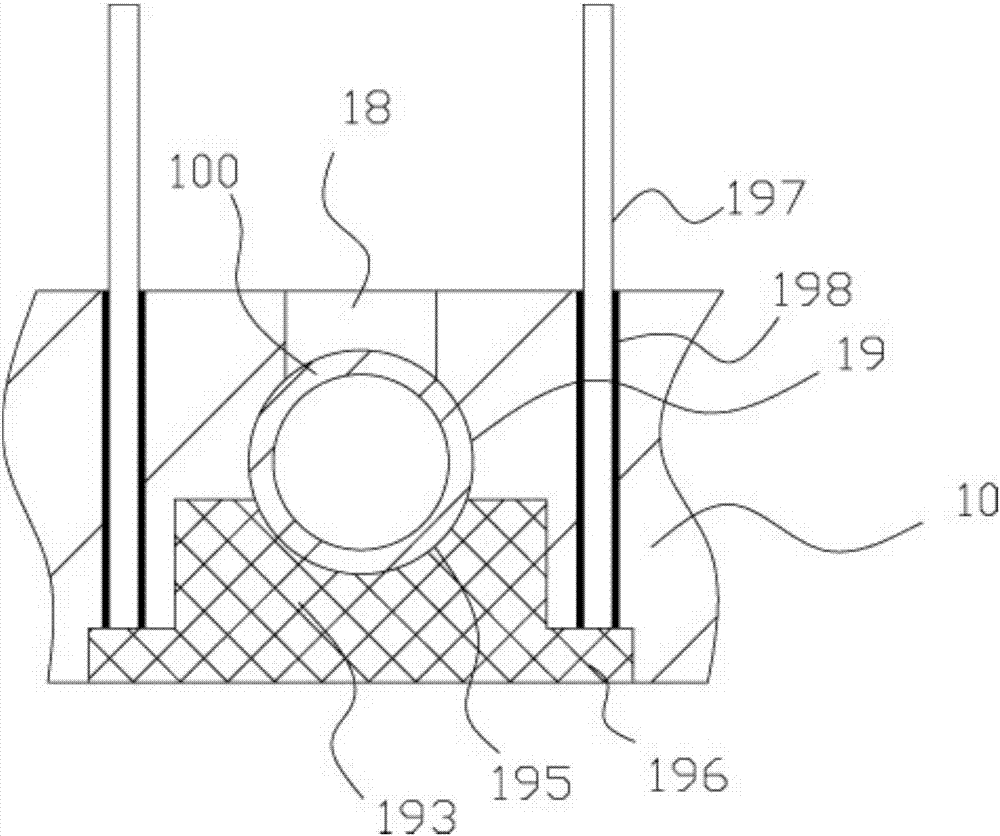

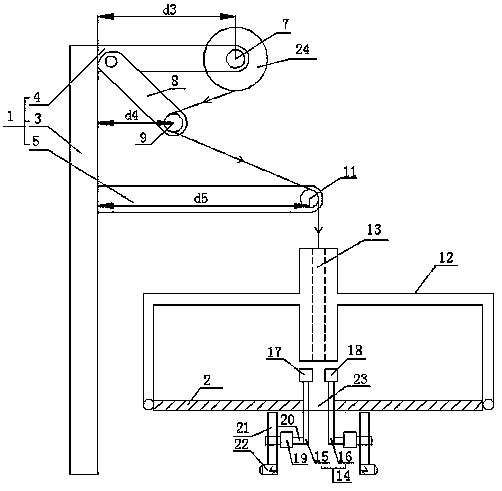

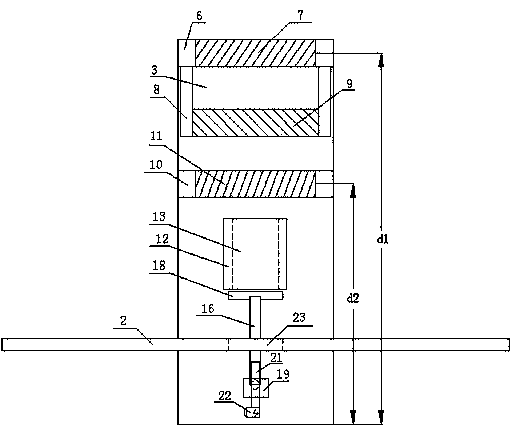

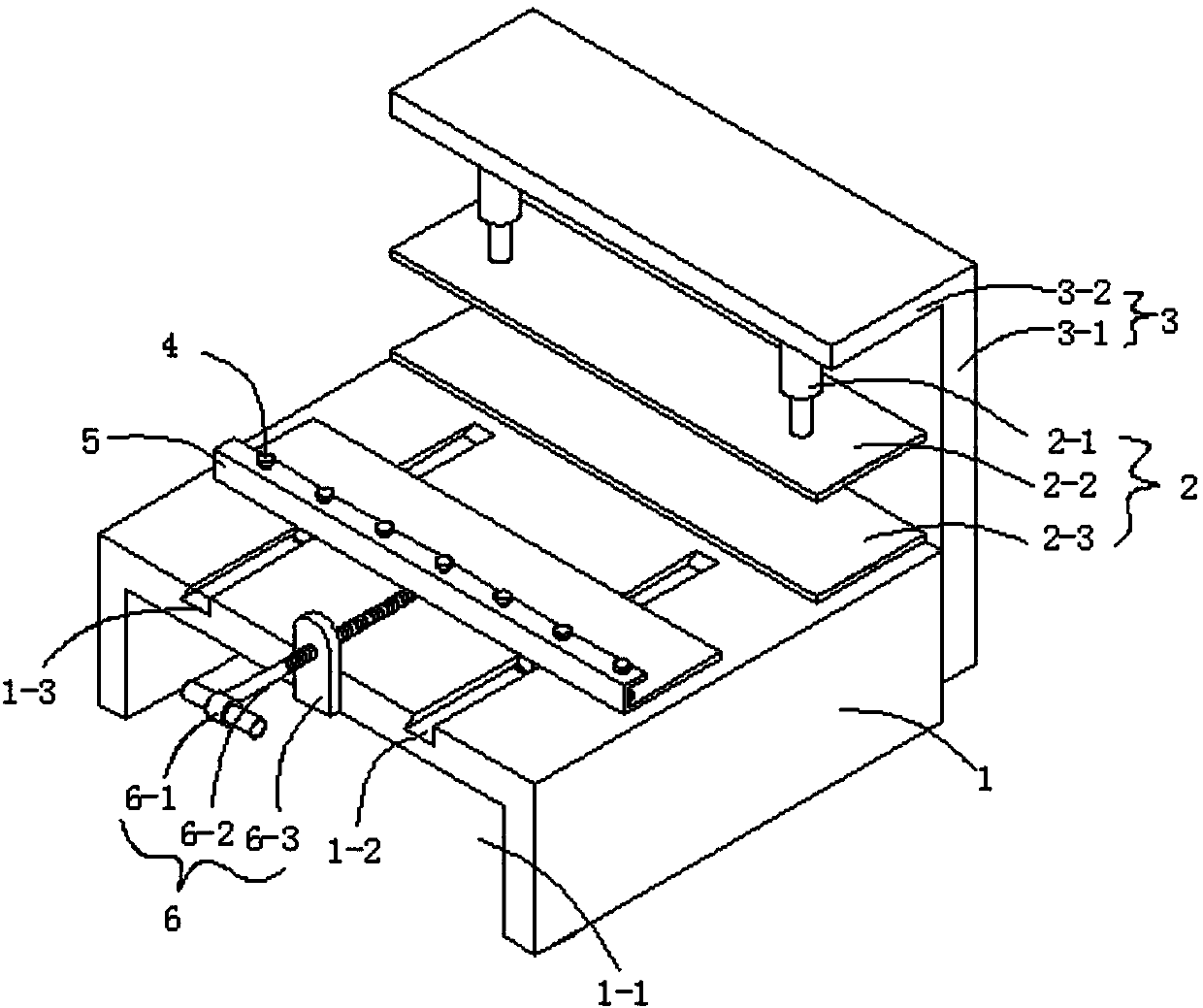

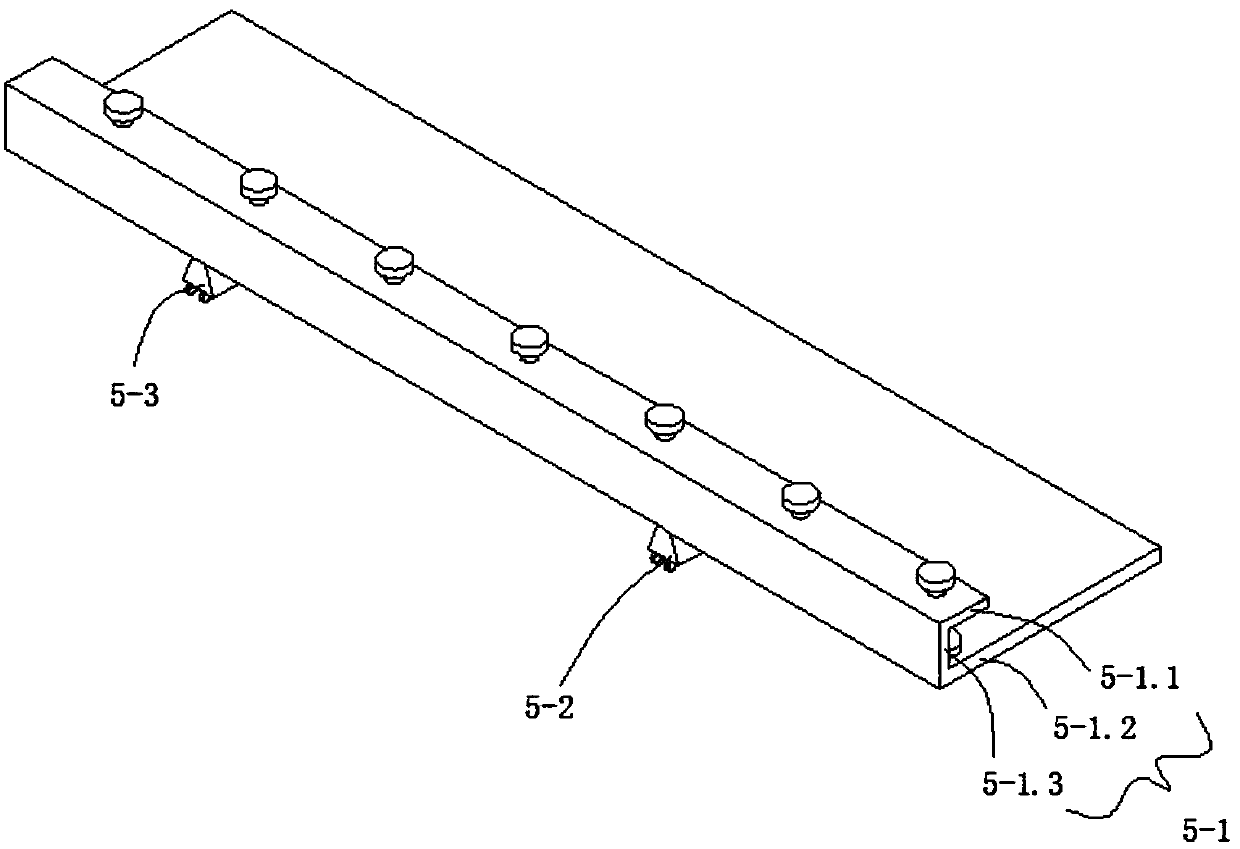

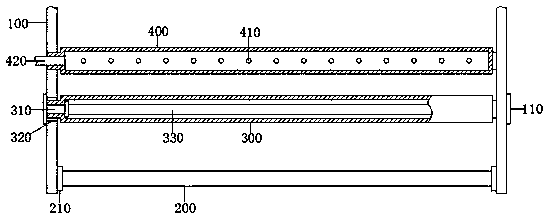

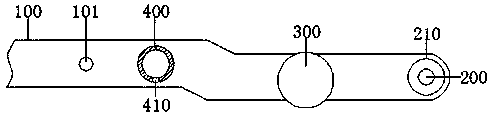

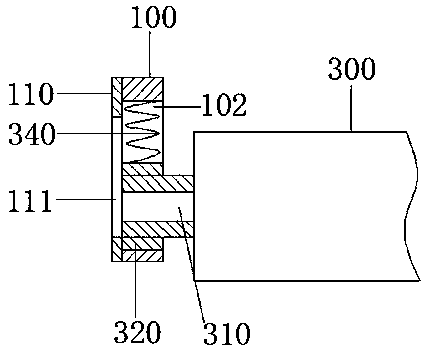

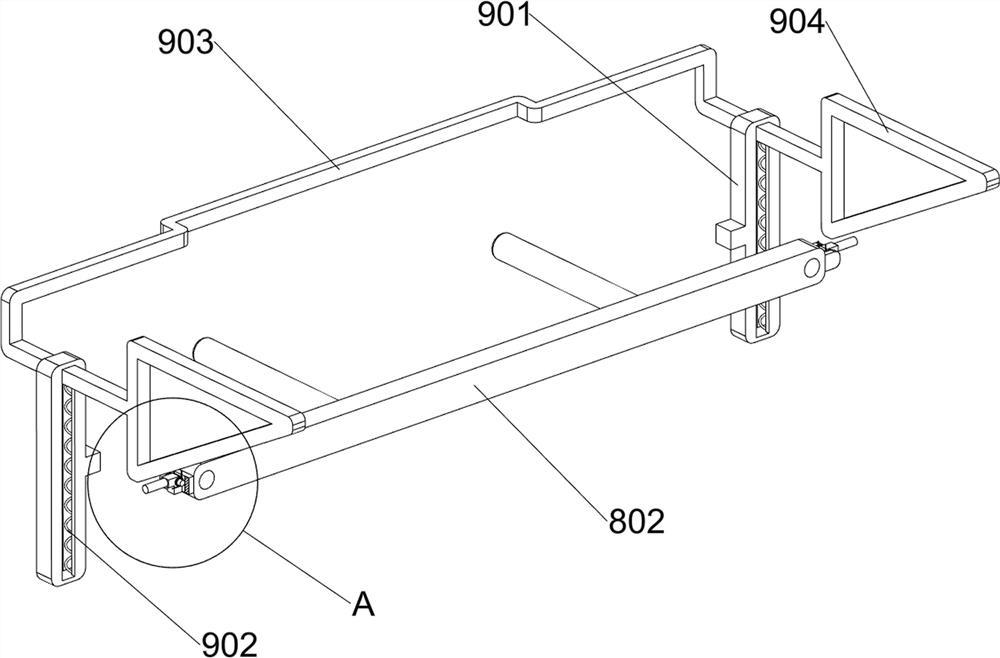

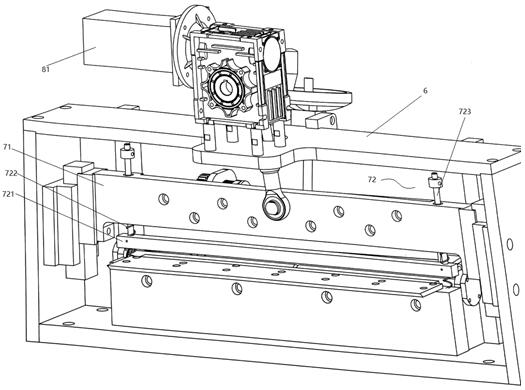

Feeding and discharging device for plastic pipe fitting cutting

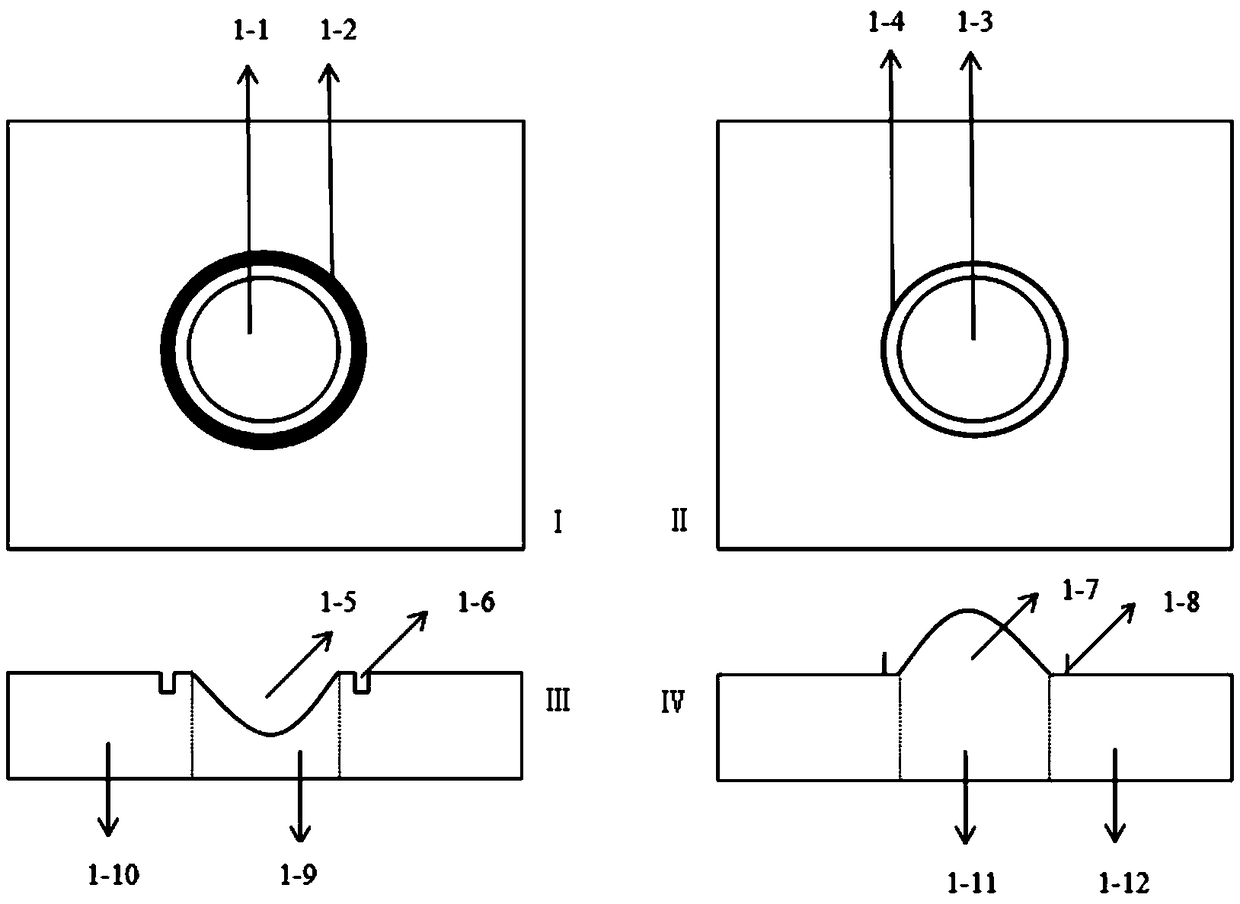

InactiveCN107160472AFor subsequent cuttingEasy to unloadMetal working apparatusPipe fittingEngineering

The invention discloses a material loading and unloading device for cutting plastic pipe fittings. On the top plate, a guide plate is fixed on the lower part of the right end of the top plate of the frame, the middle part of the guide plate has a blanking through hole, the blanking through hole corresponds to the right end of the feeding through hole, and the top edge of the guide plate has an upward extending The limit side of the frame, the outer wall of the support leg at the bottom of the right end of the frame is fixed with a material receiving plate, the bottom surface of the material receiving plate is fixed with a material receiving lifting cylinder, and the push rod of the material receiving lifting cylinder passes through the material receiving plate and is fixed with a material box Place the board. It can automatically lift and push the pipe fittings to facilitate subsequent cutting. It has high efficiency and good effect. The cut products are fed through the material box, and the material box is close to the guide plate. The product pops up, and when unloading, only the lower lifting plate needs to be lowered to unload the remaining material.

Owner:FOSHAN HUAPU RUILIAN ELECTROMECHANICAL TECH CO LTD

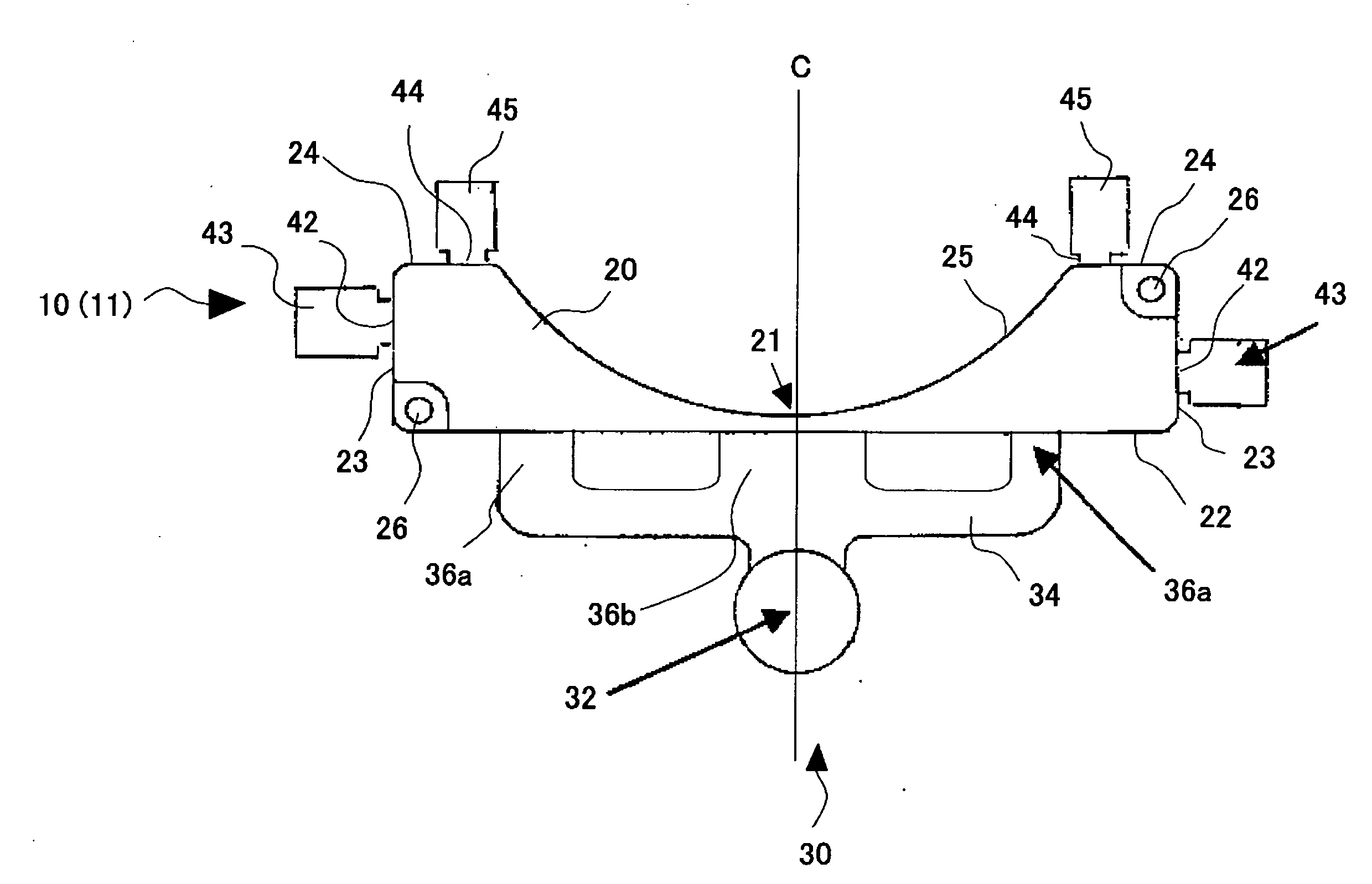

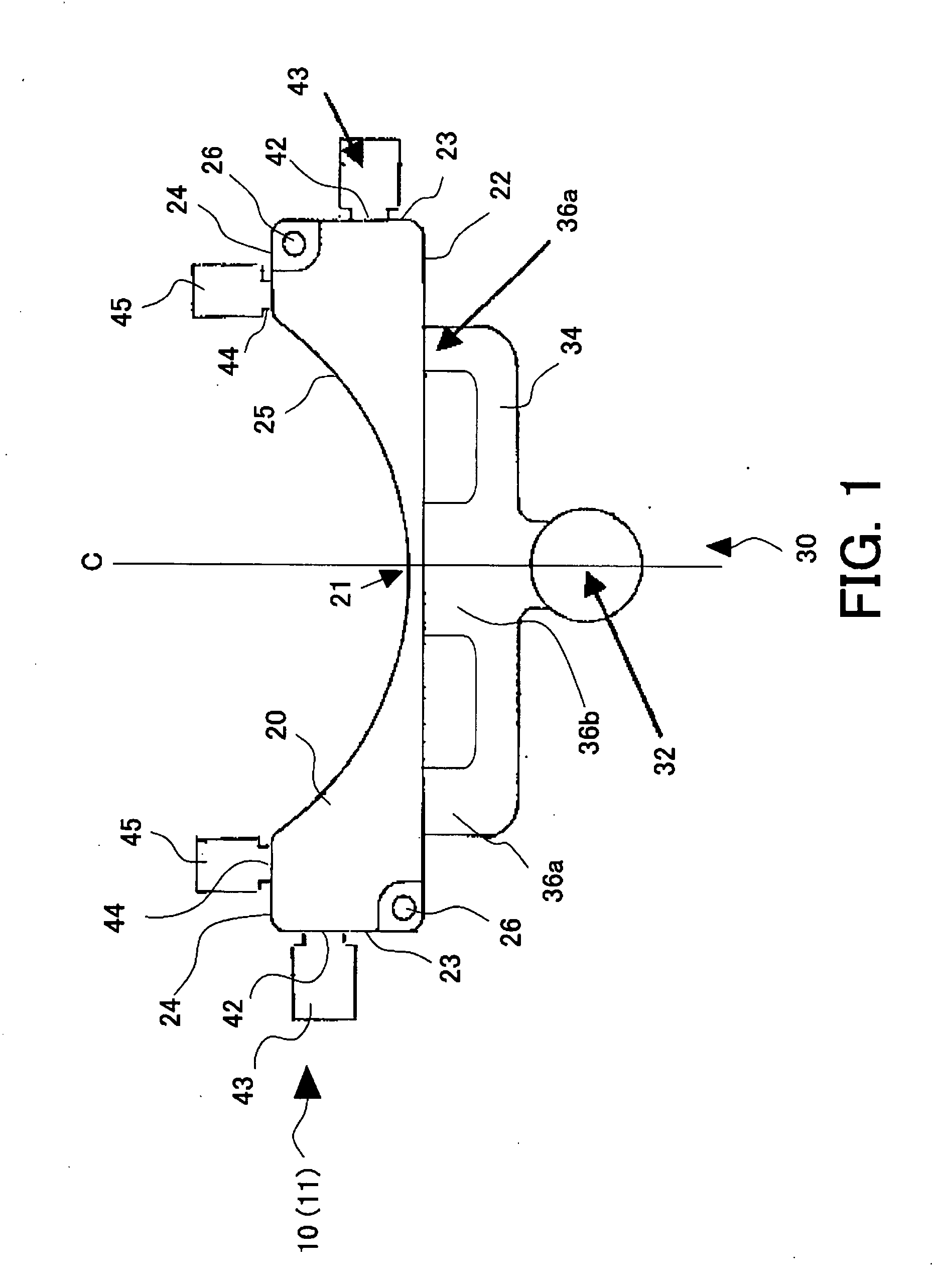

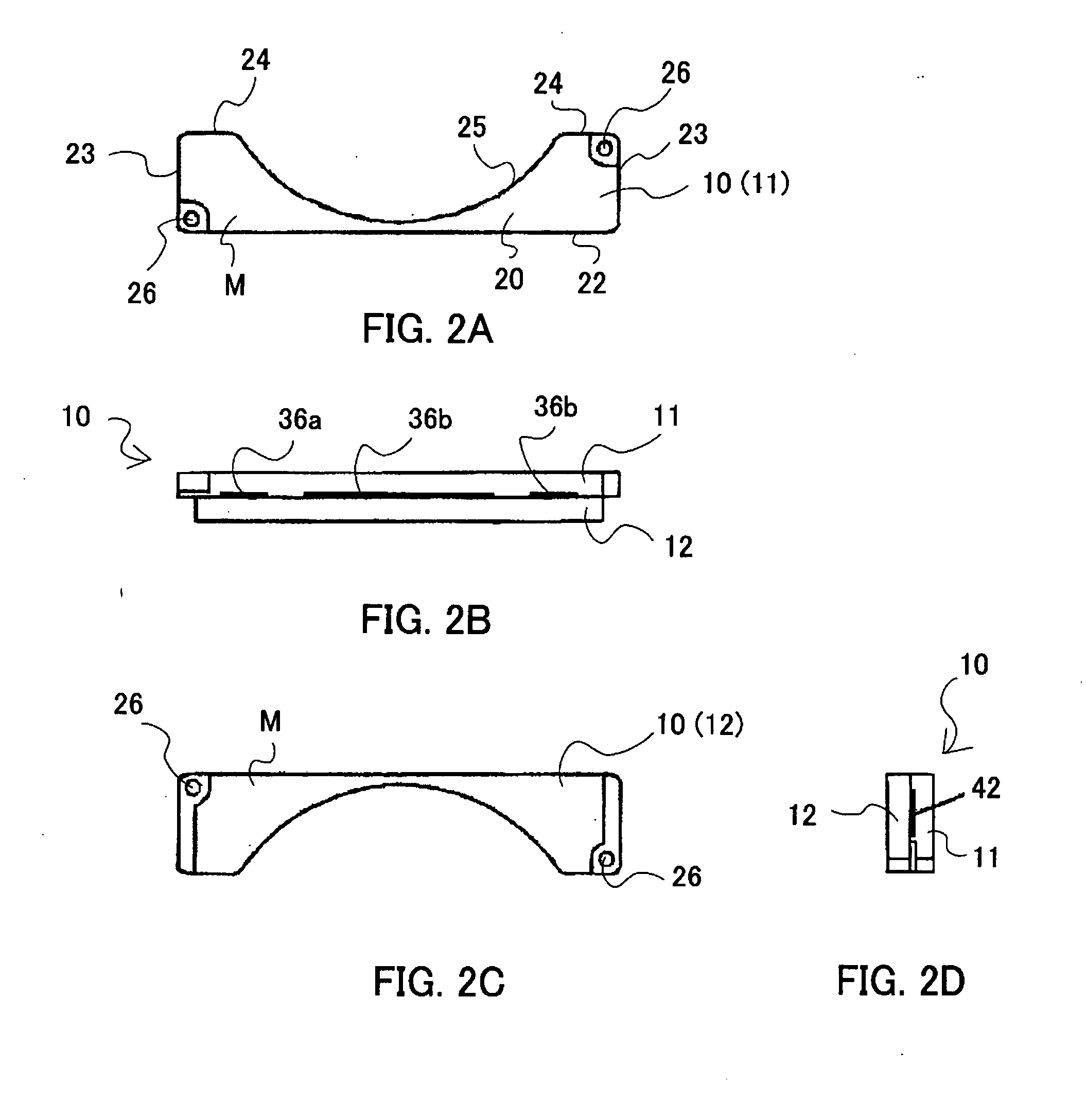

Mold used for metal mold casting, and damper manufacturing method using the mold

InactiveUS20080041549A1Reduce vibrationGood filling effectElectrical transducersUndesired vibrations/sounds insulation/absorptionMetal moldMolten metal

A mold used to manufacture, through metal mold casting, a damper that is fixed onto a housing in a disc drive and reduces a vibration of the housing, the disc drive recording information in and reproducing information from a recording medium. The mold includes a sectionally concave body that defines a shape of the damper, a first gate that introduces molten metal to the body from a runner, and is provided on a first side opposite to a concave of the body, and a second gate that introduces the molten metal to an overflow well from the body, and is provided at least one of a second side perpendicular to the first side, and a third side perpendicular to the second side and parallel to the first side.

Owner:FUJITSU LTD

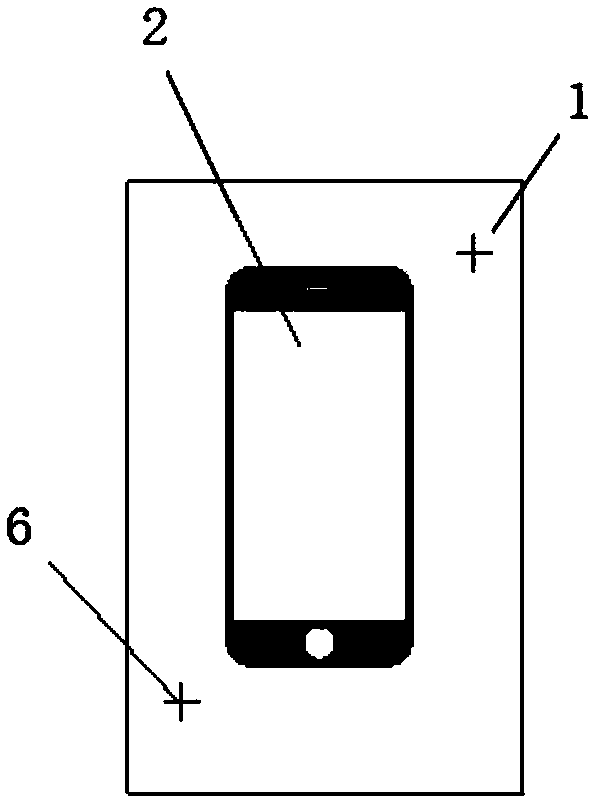

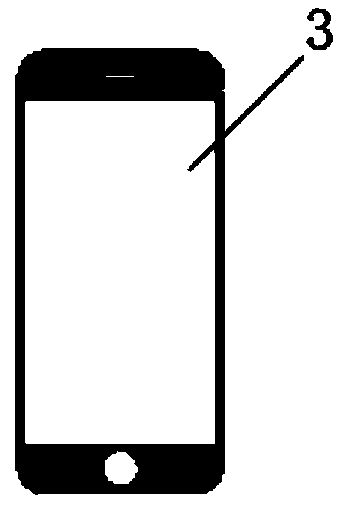

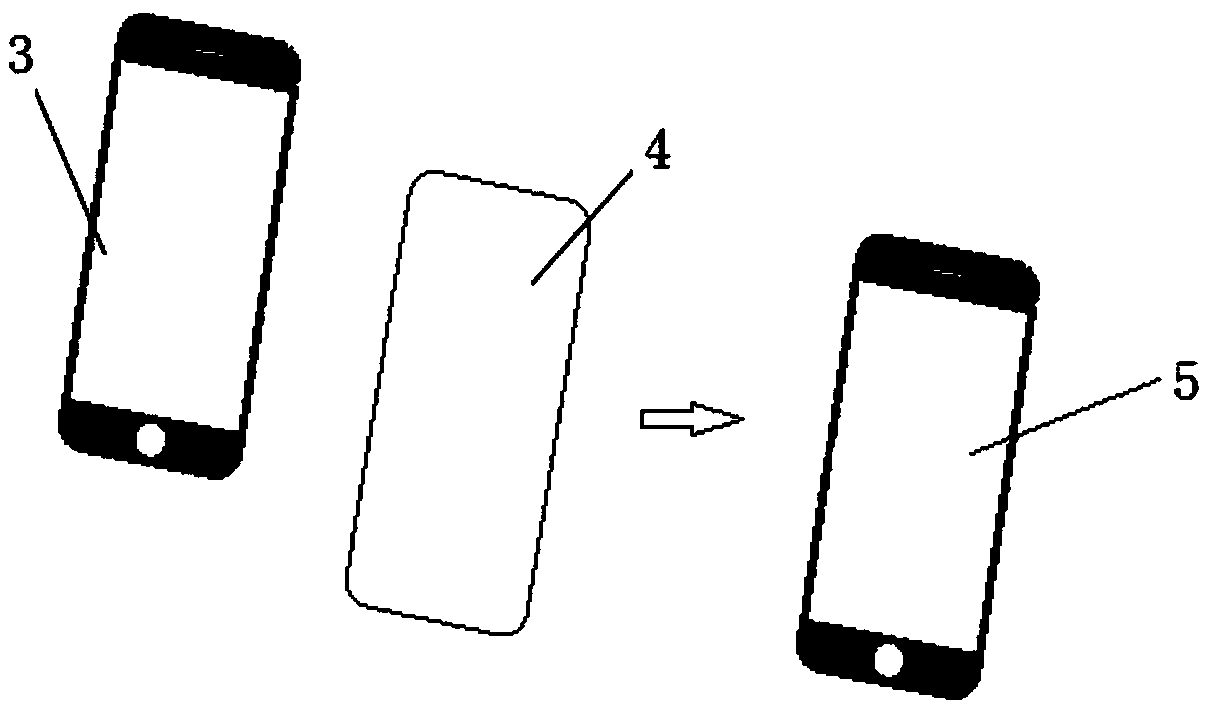

Mobile phone cover plate, manufacturing method thereof, and adopted device

ActiveCN107846485ANo time for splashing and hurting peopleReasonable choiceTelephone set constructionsAgricultural engineeringMobile phone

The invention provides a mobile phone cover plate comprising a mobile phone panel, a film sheet laminated on the mobile phone panel and a view window framework pattern printed on the film sheet, wherein the mobile phone panel, the film sheet and the view window framework pattern have the same specification. The mobile phone cover plate of the invention is simple in structure and easy to manufacture. The invention further provides a manufacturing method of the mobile phone cover plate, comprising the following steps: firstly making the view window framework pattern on the film sheet, then cutting the film sheet view window via laser, and finally laminating the film sheet view window on a glass surface to obtain the mobile phone cover plate. By adoption of the method provided by the invention, the view window framework pattern is printed on the film sheet and is cut in combination with a carbon dioxide laser machine, so no fragment is split, thereby greatly improving the construction safety; and the remaining printing link in the technical process can be recycled, the printing link does not need to be removed by adding liquid medicine, thereby greatly reducing the cost. The inventionfurther provides a device used for manufacturing the mobile phone cover plate, and the components are easy to obtain, so that the production is convenient.

Owner:LENS TECH CHANGSHA

Equipment for cutting polyimide fiber and cutting method

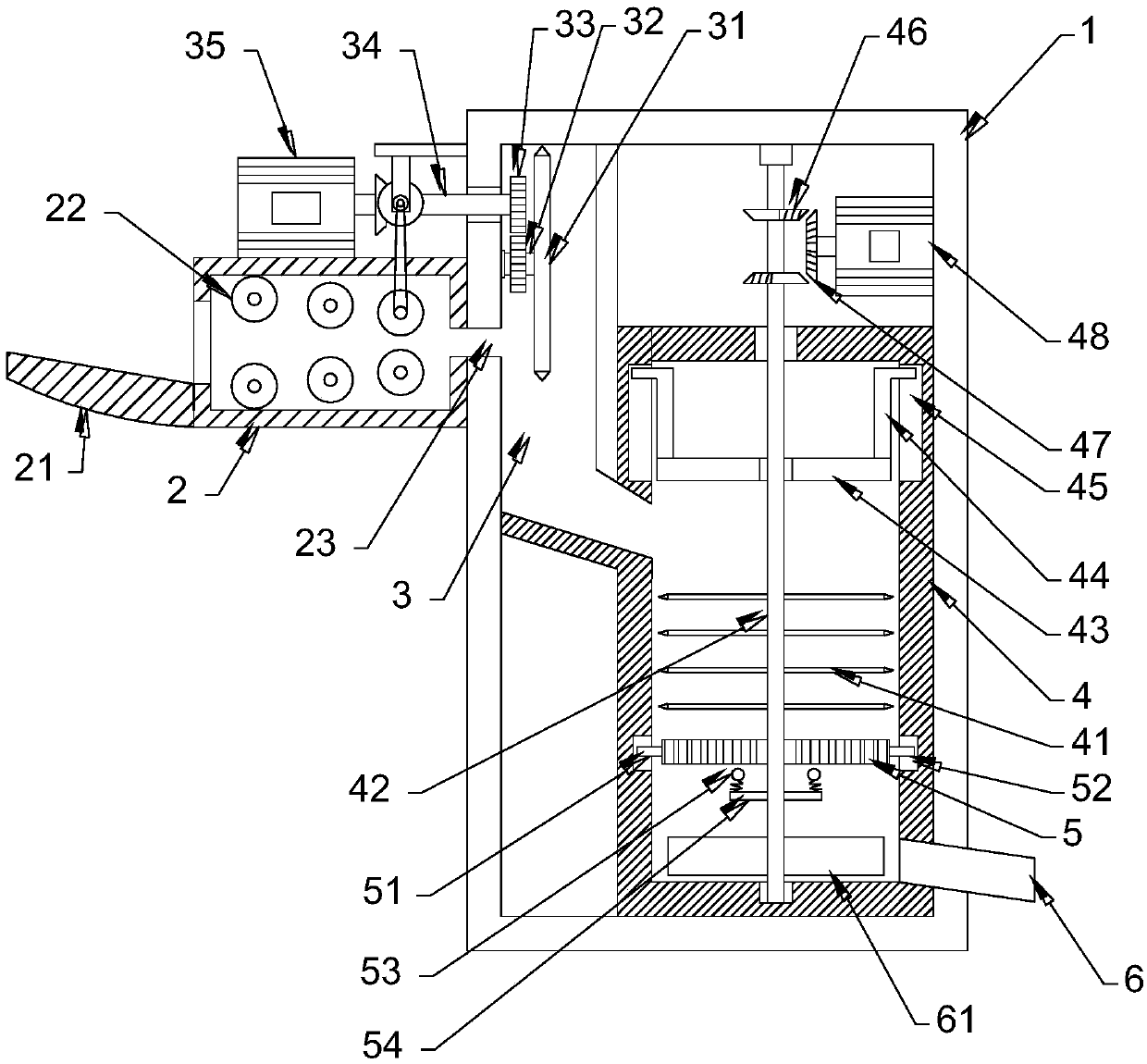

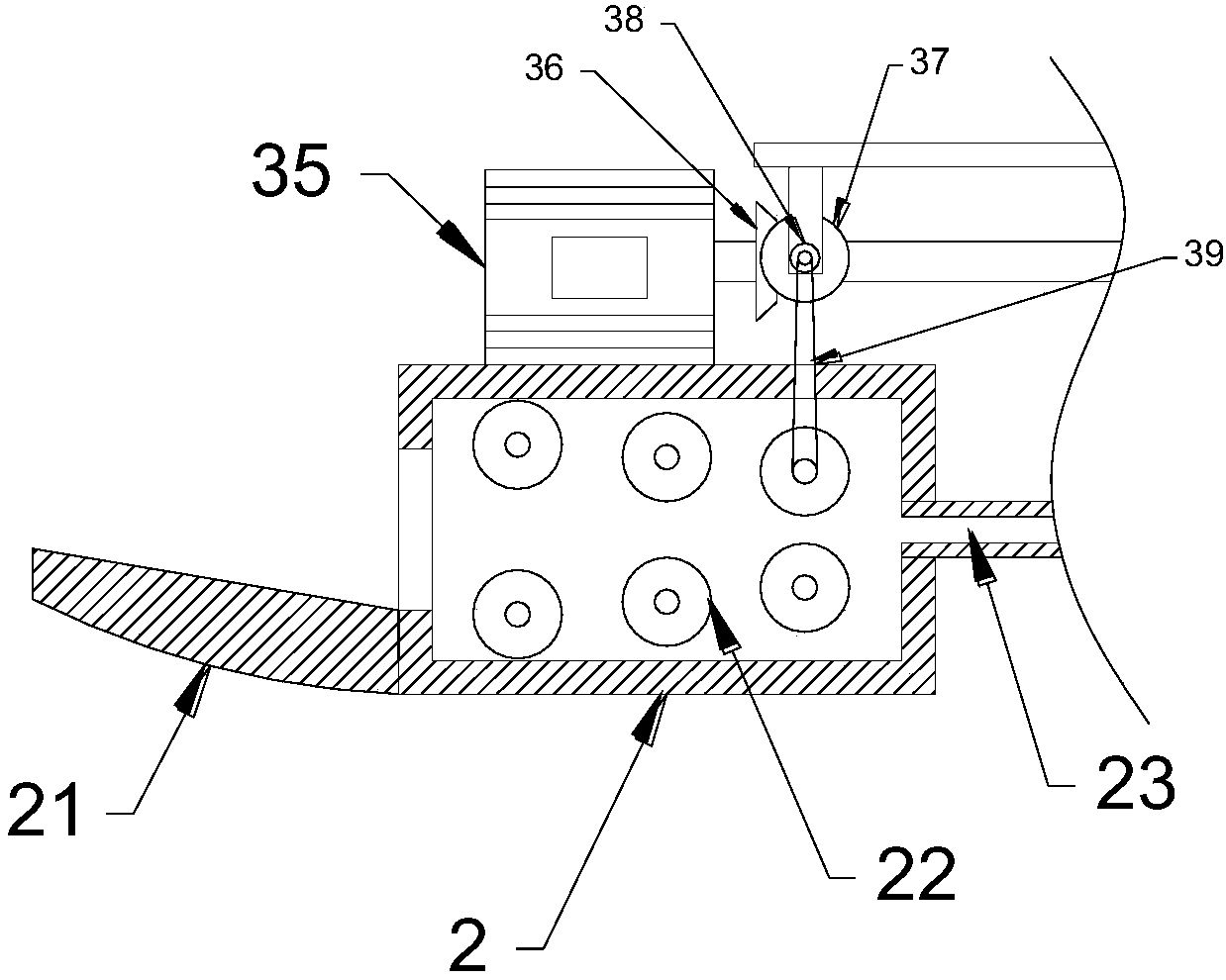

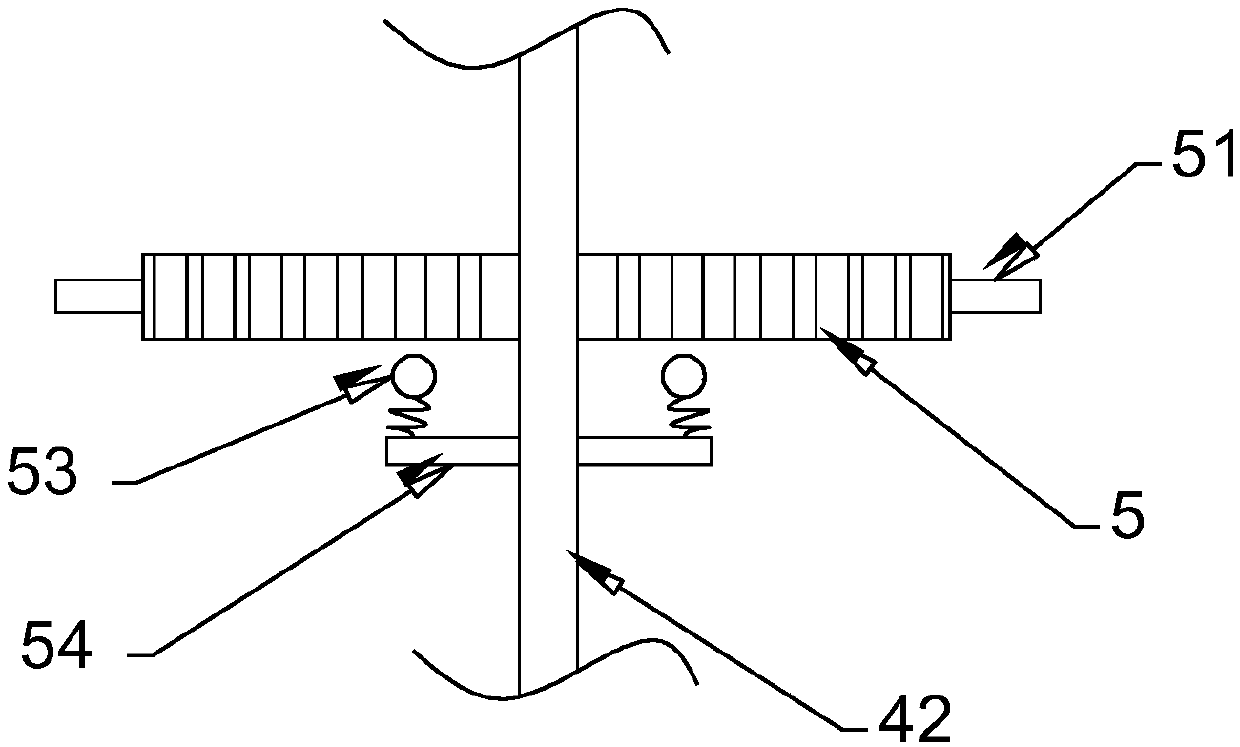

InactiveCN111139556AMeet application needsFor subsequent cuttingLiquid/gas/vapor removalTextile treatment carriersFiberEngineering

The invention discloses equipment for cutting a polyimide fiber. The equipment comprises a rack, wherein a tiling mechanism, a sizing mechanism, a setting mechanism, a feeding mechanism, a clamping mechanism, a shearing mechanism and a silk storage mechanism which are used for treating the polyimide fiber are sequentially arranged on the rack; the shearing mechanism comprises a limiting block usedfor positioning the polyimide fiber and a shearing device used for cutting the polyimide fiber; the limiting block is fixedly arranged on the rack; a shearing gap matched with the polyimide fiber isreserved between the limiting block and the clamping mechanism; and the shearing device is arranged at the shearing gap. The device is reasonable in design and good in shearing effect, a polyimide fiber segment with the specified length can be effectively cut through tiling, sizing, setting, feeding, clamping and shearing of the polyimide fiber, and the application requirements of the market in the special field can be well met.

Owner:JIANGSU AOSHEN HI TECH MATERIALS CO LTD

Method for preparing easily cut nickel-zinc magnetic core half-finished product

The invention discloses a method for preparing an easily cut nickel-zinc magnetic core half-finished product. The method comprises the following steps: mixing raw materials, performing vibration milling, pelletizing, transferring into a rotary kiln, performing pre-sintering, preparing polyvinyl alcohol glue, mixing products of the two former steps with aids, performing superfine grinding, spray pelletizing and pressing molding, thereby obtaining the easily cut nickel-zinc magnetic core half-finished product. The easily cut nickel-zinc magnetic core half-finished product prepared by using the method is relatively high in strength, good in flexibility, not liable to be fractured, uniform in texture, convenient in later cutting, not liable to be damaged or broken when being cut and tidy in notch, the rejection rate of the production process is greatly reduced, the production cost can be reduced, and the production efficiency can be improved.

Owner:ZHONGSHAN DONGCHEN MAGNETIC ELECTRONICS PROD CO LTD

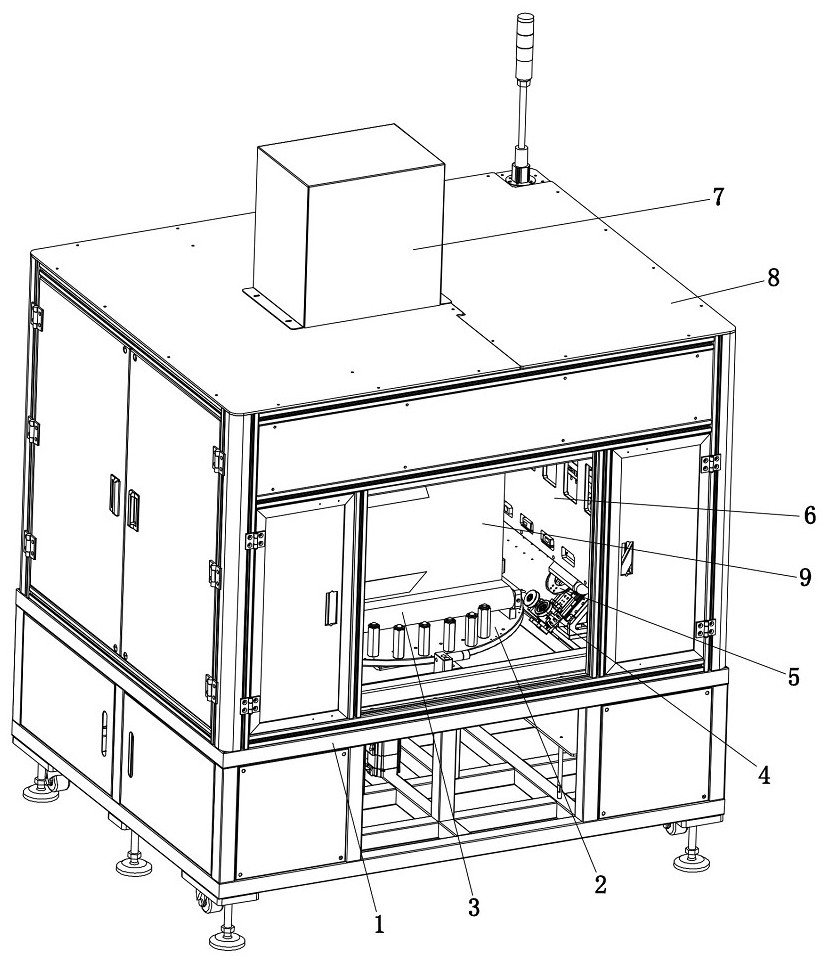

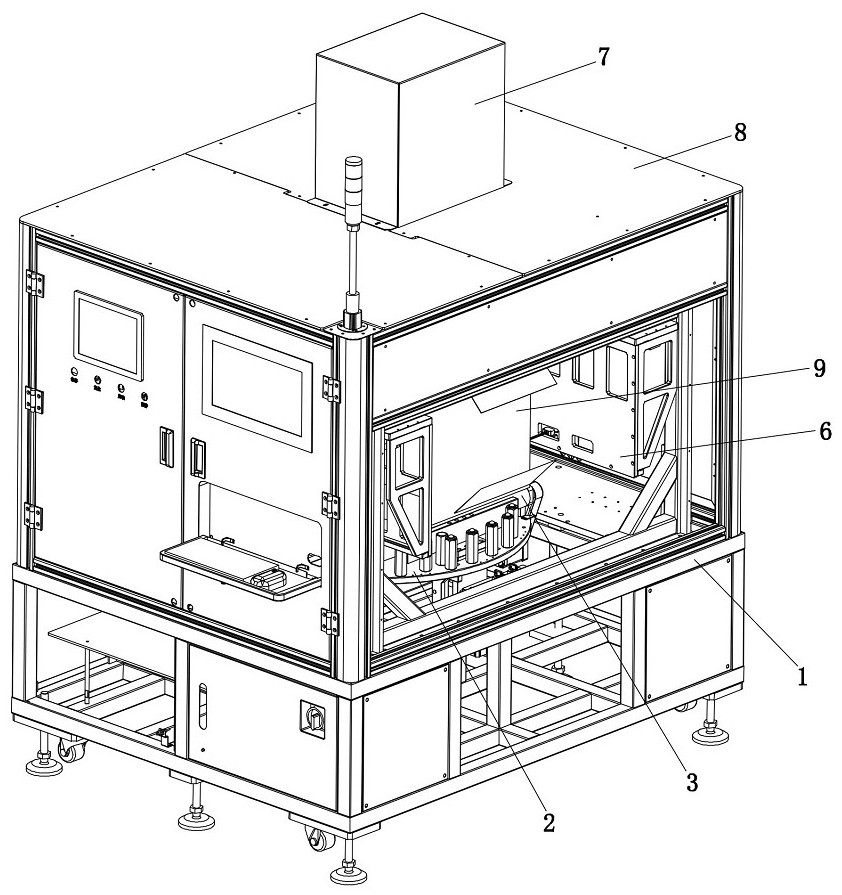

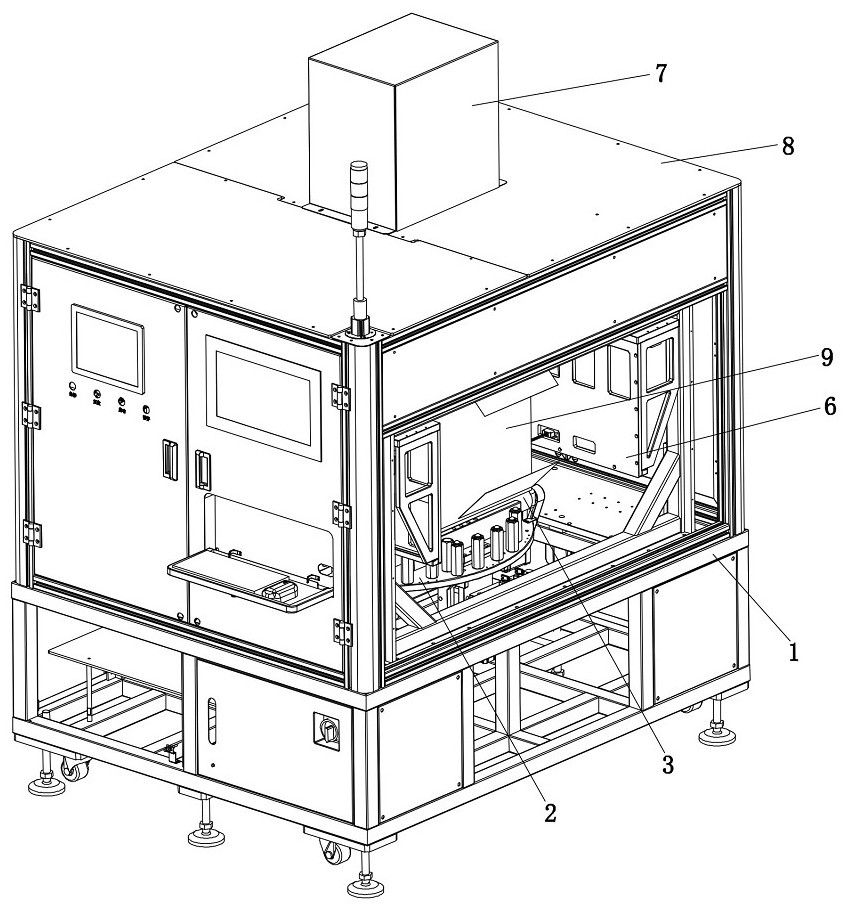

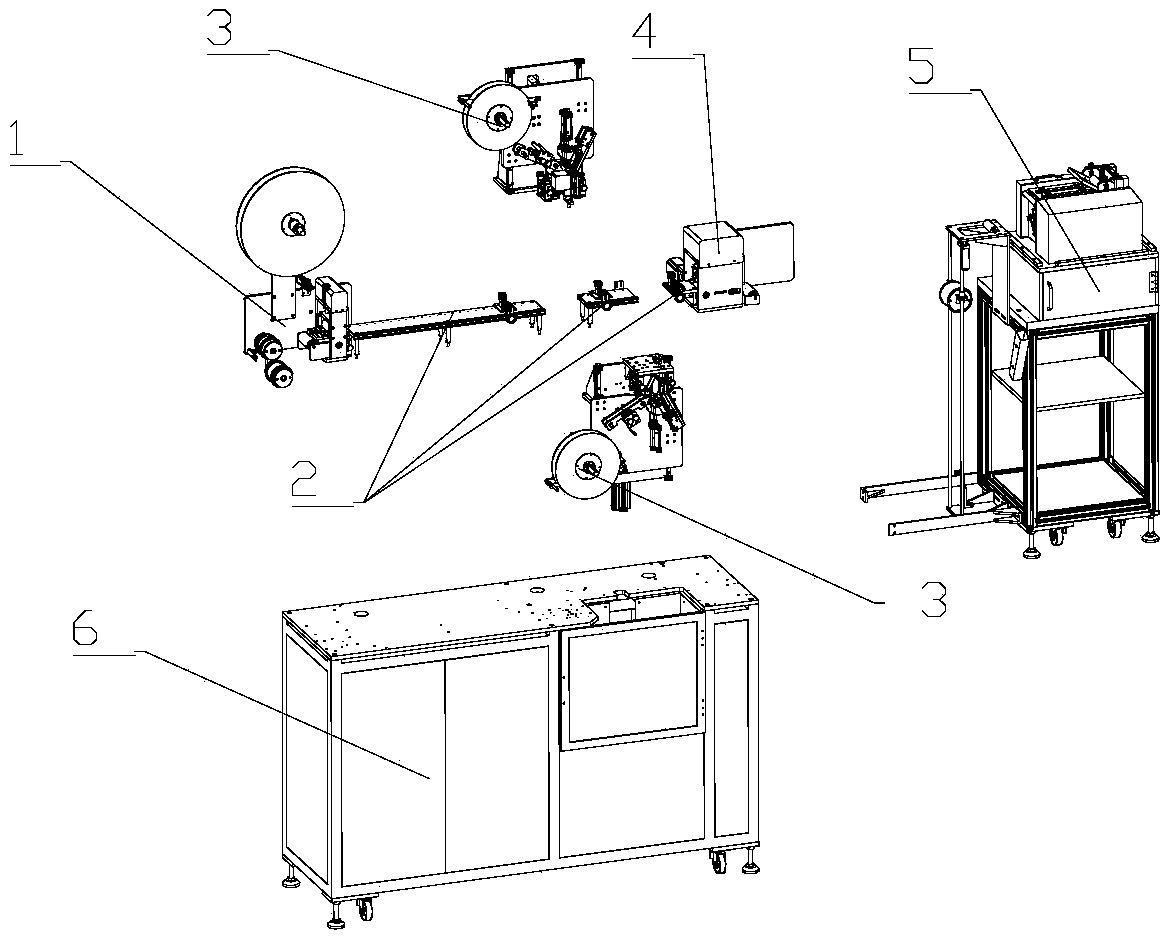

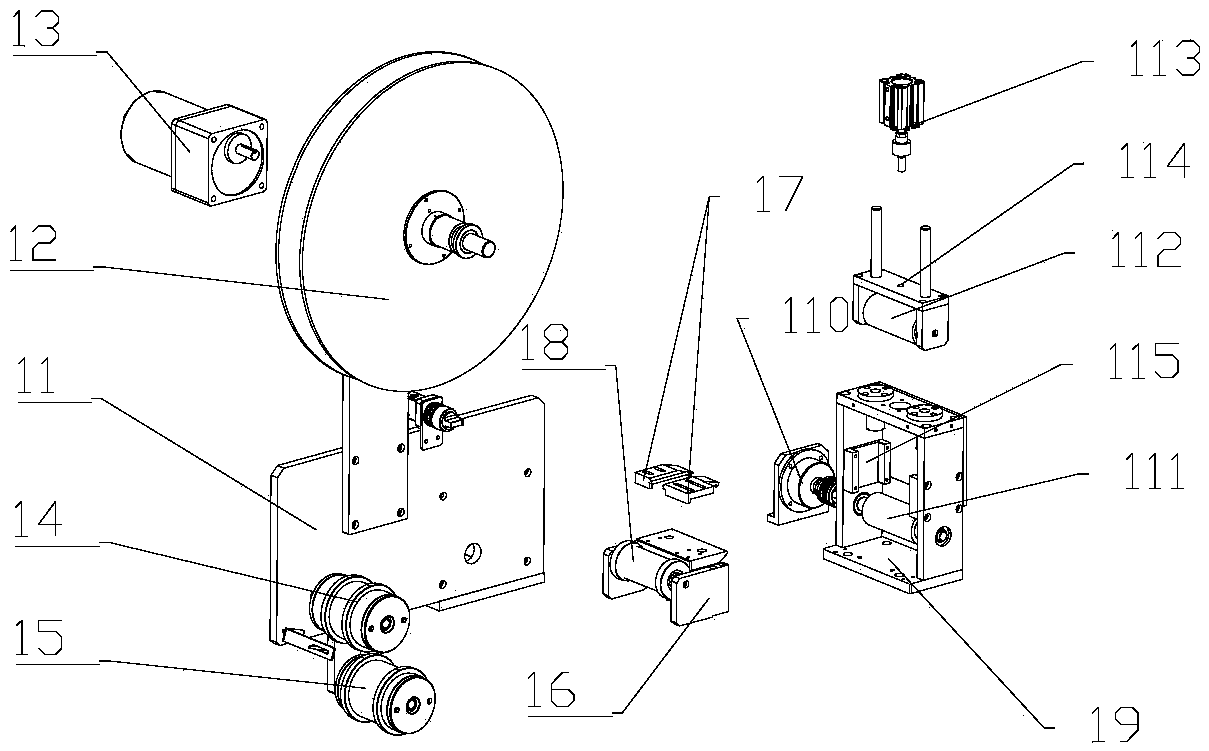

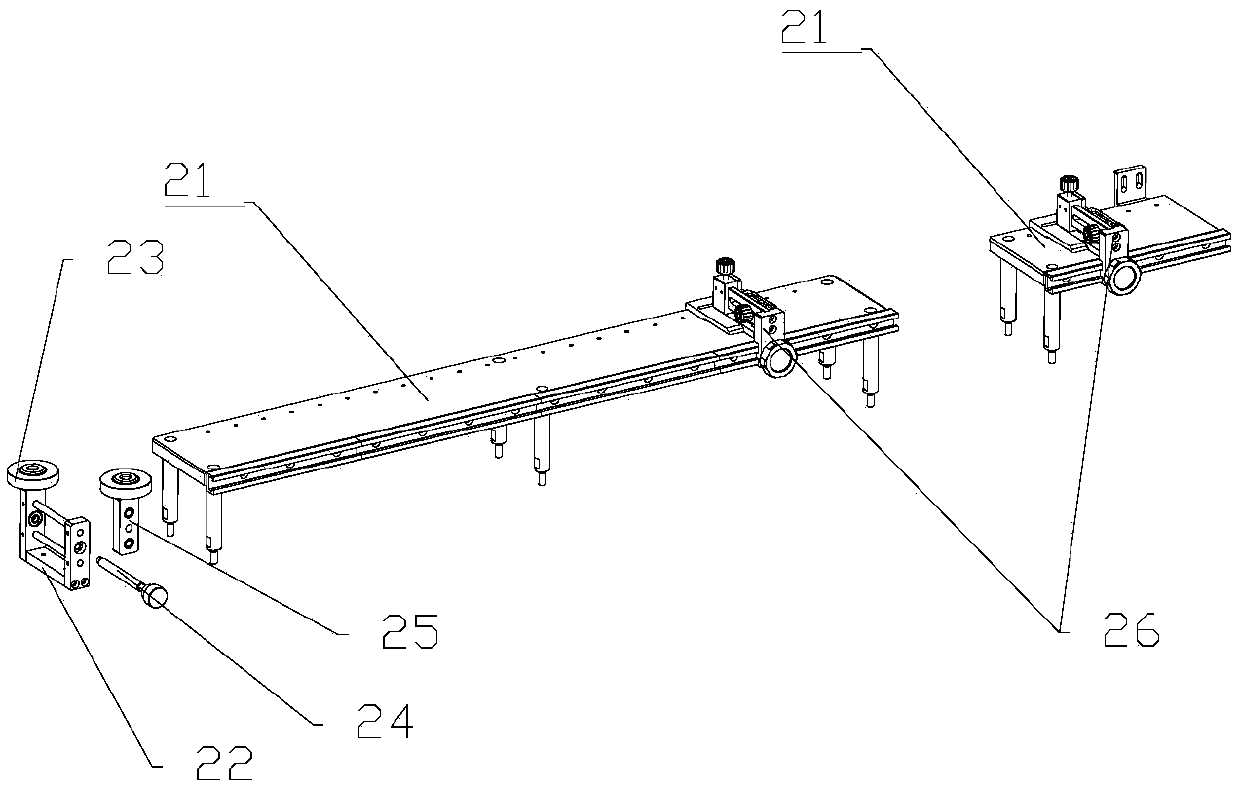

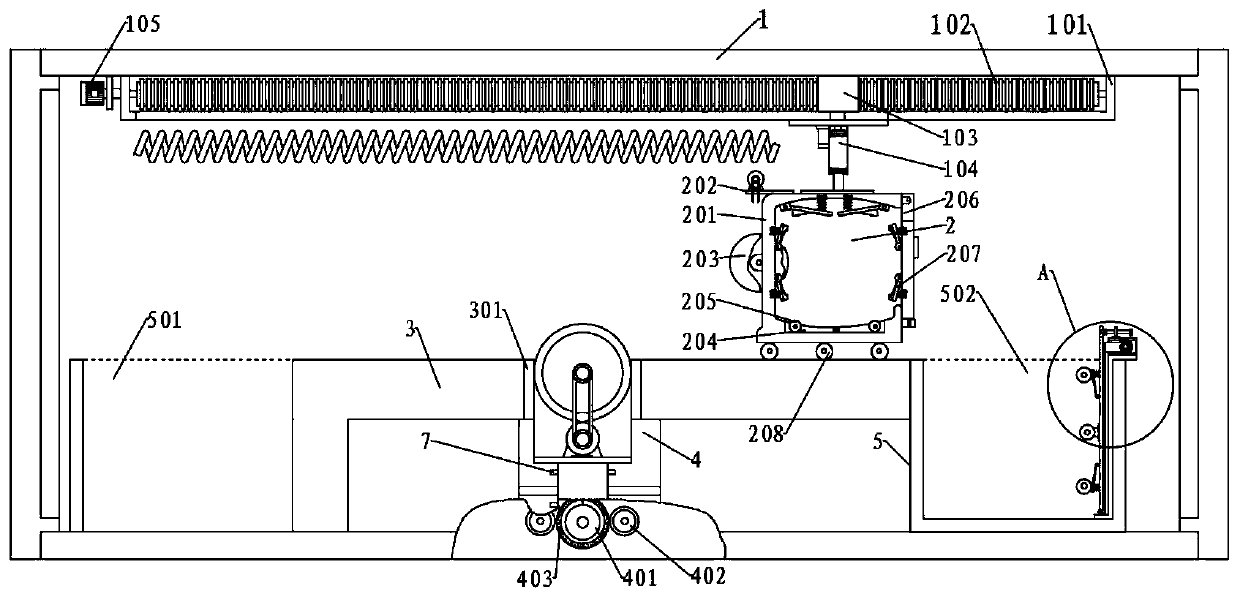

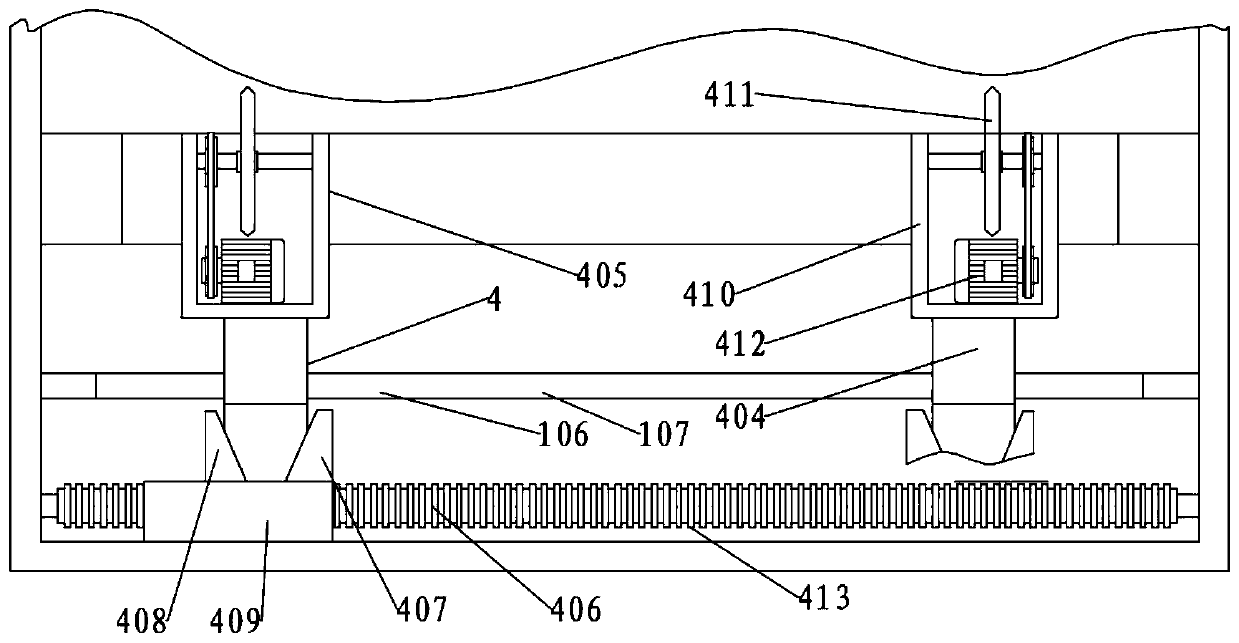

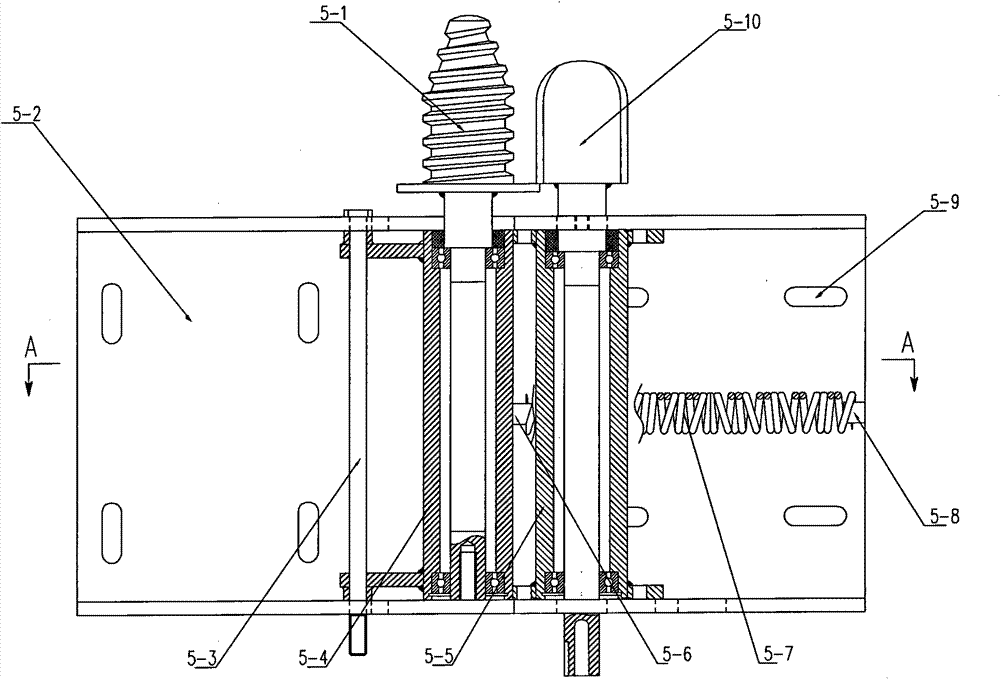

Automatic unpacking line body and automatic unpacking process thereof

ActiveCN111994398AAvoid Cutting Bad SituationsLess damageUnpacking by cuttingStructural engineeringMachine

The invention discloses an automatic unpacking line body. The automatic unpacking line body comprises a rotary disc mechanism, a conveying mechanism, a sharpening mechanism, unpacking mechanisms, a side pressing and driving mechanism and a box pressing mechanism. The rotary disc mechanism is arranged on a machine table. The conveying mechanism is horizontally arranged on the rotary disc mechanism.A frame body is erected above the rotary disc mechanism. The side pressing and driving mechanism is arranged on the frame body. The two unpacking mechanisms are arranged on the side pressing and driving mechanism. The box pressing mechanism is arranged on the frame body, the box pressing mechanism presses box bodies from top to bottom, and the box bodies are cut up along the two side edges of thebox bodies through the two unpacking mechanisms. The rotary disc mechanism drives the conveying mechanism and the box bodies to rotate by 90 degrees, and the other two side edges of the box bodies are cut up through the unpacking mechanisms. The automatic unpacking process includes the steps of S1, box body conveying and blocking; S2, box body side pressing; S3, box body downward pressing; S4, cutter feeding; S5, box cutting; S6, steering; and S7, discharging. The functions such as incoming material caching, automatic box distributing and automatic unboxing are achieved, and full-automatic splitting of the box bodies is achieved.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

Auxiliary cleaning device for quartz glass cutting machining

The invention discloses an auxiliary cleaning device for quartz glass cutting machining. The auxiliary cleaning device comprises a box body, wherein a control switch is arranged on one side of the outer part of the box body; a protective transparent plate is arranged on the upper side of the box body; a rotary placement plate is arranged at a middle position inside the box body; inclined sliding plates which are uniformly distributed in equal distance are arranged on one side, which is close to the rotary placement plate, inside the box body; a servo motor is arranged at a position, which is close to one side of the rotary placement plate, of the outer part of the box body; an output shaft of the servo motor is connected with a rotating shaft by virtue of a coupling; and a discharging cover plate is connected to one side of the lower part of the box body by virtue of a hinge. An electric blower is pushed to rotate by virtue of expansion and retraction of a second electric telescopic rod, so that multi-angle blowing cleaning can be realized. Due to a ventilating slot formed inside the rotary placement plate, the cleaning effect can be improved, subsequent cutting is conveniently performed, the powdered scrap produced by cutting can be prevented from escaping into air by virtue of the inclined sliding plates and the protective transparent plate, and the auxiliary cleaning deviceis convenient to use.

Owner:LIMING VOCATIONAL UNIV

A processing device for a flexible circuit board

InactiveCN109104816AReduce defective rateImprove yield rateControlling laminationLaminationFlexible circuitsEngineering

The invention relates to the production technical field of flexible circuit boards. A processing device for a flexible circuit board comprises a frame, a feeding device, a feeding platform assembly, aglue sticking device, a glue pressing device and a cutting device, wherein the feeding device, the feeding platform assembly, the glue sticking device and the glue pressing device are installed on the frame, the feeding device is connected with the feeding platform assembly, and the glue pressing device corresponds to the position of the feeding platform assembly, and the glue pressing device, the glue sticking device, the glue pressing device and the cutting device are connected in turn. The processing device of the flexible circuit board has the advantages of automatically completing the wire feeding, the glue paper feeding, the glue paper pasting, the glue paper cutting, the glue paper detecting, the pressing and cutting, and achieves high processing efficiency.

Owner:张金仙

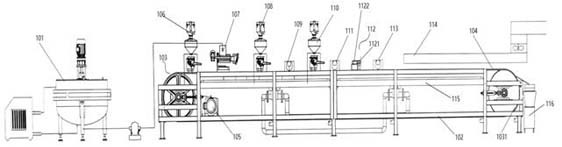

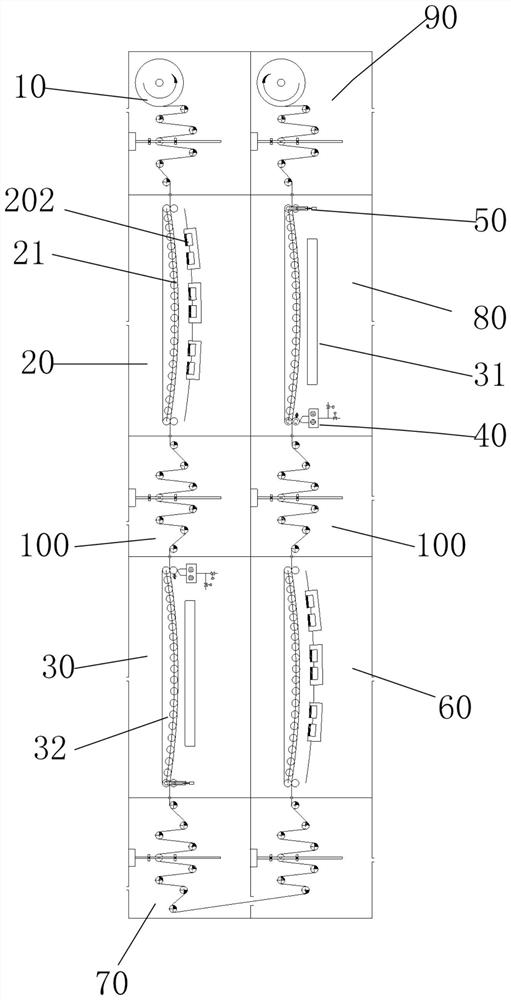

Sticky candy making system

ActiveCN112205503AIncrease productivityHigh degree of automationConfectionerySweetmeatsProcess engineeringMechanical engineering

The invention relates to a sticky candy making system. The sticky candy making system is characterized by comprising a crude product forming module, a cooling module and a slitting and dicing module,wherein the crude product forming module, the cooling module and the slitting and dicing module are sequentially arranged to form an assembly line; a flow type production line is adopted, so that themanufactured sticky candy is conveyed to an extruder through a pump, and flow type sticky candy piece production is achieved through cooperation of a sesame spreading machine, a peanut grain spreadingmachine and a pressing roller. an annular cutter roller seat can be replaced; an isolation conveying module is adopted to prevent the cut candy bars from being adhered together again; a candy bar buffer groove is formed, and sesame is placed in the groove, so that the sesame is adhered to the side surface of the split sticky candy; the problem that subsequent candy bars are still conveyed to cause extrusion when the candy bars are diced can also be avoided; a stripping pressing plate unit is arranged on the side edge of a cutter module when the candy bars are cut, so that the stripping pressing plate unit firstly makes contact with the candy bars and then leaves the candy bars when the cutter module cuts the candy bars, and the candy bars are prevented from adhering to the cutter module.

Owner:NANTONG WEALTH MASCH TECH CO LTD

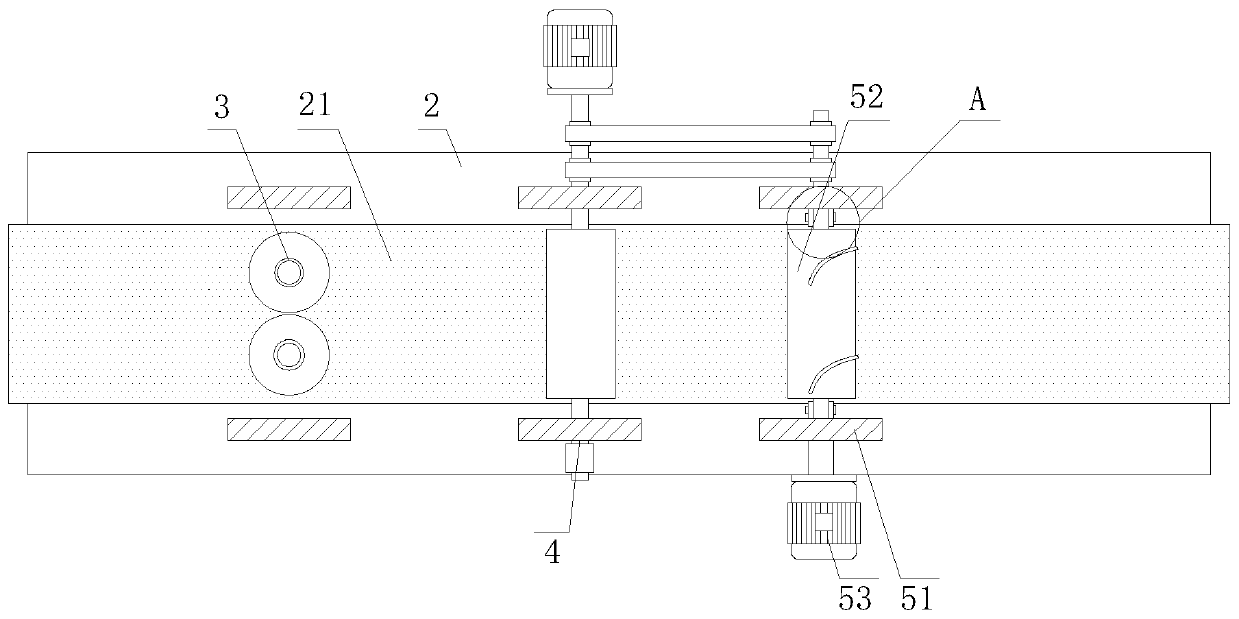

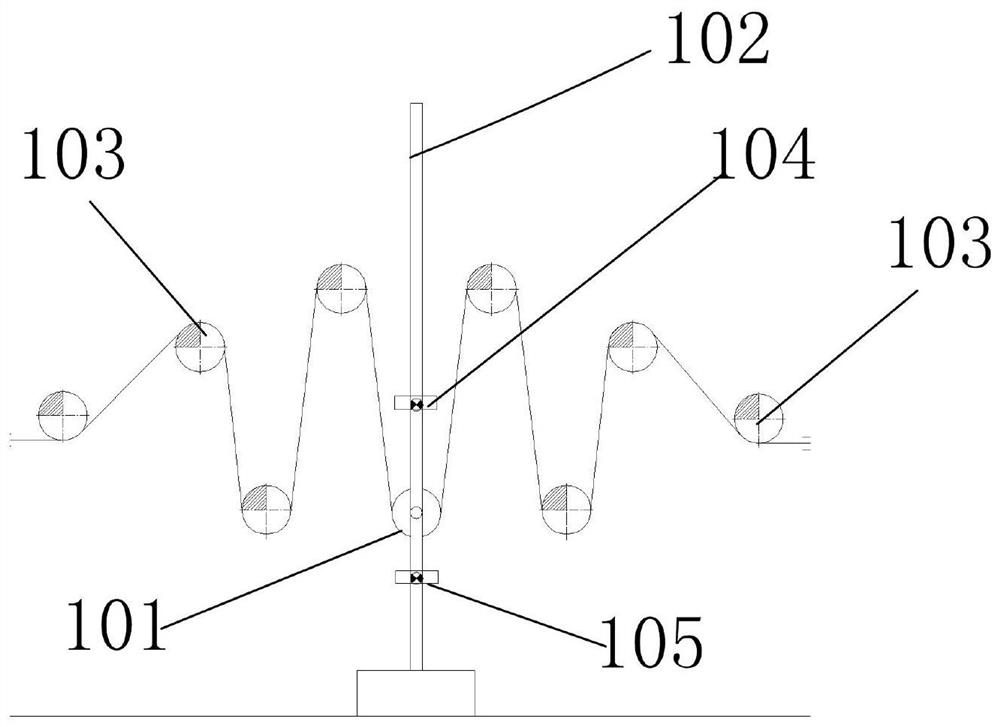

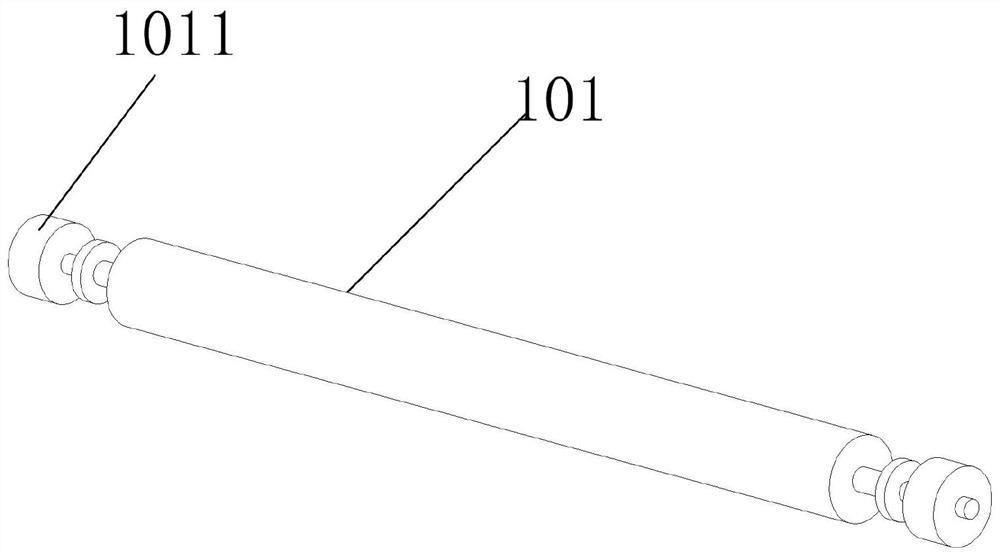

Diaphragm conveying device of accumulator packing machine

The invention relates to a diaphragm conveying device of an accumulator packing machine. The diaphragm conveying device comprises a support frame and a conveying machine, wherein the support frame consists of a vertical frame, a first horizontal frame and a second horizontal frame; first diaphragm roller is arranged between first support arms; a second diaphragm roller is arranged between connecting plates; a third diaphragm roller is arranged between second support arms; a guide frame plate is arranged on the conveying machine; a clamping mechanism is arranged at the bottom of a guide groove, and comprises a first clamping rod and a second clamping rod; the other ends of the first clamping rod and the second clamping rod penetrate through the conveying machine, and are respectively provided with cylinders; piston rods are arranged between the cylinders and the first and second clamping rods; and lead screws are arranged on the cylinders. The diaphragm conveying device is high in positioned diaphragm feeding precision, prevents the diaphragm folding marks in the conveying process, facilitates to subsequently assemble and arrange plate groups, and improves the production efficiency.

Owner:JIANGSU RONGWEI ENVIRONMENTAL PROTECTION TECH

Combined clamping tool

InactiveCN107745455ASolve the phenomenon of deviationReduce wasteWorking accessoriesEngineeringMechanical engineering

The invention discloses a combined clamping tool and relates to the technical field of clamping tools. The clamping tool of the invention comprises a workbench; a left and right ends of the workbenchsurface are respectively provided with an adjustable clamping base and a fixed holding base; the workbench is provided with a chute A and a chute B which are parallel, wherein the chute A and the chute B are non-return grooves of larger tops and smaller bottoms; the adjustable clamping base comprises a bending board assembly whose opening faces the right; a bottom of the bending board assembly isprovided with a roller assembly A and a roller assembly B which are respectively matched with the chute A and the chute B; the bending board assembly is provided with a pressing assembly. The invention has the advantages of simple structure and convenient use, and can clamp the tempered glass with different sizes.

Owner:成都鑫晨航空科技有限公司

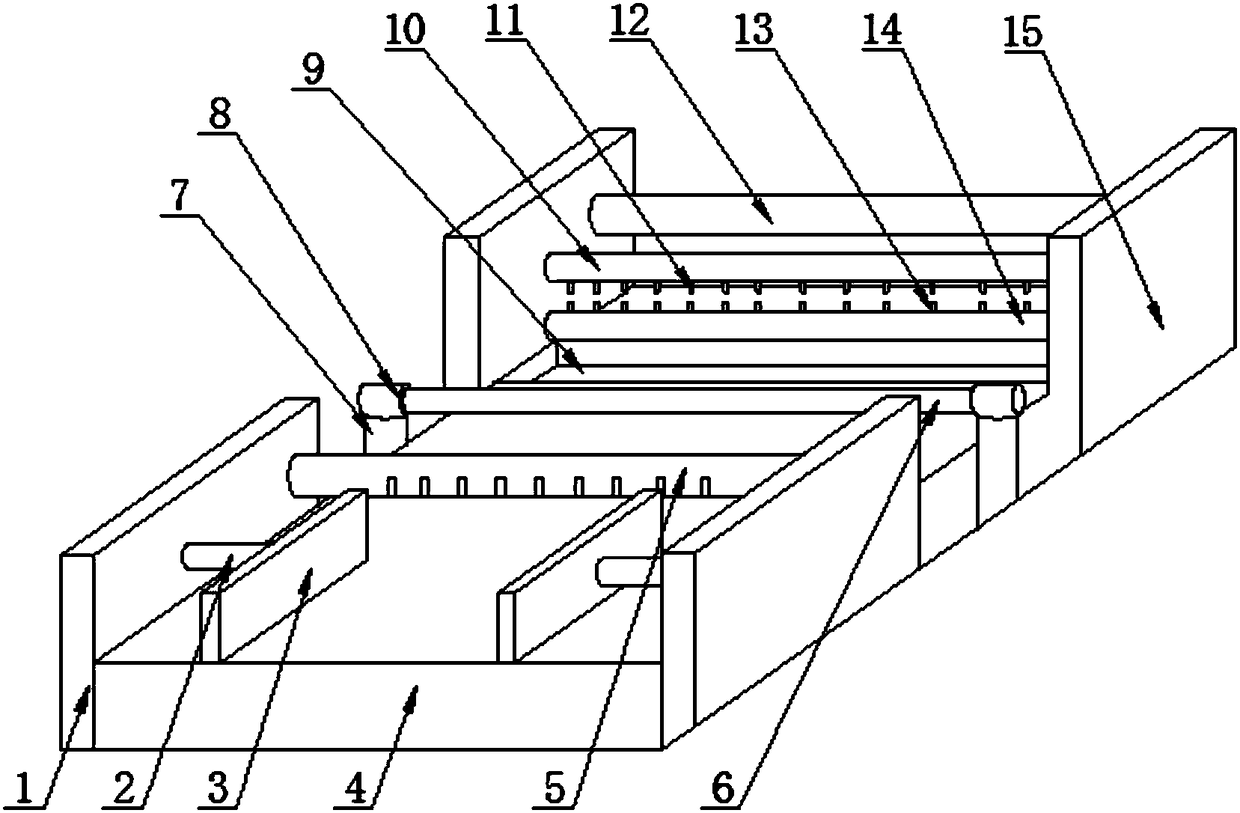

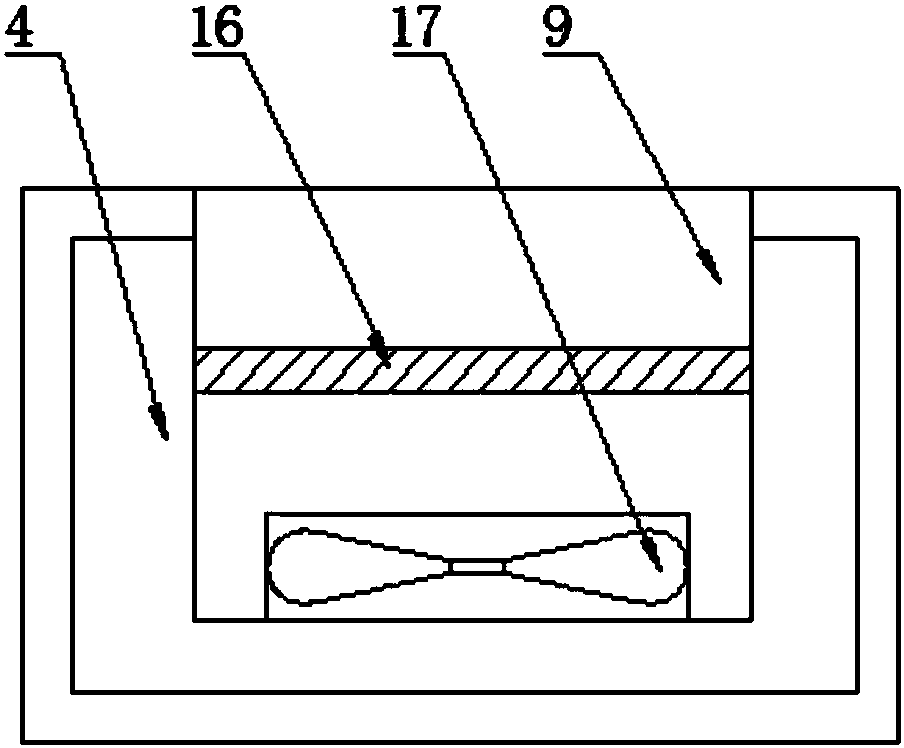

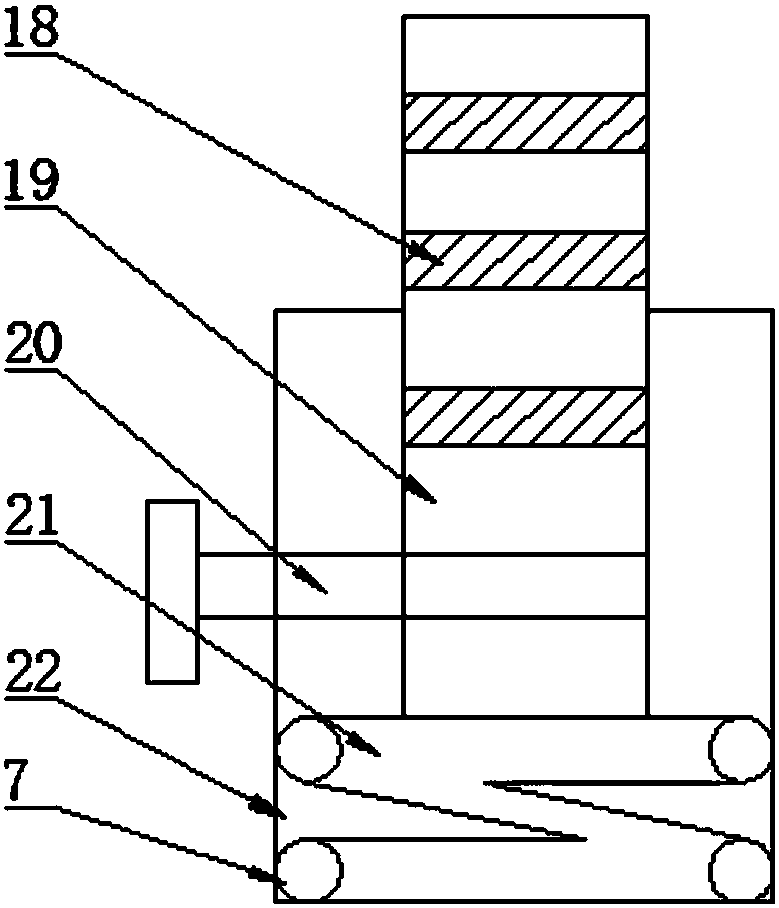

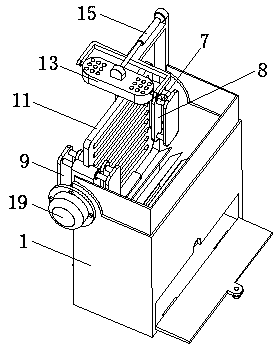

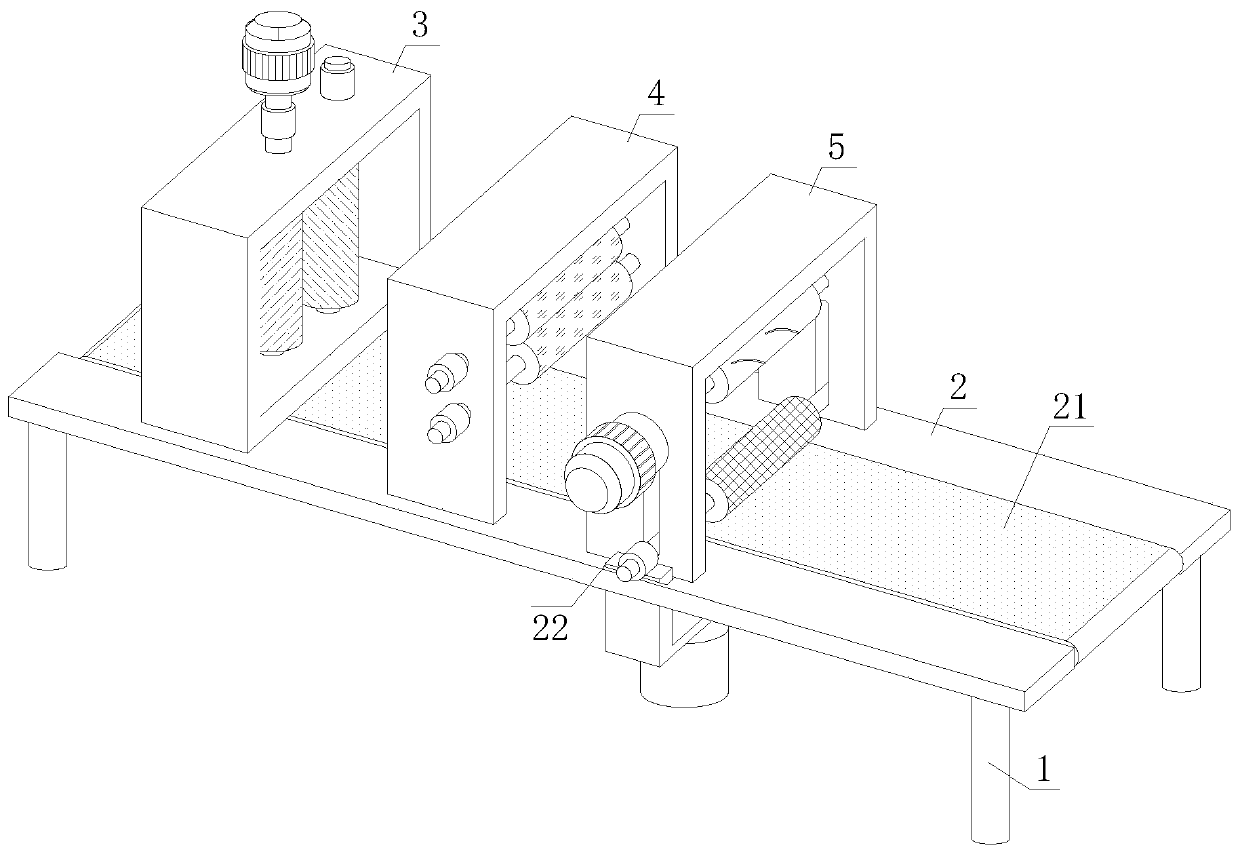

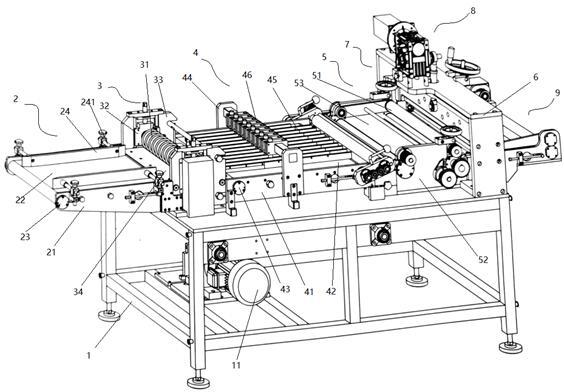

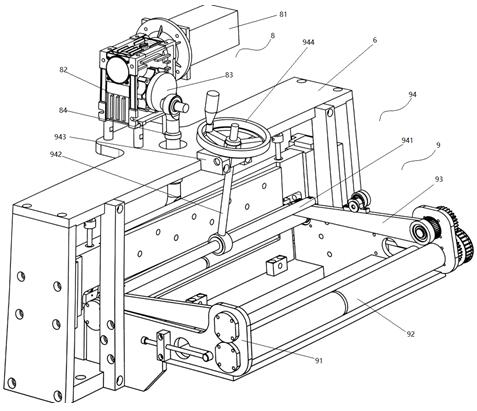

Roller-type cutting tool and method of medical folding mask

InactiveCN111409257AImprove flatnessAvoid wrinklesDomestic articlesMetal working apparatusEngineeringConveyor belt

The invention discloses a roller-type cutting tool and method of a medical folding mask, belonging to the technical field of medical folding mask cutting. The roller-type cutting tool of the medical folding mask comprises a support frame; a worktable is fixed on the support frame; a conveyor belt is arranged in the middle of the worktable; a guide device, a horizontal pressing fixing device and acutting device are arranged above the worktable; the horizontal pressing fixing device is arranged at the lateral end of the guide device; and the cutting device is arranged at the lateral end of thehorizontal pressing fixing device. The roller-type cutting tool and method of the medical folding mask disclosed by the invention shapes the material, which is convenient for subsequent cutting; two sets of cutting blades are arranged to cut two sets of materials at the same time, which improves the cutting efficiency, increases the production speed, and reduces the production costs; and the degree of compression between a butt roller and a cutting roller can be adjusted according to requirements, which increases the schedulability in production, reduces the wear of the blade while ensuring the quality of the produced product, increases the service life of the blade, facilitates replacement and maintenance, and avoids the occurrence of bad products produced due to blade aging and wear.

Owner:MAANSHAN HENGLIDA MACHINE BLADE

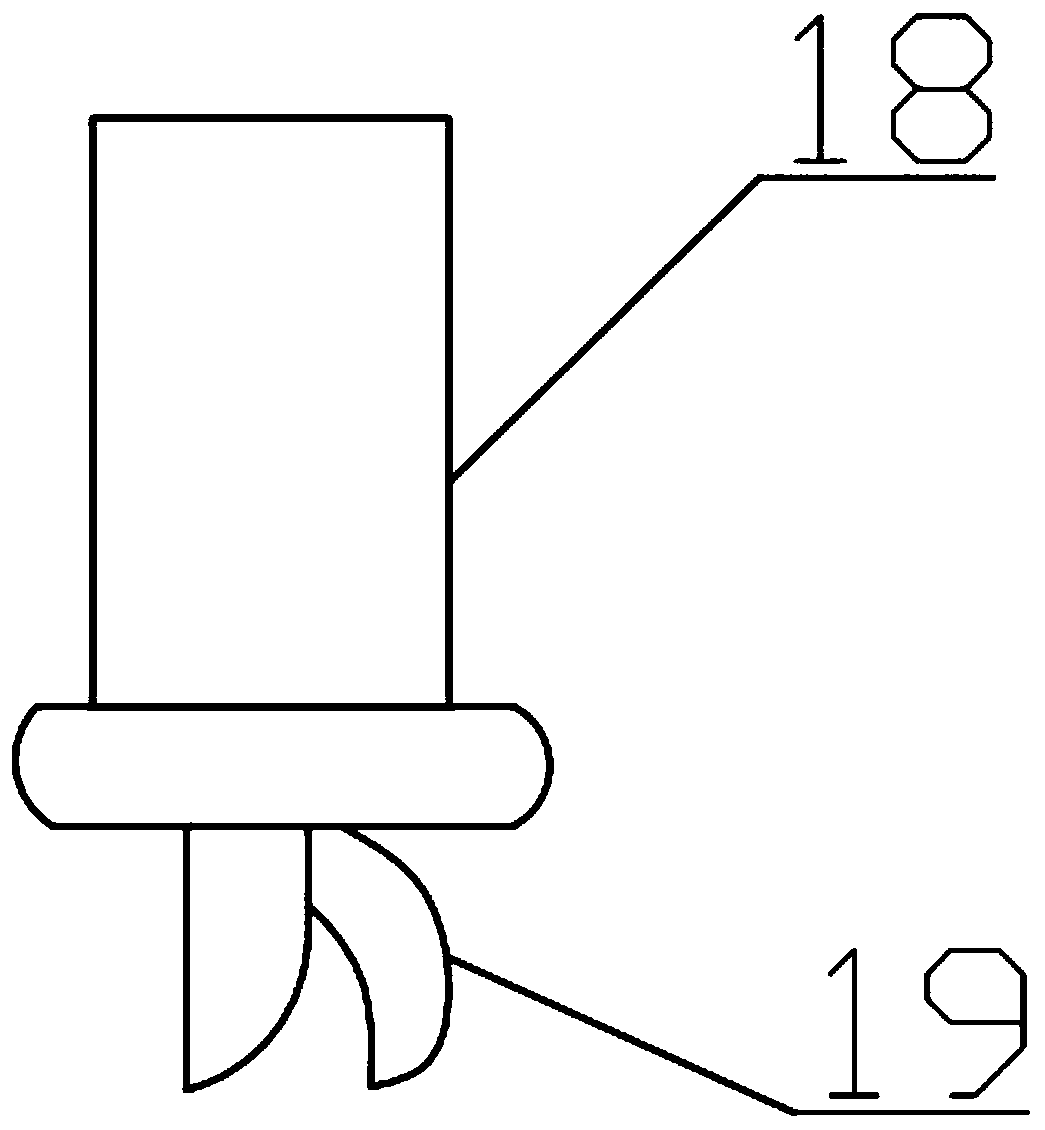

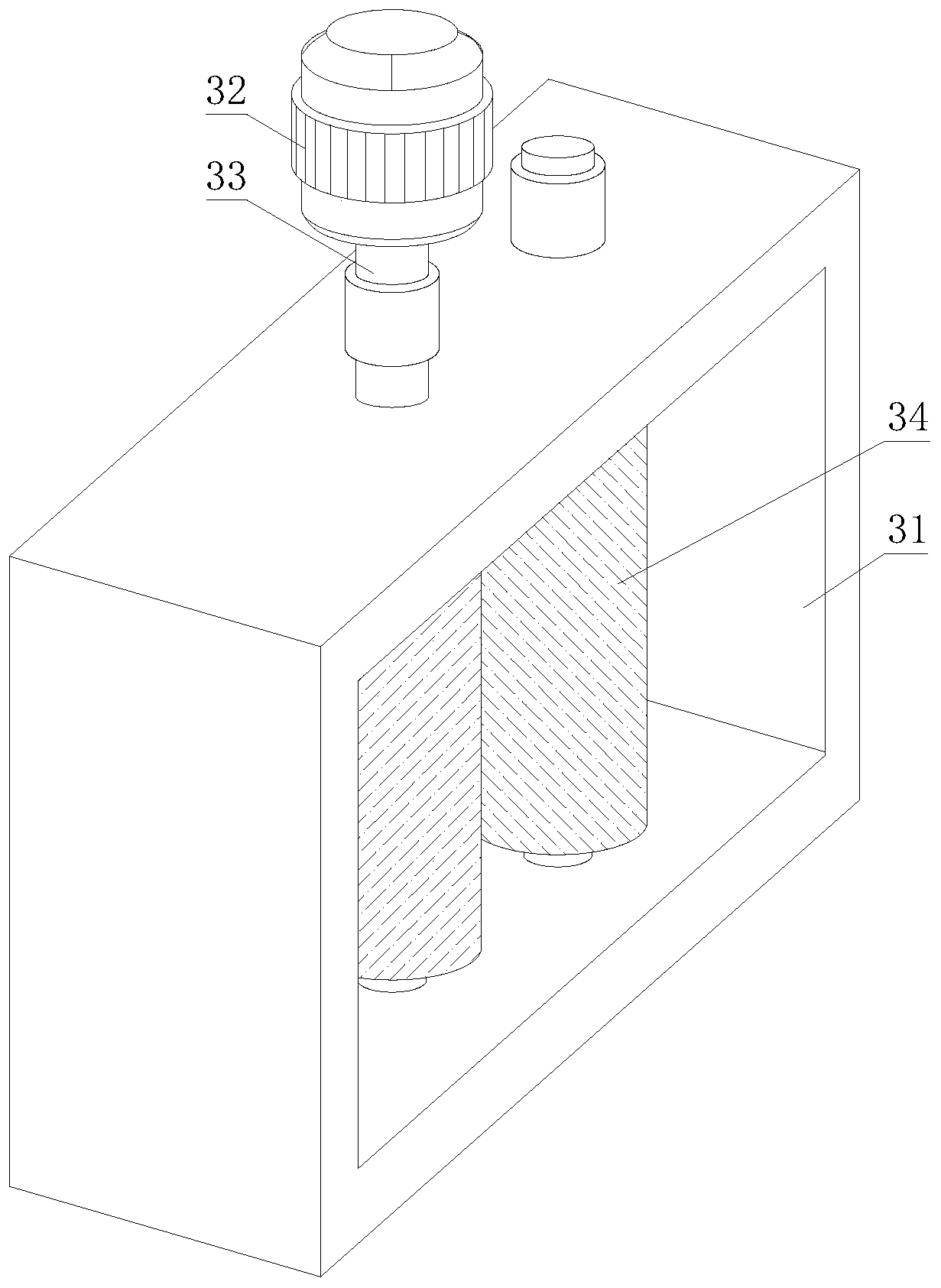

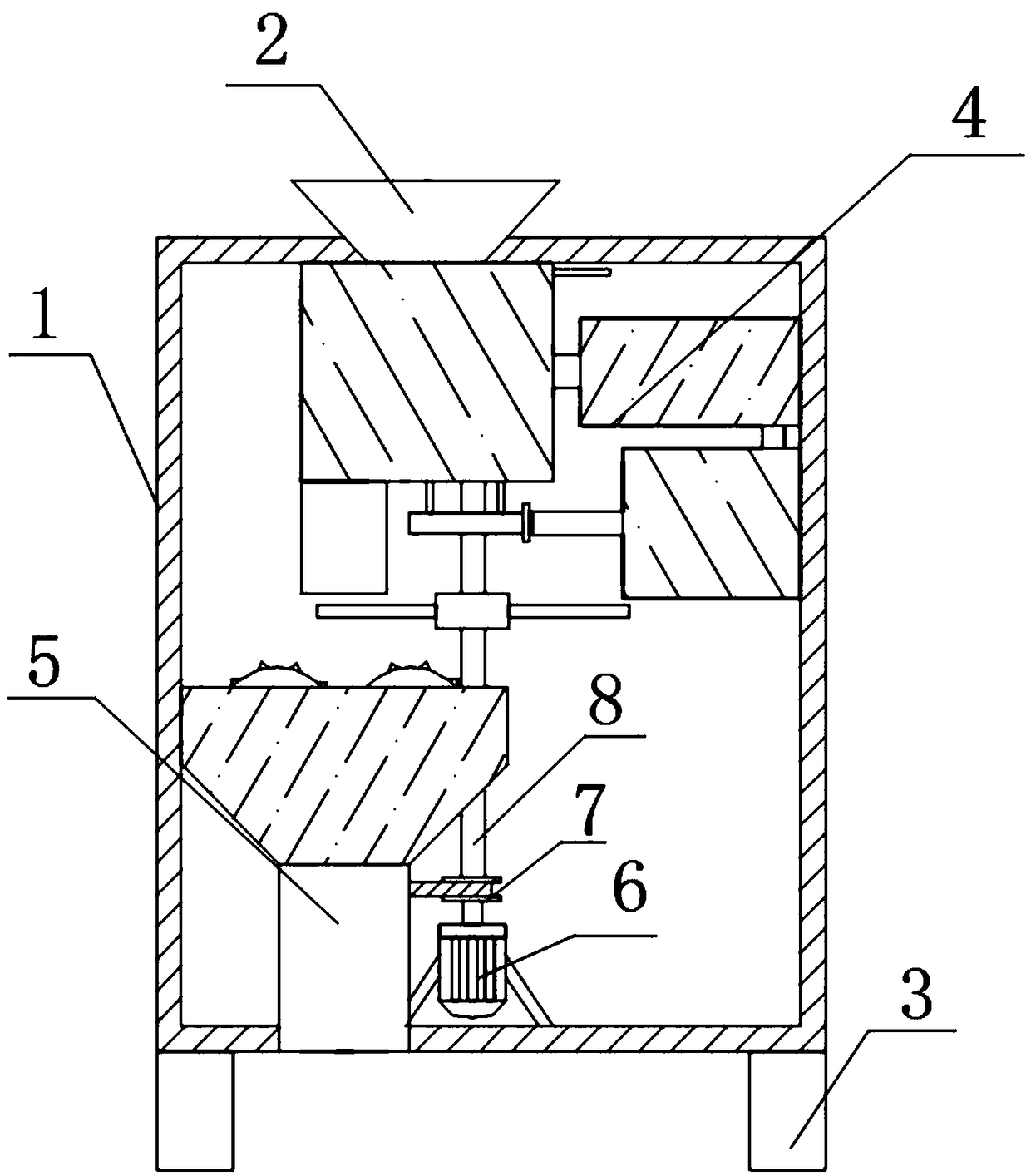

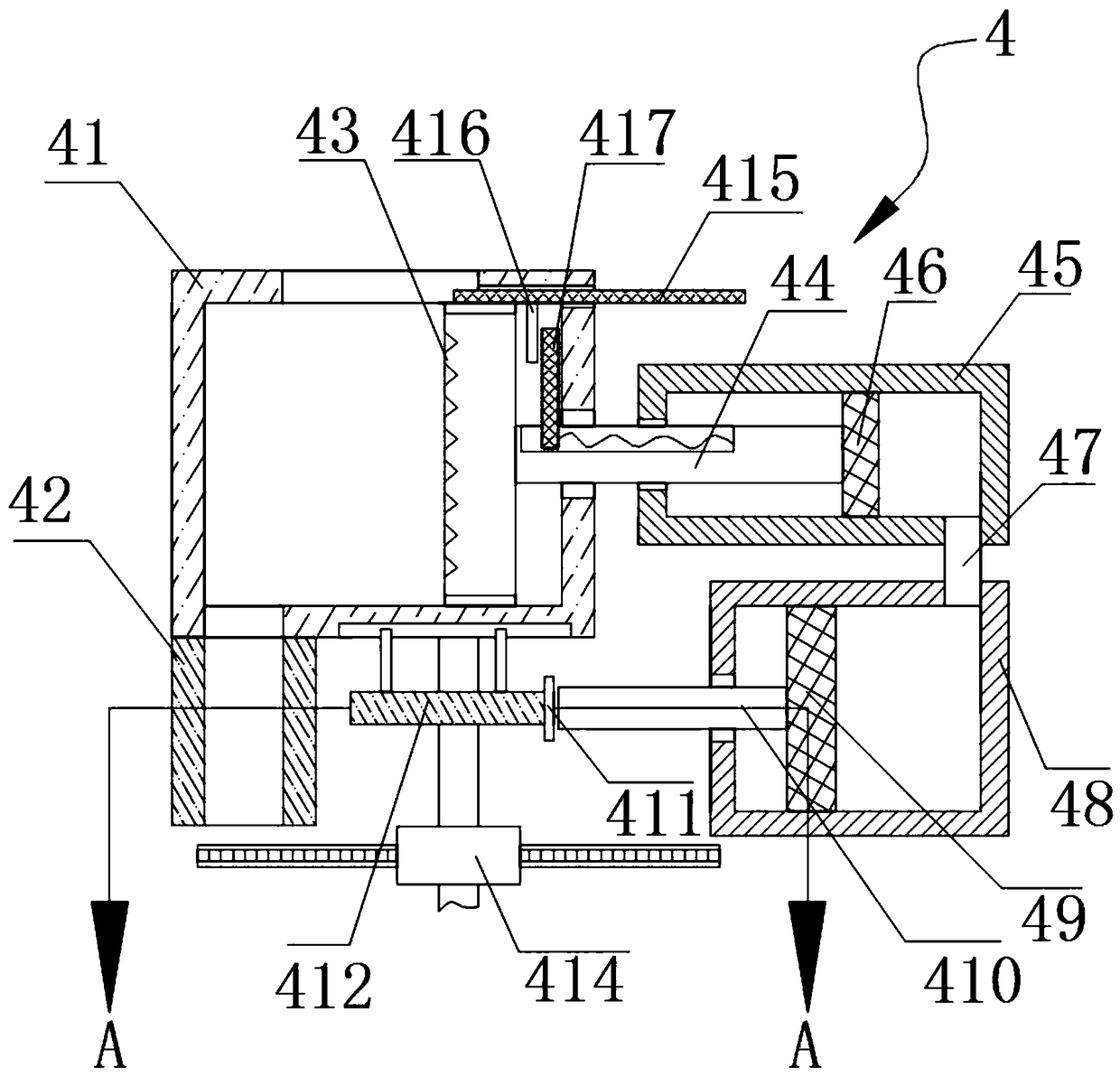

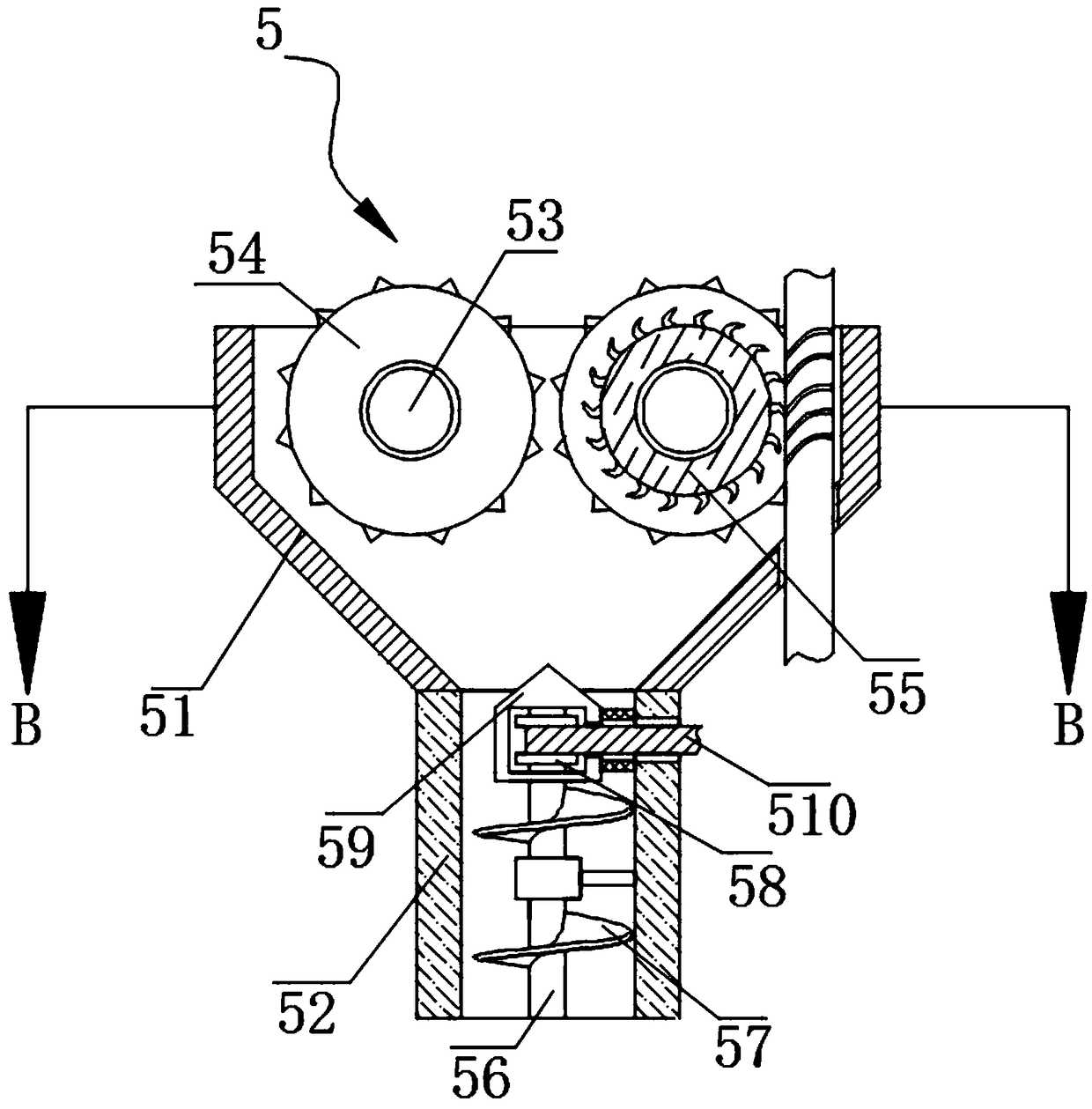

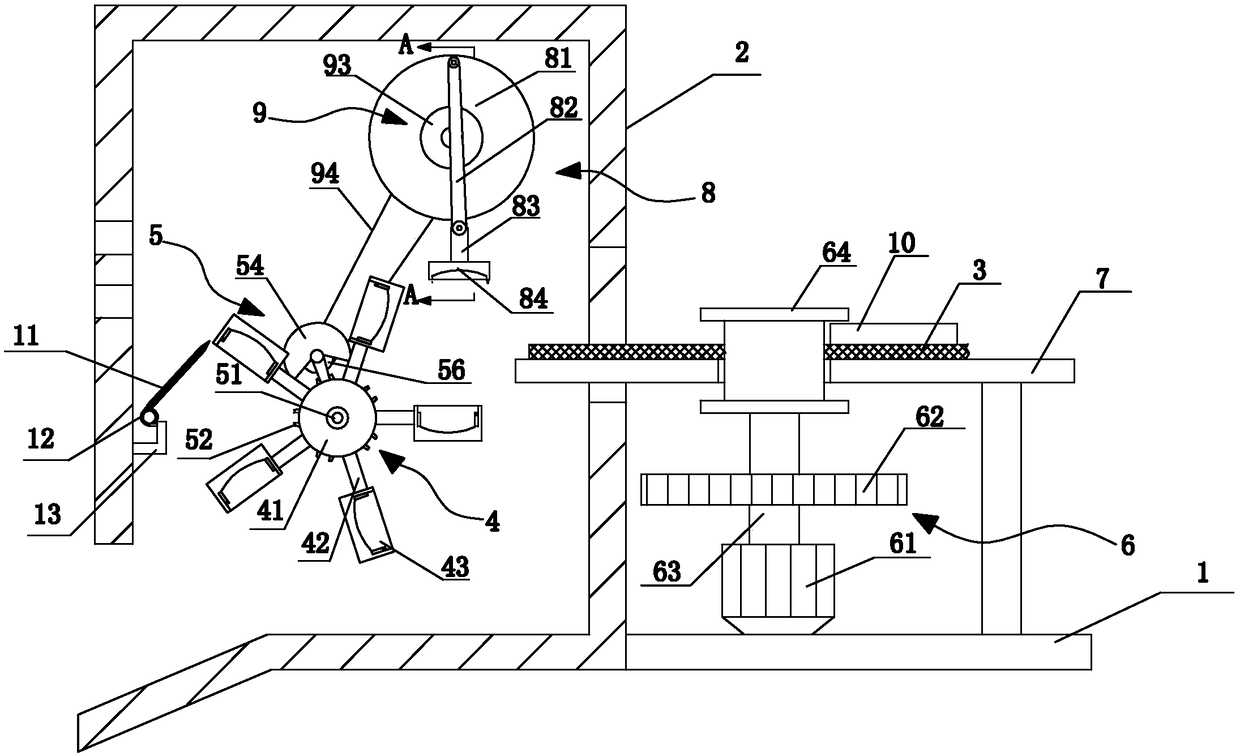

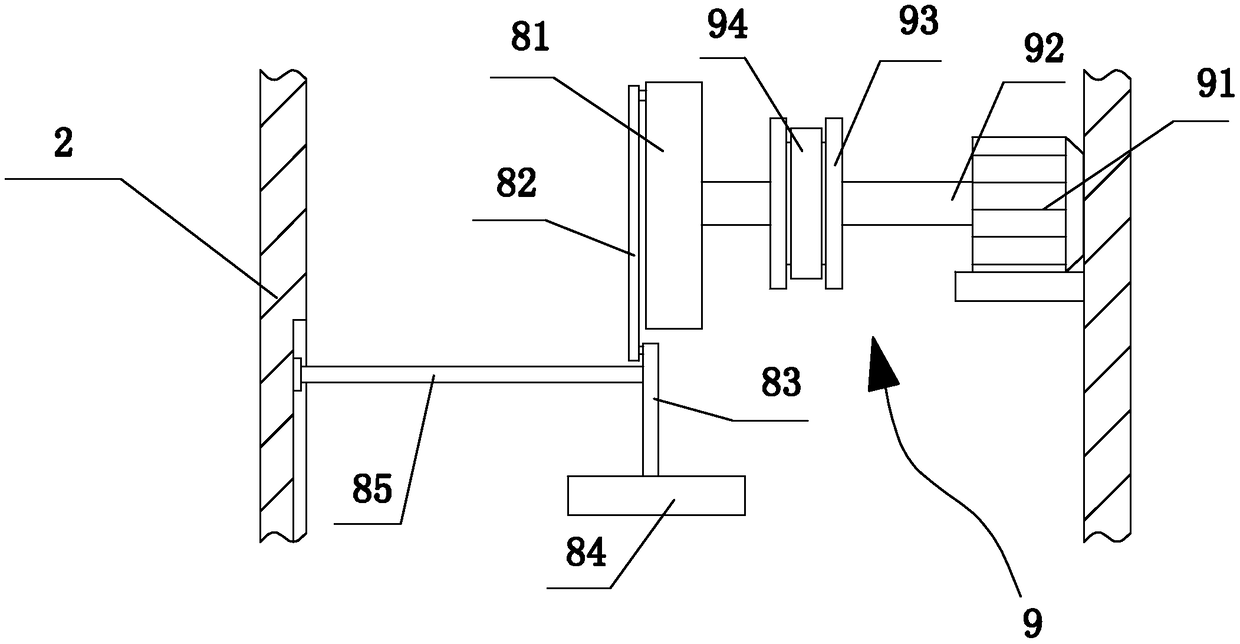

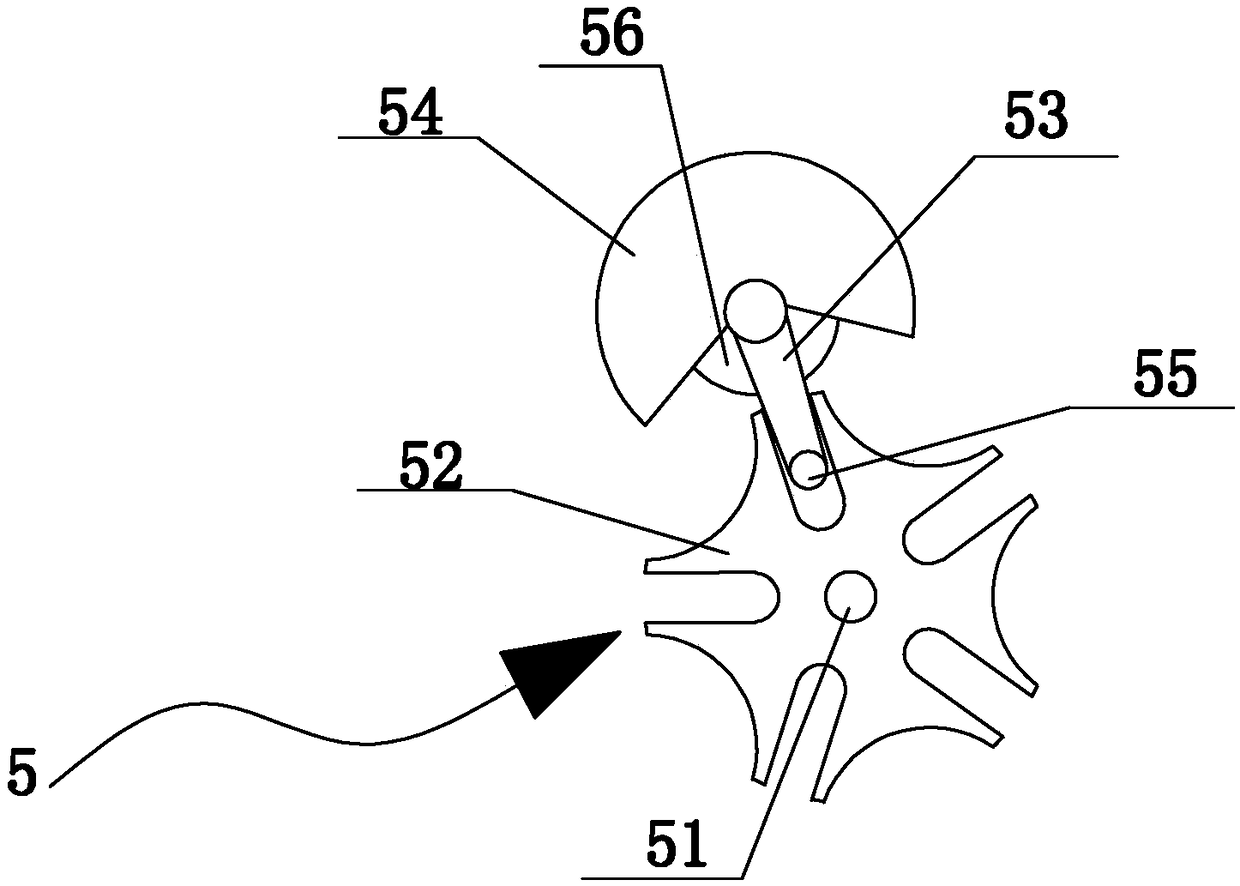

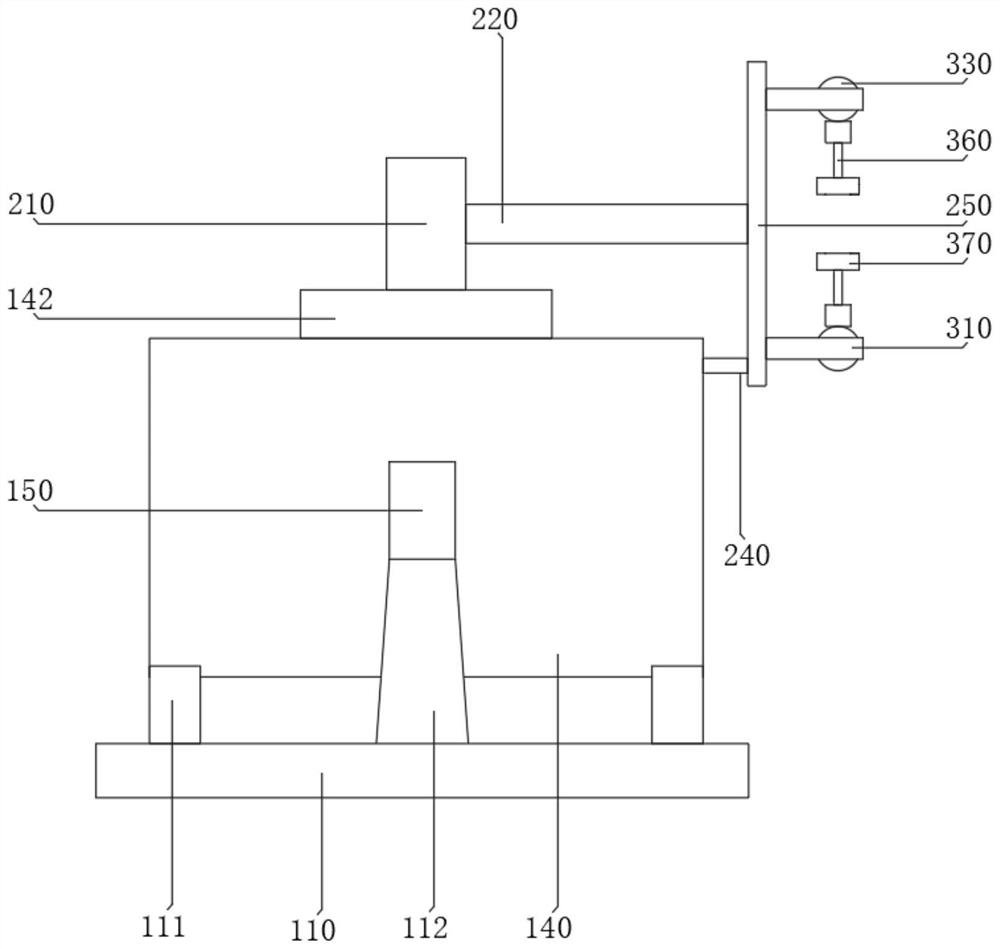

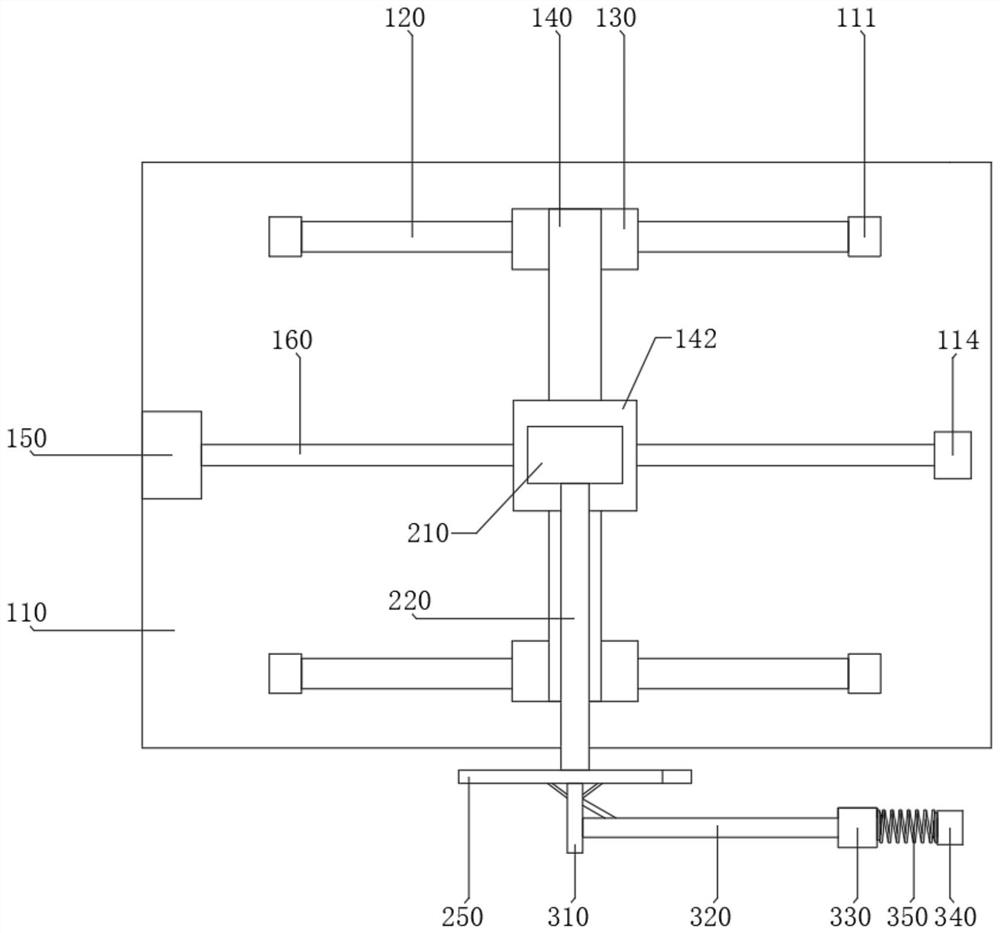

Chicken shell and chicken smashing device

ActiveCN109261268AFor subsequent cuttingEasy to crushGrain treatmentsPress ramElectric machineryEngineering

The invention provides an chicken shell and chicken smashing device, which comprises a tank, a feed funnel which is connected with the upper end of the tank in a penetrating way, a plurality of supporting legs connected to the lower end of the tank, a motor connected to the internal bottom wall of the tank through a first support, and a worm connected to the rotary shaft of the motor, and the smashing device is characterized by further comprising a cutting unit and a smashing unit connected to the worm. According to the device, the defects of the prior art are overcome, the design is reasonable, the structure is compact, the cutting unit is utilized to squash and then cut cleaned chickens into strips, a smashing sleeve is then utilized to smash the chicken strips, and thereby the efficiency of samshing is increased.

Owner:安徽标王农牧股份有限公司

Continuous forming and cutting device for candy production

ActiveCN108991217AUniform widthFor subsequent cuttingConfectionerySweetmeatsEngineeringMechanical engineering

The invention discloses a continuous forming and cutting device for candy production. The device comprises a bottom plate, a casing and a candy bar, wherein the bottom plate is fixedly connected to the outer side wall of the casing, and the upper end surface of the bottom plate is connected with a conveying plate through a stay rod; a feed port is formed in the side wall of the casing, the conveying plate movably extends into the casing through the feed port, and two symmetric guide plates are fixedly connected to the side edge of the conveying plate. By limit of the guide plates and movementof two candy feeding rollers, width of all parts of the candy bar is ensured to be uniform while the candy bar is continuously fed, and subsequent dicing is convenient; by closing of a lower press mold and an upper press mold, the candy bar can be cut and pressed, so that candies are formed and uniform in shape, the candies are formed after cutting-off, and cuts are neat.

Owner:HOLEYWOOD FUJIAN FOODS

Single-piece type disc cutter structure for labelling machine

The invention discloses a single-piece type disc cutter structure for a labelling machine, which comprises a moving assembly, a cutting assembly and a material pressing assembly; the cutting assembly is installed on the upper portion of the moving assembly; the material pressing assembly is installed on the side portion of the cutting assembly; the moving assembly comprises a supporting plate, a sliding rail, a sliding block, a bearing plate, a moving motor and a threaded rod; the cutting assembly comprises a cutting motor, a transmission shaft, a cutter body, a supporting frame and a cutter cover; and the material pressing assembly comprises a connecting rod, a guide rod, a connecting column, a limiting block, an elastic piece, an electric push rod and a pressing block. According to the invention, movement of the cutting assembly and the material pressing assembly is effectively achieved through the moving assembly; rotation of the cutter body is easily achieved through the cutting assembly; under cooperation of the moving assembly, cutting of a film is achieved; the film is pressed on the outer side of a to-be-labelled material through the material pressing assembly before cutting; in the cutting process, the film deviation is prevented; and the subsequent labelling quality is guaranteed.

Owner:上海鸿富包装机械有限公司

Dangerous goods storage tank scrapping and recycling device

ActiveCN110038878AFixed tightlyIncrease elasticitySolid waste disposalHollow article cleaningBiochemical engineeringFixed frame

The embodiment of the invention discloses a dangerous goods storage tank scrapping and recycling device. The dangerous goods storage tank scrapping and recycling device comprises a main body framework, wherein a lead screw fixed hood is mounted on the upper inner wall of the main body framework; the inner part of the lead screw fixed hood is rotatably connected with a movable lead screw; the outerwall of the movable lead screw is connected with a lead screw sliding sleeve in a sliding manner; the lead screw sliding sleeve is positioned in the lead screw fixed hood; an electric push rod frameis fixedly mounted under the lead screw sliding sleeve; a tank body fixing frame is mounted at the lower end of the electric push rod frame; the equipment is equipped with the tank body fixing frame which can be used for fixing different tank bodies through position clamping assemblies; a tank body rotating wheel is arranged on the tank body fixing frame and can be automatically rotated when a tank body is fixed, so that the tank body can be cleaned more conveniently, the flow velocity of the water flow can be increased, and the cleaning efficiency is improved; and moreover, an auxiliary partis not needed when the tank body is pre-cleaned by a user, so that the cleaning efficiency of the tank body is improved, and an operation is carried out more practically and simply.

Owner:青岛星空净化科技有限公司

Efficient laminating mechanism of cutting bed

PendingCN110901202AQuick Fit FixationImprove fitLamination ancillary operationsLaminationEngineeringPlastic film

The invention discloses an efficient film laminating mechanism of a cutting bed. The laminating mechanism comprises supporting arms at two ends, laminating rollers, hot pressing rollers and air supplyrods, end covers are arranged at the central positions of the supporting arms at the two ends; end cover grooves are formed in the end covers; the laminating rollers are arranged at the bottoms of the supporting arms at the two ends; rubber coating wheels are arranged at the connecting positions of the two ends of the film coating roller and the supporting arms, the hot pressing rollers are arranged in the centers of the supporting arms at the two ends; a hot pressing cavity is formed in each hot pressing roller; bearings are arranged at the connecting positions of the two ends of the hot pressing rollers and the supporting arms. The air supply rods are arranged at the tops of the supporting arms at the two ends, so that air outlet holes blow air outwards to cool cloth laminated by the hot pressing rollers, a plastic film is quickly laminated and fixed, meanwhile, dust on the surface of the plastic film can be blown away, the top of the plastic film is prevented from being stained with the dust due to poor workshop environment, and bubbles generated by untight lamination during film lamination are avoided.

Owner:JIANGSU YUANHUA LIGHT CHEM EQUIP

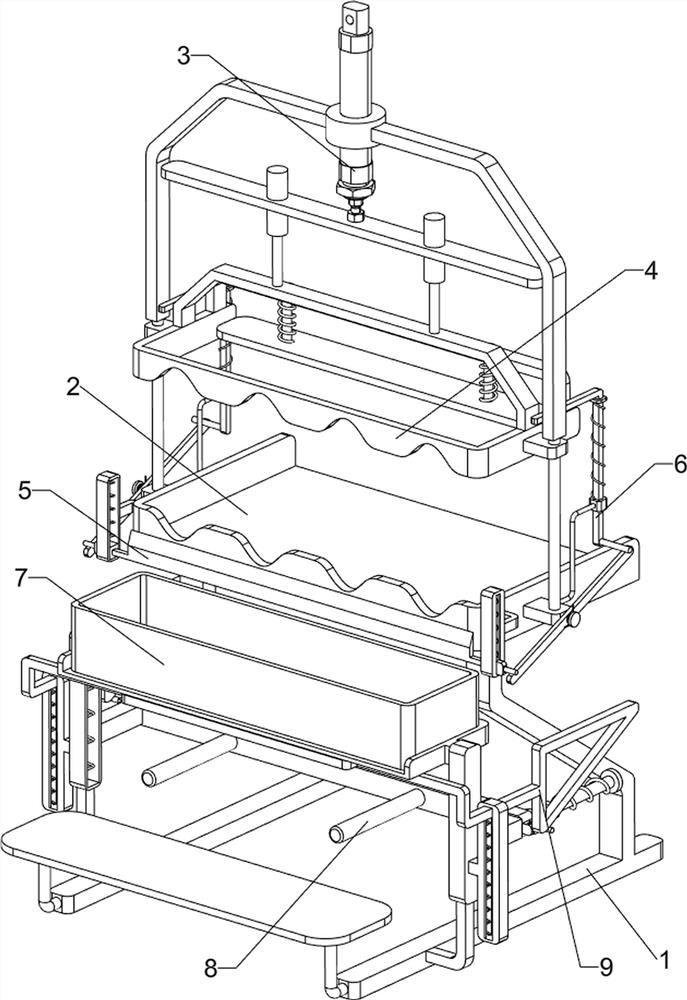

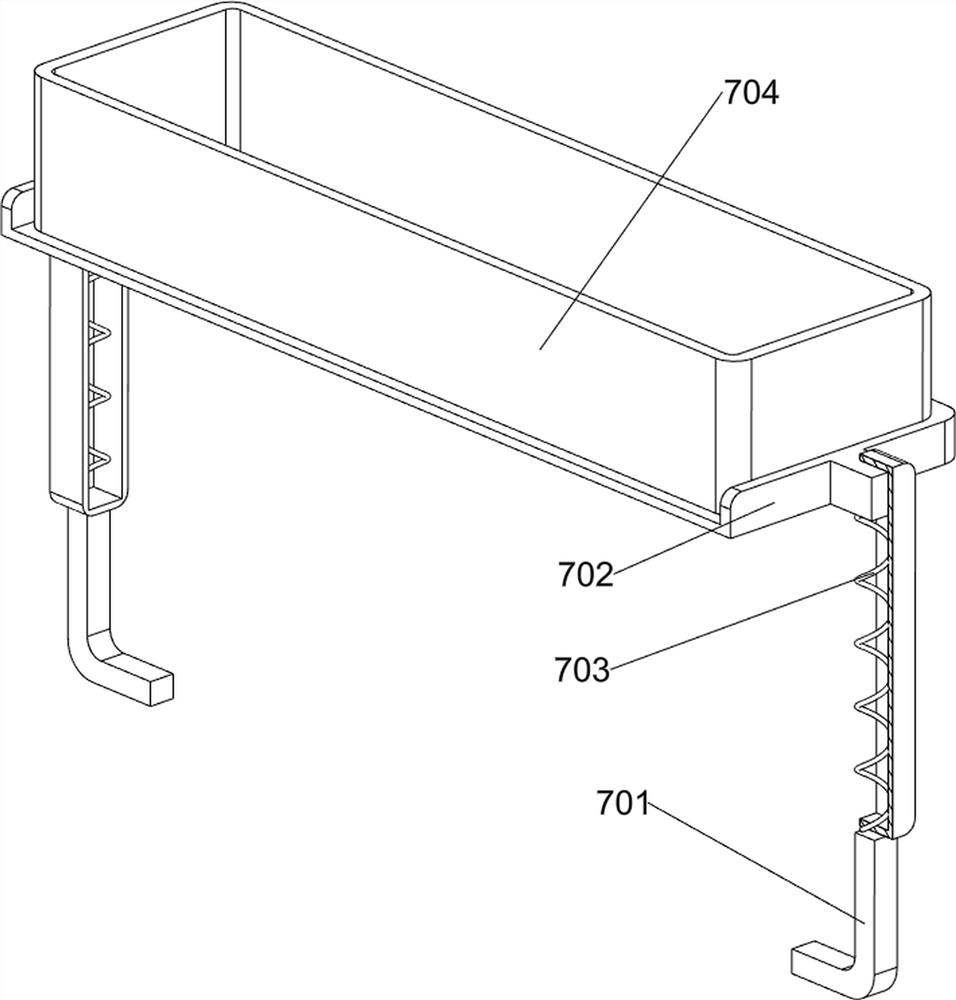

Fabric three-dimensional fixing device and method thereof

ActiveCN109023806AShorten the timeIncrease productivitySevering textilesHeating/cooling textile fabricsEngineeringRaw material

The invention discloses a fabric three-dimensional fixing device and a method thereof, which belong to the technical field of fabric fixing. By using the difference in temperature between different areas of the upper and lower molds in the device, the thermodynamic properties of the fabric are changed, which facilitates subsequent cutting. A cutting device is used again to make the edge of the formed fabric dense and smooth, the molds is smoothly released, so that the manual cutting part is eliminated, the time can be greatly saved, the production efficiency is improved and the cost is reduced; at the same time, the fabric to-be-fixed and cut is pre-cut to a size corresponding to the size of the upper and lower molds, and the raw material can be saved.

Owner:JIANGNAN UNIV

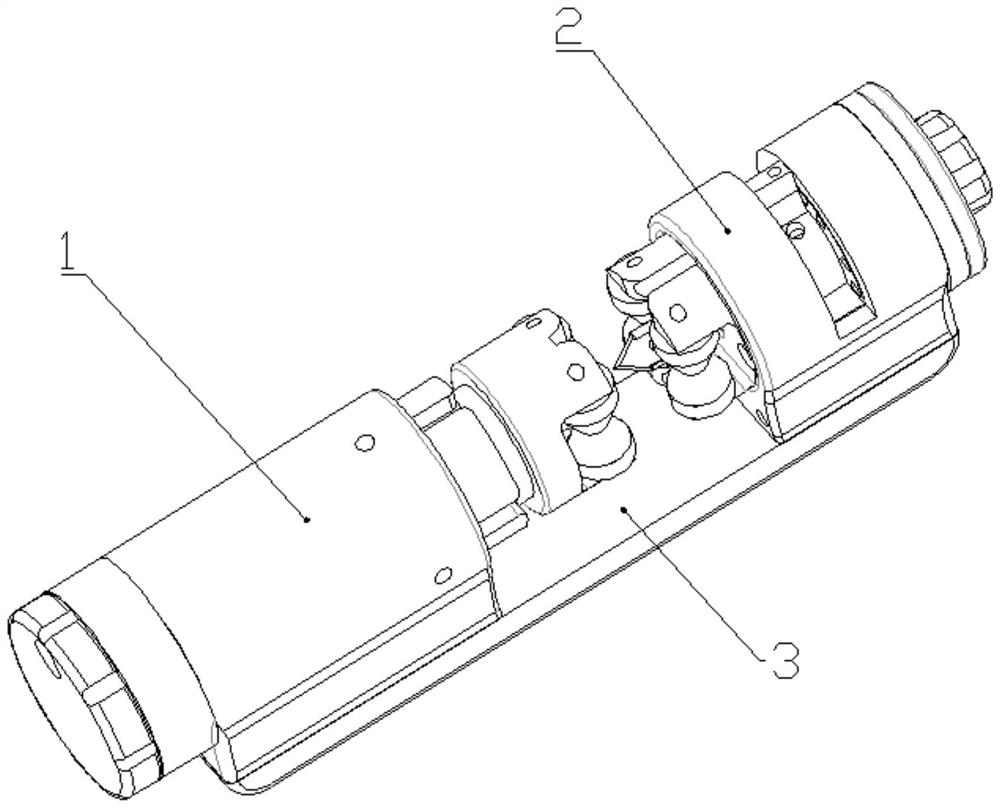

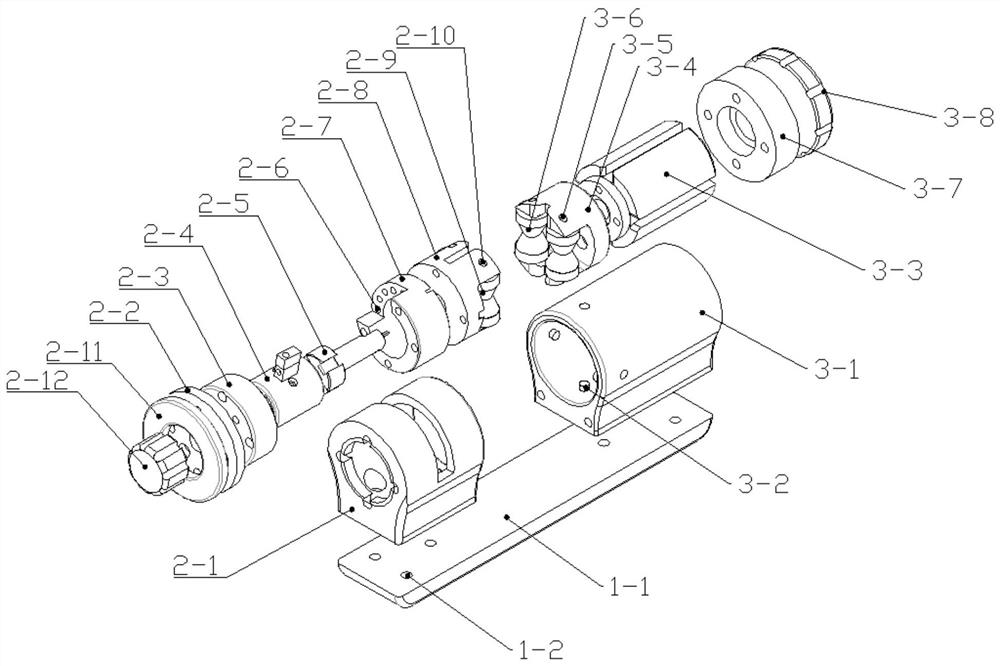

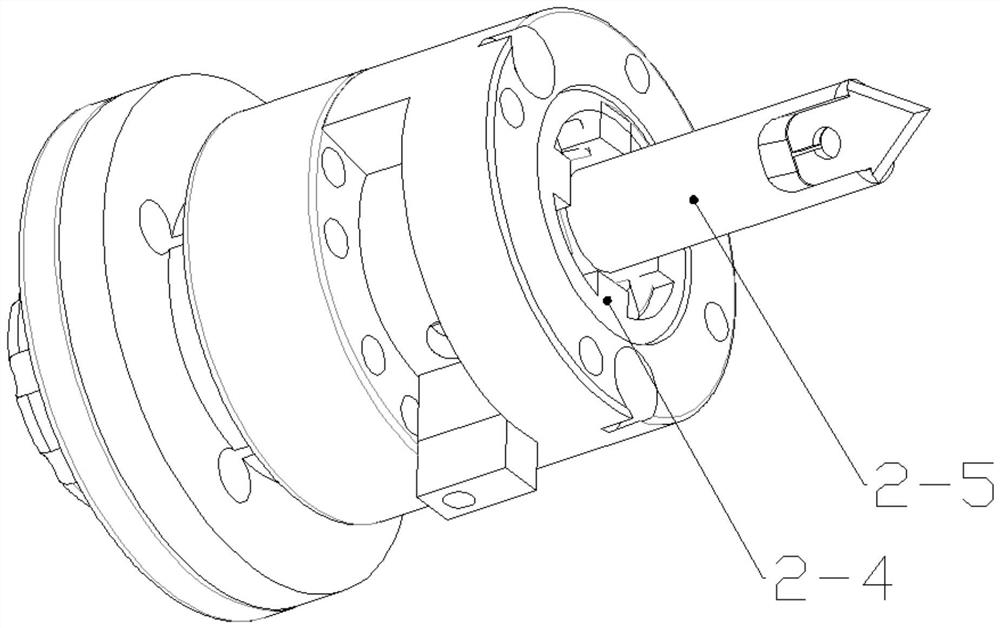

High-precision cable peeler

PendingCN112838527AImprove cutting efficiencyReduce use costApparatus for removing/armouring cablesStructural engineeringKnife blades

The invention provides a high-precision cable peeler, and relates to the technical field of cable peeling, the high-precision cable peeler comprises a connecting mechanism, a cutting mechanism and a telescoping mechanism, wherein the connecting mechanism comprises a connecting plate and connecting screws, and the two ends of the connecting plate are connected with the cutting mechanism and the telescoping mechanism through the connecting screws respectively; the cutting mechanism comprises a cutting column frame, a horizontal rotary positioning piece, a direction positioning piece top cover, a direction positioning piece and a first roller frame, and is used for controlling rotation of parts in the cutting column frame and telescopic adjustment of a blade; the telescopic mechanism comprises a telescopic column frame, a second positioning pin, a positioning telescopic column and a second roller carrier and is used for controlling axial stretching and horizontal rotation of parts in the telescopic column frame. According to the cable peeler, cable cutting with any switching of two modes and three mmanners can be achieved, the problem that the cable is prone to horizontal and vertical displacement in the cutting process is effectively solved, meanwhile, the cutting depth can be accurately controlled, and therefore high-precision cutting of the blade to the cable is achieved.

Owner:董建雄

Automatic root removing equipment for hydroponic vegetables

ActiveCN113208137AFor subsequent cuttingImprove operating speedAgriculture gas emission reductionMetal working apparatusAgricultural engineeringMechanical engineering

The invention relates to root removing equipment, in particular to automatic root removing equipment for hydroponic vegetables. According to the automatic root removing equipment for the hydroponic vegetables, the roots of the hydroponic vegetables are automatically removed, the operation process of the hydroponic vegetables is accelerated, and the mechanical operation process and the automatic operation process are realized. According to the technical scheme, the automatic root removing equipment for the hydroponic vegetables is characterized by comprising a containing plate, a downward pressing assembly, a clamping assembly and cutting assemblies, wherein the containing plate is connected between the top sides of first supporting frames on the two sides; the top side of the containing plate is connected with the downward pressing assembly; the bottom side of the downward pressing assembly is connected with the clamping assembly; and the cutting assemblies are connected to the two sides of the containing plate correspondingly. Through cooperation of an air cylinder, a first connecting rod, a first pressing rod and a first spring, the purposes of providing driving force for the device and achieving the automatic operation process are achieved.

Owner:稷青科技(上海)有限公司

Roll paper virtual cutting machine

The invention relates to the technical field of tissue production, in particular to a roll paper virtual cutting machine. The roll paper virtual cutting machine comprises a paper feeding roller, and apaper rolling roller made of an electromagnet is arranged in the paper outlet direction of the paper feeding roller; a first incomplete gear is arranged on one side of the paper rolling roller, a transmission part is connected between the first incomplete gear and the paper rolling roller, and a gear set is arranged on one side of the first incomplete gear; a conveying channel is arranged above the paper rolling roller, a plurality of iron virtual cutters are arranged in the conveying channel, iron supporting seats are arranged at one ends, facing the discharging end of the conveying channel,of the virtual cutters, the mass of the supporting seats is larger than that of the virtual cutters, a pushing mechanism is arranged at the other end of the conveying channel, and another transmission part is also connected between the pushing mechanism and a small gear in the gear set; and a magnet is arranged below the paper rolling roller, a switch is arranged on the magnet, the switch is electrically connected with the paper rolling roller, a driving mechanism is arranged on one side of the switch, and another transmission part is also connected between the driving mechanism and the firstincomplete gear. According to the roll paper virtual cutting machine, the problem that a roll paper virtual cutting line in the prior art is staggered is solved.

Owner:CHONGQING SAN HAO PAPER IND

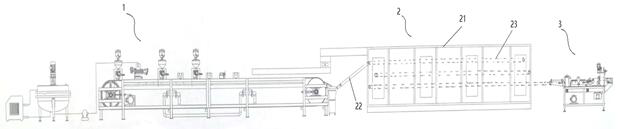

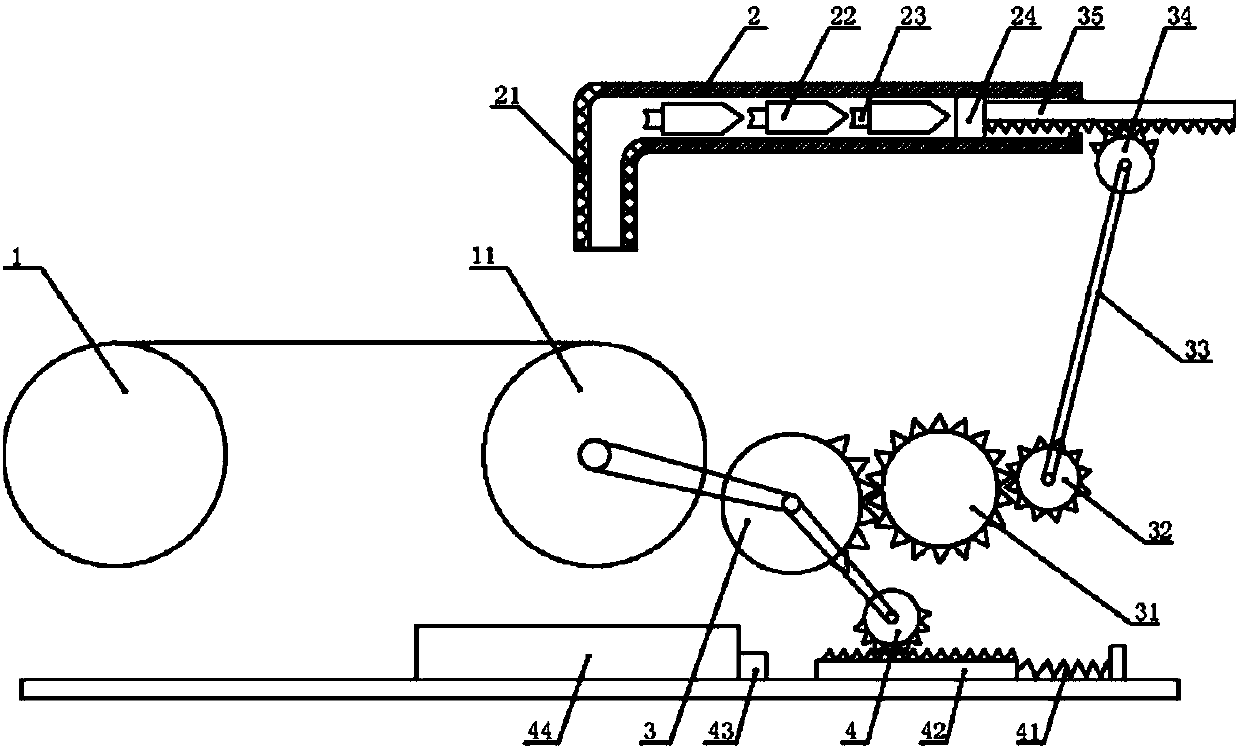

Sticky candy slice slitting and dicing system

The invention relates to a sticky candy slice slitting and dicing system. The sticky candy slice slitting and dicing system is characterized by comprising a supporting frame, a candy slice input module, a candy slice segmentation module, an isolation conveying module, a candy strip input module, a cutter rest, a cutter module, a cutter driving module and a candy block output module; cutting ring roller seats are movably connected, and a cutting ring roller can be replaced according to different candy stick breadth requirements; the isolation conveying module is adopted to prevent cut candy strips from adhering together again in the conveying process; a candy strip buffer groove is formed in the input end of the cutter module, sesame is placed in the groove, and the sesame can be stuck to the side face of the sticky candy which is cut into strips; the problem that subsequent candy strips are still conveyed to cause extrusion when being diced can also be avoided; and a stripping pressingplate unit is arranged on the side edge of the cutter module when the candy strips are cut, so that the stripping pressing plate unit firstly makes contact with the candy strips and then leaves the candy strips when the cutter module cuts the candy strips, and the candy strips are prevented from adhering to the cutter module.

Owner:NANTONG WEALTH MASCH TECH CO LTD

PET film double-sided rapid coating and coating equipment

PendingCN111785916AEasy to produceIncrease productivityElectrode rolling/calenderingElectrode thermal treatmentMetallic electrodeElectrical battery

The invention discloses a PET film double-sided rapid coating and coating equipment. The equipment comprises an unwinding mechanism for conveying a PET film in a first direction, a first coating mechanism, a first drying and calendering mechanism, a reversing mechanism which is used for overturning the front and back surfaces of the PET film, a second film coating mechanism which is the same as the first film coating mechanism in structure and is arranged right above the first drying and calendering mechanism, a second drying and calendering mechanism which is the same as the first drying andcalendering mechanism in structure, and a winding mechanism which is used for recycling the PET film in a second direction. According to the invention, a plurality of vacuum cavities are arranged, themechanisms are respectively arranged in respective cavities to enable the PET film of a battery pole piece to pass through all the mechanisms in sequence, the processing and forming of the aluminum film and the copper film and the functions of coating the positive electrode material and the negative electrode material are completed at one time, and the processing of the cathode metal electrode, the cathode material, the anode metal electrode and the anode material of the battery can be completed in one unwinding and winding process, so that the production process of the lithium ion battery issimplified, the production efficiency is improved, and the cost is reduced.

Owner:JILIN UNIV +1

A kind of slitting and cutting system for brown sugar slices

Owner:NANTONG WEALTH MASCH TECH CO LTD

Waste rubber tire horizontal composite dicer

InactiveCN101850583BEasy feedingRealize feeding automationPlastic recyclingMetal working apparatusGear wheelWaste rubber

The invention relates to a waste rubber tire horizontal composite dicer which comprises a frame, a power source, a transmission gear, a slitter, a dicing device and a tire feeding device, wherein the slitter and the dicing device are installed on the upper part of the frame; the power source and the transmission gear are installed on the bottom of the frame; the tire feeding device is installed near the slitter; the slitter comprises an upper horizontal cutter head and a lower cutter head which contact the working surface; the shafts of the two cutter heads form a mesh transmission through various gears which match each other; the lower end of the shaft of one cutter head is connected with the power source through the transmission gear; the dicing device comprises a dicing shaft, a dicing cutter and an inertia wheel, the dicing shaft is installed on the frame, the dicing cutter and the inertia wheel are installed on the dicing shaft, and the dicing main shaft is connected with the power source through the transmission gear; and a guide chute is arranged between the slitter and the dicing device. The dicer provides convenience for feeding waste tires, can realize automatic feeding, and maximally reduces manual work.

Owner:HENAN ZHONGYING RUBBER TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com