Patents

Literature

32results about How to "Realize feeding automation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

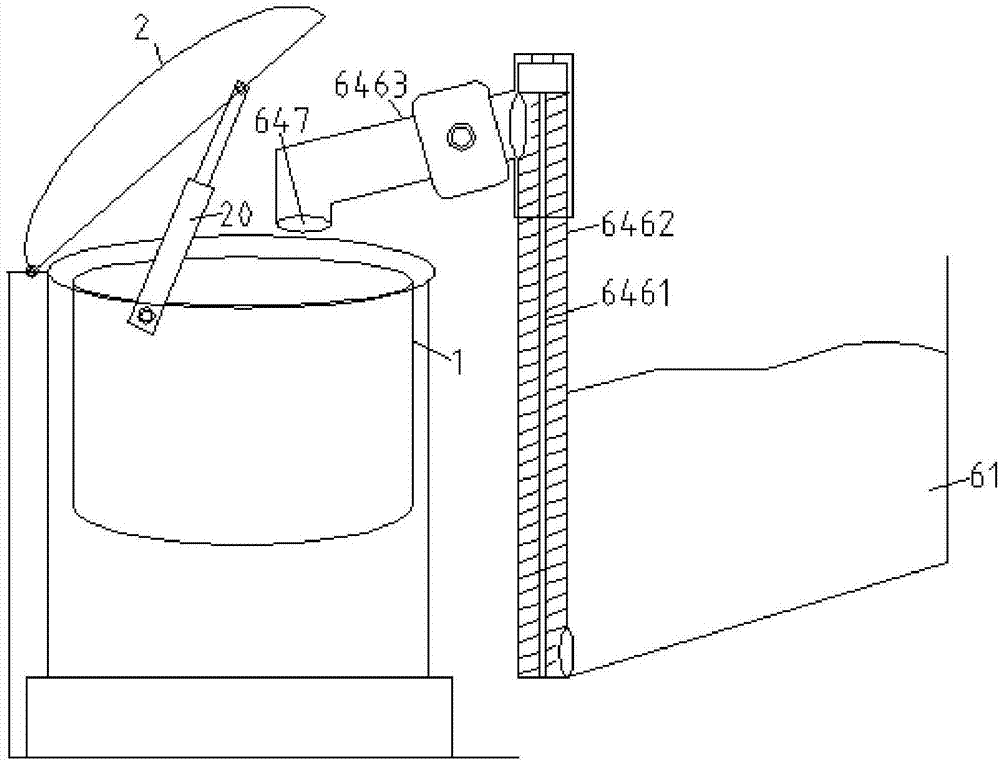

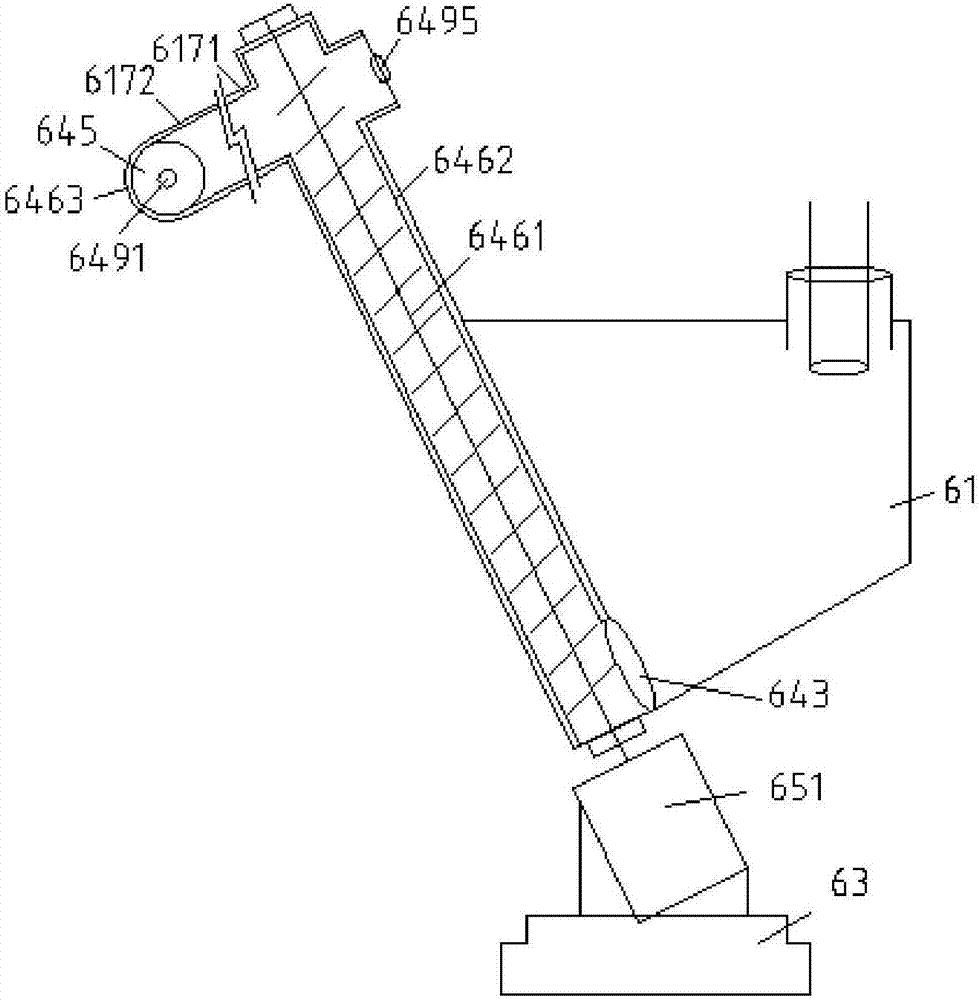

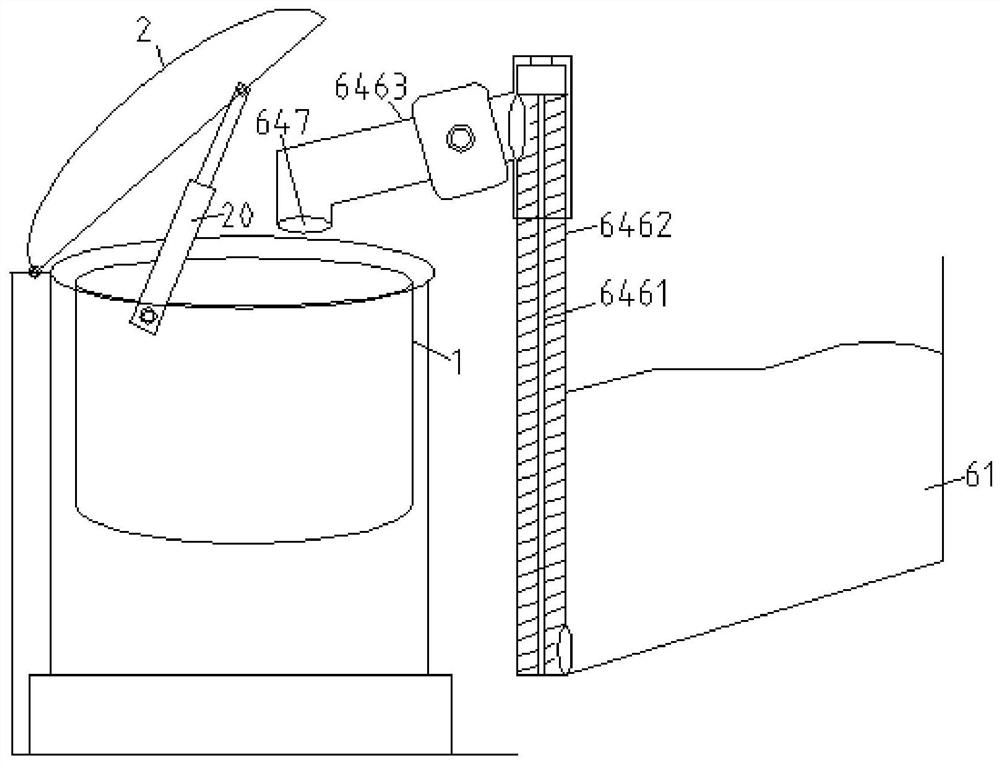

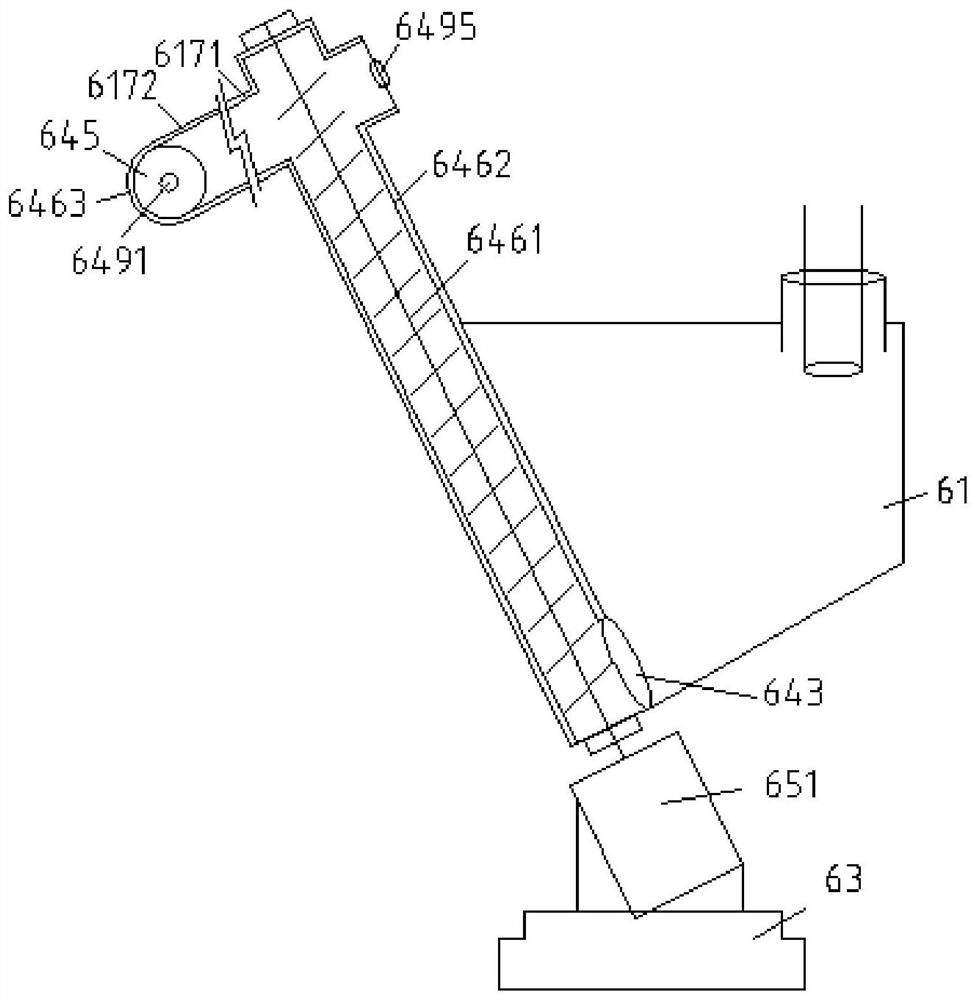

Supplying, dividing and feeding devices, cooking equipment and feeding method thereof

InactiveCN106419587ARealize feeding automationReduce labor workloadCooking-vessel lids/coversCooking vessel constructionsElectricityMating

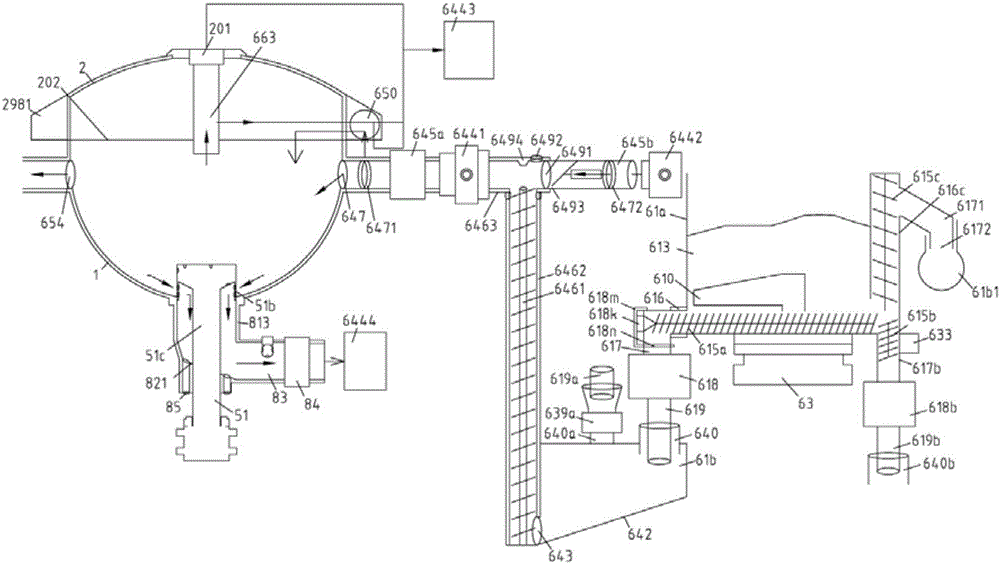

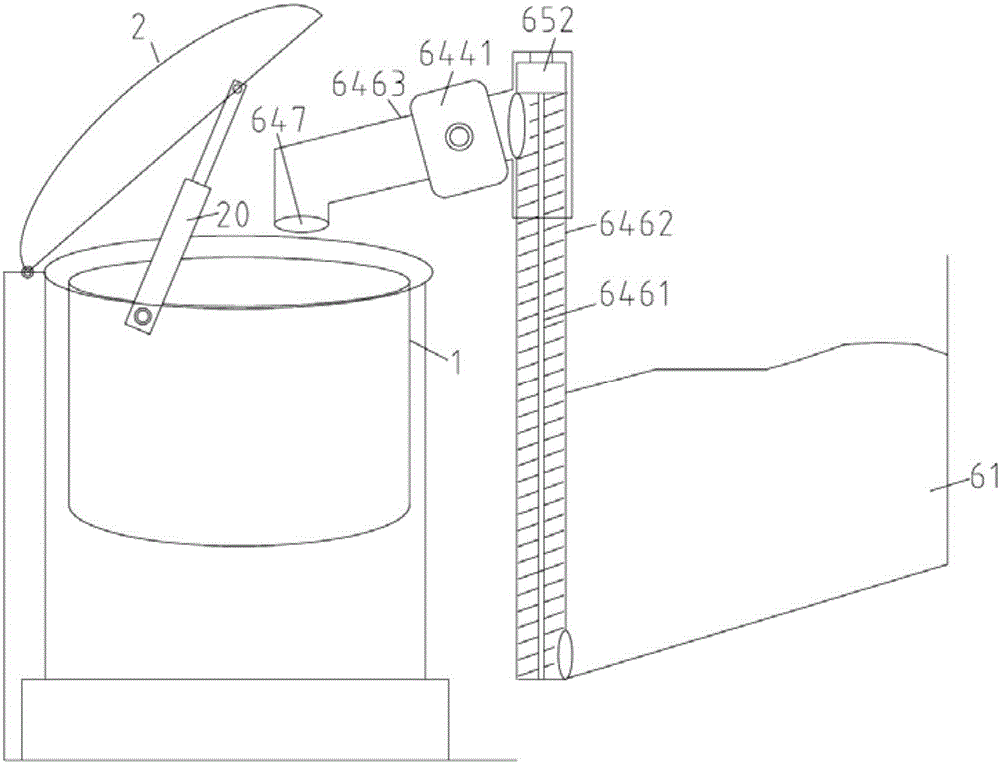

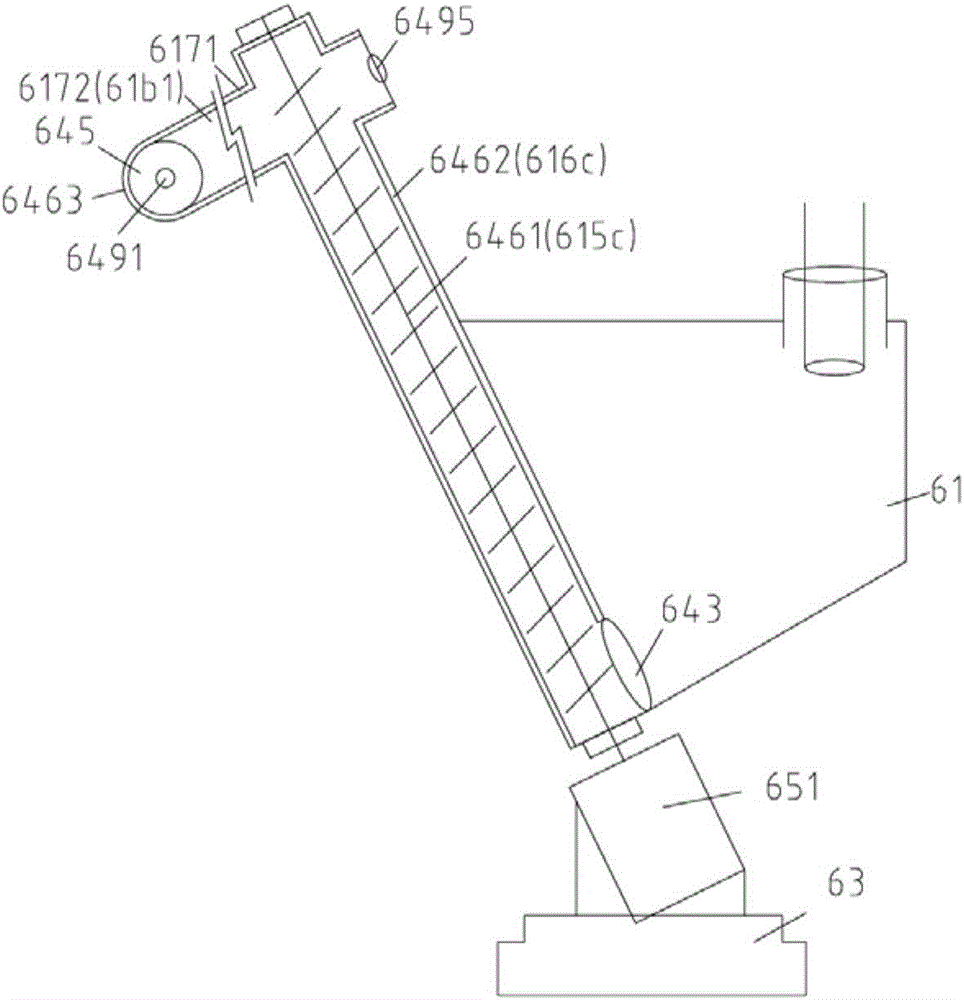

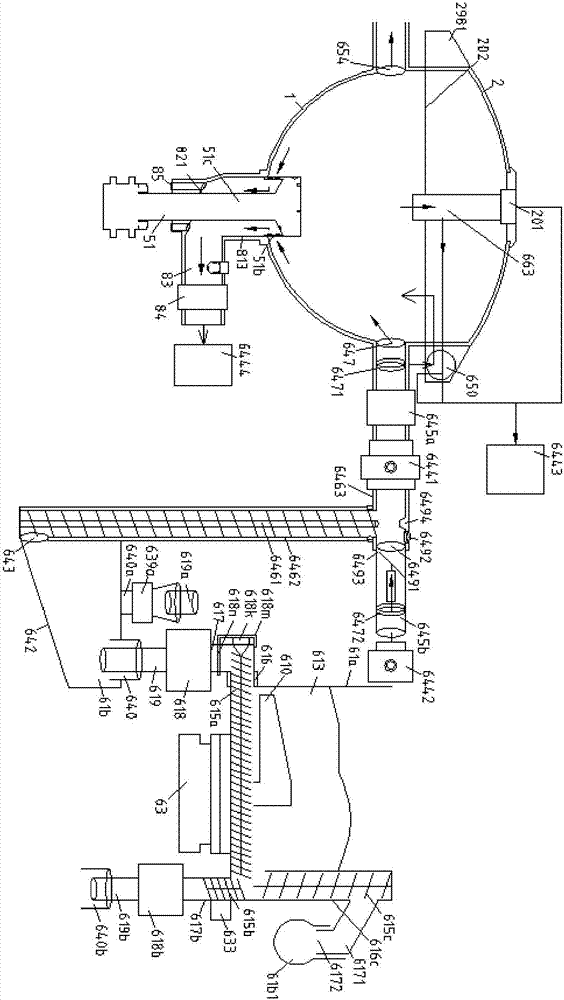

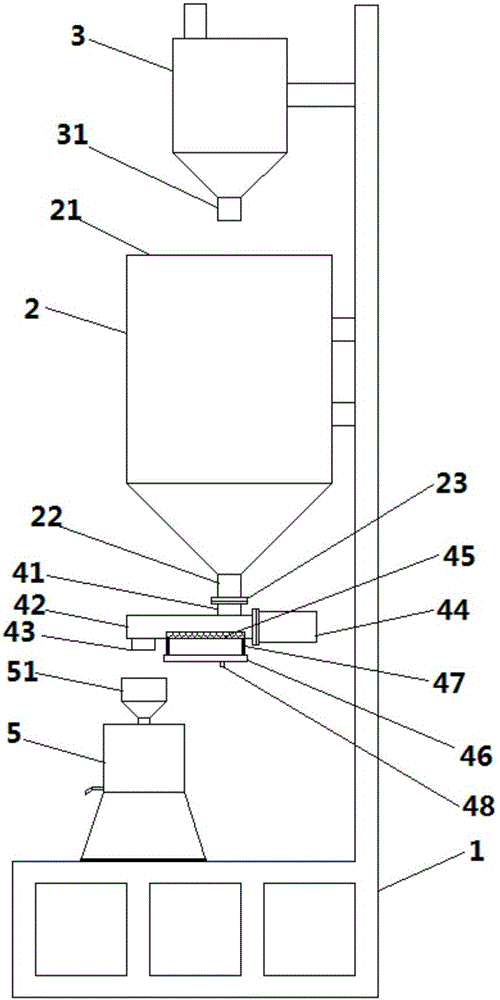

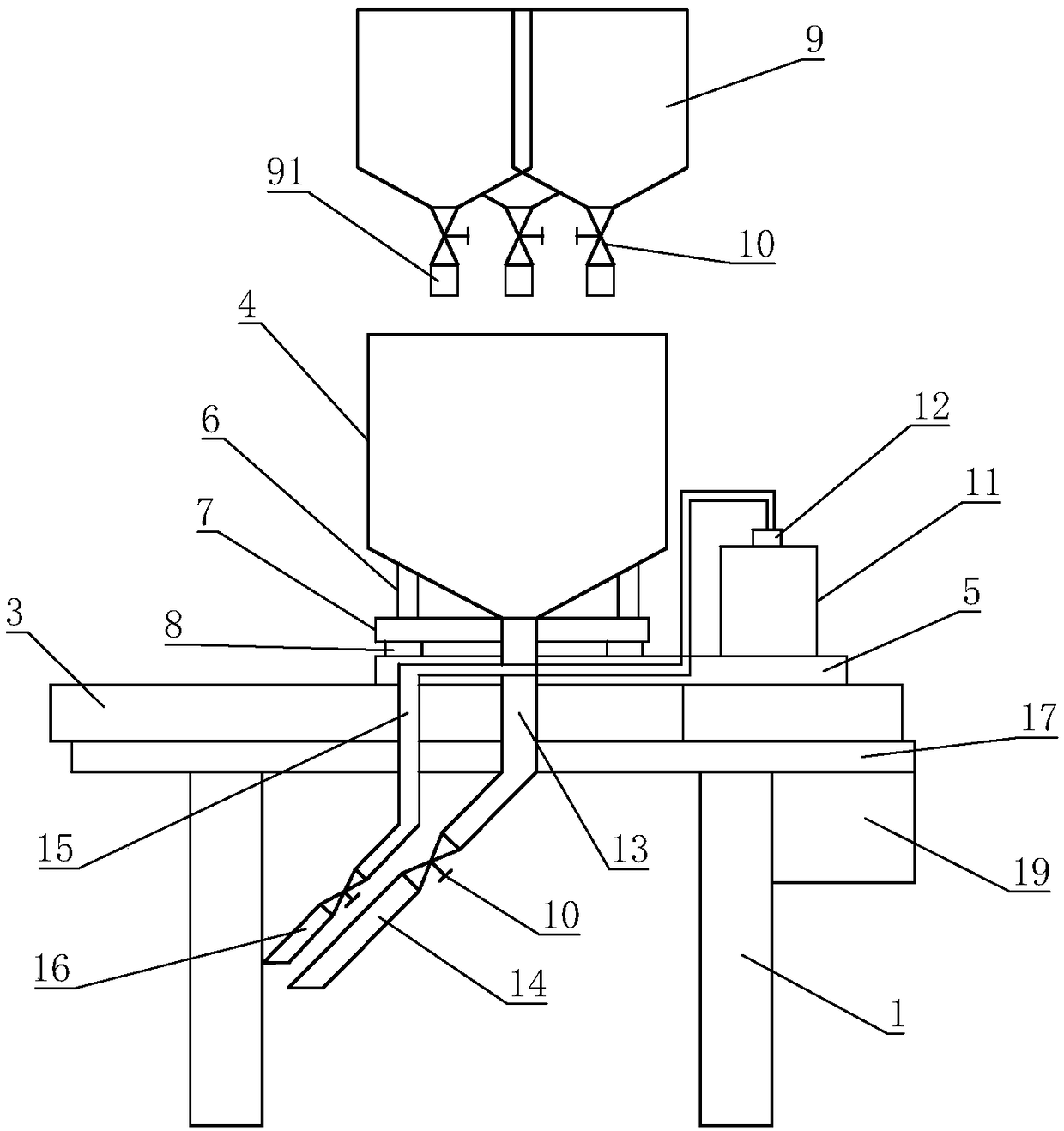

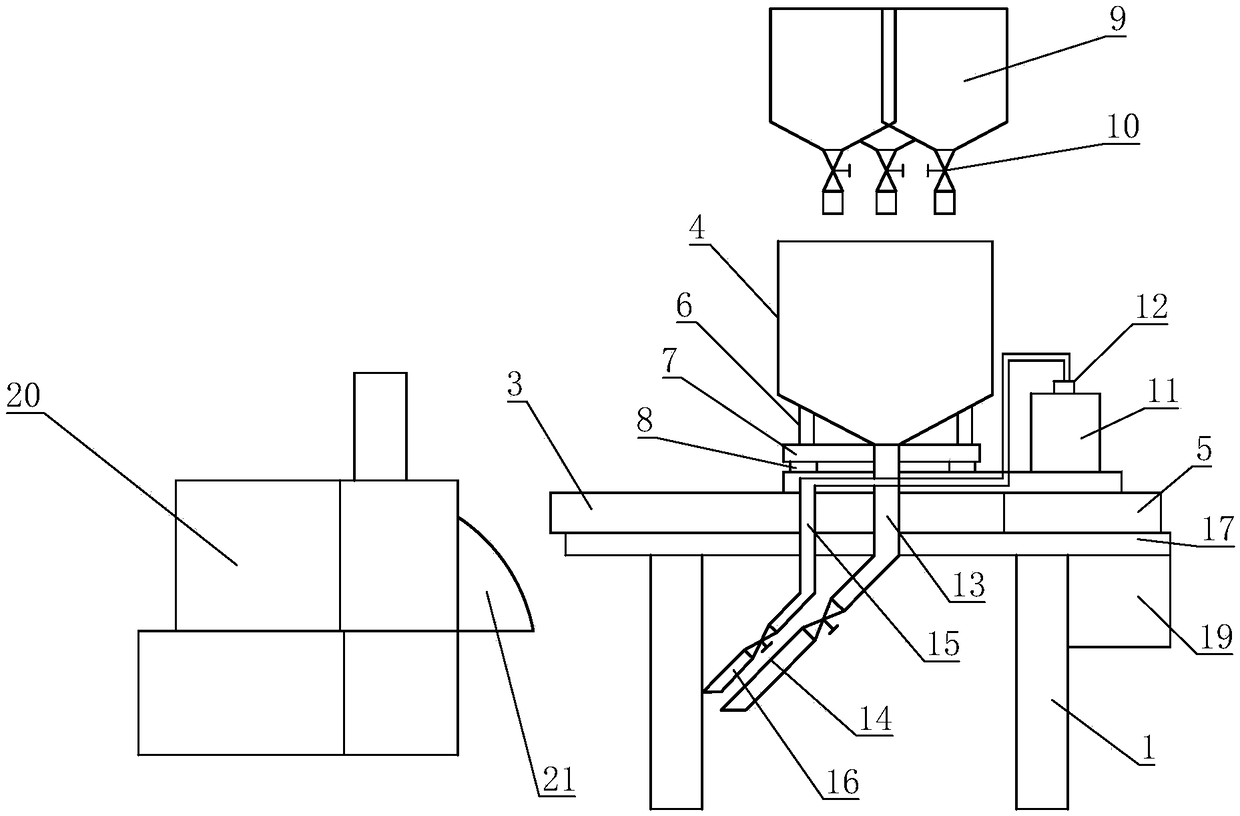

According to the embodiment, the invention relates to the technical field of smart home, and discloses a feeding device of cooking equipment and the cooking equipment. The feeding device comprises a dividing device and a supplying device, wherein the dividing device adopts a worm or a disc provided with a charging groove; cooking raw materials in a storage box are supplied to a supplying device; and the dividing device and the supplying device are separated when the cooking raw materials are weighed. According to the supplying device, the cooking raw materials are conveyed into a pot body of the cooking equipment by virtue of a wind power device / vacuum device, or by virtue of a horizontal worm in a horizontal conduit and through self-gravity of the cooking raw materials, so that automatic feeding of the cooking equipment is achieved and workload of a user is reduced; a multipurpose mating device is provided for a plurality of intelligent home products, and a foundation is created for intelligent kitchen appliances or the smart home. The dividing device is applicable to such intelligent cooking equipment as an electric cooker, a bread maker, a frying machine, a soybean milk making machine, a bean curd machine, a stirrer, a coffee machine or a tea maker and the like.

Owner:李亚锐

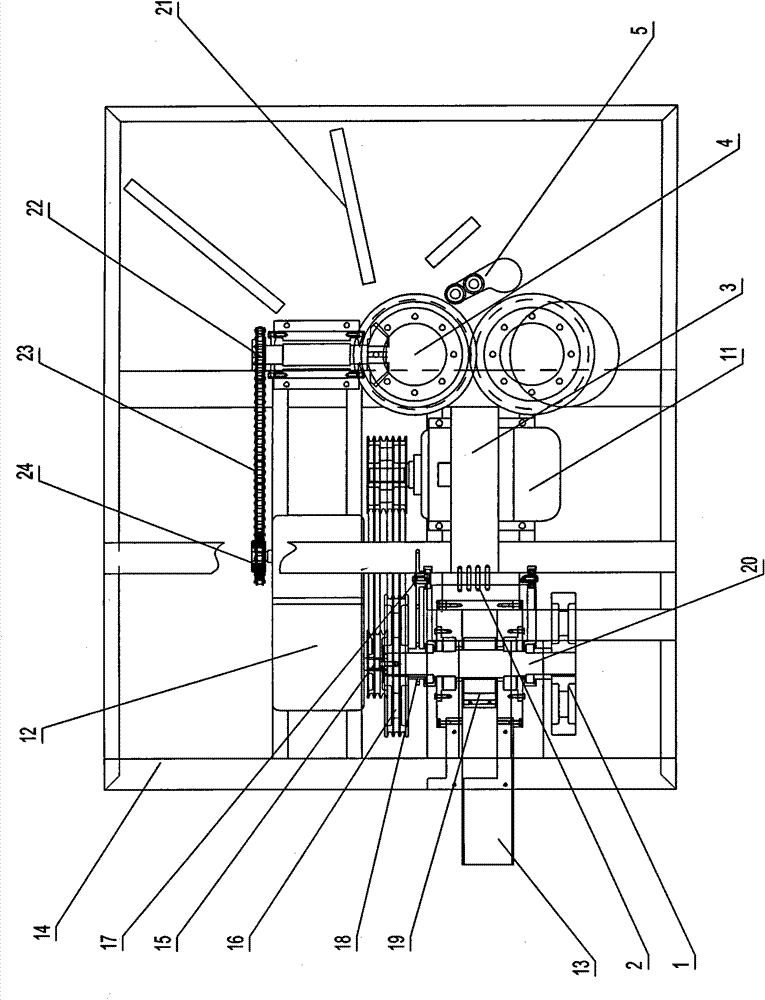

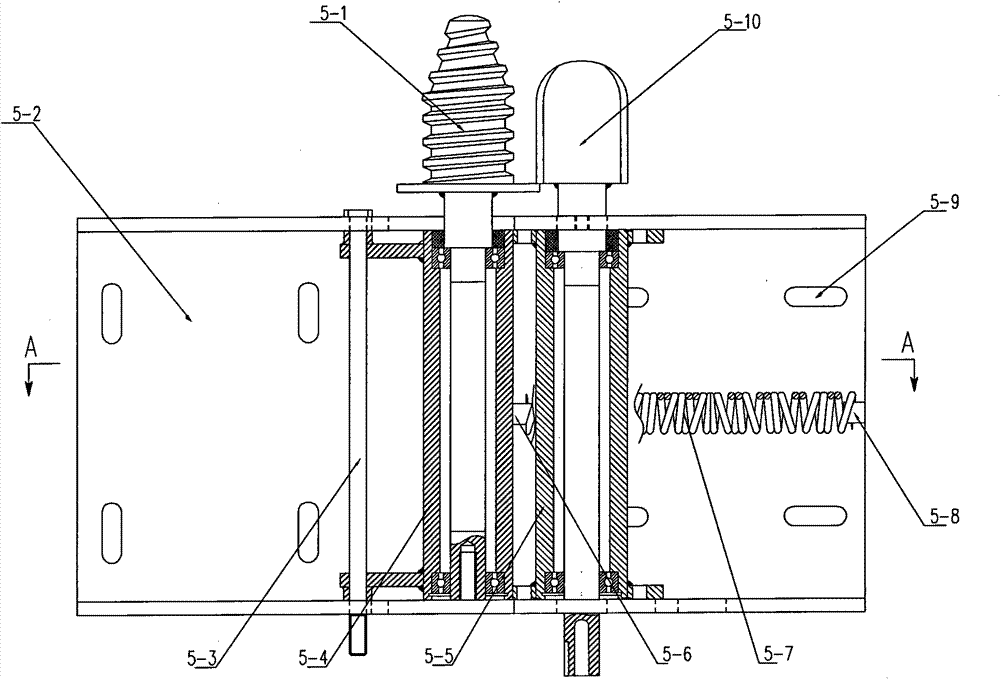

Feeding, distributing and charging device of cooking device and charging method of cooking device

ActiveCN107960873ARealize feeding automationReduce labor workloadCooking-vessel lids/coversCooking vessel constructionsElectricityEngineering

The embodiment of the invention relates to the technical field of smart home, and discloses a charging device of a cooking device and the cooking device. The charging device comprises a distributing device, a weighing device and / or a feeding device, wherein the distributing device is used for feeding cooking raw materials in a material storage box to the weighing device, the weighing device is used for feeding the cooking raw materials to the feeding device, the feeding device is used for feeding the cooking raw materials to a pot, and when weighing is needed, the weighing device is separatedfrom the feeding device. Or, the charging device comprises the distributing device and the feeding device, the distributing device adopts a worm or a round plate with a loading groove, the cooking rawmaterials in the material storage box are fed to the feeding device, the feeding device feeds the cooking raw materials to the pot, and when weighing is needed, the distributing device is isolated from the feeding device. With the adoption of the technical scheme, the automation and accuracy of charging of the cooking device are realized, a matched device wide in application is provided for various smart home products, and a foundation is laid for smart kitchen appliances or smart home.

Owner:李亚锐

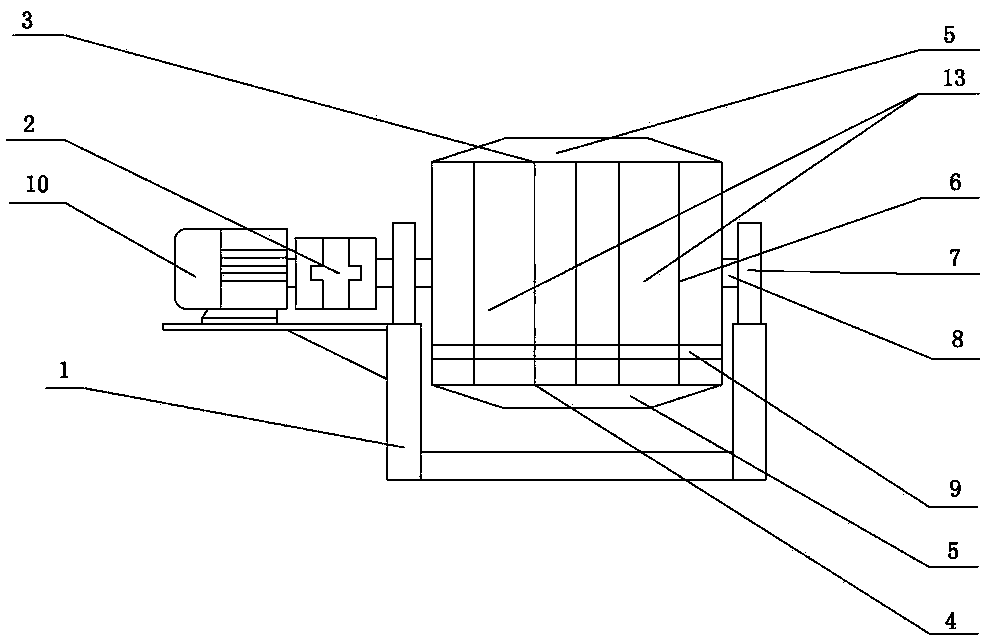

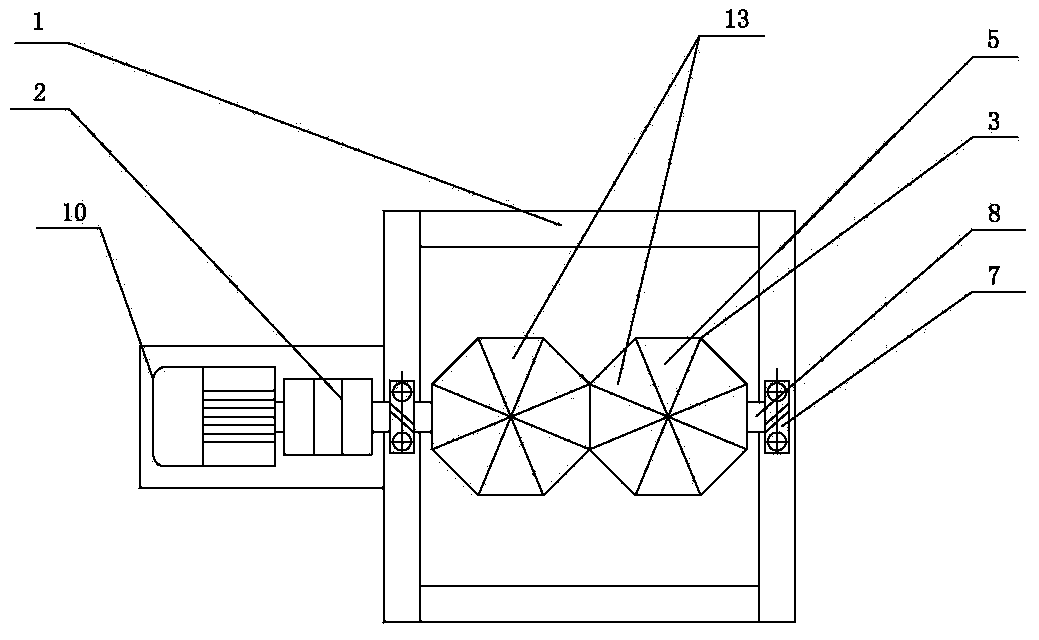

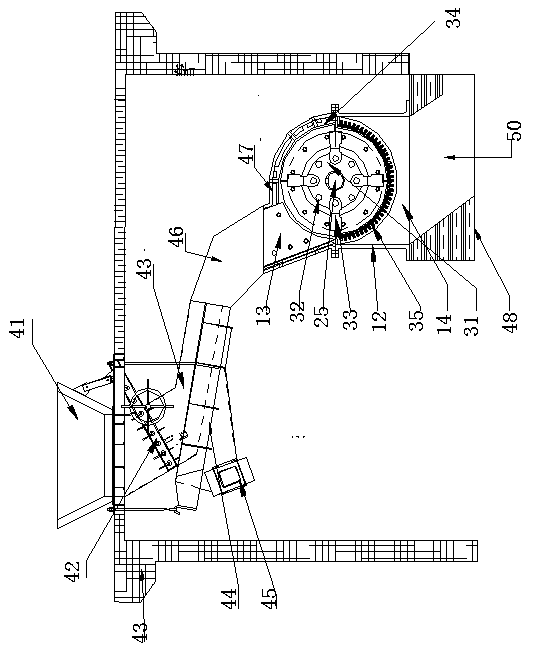

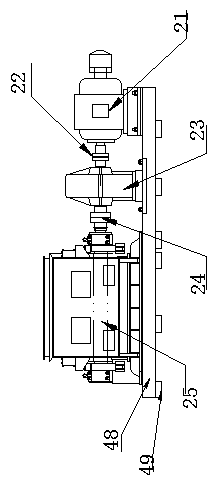

Double-bag overturning device

The invention discloses a double-bag overturning device which comprises a support. The double-bag overturning device further comprises a material overturning hopper composed of two frames, the inner sides of the two frames are connected together, the two sides of the material overturning hopper are supported on the support through rotating shafts and bearings, and the rotating shaft on one side extends out to be connected with a gear motor through a coupler; each frame is formed by connecting an octagonal upper opening edge, an octagonal lower opening edge and a sliding way between the octagonal upper opening edge and the octagonal lower opening edge, and self-locking doors are arranged on the outer sides of an upper opening and a lower opening respectively; a sliding chassis capable of vertically sliding through the sliding way is arranged in each frame. The double-bag overturning device has the advantages that material hitting automation is achieved; the labor strength of a worker is reduced, and the operation environment of the worker is improved; the using efficiency of a crown block is improved; two bags can be overturned at the same time, continuous bag overturning is achieved, and the labor efficiency of an operator is improved in a multiplied mode; the good conditions of the bags can be kept after bag overturning, and the bags can be recycled and repeatedly used; the sliding chassis is used, and discharging space is saved; meanwhile, manufacturing materials are greatly saved, and the manufacturing cost is reduced.

Owner:FUSHUN ALUMINUM

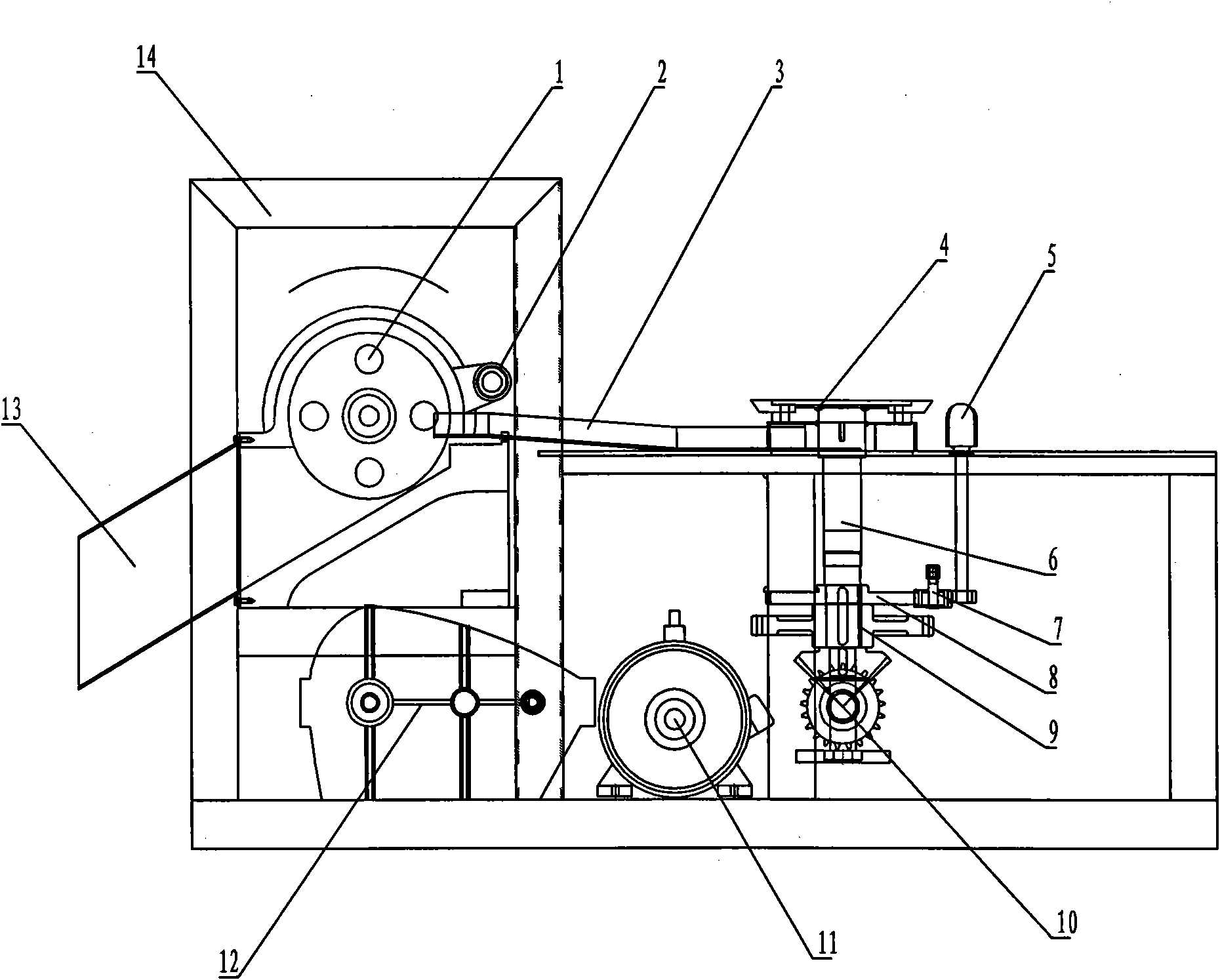

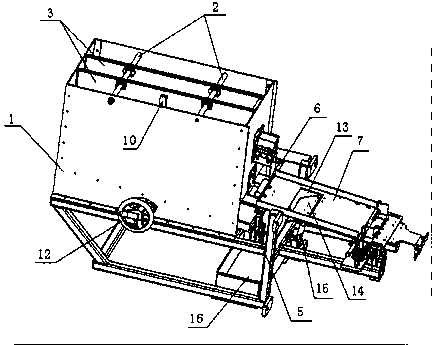

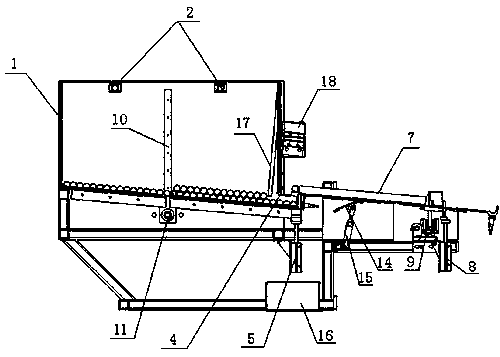

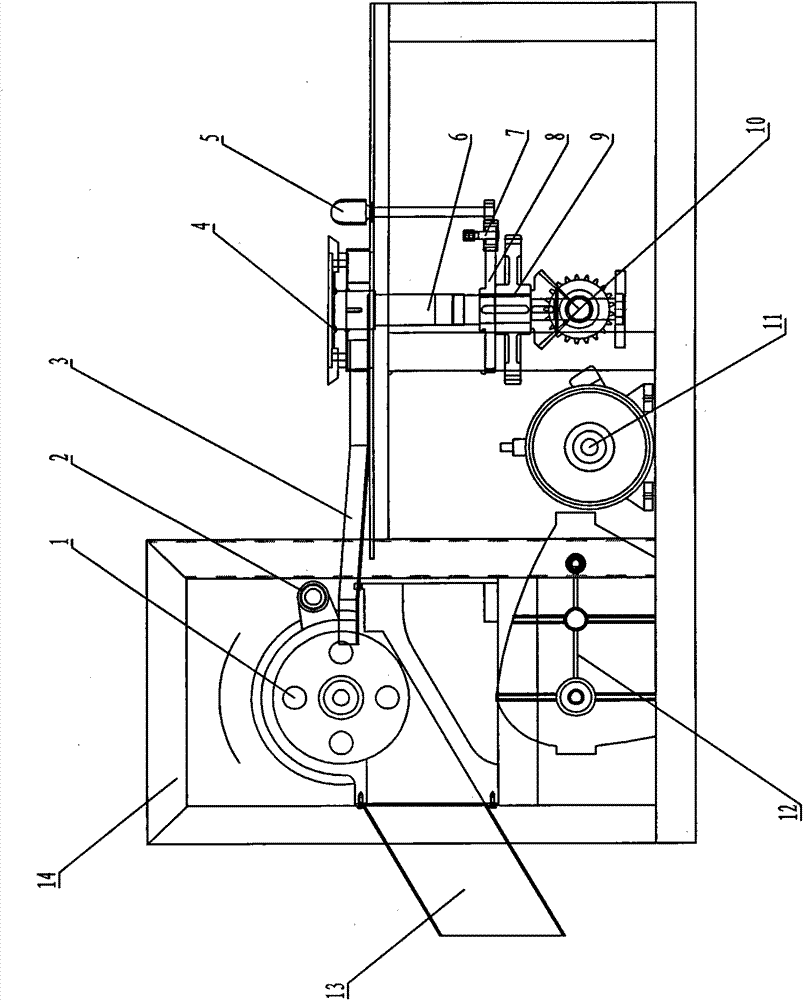

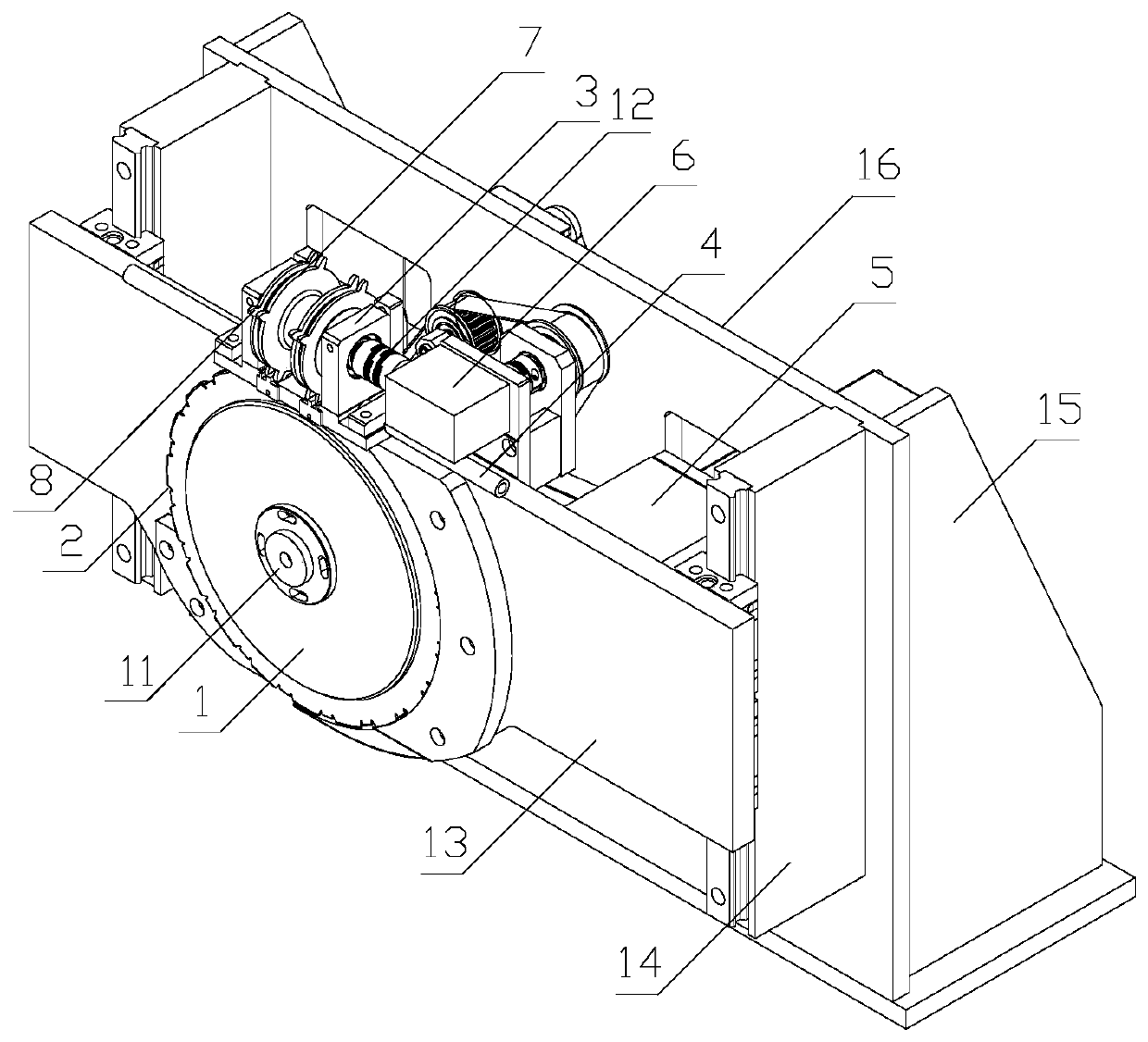

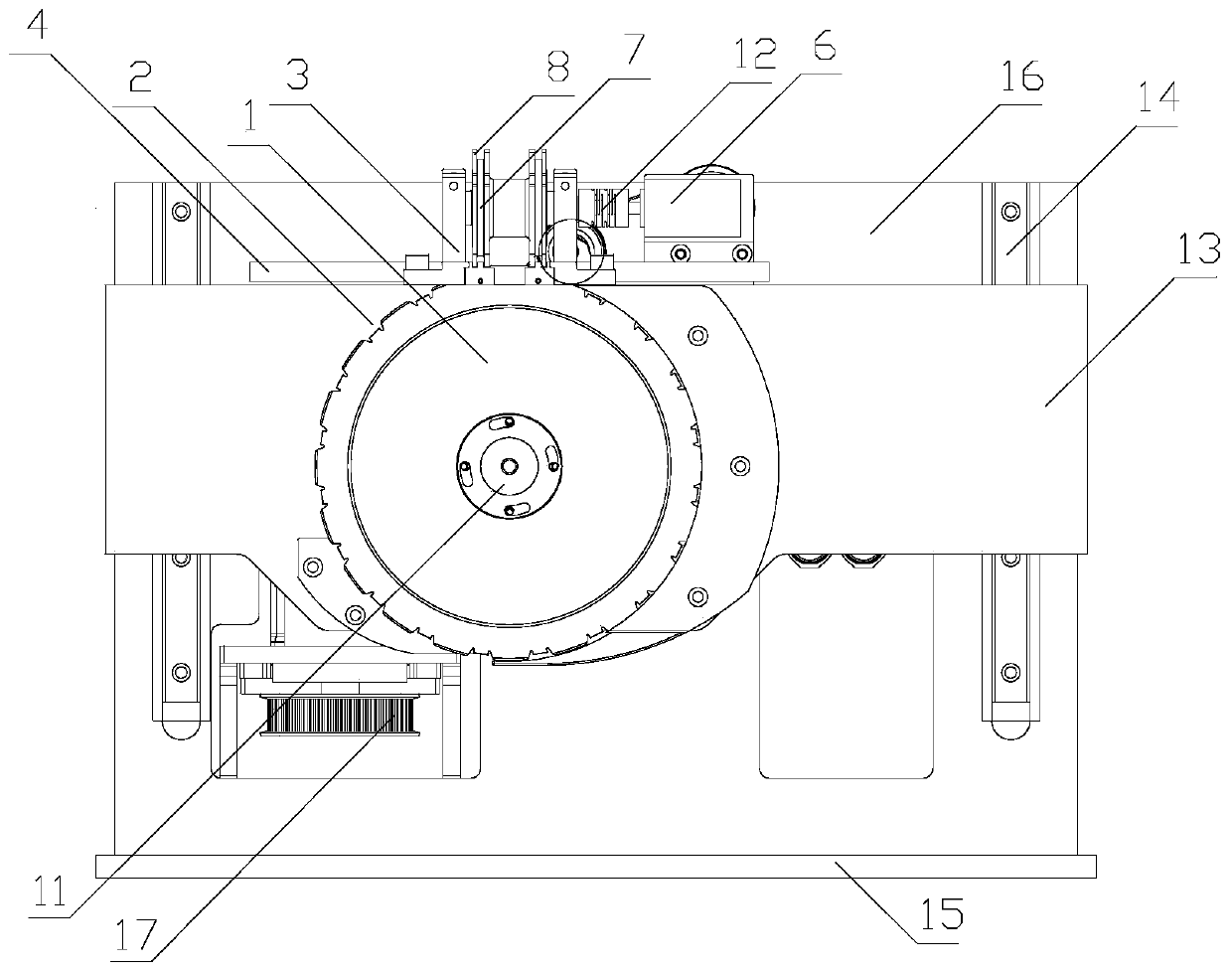

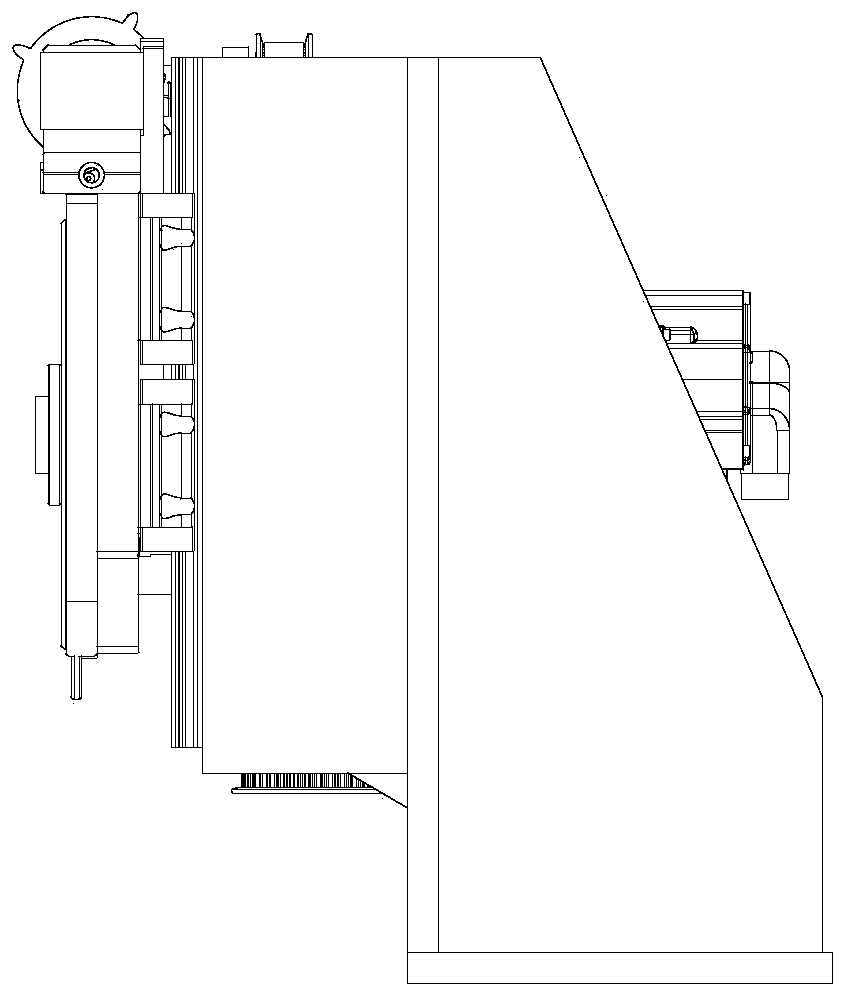

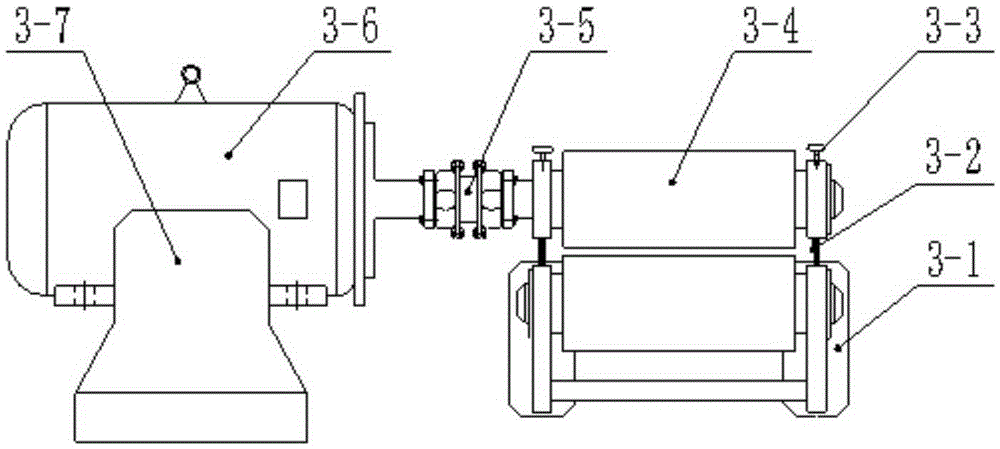

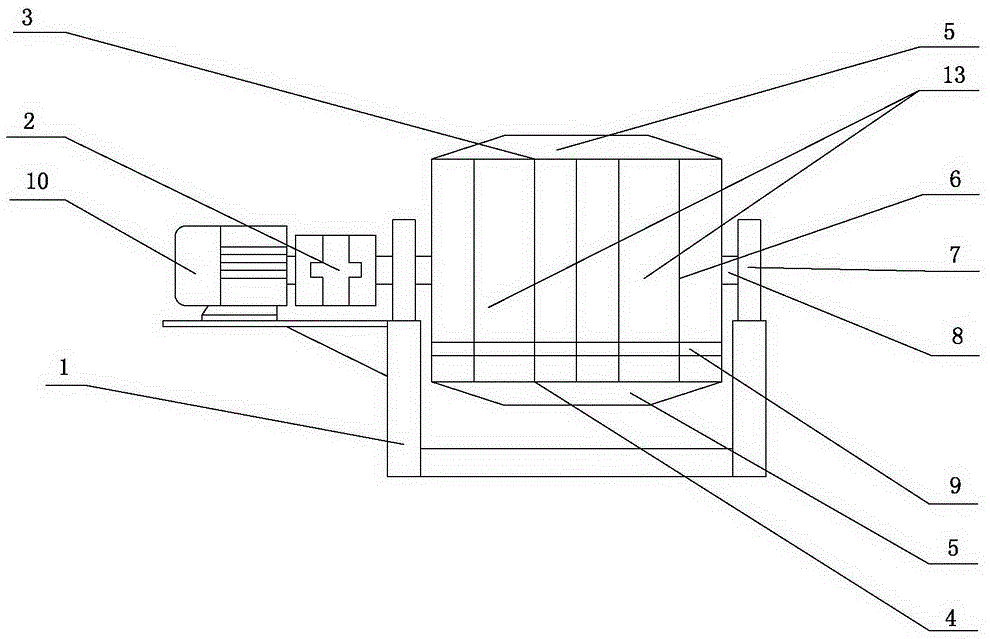

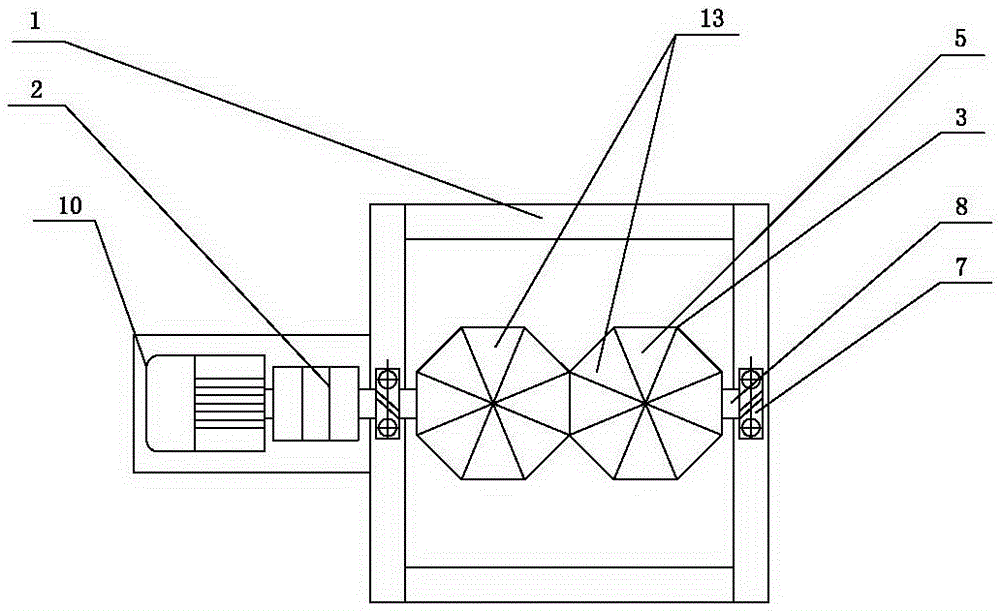

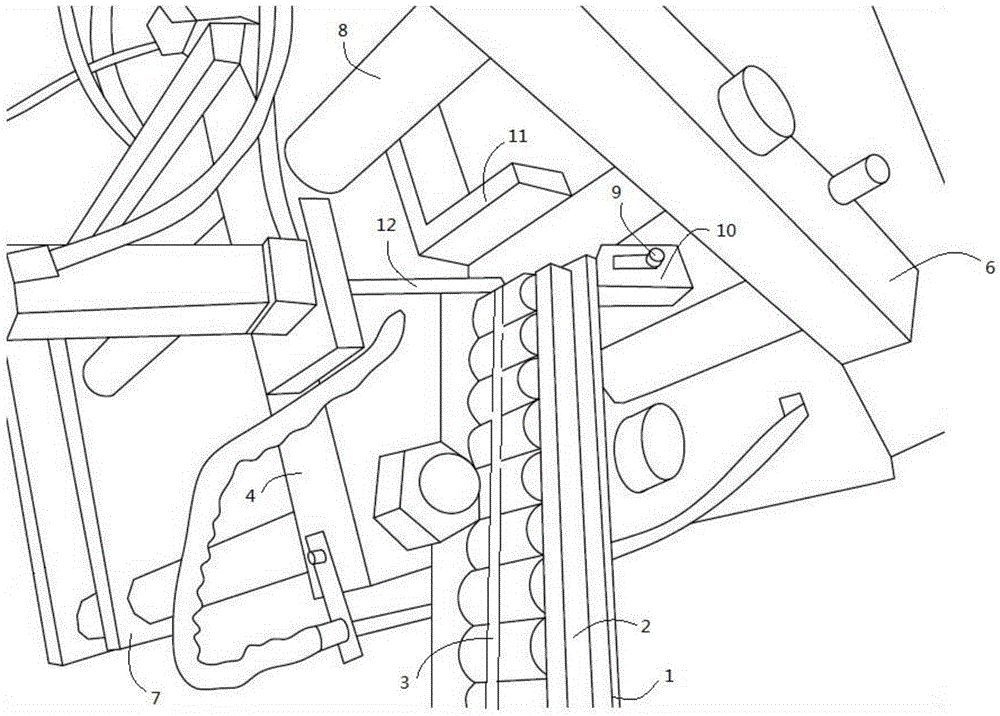

Waste rubber tire horizontal composite dicer

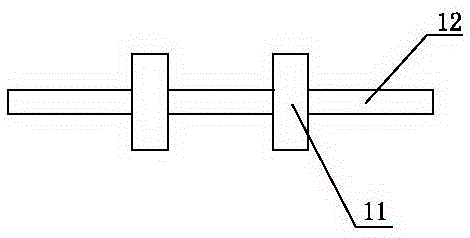

InactiveCN101850583AEasy feedingRealize feeding automationPlastic recyclingMetal working apparatusGear wheelWaste rubber

The invention relates to a waste rubber tire horizontal composite dicer which comprises a frame, a power source, a transmission gear, a slitter, a dicing device and a tire feeding device, wherein the slitter and the dicing device are installed on the upper part of the frame; the power source and the transmission gear are installed on the bottom of the frame; the tire feeding device is installed near the slitter; the slitter comprises an upper horizontal cutter head and a lower cutter head which contact the working surface; the shafts of the two cutter heads form a mesh transmission through various gears which match each other; the lower end of the shaft of one cutter head is connected with the power source through the transmission gear; the dicing device comprises a dicing shaft, a dicingcutter and an inertia wheel, the dicing shaft is installed on the frame, the dicing cutter and the inertia wheel are installed on the dicing shaft, and the dicing main shaft is connected with the power source through the transmission gear; and a guide chute is arranged between the slitter and the dicing device. The dicer provides convenience for feeding waste tires, can realize automatic feeding,and maximally reduces manual work.

Owner:HENAN ZHONGYING RUBBER TECH

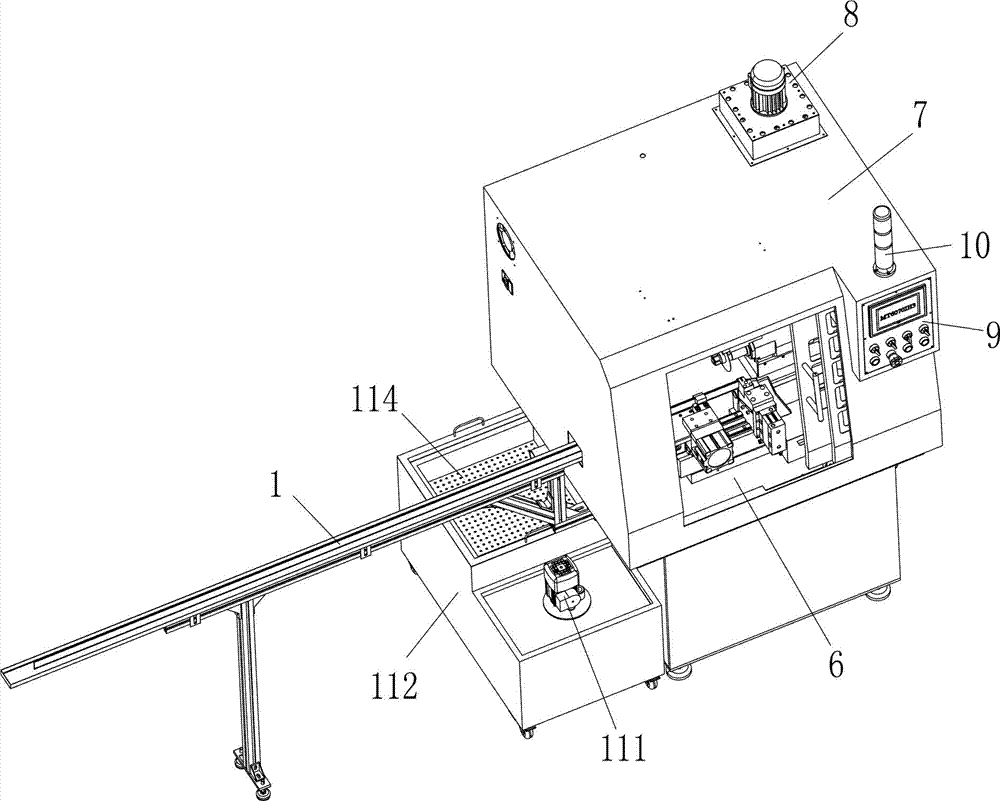

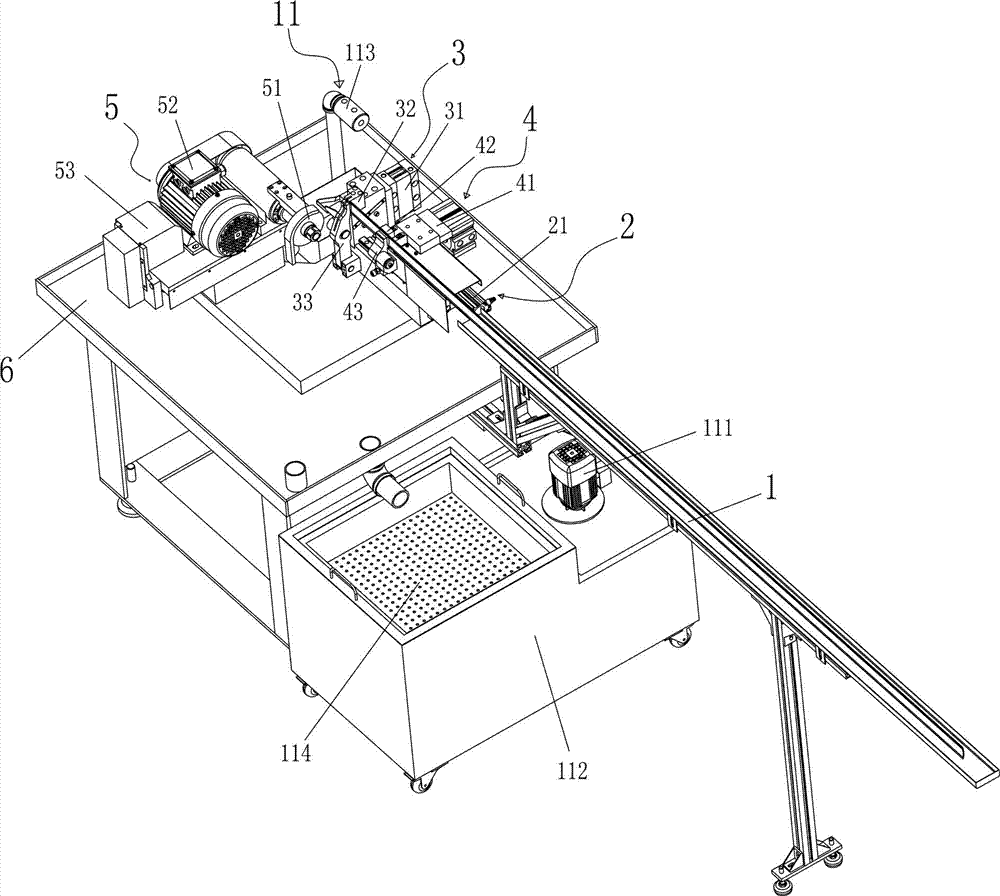

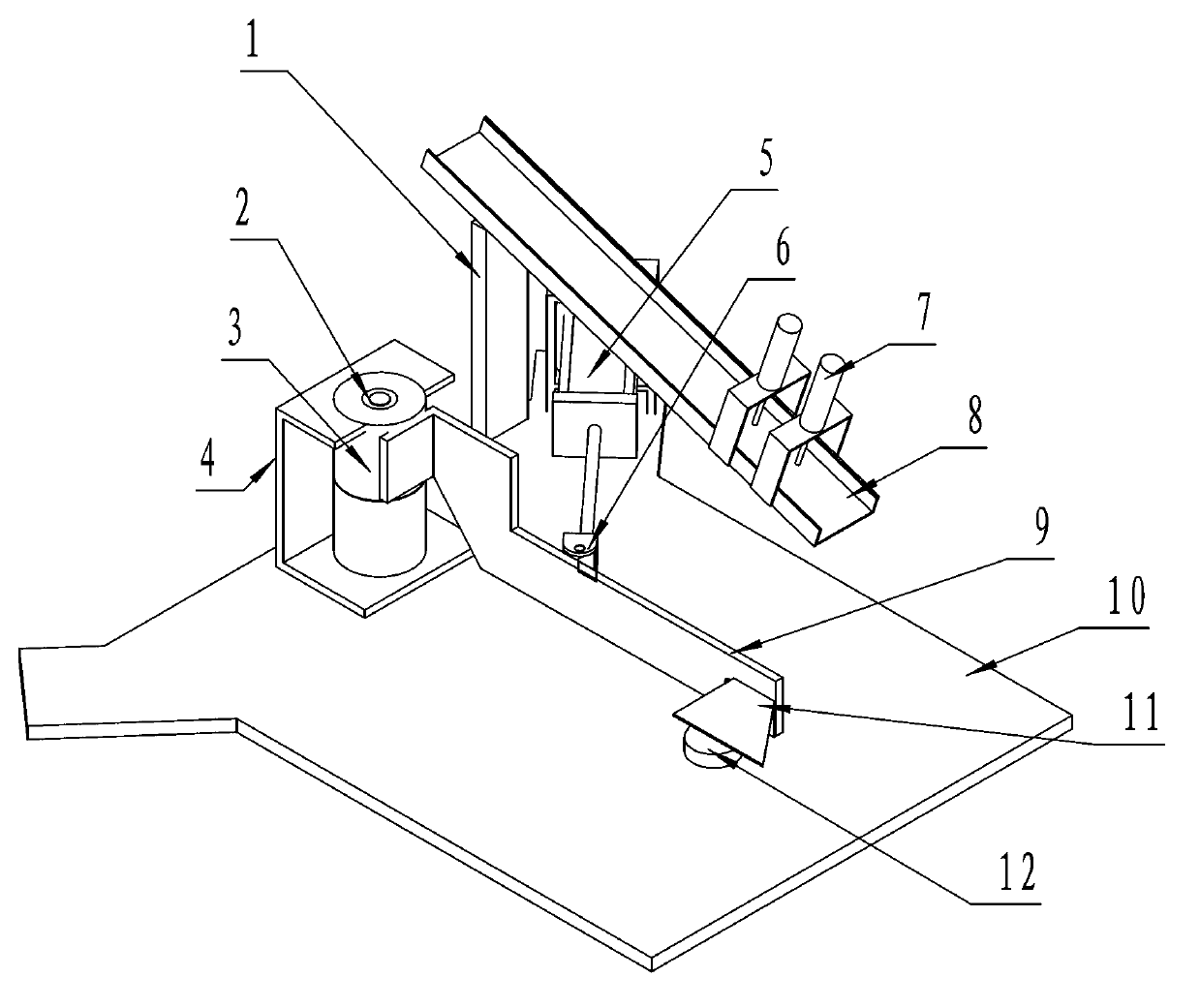

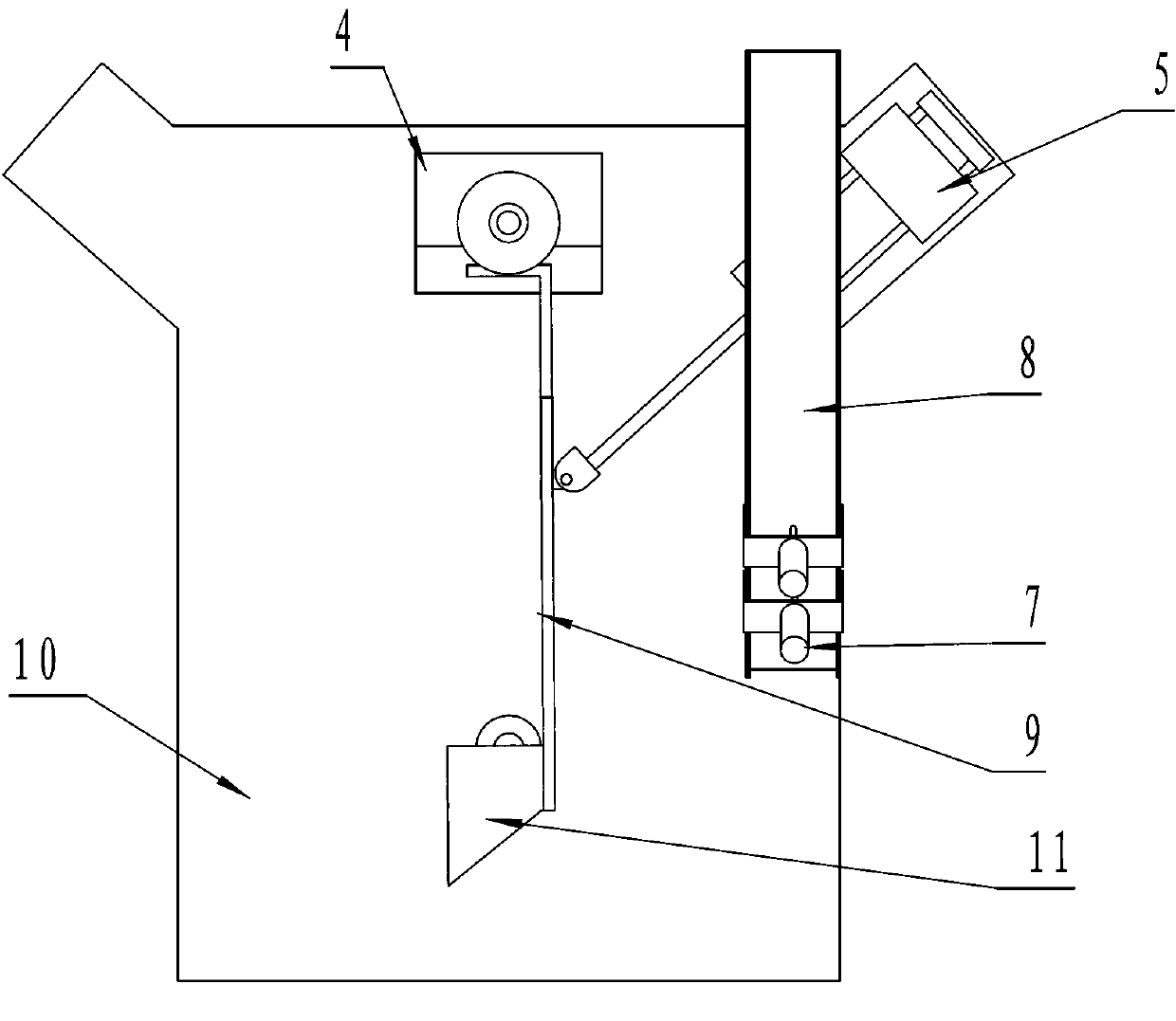

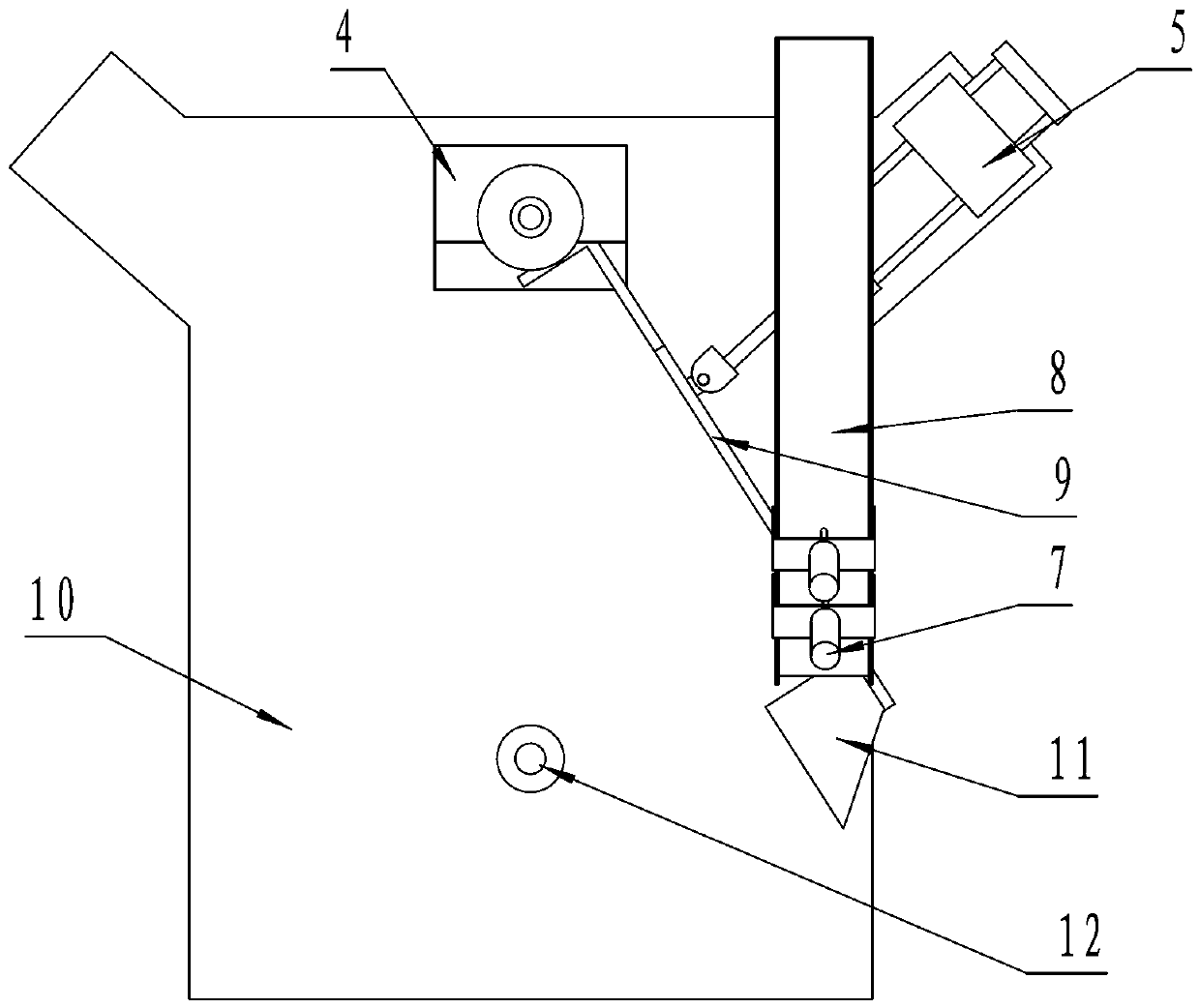

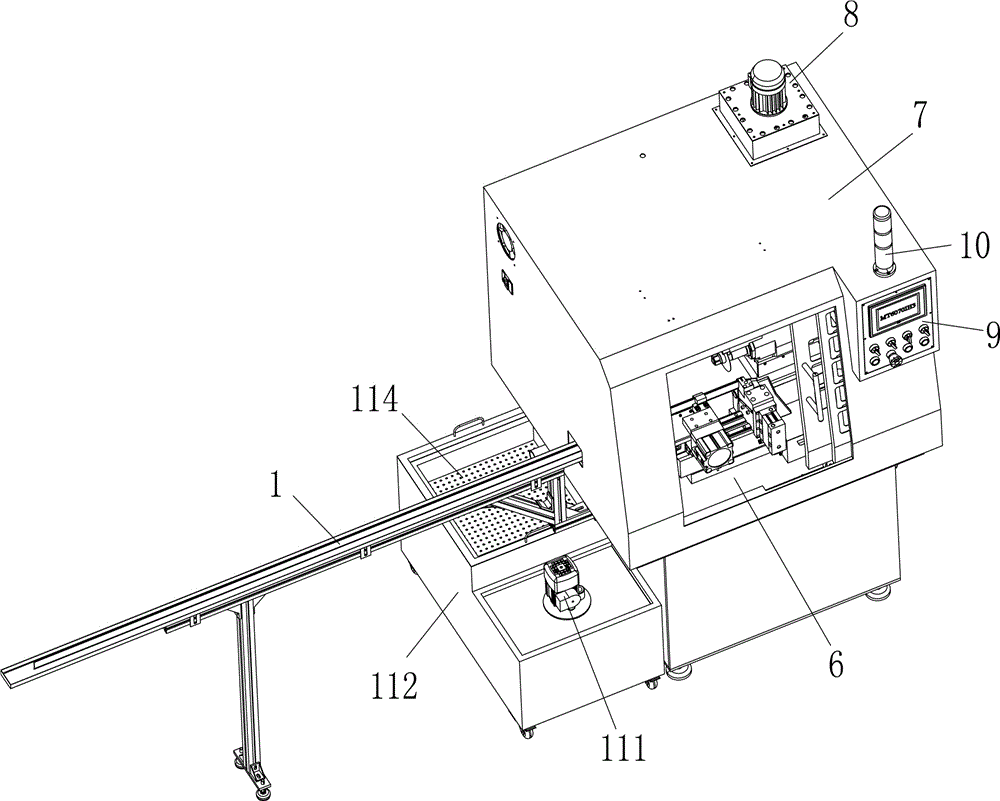

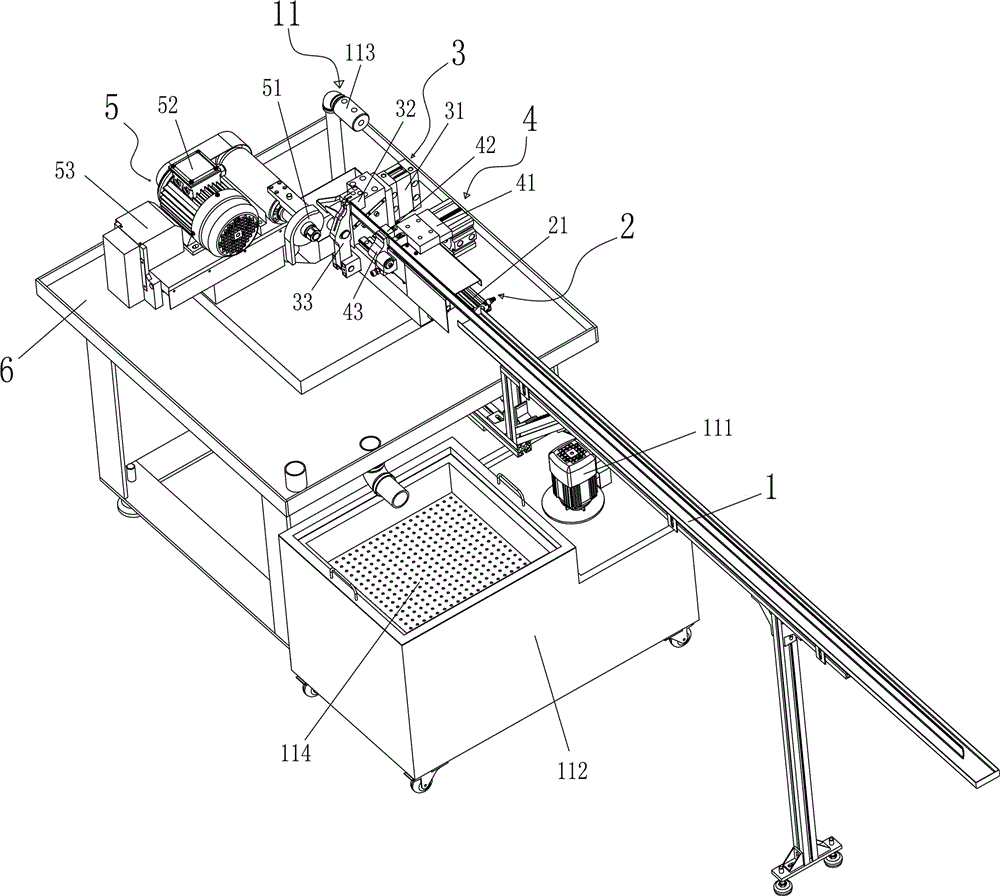

Automatic feeding cutter for metal bar stock

InactiveCN104772524ARealize feeding automationReduce labor intensityMetal sawing devicesMetal sawing accessoriesUltimate tensile strengthBar stock

The invention discloses an automatic feeding cutter for a metal bar stock. The automatic feeding cutter for the metal bar stock comprises an automatic feeding mechanism and an automatic cutting mechanism, wherein the automatic feeding mechanism comprises a feeding device and a material clamping device; the feeding device is used for controlling the material clamping device to regulate a position so as to conveniently position the cutting position of the metal bar stock in the material clamping device; the automatic cutting mechanism comprises a saw blade, a first motor and a second motor, wherein the first motor is used for controlling the saw blade to rotate; the saw blade is controlled by the second motor to advance and retreat from the metal bar stock. According to the automatic feeding cutter for the metal bar stock, the ultralong metal bar stock can be automatically fed and cut off, the production efficiency and product quality are improved, enterprise cost is saved, the labor intensity of workers is lightened, and safety is improved.

Owner:CHANGHONG PRECISION TOOL DONGGUAN CO LTD

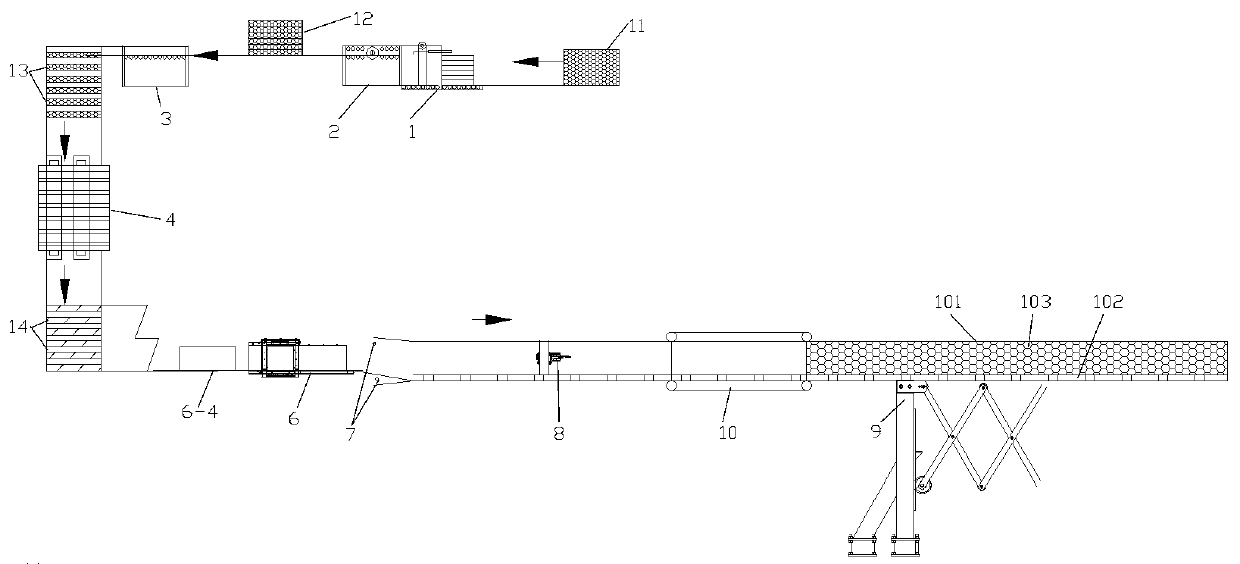

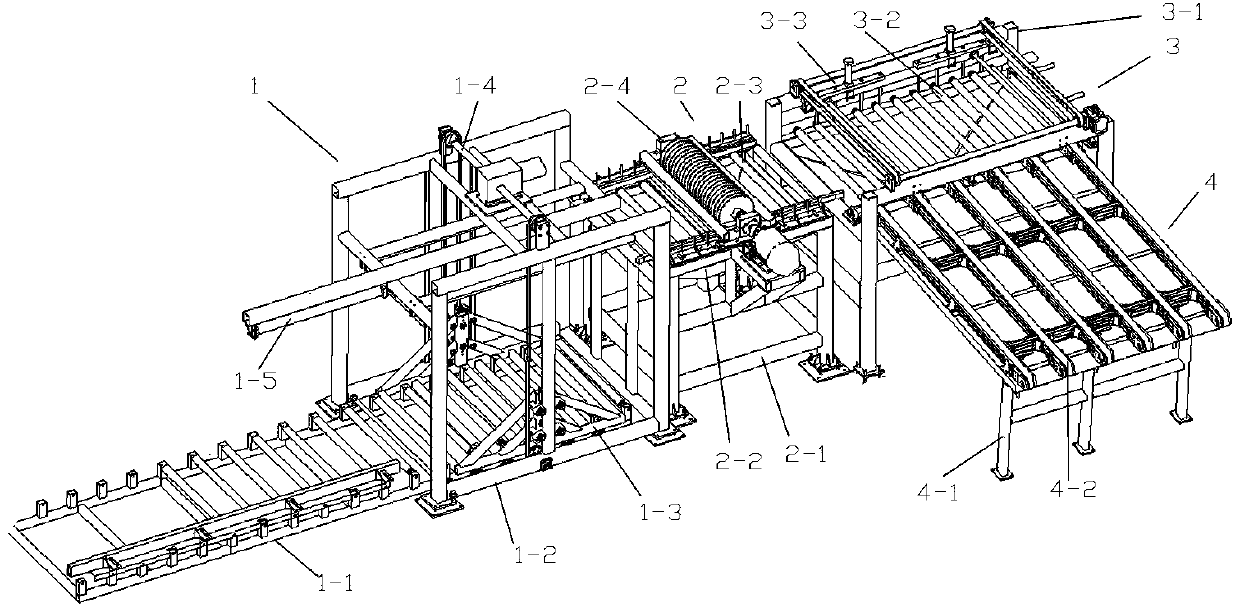

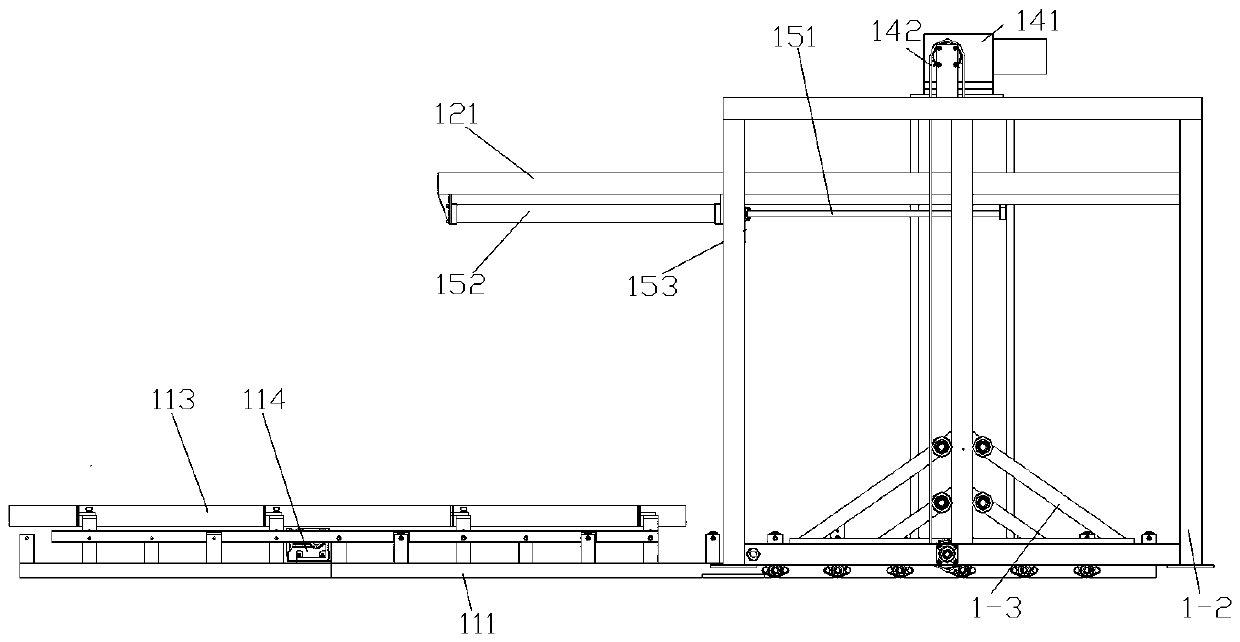

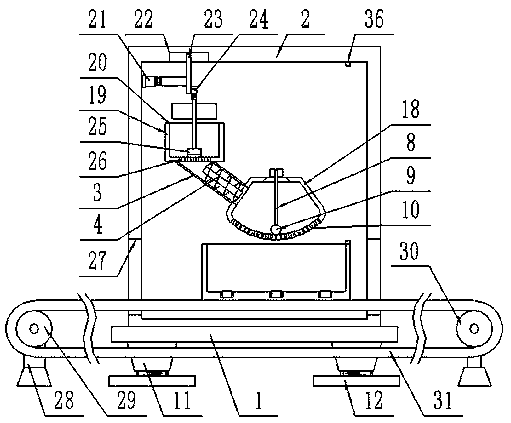

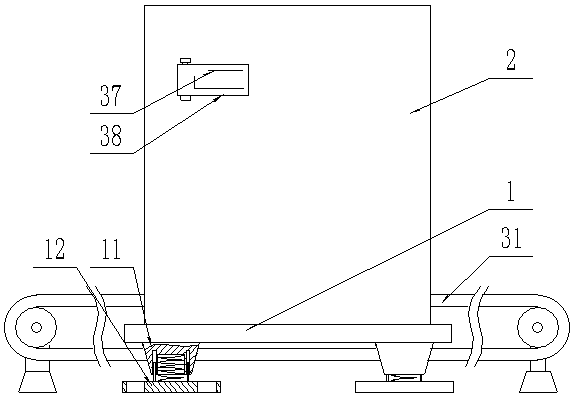

Production line of light composite wallboard

PendingCN111468328ARealize feeding automationNo pollution in the processLamination ancillary operationsSpraying apparatusProduction lineThermal insulation

The invention discloses a production line of a light composite wallboard. The production line comprises a rock wool cutting device, a steel board glue spraying device and a composite board forming device. The rock wool cutting device is used for cutting to-be-slit rock wool blocks into slit rock wool blocks and conveying the rock wool blocks to the composite board forming device. The a steel boardglue spraying device is used for spraying glue to the inner end faces of steel boards and conveying the steel boards to the composite board forming device. The composite board forming device is usedfor attaching and carrying out aftertreatment on the steel boards and inner sandwich layers. The rock wool cutting device comprises a feeding lifting mechanism, a rock wool block cutting mechanism, arock wool strip separating mechanism and a rock wool strip conveying mechanism. The composite board forming device receives output rock wool strips from the rock wool cutting device and output color steel boards of the steel board glue spraying mechanism at the same time, and a distribution mechanism, a crawler belt heating machine and a slitting mechanism are sequentially arranged in the conveying direction of a conveying belt. Fire resistance, thermal insulation properties and other indexes of composite boards produced through the production line are all improved.

Owner:XUCHANG SUPERELEVATOR ELECTRICAL & MECHANICAL EQUIP

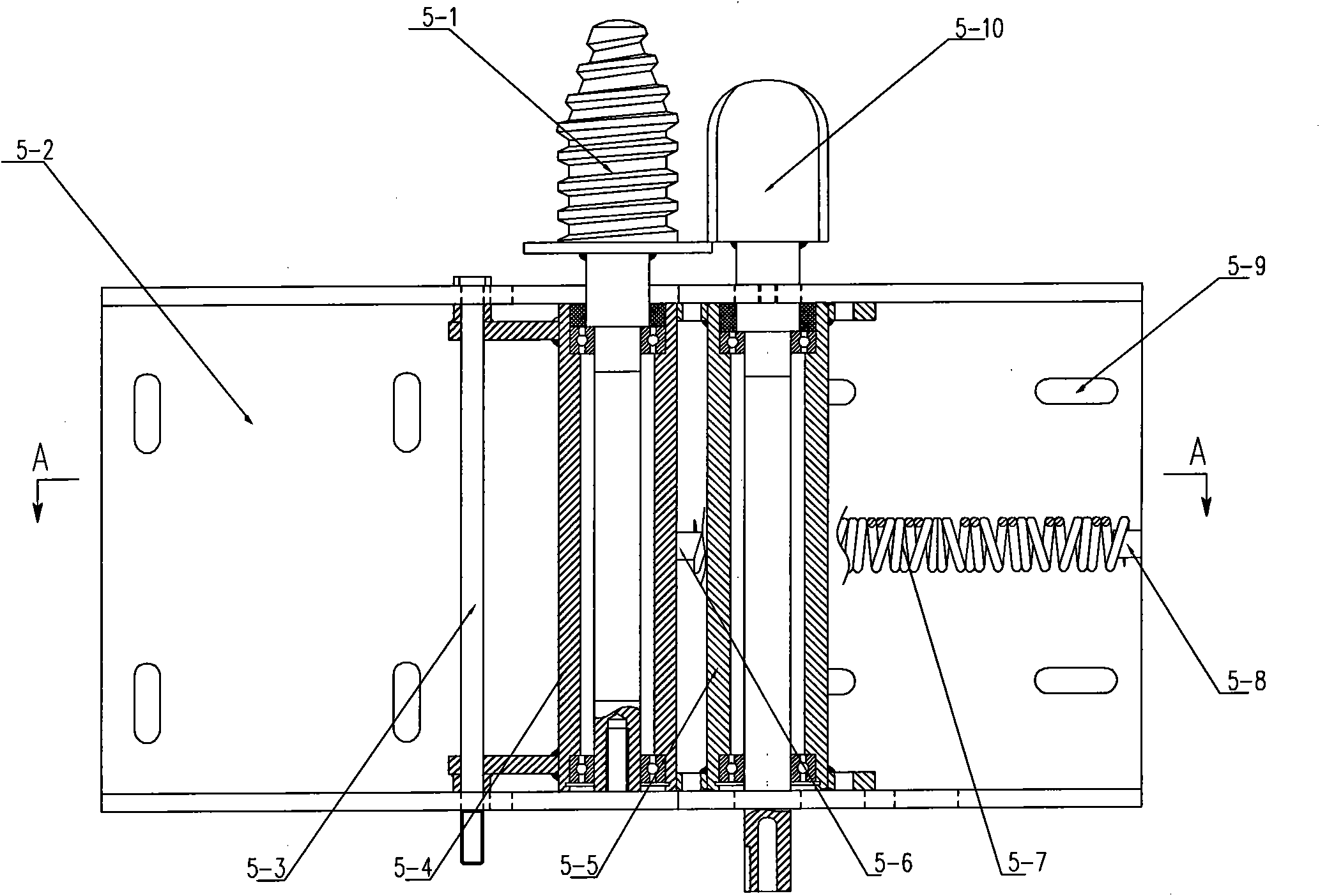

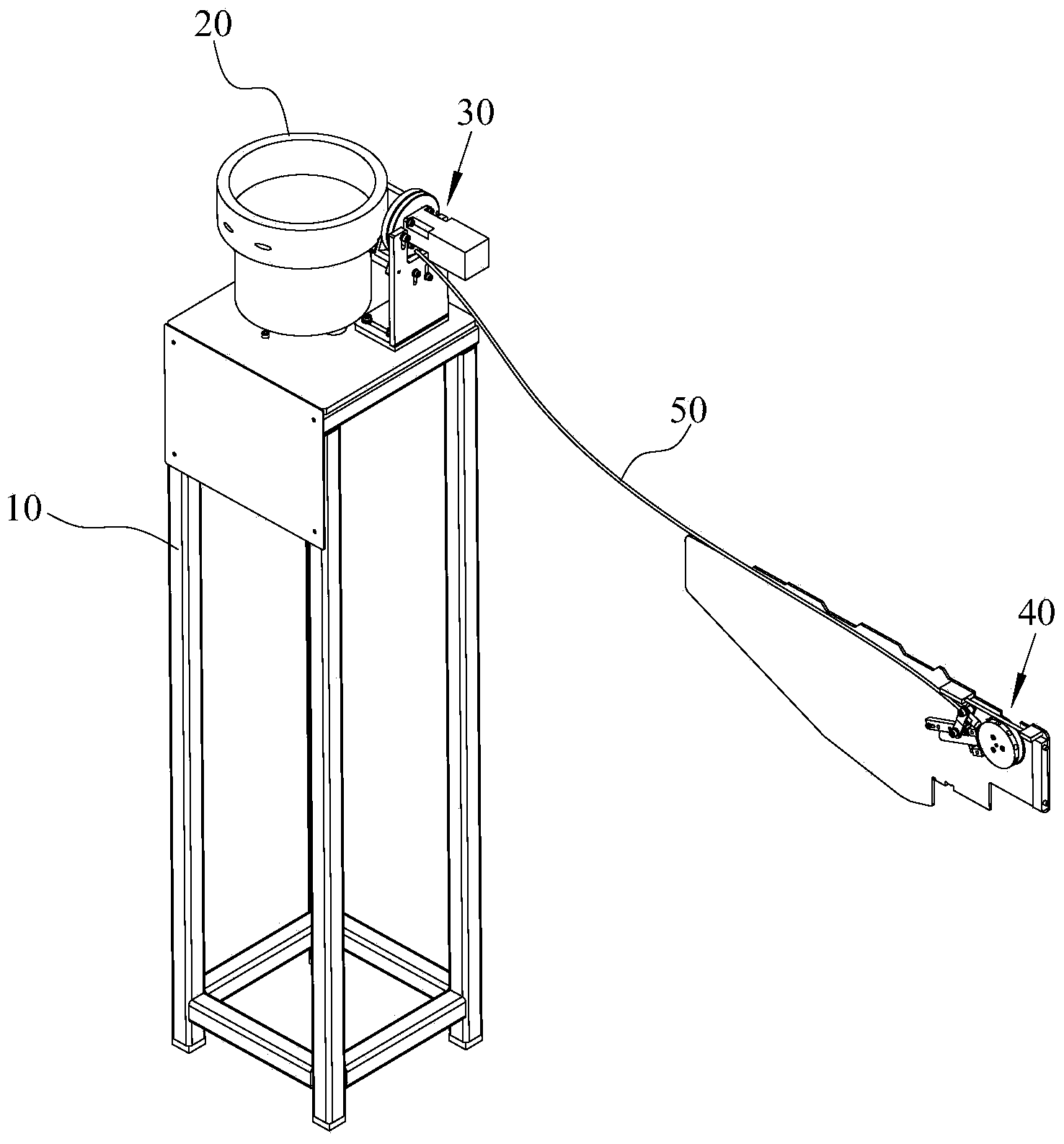

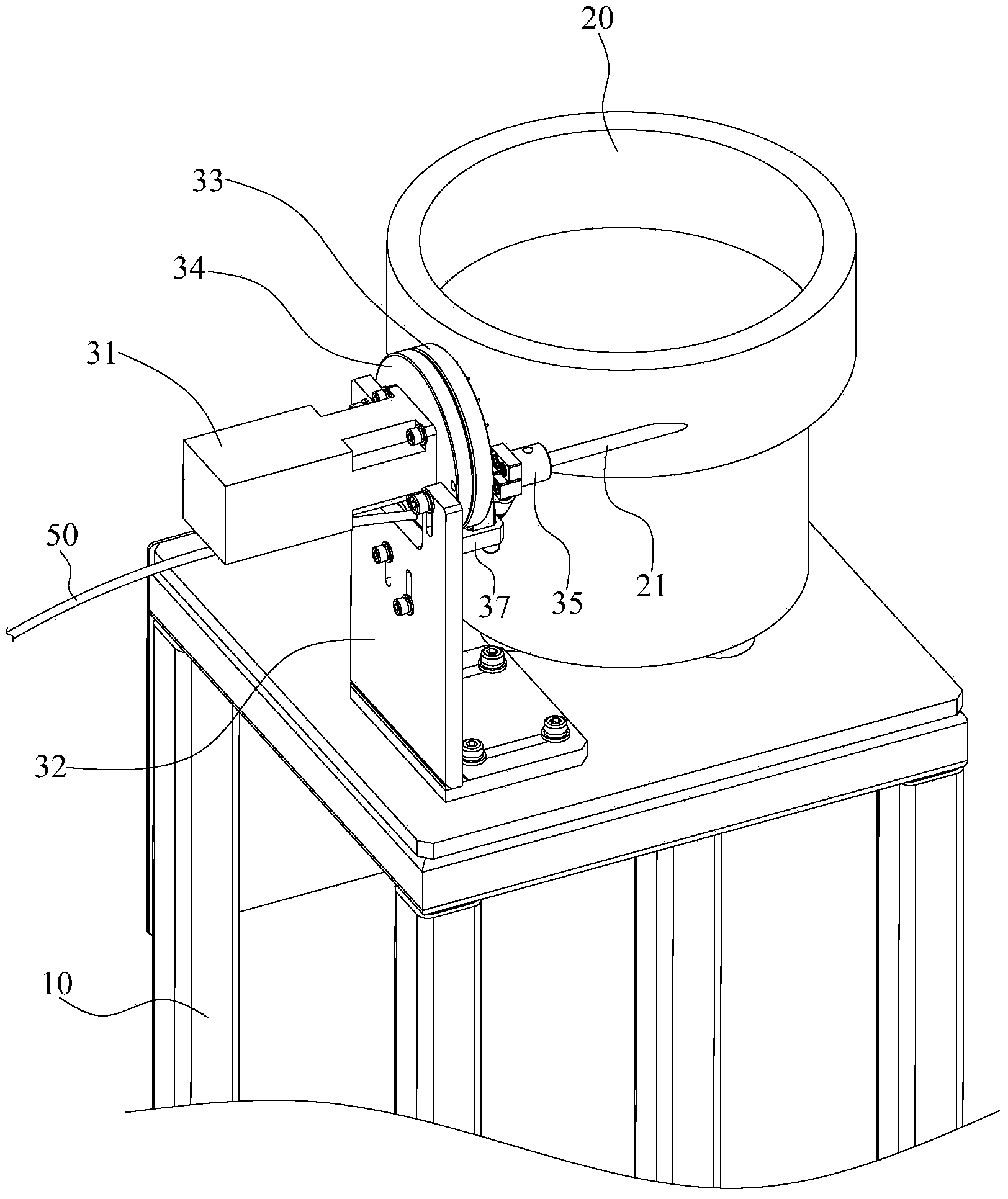

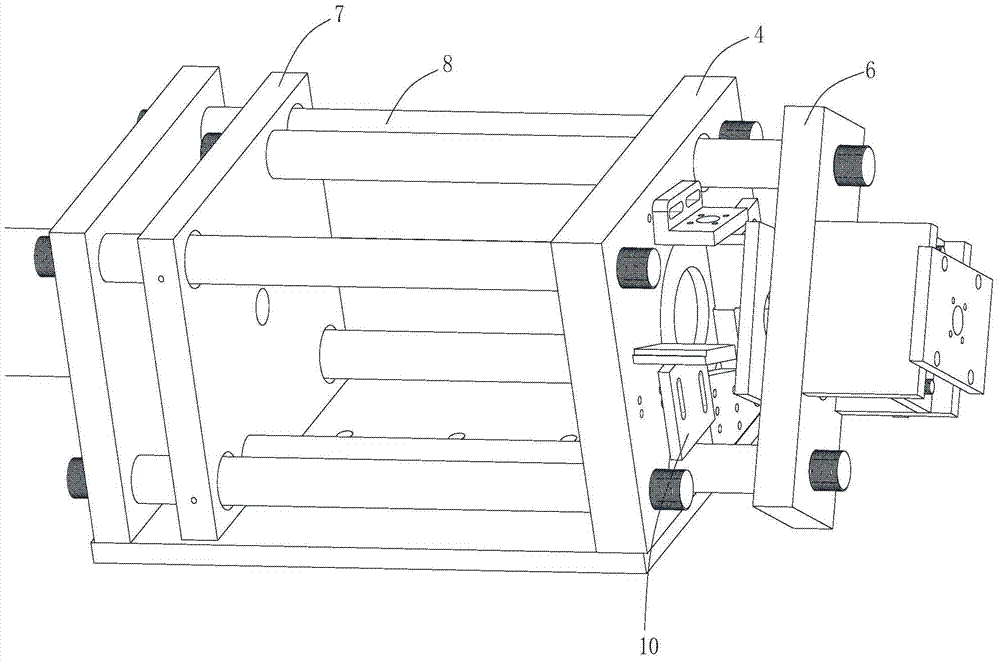

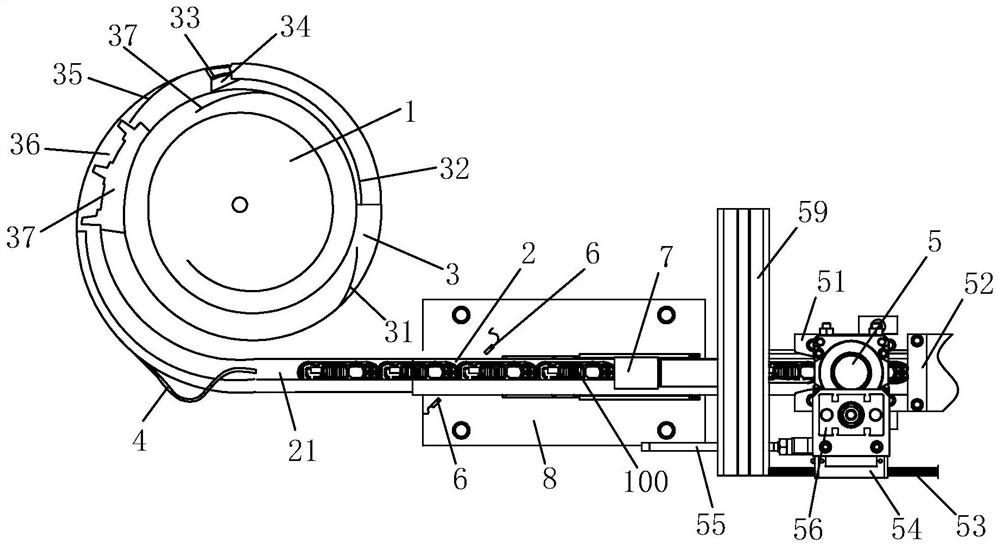

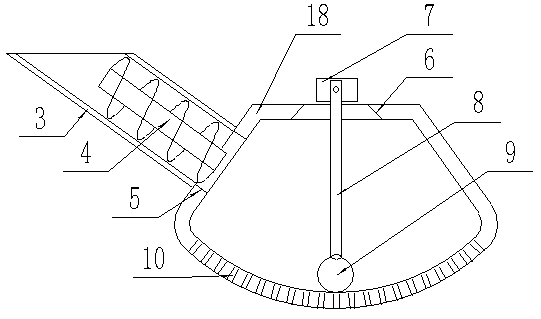

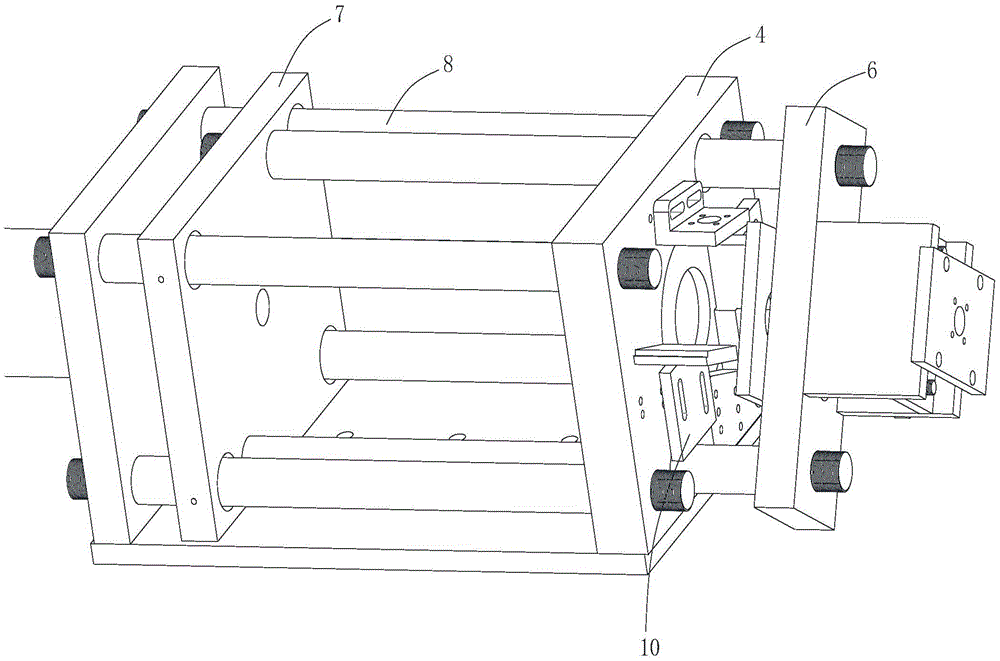

Pin feeding system for surface mounting technology (SMT) chip mounter

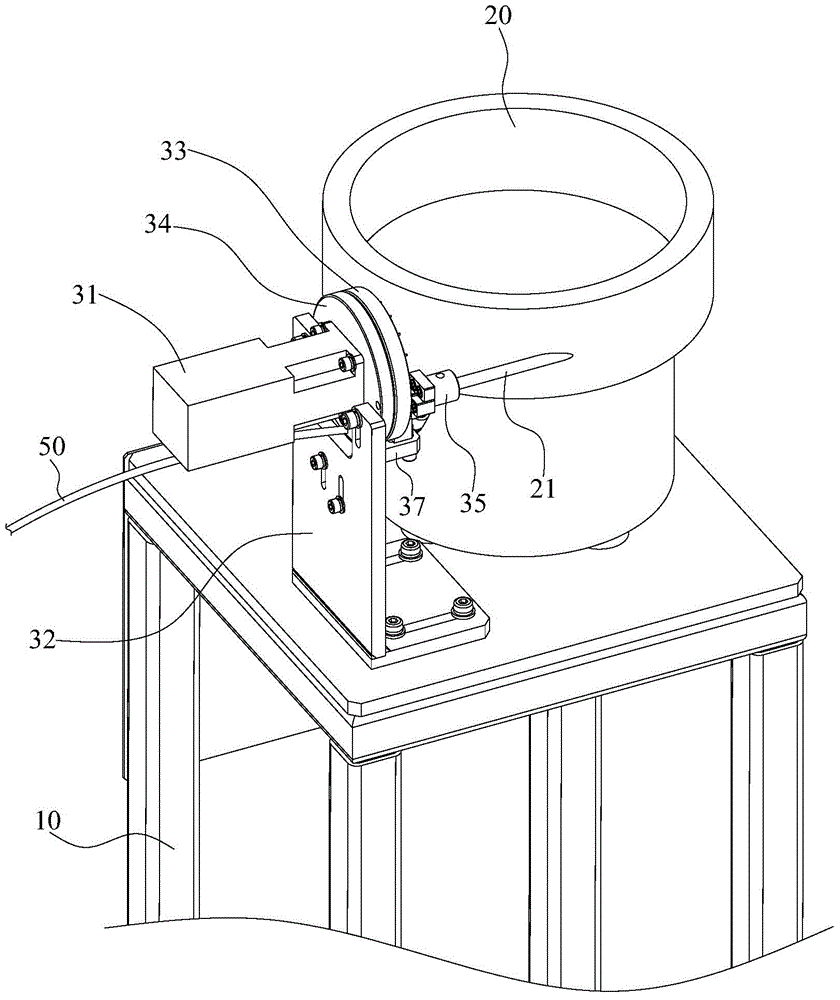

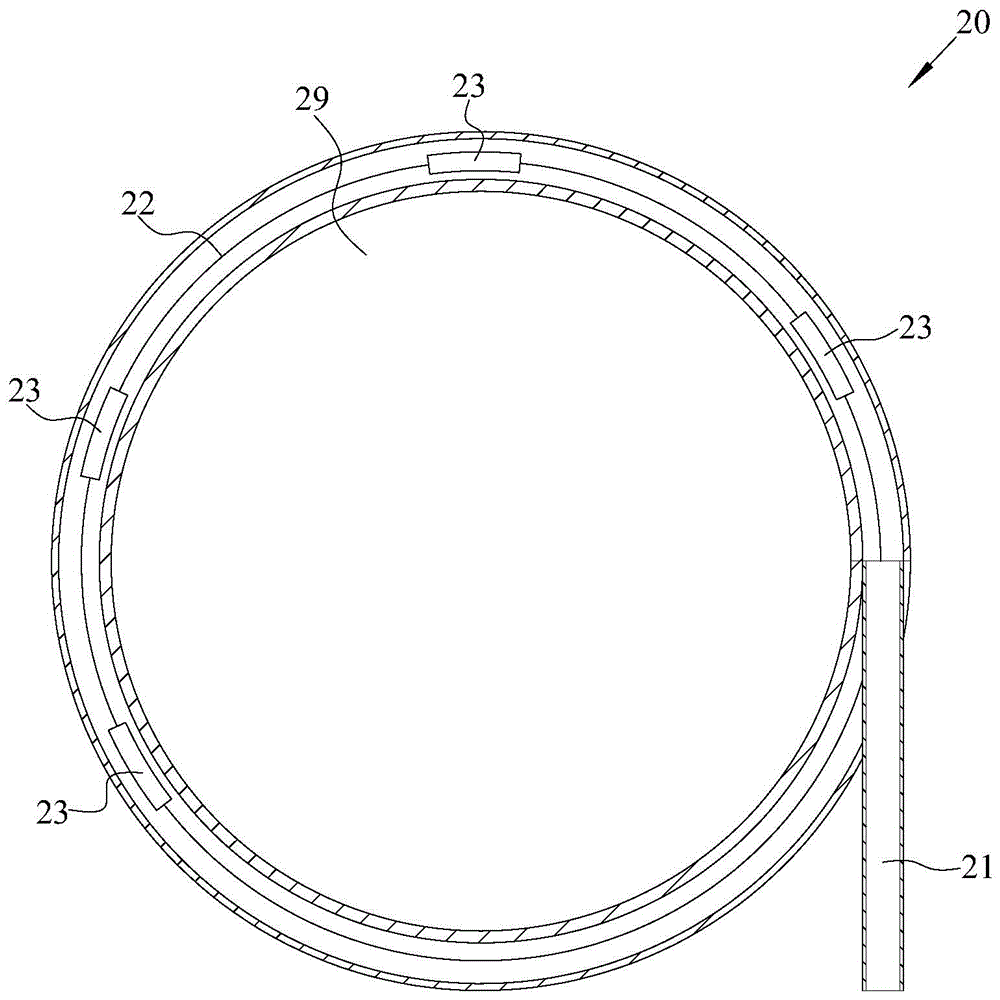

ActiveCN103693404ARealize feeding automationRealize automatic supplyBulk conveyorsConveyor partsCircular discElectricity

The invention relates to a pin feeding system for a surface mounting technology (SMT) chip mounter. A material conveying module in the feeding system comprises a storage disc, a first motor and a blowing air port, wherein the first motor is used for driving the storage disc to rotate and electrically connected with a main control unit. The storage disc is provided with storage through holes, the blowing air port corresponds to one storage through hole so as to push pins positioned in the storage through hole to a module which is to take materials through air. According to the feeding system, first the scattered pins are tidied through a vibration disc, the pins are blown through the material conveying module to the module which is to take the materials, finally the SMT chip mounter takes away the pins, full automatic feeding of the scattered pins is achieved through seamless connection of a whole scheme, feeding efficiency and the production rate are effectively improved, full feeding automation of the pins is achieved, the problem that the pins cannot be automatically mounted in large volumes through the SMT chip mounter is solved, and a novel and reliable solution is provided for automatic pin production of an electronic processing industry.

Owner:深圳市睿勤科技有限公司

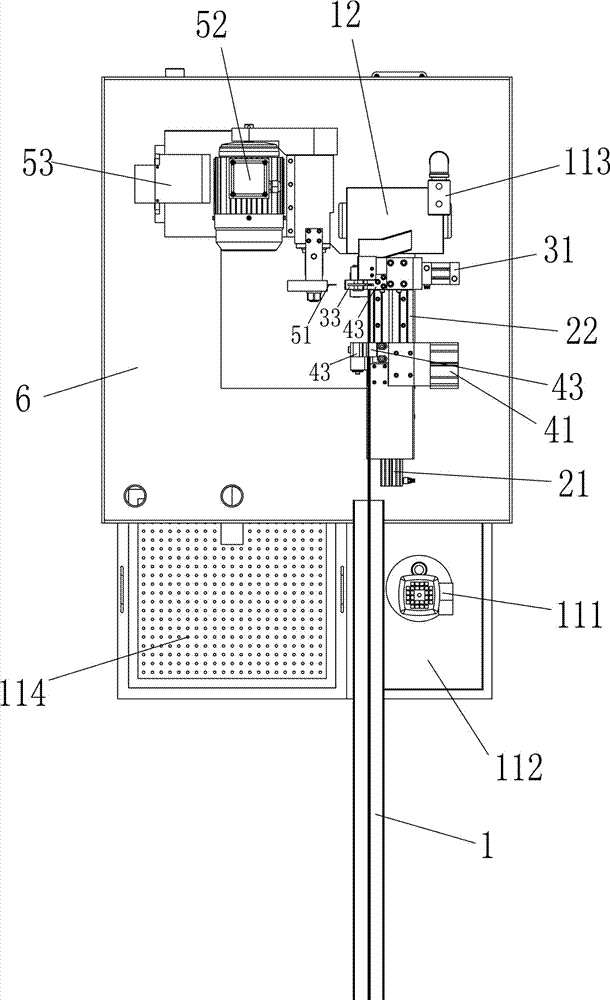

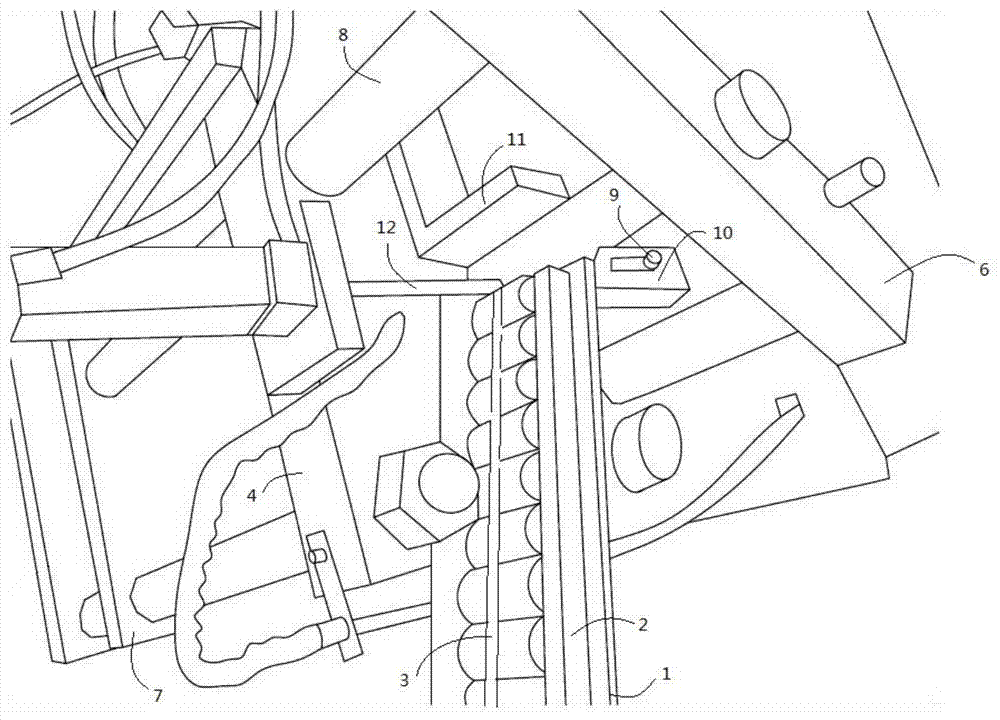

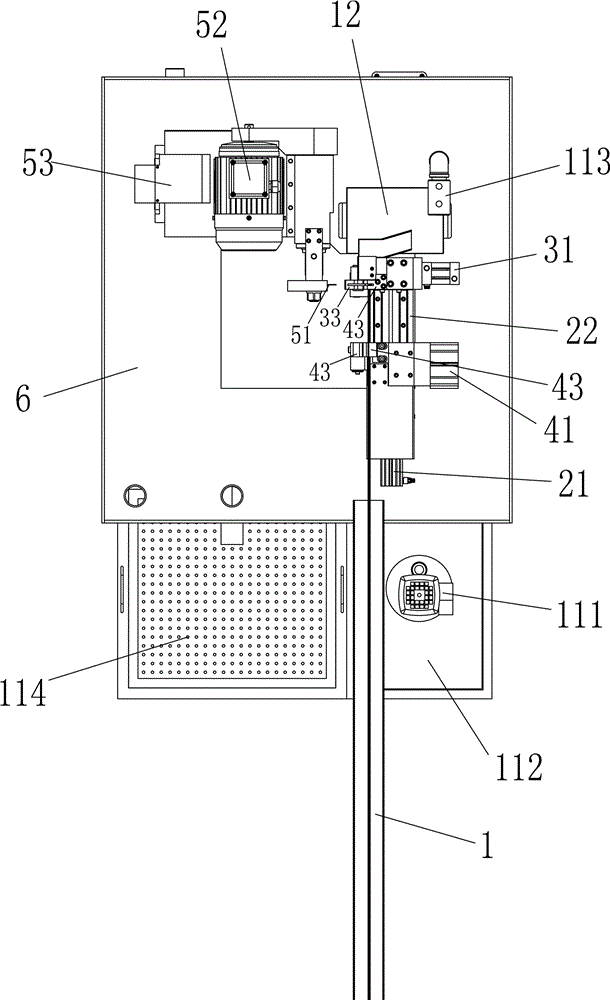

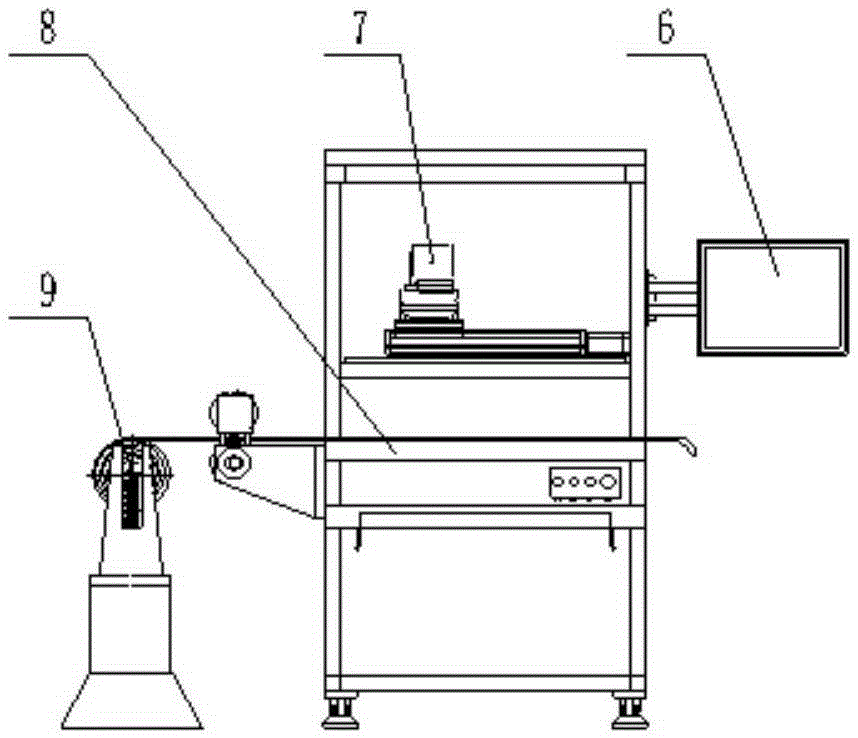

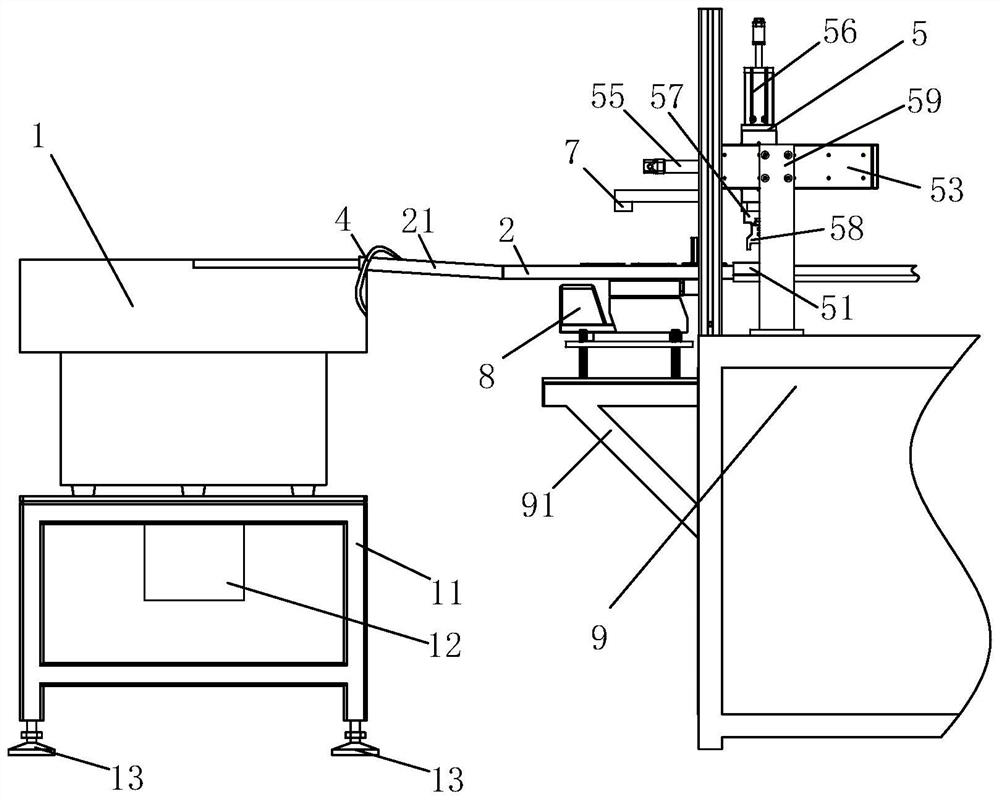

Contact tube perforating machine feeding system

ActiveCN104690591AOverwork works wellImprove cleanlinessMetal working apparatusEngineeringAutomation

The invention relates to a contact tube perforating machine feeding system which comprises a machine frame, a machining spindle, a vibration disc and an induction head, a loading unit, a first ejection assembly, a transfer unit, a second ejection assembly and a material collection assembly. A machining hole used for clamping workpieces is formed in the machining spindle, a feeding port of the vibration disc is arranged opposite to the induction head of the feeding port, the charging unit is arranged between the feeding port and the induction head, and the transfer unit is arranged on one side of the charging unit. The workpieces are charged into the charging unit through the vibration disc and transferred into the transfer unit through the first ejection assembly, then moved into the machining spindle through the transfer unit to be machined and finally placed into the material collection assembly through the second ejection assembly and the transfer unit. The contact tube perforating machine feeding system is high in automation degree, capable of machining workpieces simultaneously, greatly improves production efficiency and reduces production cost.

Owner:CHANGZHOU YI WIDE AUTOMATION EQUIP CO LTD

Feeding device for automatic shaping machine

InactiveCN102989919ARealize feeding automationImprove work efficiencyMetal-working feeding devicesPositioning devicesPunchingEngineering

The invention discloses a feeding device for an automatic shaping machine, which belongs to accessory equipment of a machining device, and in particular relates to a feeding device used for feeding a punching device. The feeding device for the automatic shaping machine comprises a worktable and a shaping punch fixedly arranged on the worktable. The feeding device for the automatic shaping machine is characterized by consisting of a trough installed in the worktable, a rotary shaft and a feeding cylinder which drives a feeding arm to rotate around the rotary shaft. The rotary shaft is fixedly arranged on the worktable through a rotary shaft bracket, a feeding arm bearing provided with the feeding arm is sleeved on the rotary shaft, and a retainer plate is installed at the front end of the feeding arm. A cylinder connecting lug connected with the feeding arm is installed at the front end of a push rod of the feeding cylinder. The feeding device for the automatic shaping machine provided by the invention has the benefits that a workpiece is taken down from the outlet of the trough by using the rotatable feeding arm and sent to the shaping punch, so that automatic feed is realized. Therefore, not only is the work efficiency improved, but also the safety is guaranteed. The feeding device for the automatic shaping machine can be applied to technical improvement of similar punching devices.

Owner:JINAN MEIDE CASTING CO LTD

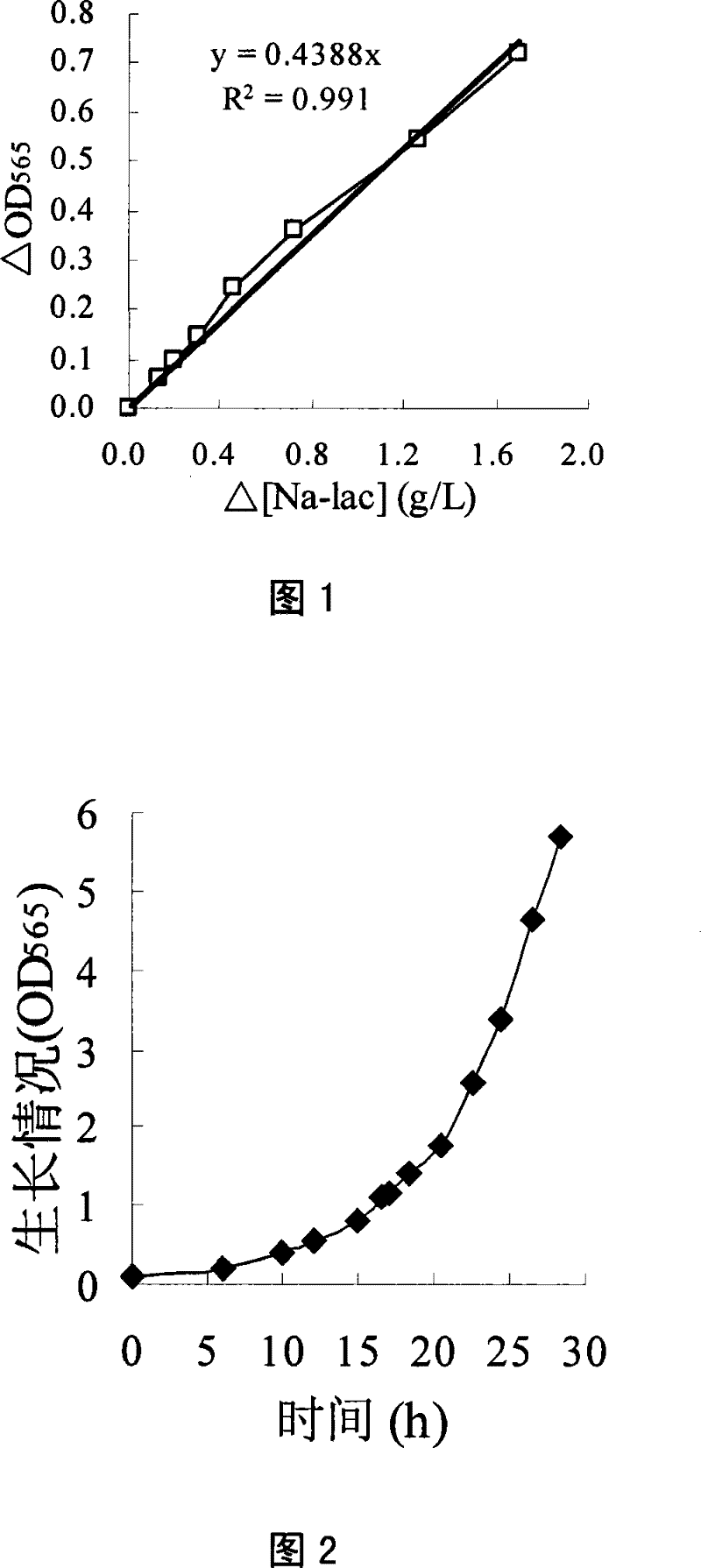

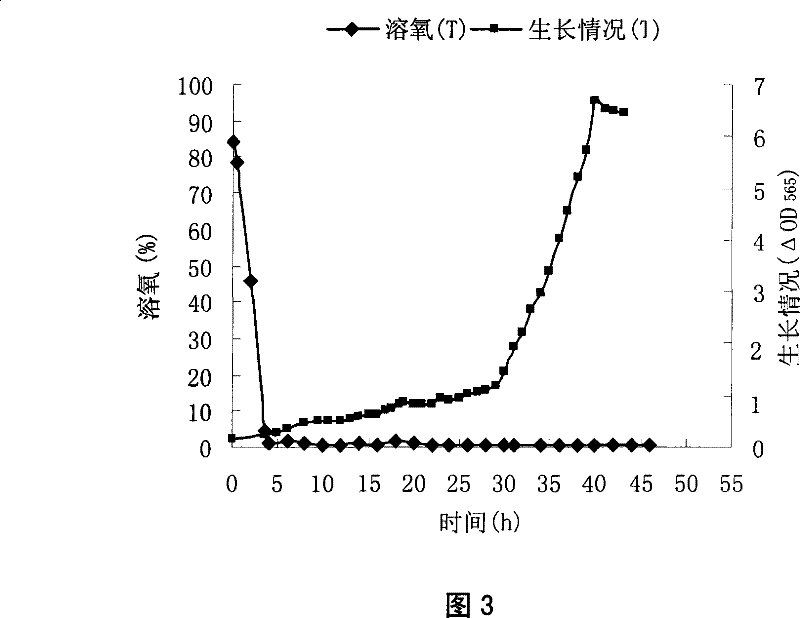

Method for producing magnetosome by cultivating magnetotactic bacteria

InactiveCN101434921BGuaranteed normal growthEasy to operateBacteriaMagnetotactic bacteriaMagnetosome

The invention provides a method for producing magnetosome by cultivating magnetic bacteria, which takes air as an oxygen supplying way and maintains the continuous growth of the magnetic bacteria with a material feeding way, and when dissolved oxygen reaches or gets lower than the dissolved oxygen suitable for magnetosome production, the dissolved oxygen is controlled at a proper dissolved oxygenrange that is suitable for magnetosome production through agitating rotation speed, air flow speed and the dissolved oxygen in cascade. The magnetic bacteria cultivating method does not need air distribution and pure inert gases, but uses air aeration for oxygen supply, thus lowering initial dissolved oxygen from the saturation state of 100 percent to 0 percent, and the coordinated adjustment of agitating rotation speed and air flow speed can control the dissolved oxygen to be any value between the saturation states of 0 percent and 20 percent, thus lowering the production cost of magnetosomeand providing technical guarantee for researching the physiological and biochemical characteristics of the magnetic bacteria under different dissolved oxygen levels.

Owner:CHINA AGRI UNIV

Shaft sleeve shaper and working method thereof

InactiveCN104190748AAvoid manual feedingAvoid dischargeMetal-working feeding devicesStripping-off devicesAgricultural engineeringSlide plate

The invention discloses a working method of a shaft sleeve shaper. The shaft sleeve shaper consists of a feeding mechanism, a shaping mechanism, a connecting mechanism and a motor, wherein the shaping mechanism comprises a base, a baseplate, a mold frame mounting structure, a left slide plate and a right slide plate; the middle of the base is opened; a through hole is formed in the surface of the base; the left slide plate and the right slide plate are respectively arranged at the left and right sides of the base; the left slide plate and the right slide plate are connected through a first stand column penetrating through the through hole in the surface of the base; the motor provides the traction force to the right slide plate; a shaping ejector pin is mounted in the middle of the right slide plate; a stripping ejector pin is mounted in the middle of the left slide plate; the connecting mechanism comprises a lower positioning plate, a front positioning plate and a limiting needle; the side surface of the front positioning plate is L-shaped; the vertical part of the front positioning plate is fixedly connected to the base; the projection part of the front positioning plate is connected to the top of the through ole of a pressure plate; the lower positioning plate is driven by a cylinder, and is connected with the base through a second stand column; a bracket is arranged on the inclined surface of the lower positioning plate; the middle of the bracket is inclined; and the bottom and top of the bracket horizontally extend to one side.

Owner:嘉善新易能精密机械设备厂

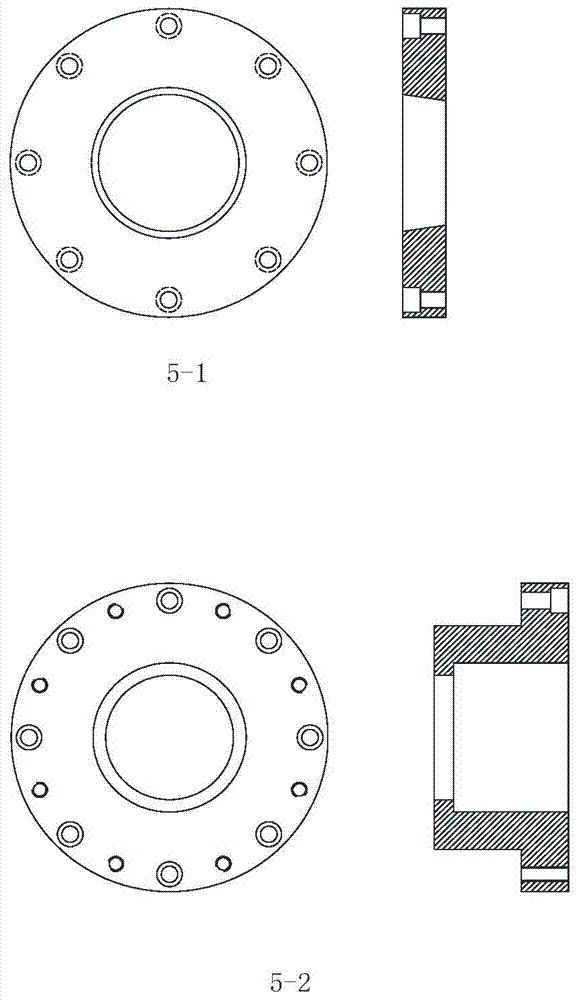

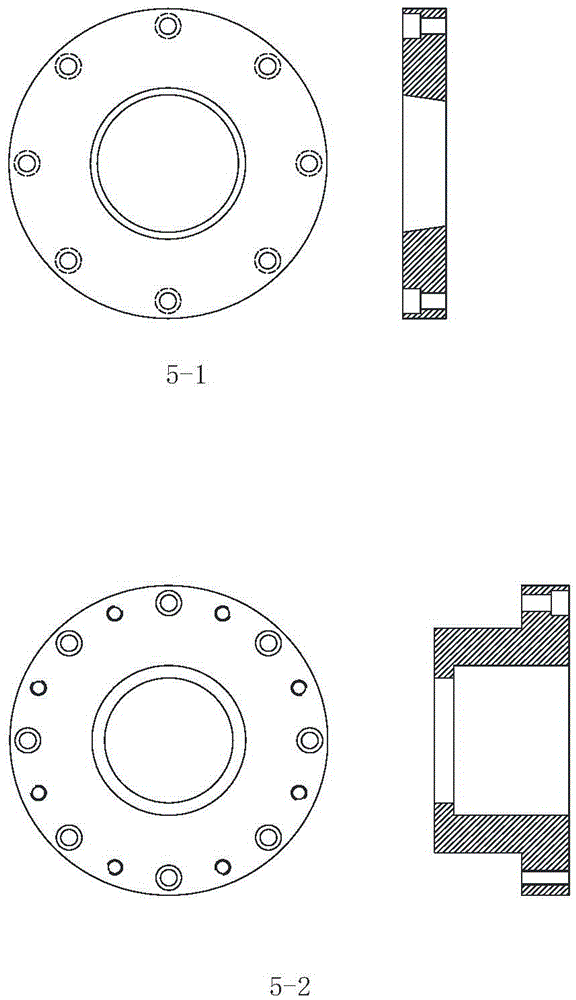

Feeding device for soybean grinding machine

PendingCN106044082AImprove qualityReduce labor costsPackagingGrain treatmentsScrew conveyorEngineering

The invention discloses a feeding device for a soybean grinding machine. The feeding device comprises a rack and a storage hopper, wherein the storage hopper is fixed on the rack; the top of the storage hopper is cylindrical, and the bottom of the storage hopper is conical; a suction machine is arranged on the rack located above the storage hopper; a discharge port of the suction machine is located just above a hopper opening in the upper end of the storage hopper; a vertically downward discharge tube is arranged at the bottom of the storage hopper; the discharge tube is connected and fixed with a charge port of a spiral conveyer through a flange; the charge port is located in the sidewall of a barrel body of the spiral conveyer; the spiral conveyer is suspended and fixed at the bottom of a discharge hopper in a horizontal direction; a discharge port of the spiral conveyer is located just above a charge hopper of the soybean grinding machine; and an output shaft of a motor of the spiral conveyer is connected with a spiral rod of the spiral conveyer. The feeding device disclosed by the invention is simple in structure and convenient to operate; feeding automation of the grinding machine is realized, the enterprise cost is reduced while the production efficiency is increased, and the product quality is improved.

Owner:安徽省味之源生物科技有限公司

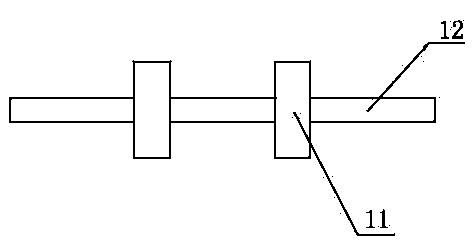

To-be-processed material bin structure for spinning machine

InactiveCN105363944ARealize feeding automationSimple structureMetal-working feeding devicesMetal working apparatusAutomationRaw material

The invention relates to a to-be-processed material bin structure for a spinning machine. The to-be-processed material bin structure comprises a bin body, wherein two guide rods are arranged inside the bin body in parallel; two drive limiting plates are arranged on the two guide rods in parallel and are perpendicular to the center lines of the guide rods; the bottom face of the bin body is inclined; a discharge outlet is formed in the low end of the inclined bottom face of the bin body; a lifting air cylinder is arranged at the discharge outlet position; a detection air cylinder is arranged near the lifting air cylinder; an inclined bending plate is arranged at the discharge outlet, the high end of the inclined bending plate is higher than the discharge outlet, and a limiting air cylinder and a centering device are arranged at the low end of the inclined bending plate. By the adoption of the structure, raw materials of multiple specifications can be fed through the drive limiting plates, feeding automation is achieved, and rejected products can be collected after being detected out; the to-be-processed material bin structure is simple in structure and convenient to use; the product feeding efficiency and the production efficiency are improved.

Owner:SUZHOU SANFU AUTOMATION TECH CO LTD

smt placement machine pin feeding system

ActiveCN103693404BRealize feeding automationRealize automatic supplyBulk conveyorsConveyor partsProduction rateCircular disc

The invention relates to a pin feeding system for a surface mounting technology (SMT) chip mounter. A material conveying module in the feeding system comprises a storage disc, a first motor and a blowing air port, wherein the first motor is used for driving the storage disc to rotate and electrically connected with a main control unit. The storage disc is provided with storage through holes, the blowing air port corresponds to one storage through hole so as to push pins positioned in the storage through hole to a module which is to take materials through air. According to the feeding system, first the scattered pins are tidied through a vibration disc, the pins are blown through the material conveying module to the module which is to take the materials, finally the SMT chip mounter takes away the pins, full automatic feeding of the scattered pins is achieved through seamless connection of a whole scheme, feeding efficiency and the production rate are effectively improved, full feeding automation of the pins is achieved, the problem that the pins cannot be automatically mounted in large volumes through the SMT chip mounter is solved, and a novel and reliable solution is provided for automatic pin production of an electronic processing industry.

Owner:深圳市睿勤科技有限公司

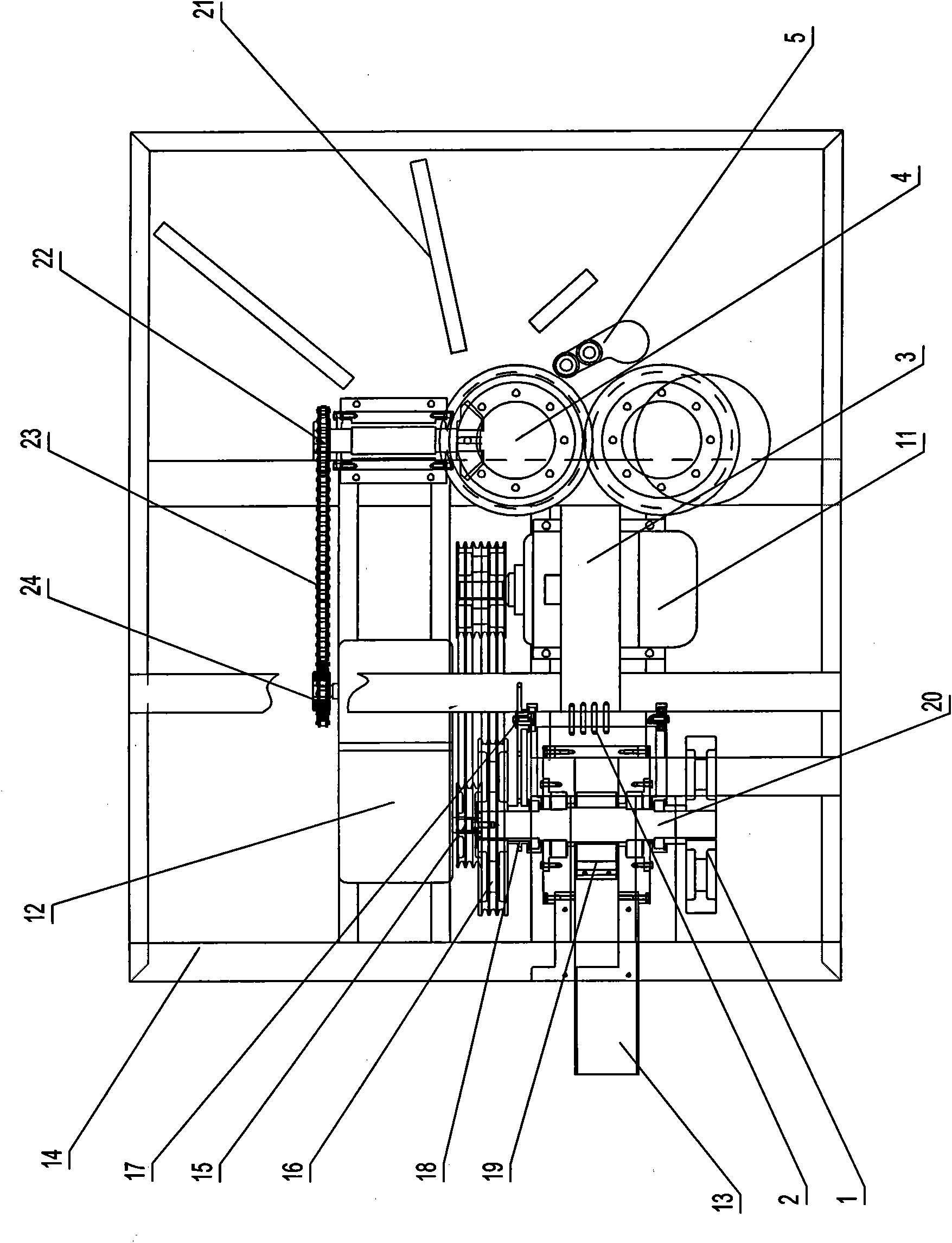

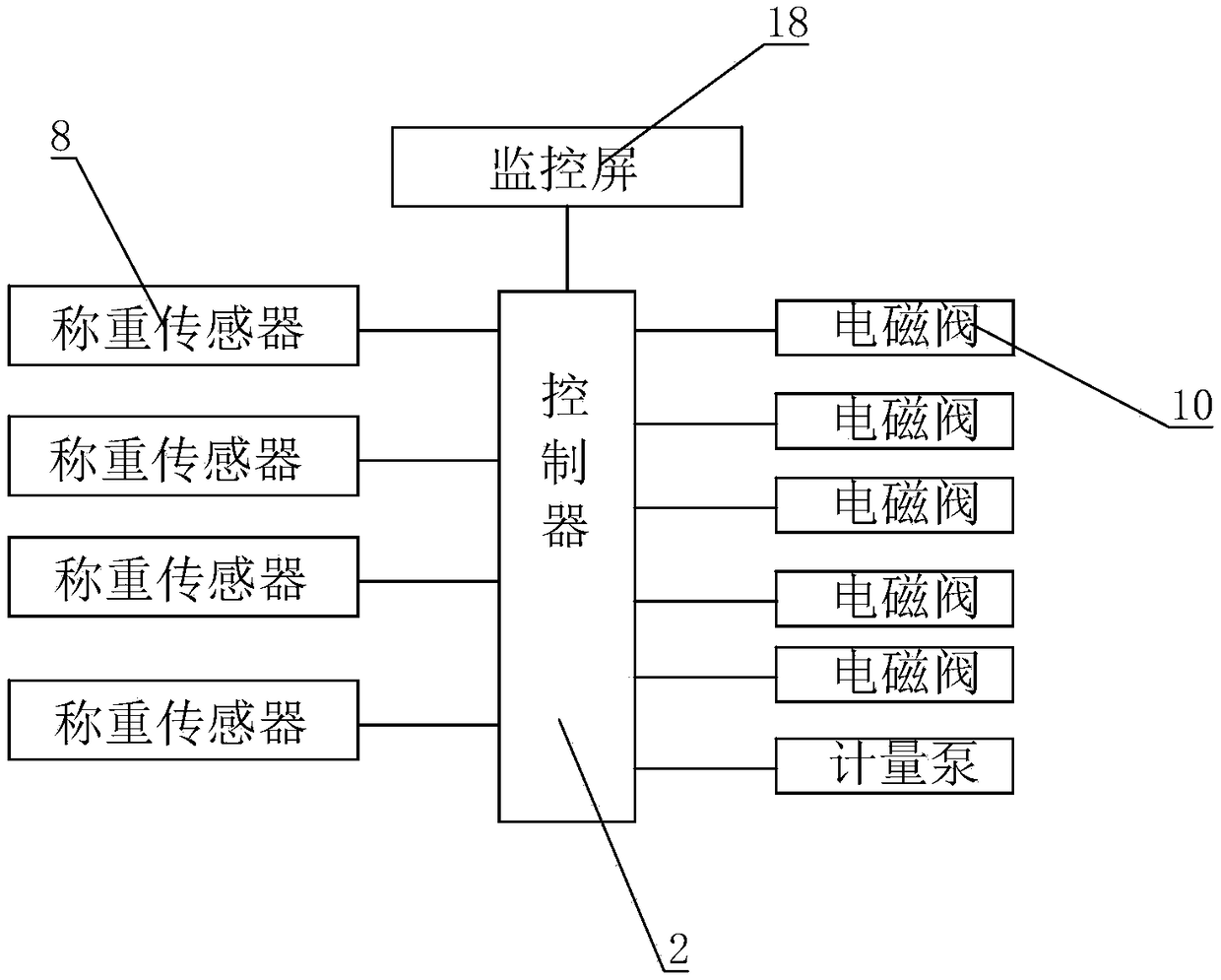

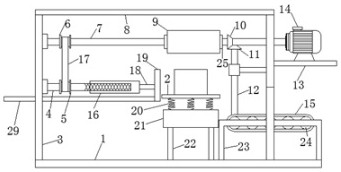

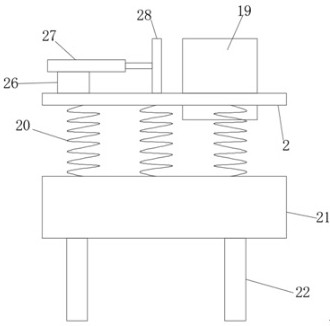

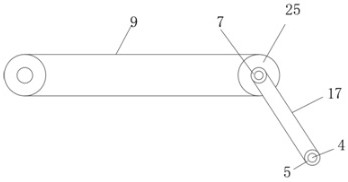

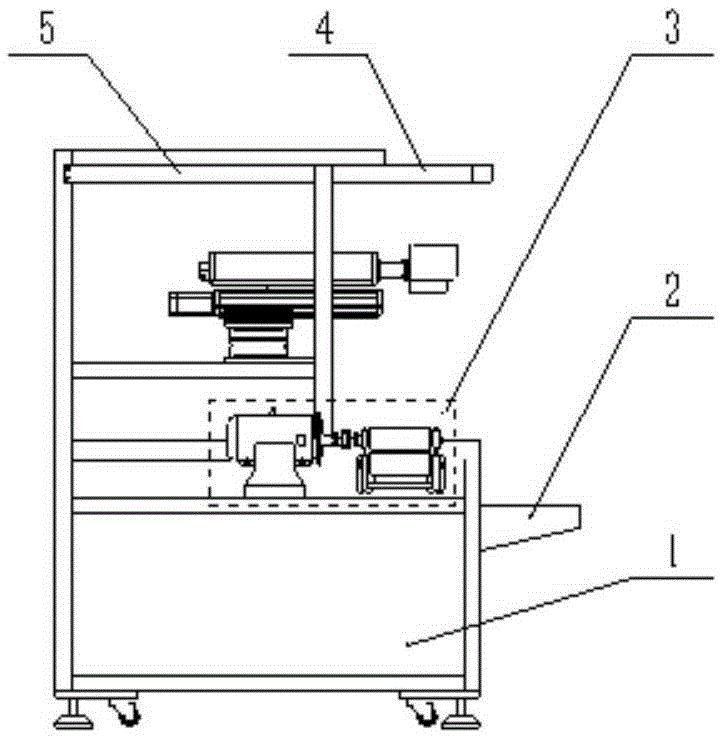

Internal mixer feeding system

The invention discloses an internal mixer feeding system. The internal mixer feeding system comprises a frame and a controller, wherein the frame is provided with a rodless air cylinder and an electrode weighing tank; the rodless air cylinder is provided with a sliding plate; the electronic weighing tank is arranged on a fixing plate through a support rack, and the fixing plate is connected with the sliding plate through a weighing sensor; above the start end of the rodless air cylinder is provided with a plurality of buckets, the bottom end of every bucket is connected with an outlet pipe provided with an electromagnetic valve, and one end of the sliding plate is provided with a liquid container provided with a measuring pump; the bottom end of the electronic weighing tank is provided with a vertical first discharging pipe and an inclined first feeding pipe, the first feeding pipe is provided with an electromagnetic valve, the measuring pump is connected with a second discharging pipeand an inclined second feeding pipe, and the second feeding pipe is also provided with an electromagnetic valve; the electromagnetic valves, the measuring pump and a control valve on the air path ofthe rodless air cylinder are all electrically connected with the controller. The internal mixer feeding system achieves automatic material preparation and feeding and ensures accuracy and product quality.

Owner:宁国市中英橡胶有限公司

Quick weighing device for breadcrumb production

The invention discloses a quick weighing device for breadcrumb production, relates to the technical field of quick weighing, and aims to solve the problems that when breadcrumbs are weighed, automation of feeding and taking of the breadcrumbs cannot be achieved, the breadcrumbs with the weight not reaching the standard cannot be classified, time and labor are wasted, operation is complex, the labor cost is increased, and the production efficiency is improved. According to the technical scheme, the quick weighing device comprises a base, two supporting plates are fixedly connected to the top ofthe base, and a cover plate is fixedly connected to the tops of the two supporting plates. According to the quick weighing device, through starting a motor, automatic feeding and automatic taking ofproducts can be achieved, meanwhile, when the products fall onto an electronic scale, qualified products and unqualified products can be well screened out, the qualified products can be pushed to a third belt, and the unqualified products can be pushed through a push rod motor to be treated in a centralized mode, so that time and labor are saved, labor cost is reduced, and weighing efficiency is improved.

Owner:淮北市麦祺食品有限公司

An automatic feeding and cutting machine for metal bars

InactiveCN104772524BRealize feeding automationReduce labor intensityMetal sawing devicesMetal sawing accessoriesEngineeringBar stock

The invention discloses an automatic feeding and cutting machine for metal bars, which includes an automatic feeding mechanism and an automatic cutting mechanism; wherein, the automatic feeding mechanism includes a feeding device and a clamping device, and the feeding device controls the clamping device to adjust the position , so as to locate the cutting position of the metal bar in the clamping device; the automatic cutting mechanism includes a saw blade, a first motor that controls the rotation of the saw blade, and a second motor that controls the advance and retreat of the saw blade to the metal bar. motor. The invention can automatically complete the feeding and cutting of the ultra-long metal bar, improves the production efficiency and product quality, saves the cost of the enterprise, reduces the labor intensity of the workers and improves the safety.

Owner:CHANGHONG PRECISION TOOL DONGGUAN CO LTD

Waste rubber tire horizontal composite dicer

InactiveCN101850583BEasy feedingRealize feeding automationPlastic recyclingMetal working apparatusGear wheelWaste rubber

The invention relates to a waste rubber tire horizontal composite dicer which comprises a frame, a power source, a transmission gear, a slitter, a dicing device and a tire feeding device, wherein the slitter and the dicing device are installed on the upper part of the frame; the power source and the transmission gear are installed on the bottom of the frame; the tire feeding device is installed near the slitter; the slitter comprises an upper horizontal cutter head and a lower cutter head which contact the working surface; the shafts of the two cutter heads form a mesh transmission through various gears which match each other; the lower end of the shaft of one cutter head is connected with the power source through the transmission gear; the dicing device comprises a dicing shaft, a dicing cutter and an inertia wheel, the dicing shaft is installed on the frame, the dicing cutter and the inertia wheel are installed on the dicing shaft, and the dicing main shaft is connected with the power source through the transmission gear; and a guide chute is arranged between the slitter and the dicing device. The dicer provides convenience for feeding waste tires, can realize automatic feeding, and maximally reduces manual work.

Owner:HENAN ZHONGYING RUBBER TECH

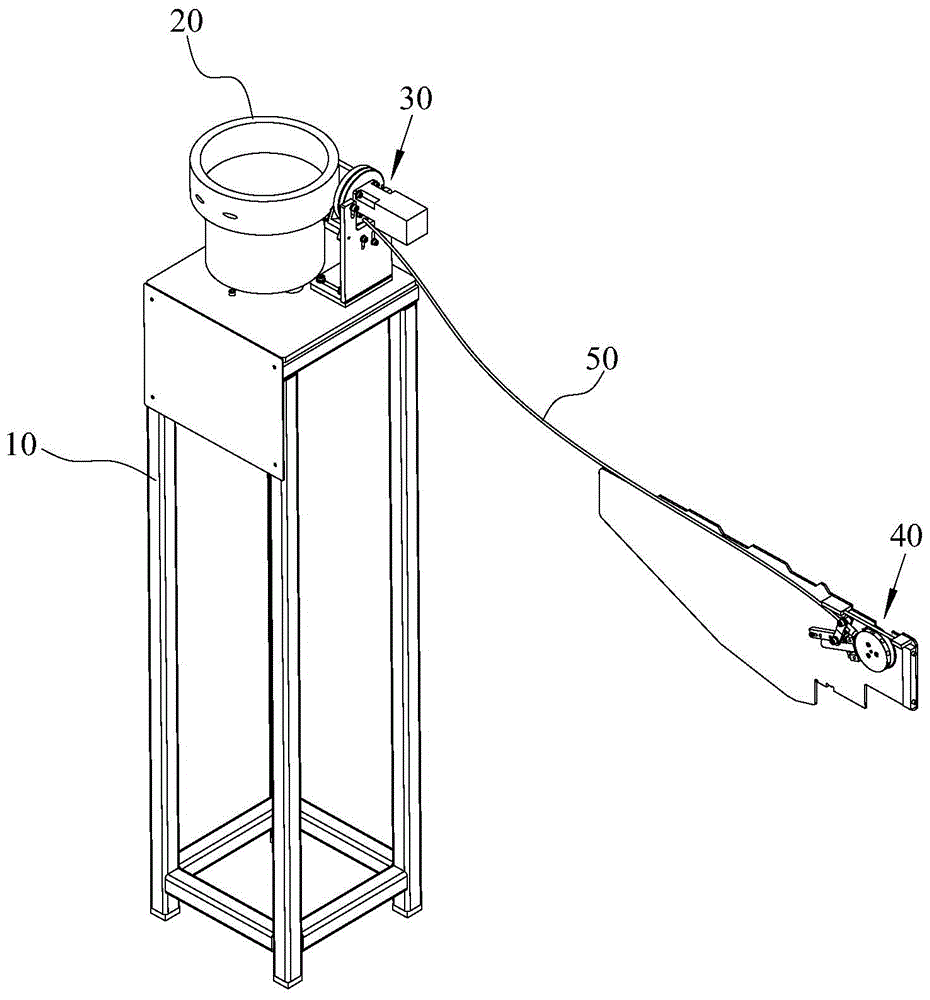

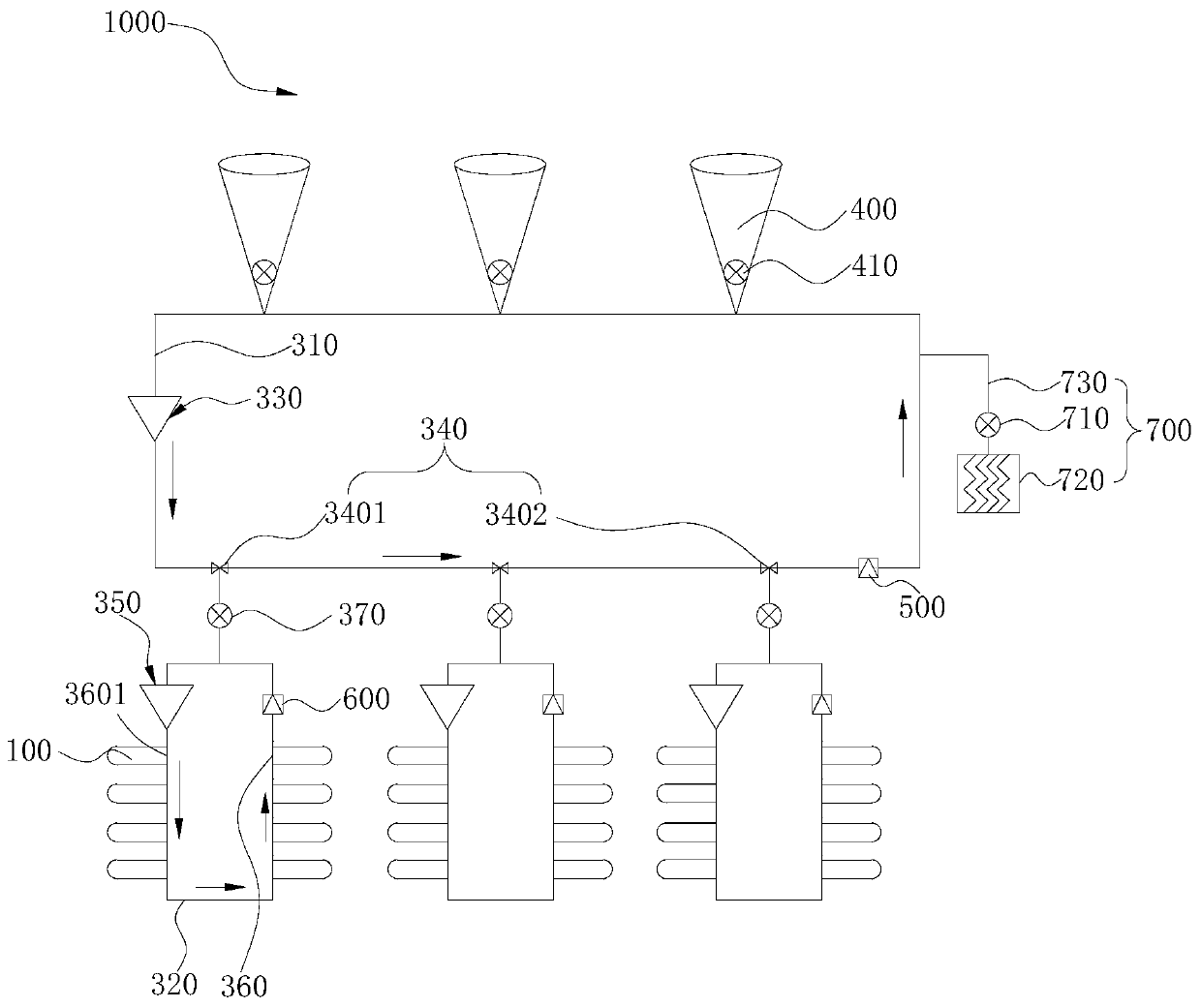

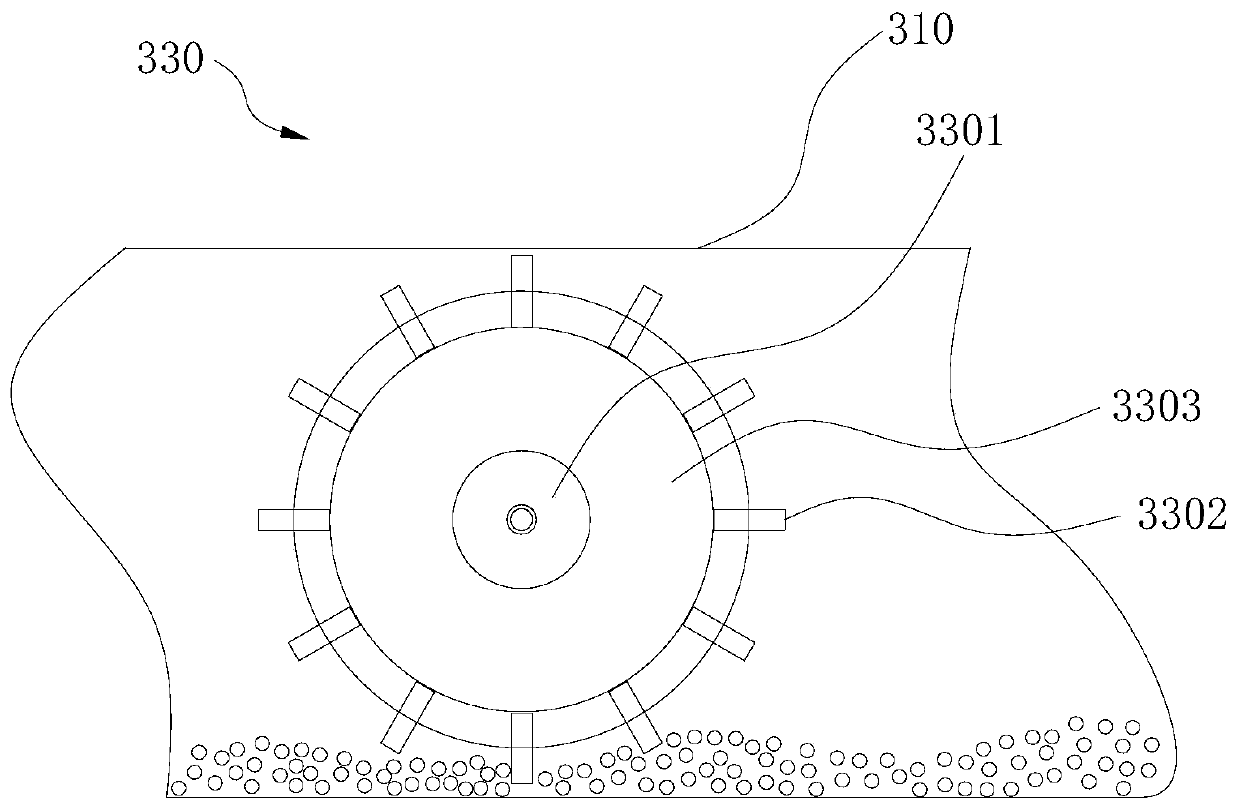

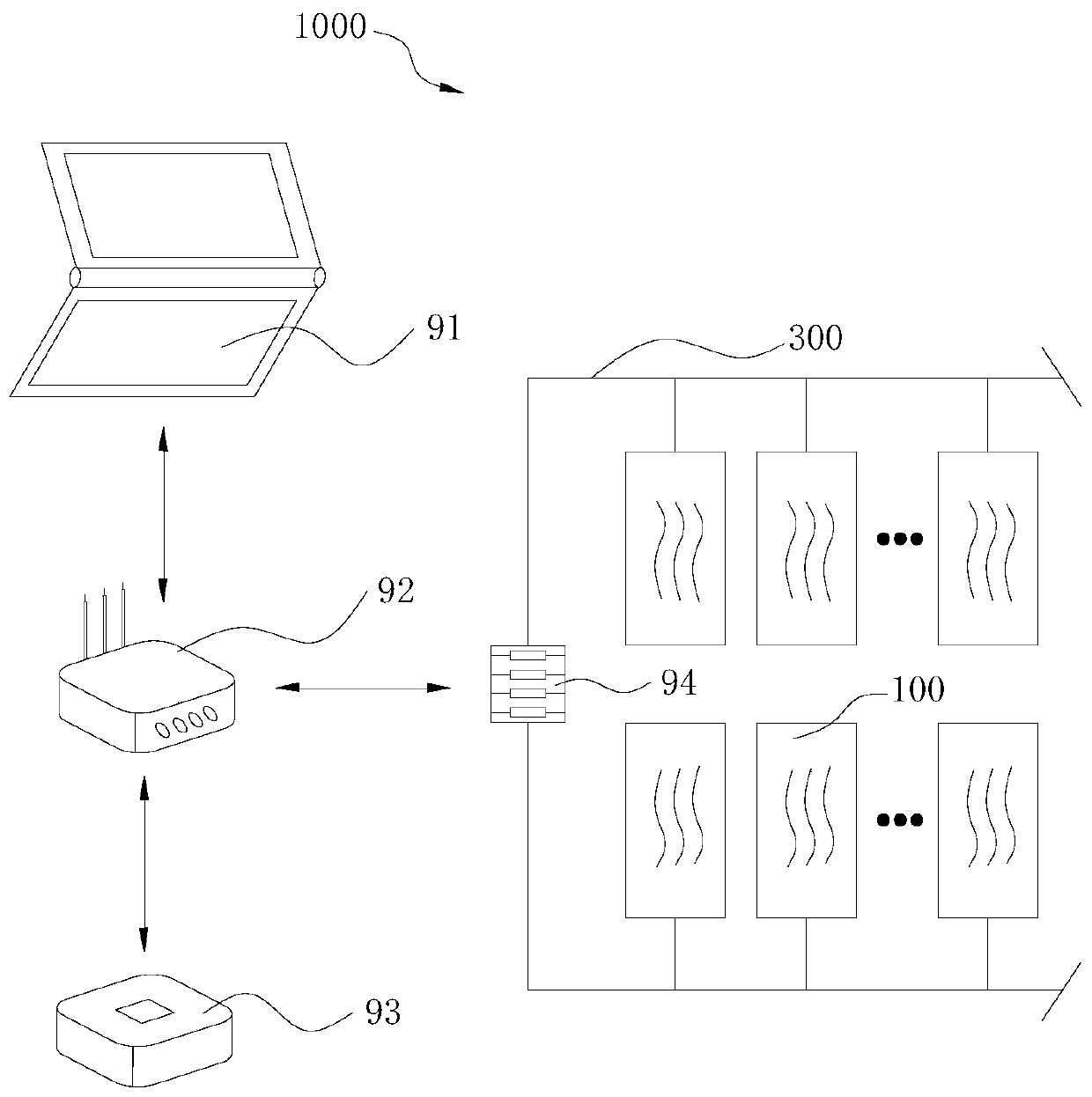

Feeding system

PendingCN109769704ARealize feeding automationReduce labor costsAnimal feeding devicesEngineeringAutomation

The invention discloses a feeding system. The feeding system comprises a feeding device, a conveying pipe and a storage bin; the conveying pipe is used for conveying food; the feeding device is connected with the conveying pipe, and the feeding device is used for putting the food located in the feeding device; the storage bin is connected with the conveying pipe, and the storage bin is used for storing the food and conveying the food into the feeding device through the conveying pipe. The feeding system has the advantages that the storage bin can convey the food into the feeding device throughthe conveying pipe, the food does not need to be manually put into the feeding device, the feed automation of the feeding device is achieved, and the labor cost is reduced.

Owner:GUANGZHOU YINGZI TECH CO LTD

Conductive nozzle punching machine feeding system

ActiveCN104690591BOverwork works wellImprove cleanlinessMetal working apparatusEngineeringAutomation

The invention relates to a contact tube perforating machine feeding system which comprises a machine frame, a machining spindle, a vibration disc and an induction head, a loading unit, a first ejection assembly, a transfer unit, a second ejection assembly and a material collection assembly. A machining hole used for clamping workpieces is formed in the machining spindle, a feeding port of the vibration disc is arranged opposite to the induction head of the feeding port, the charging unit is arranged between the feeding port and the induction head, and the transfer unit is arranged on one side of the charging unit. The workpieces are charged into the charging unit through the vibration disc and transferred into the transfer unit through the first ejection assembly, then moved into the machining spindle through the transfer unit to be machined and finally placed into the material collection assembly through the second ejection assembly and the transfer unit. The contact tube perforating machine feeding system is high in automation degree, capable of machining workpieces simultaneously, greatly improves production efficiency and reduces production cost.

Owner:CHANGZHOU YI WIDE AUTOMATION EQUIP CO LTD

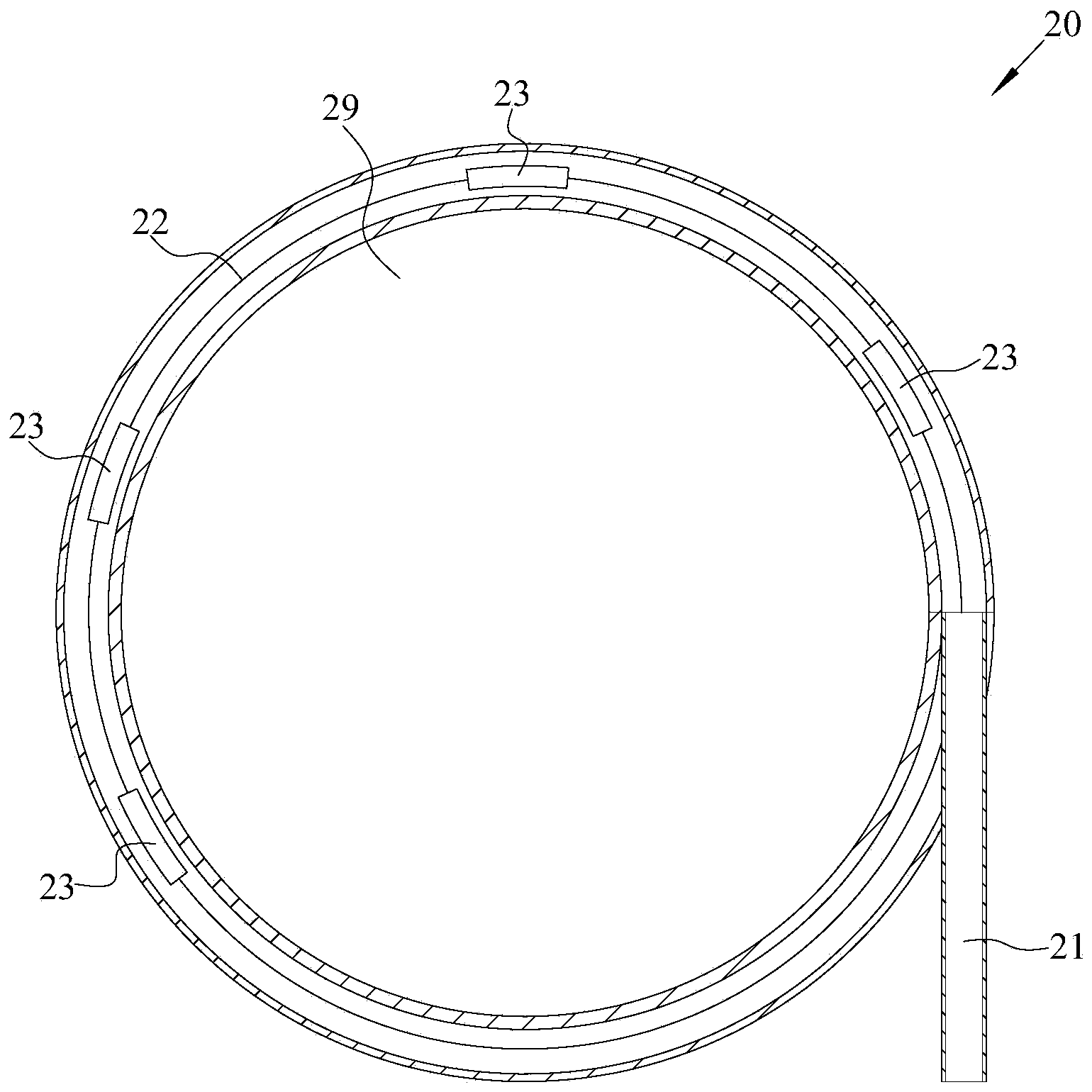

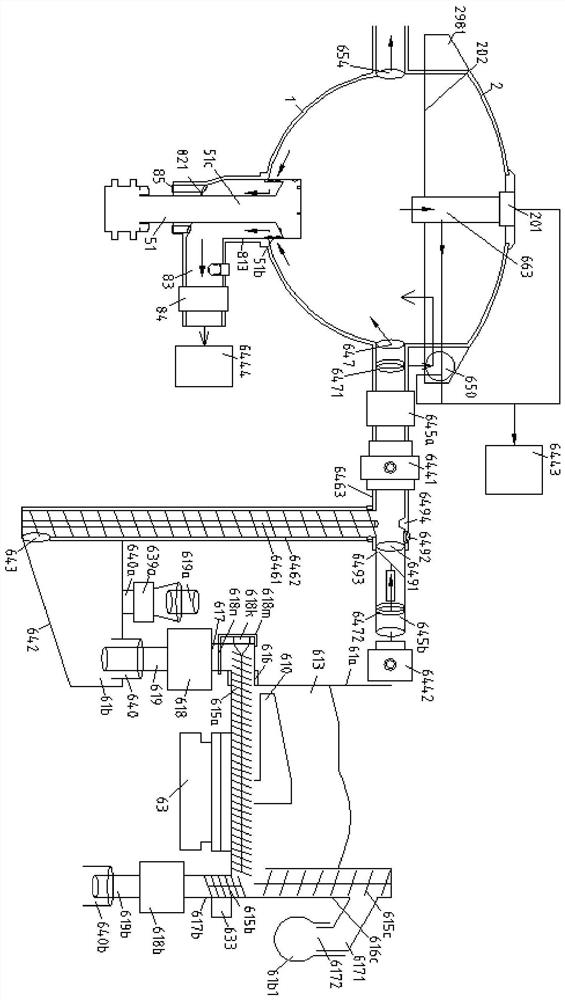

On-line implantation device of cigarette filter tip water firmware

PendingCN110236225AImplanted accuratelyImproving Implantation EfficiencyCigarette manufactureTobacco smoke filtersMouth pieceEngineering

The invention relates to an on-line implantation device of cigarette filter tip water firmware. The on-line implantation device comprises a feeding assembly, a driving assembly, a distributing runner and a back plate vertically arranged, stand columns are correspondingly arranged at the two ends of the back plate, and the two ends of the back plate are correspondingly connected with the corresponding stand columns, the distributing runneris arranged on one side of the back plate, a plurality of grooves are evenly formed in the side walls of the periphery of the distributing runner, a storing part is arranged on the position, above the distributing runner, of the back plate, the feeding assembly communicates with the storing part and conveys water firmware into the storing part, the driving assembly drives the distributing runnerto rotate, the water firmware located in the storing part is further sequentially toggled into the corresponding grooves in the distributing runnerthrough the driving assembly, and the water firmware moving to the lowest point of the distributing runner falls due to gravity and is implanted into the fabric used for forming a cigarette filter tip. According to the on-line implantation device, the water firmware can be implanted precisely, the implantation efficiency of the water firmware is greatly improved, it is guaranteed that the implantation direction of the water firmware is correct, and the using experience of consumers is ensured.

Owner:WUHAN MICROPOWER ROBOT TECH CO LTD

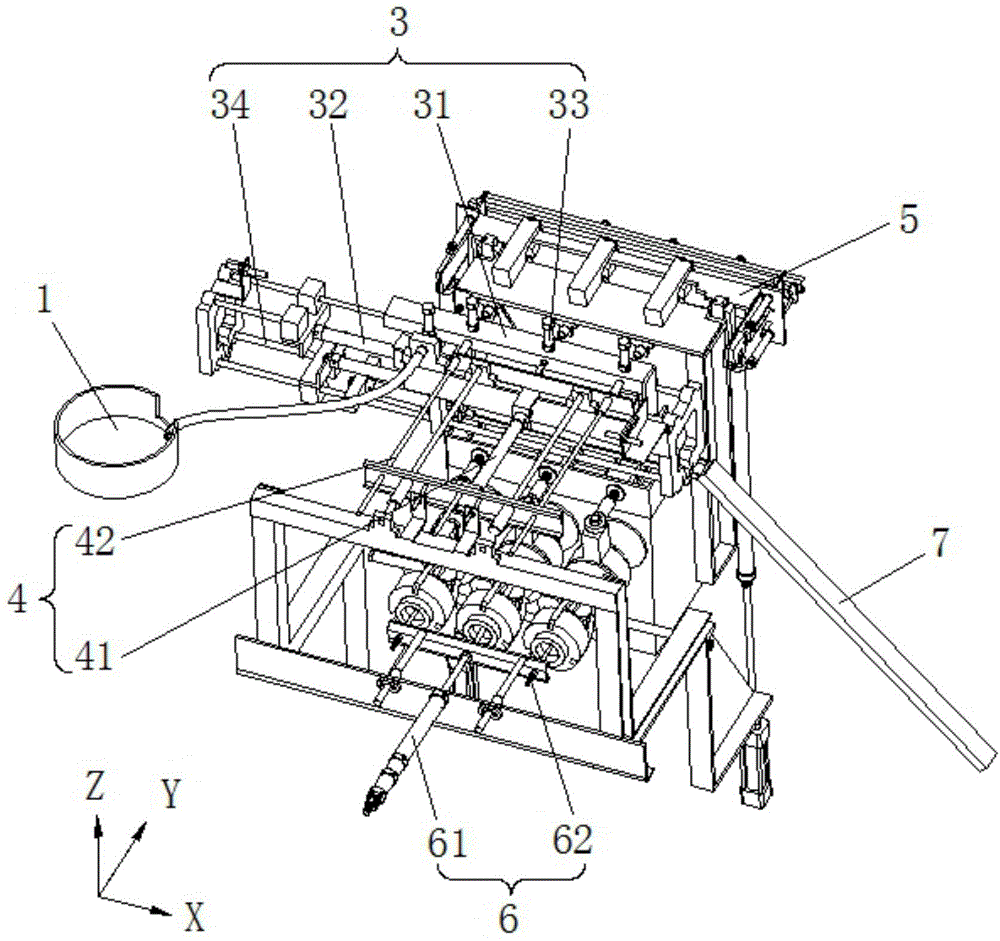

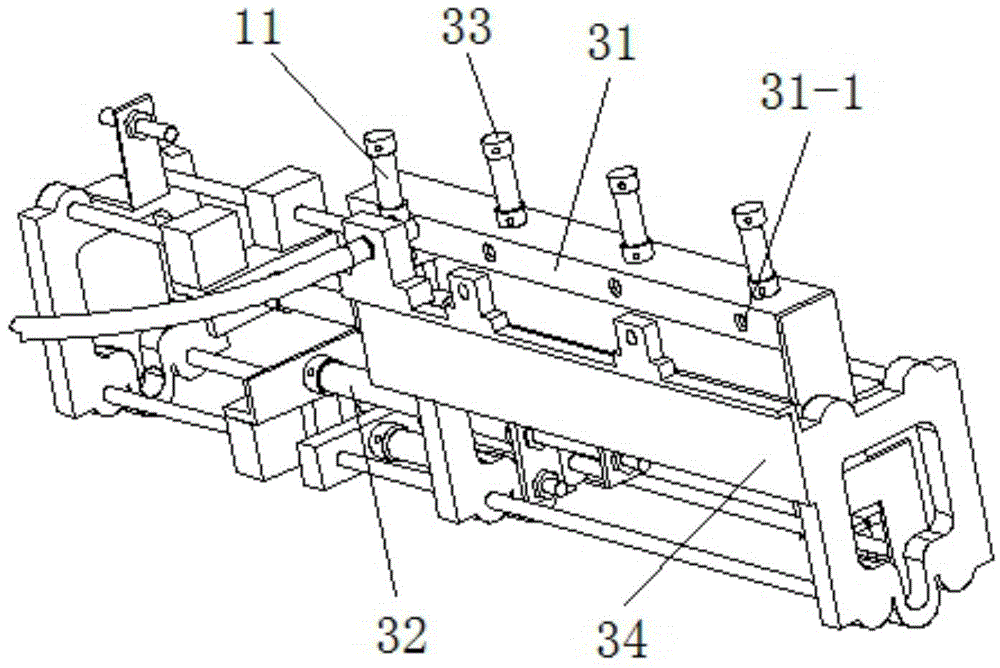

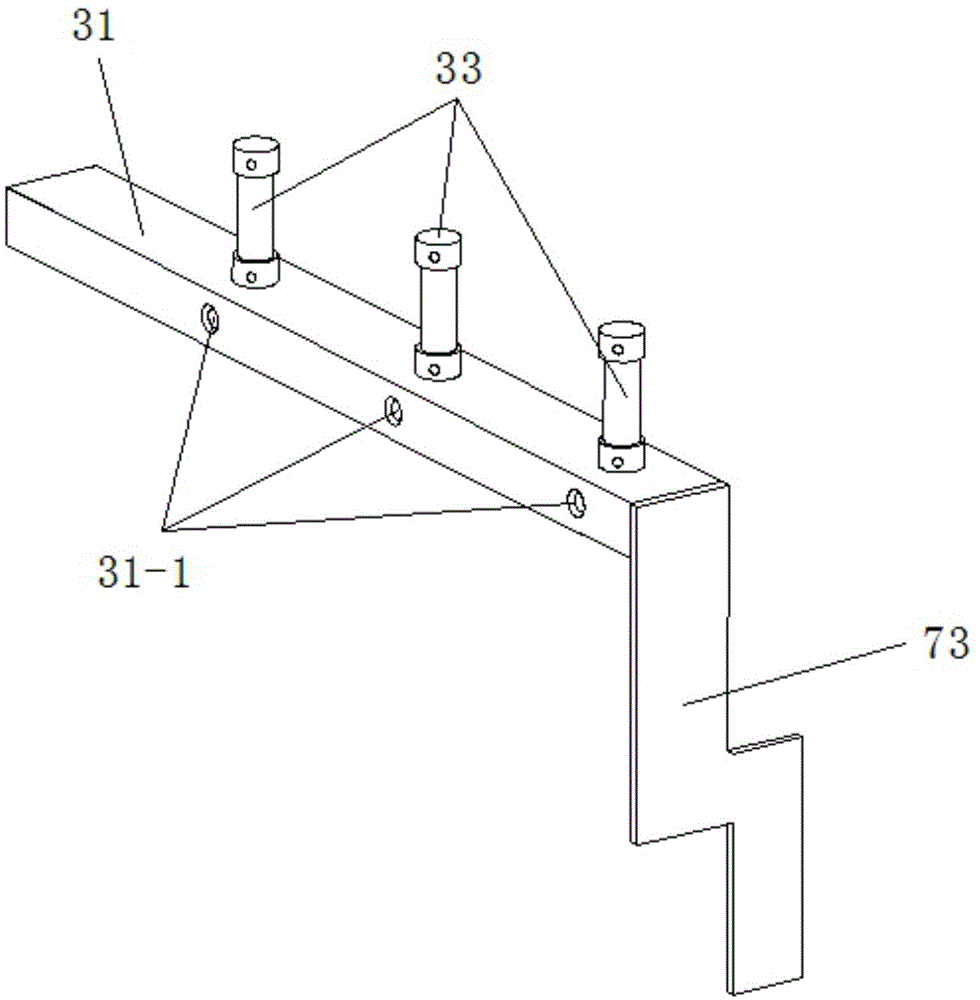

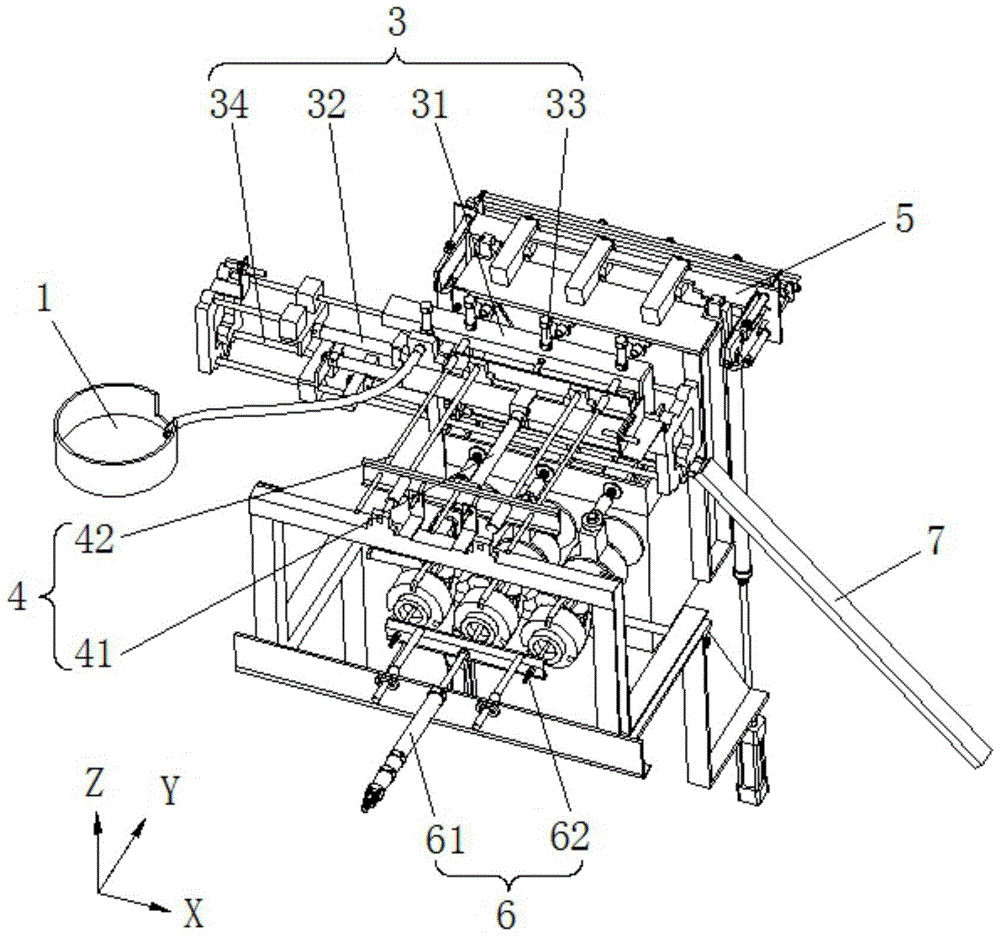

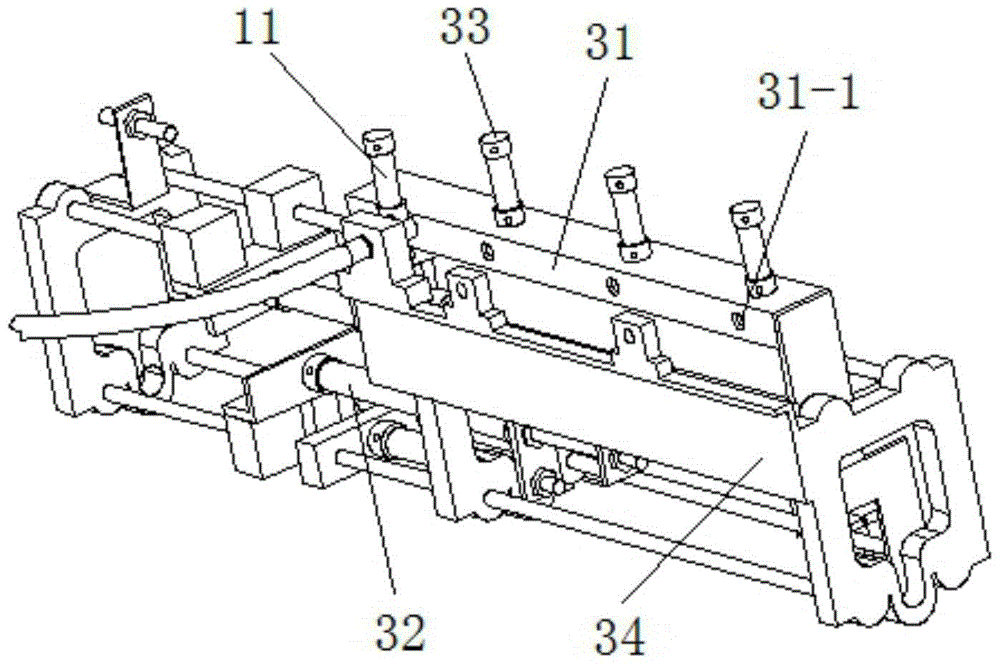

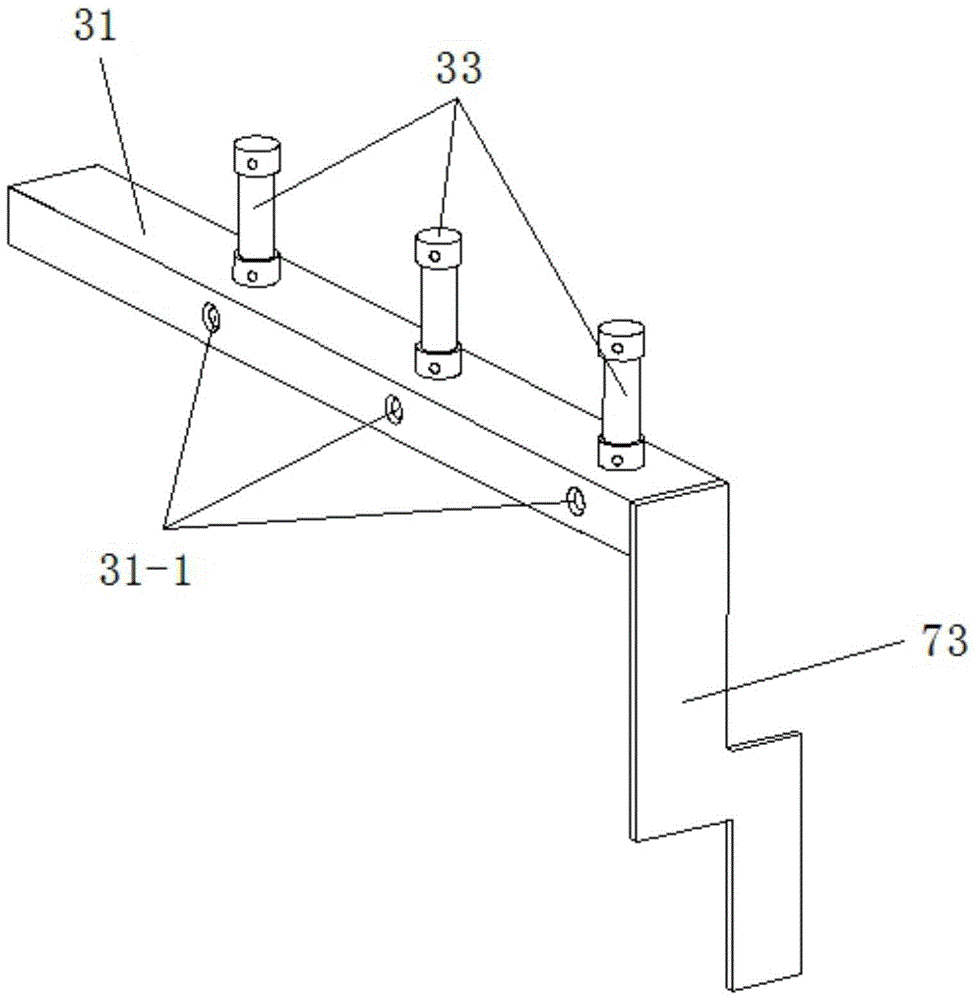

An automatic tape feeding system for laser marking, cutting and welding

ActiveCN104588891BIncrease the level of automationIncrease productivityLaser beam welding apparatusControl systemLaser cutting

Owner:广东省正亚聚成智能装备有限公司

Split type photovoltaic junction box feeding device

PendingCN114056925AHeight adjustablePositive effectJigging conveyorsConveyor partsControl cellControl theory

The invention discloses a split type photovoltaic junction box feeding device. The split type photovoltaic junction box feeding device comprises a vibration disc, a discharging track, a translation clamping mechanism, a camera shooting unit and a control unit, wherein the inner wall of the vibration disc is provided with a spiral feeding track, the translation clamping mechanism comprises a positioning seat, a limiting seat, a mechanical claw and a driving unit used for driving the mechanical claw, one end of the discharging track is connected with a top discharging opening of the feeding track, the other end of the discharging track is connected with the positioning seat, when the camera shooting unit detects that the direction of the corresponding junction box is the forward direction, the control unit drives the mechanical claw through the driving unit to clamp and translate the junction box in the positioning seat into the limiting seat, and when the camera shooting unit detects that the direction of the junction box is the reverse direction, the control unit drives the mechanical claw through the driving unit to clamp the junction box in the positioning seat, horizontally rotate the junction box by 180 degrees and then translate the junction box into the limiting seat. According to the split type photovoltaic junction box feeding device, automation can be achieved, the operation is stable and orderly, and the efficiency is high.

Owner:江苏晖朗电子科技股份有限公司

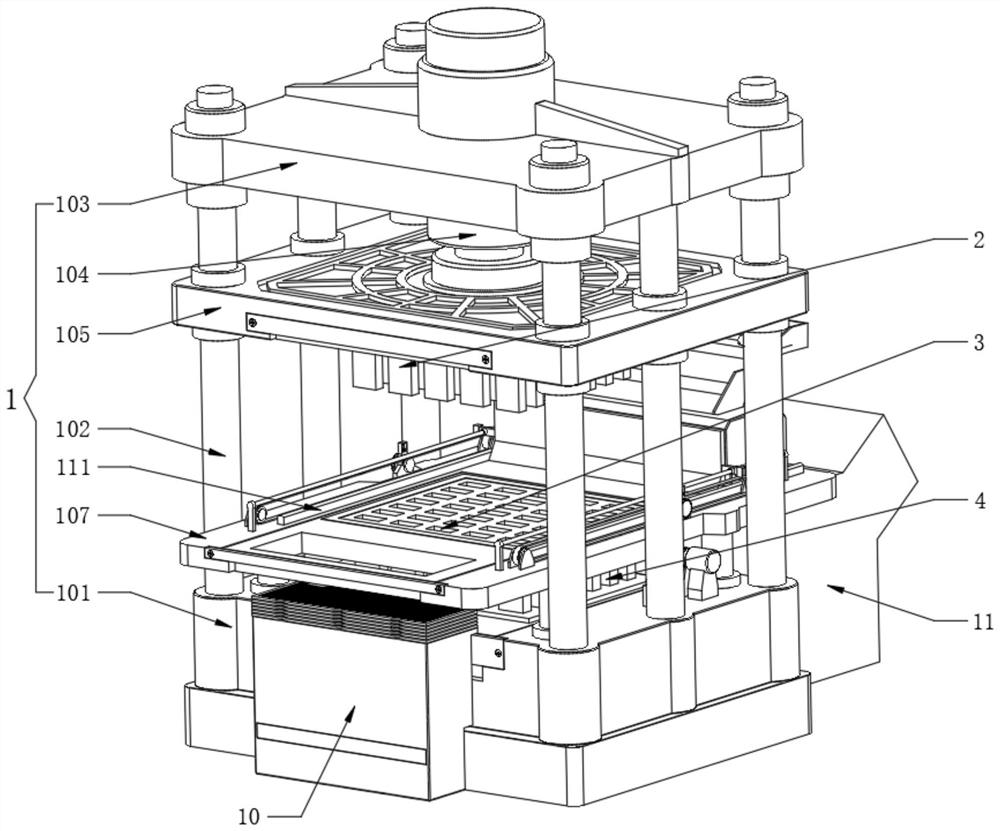

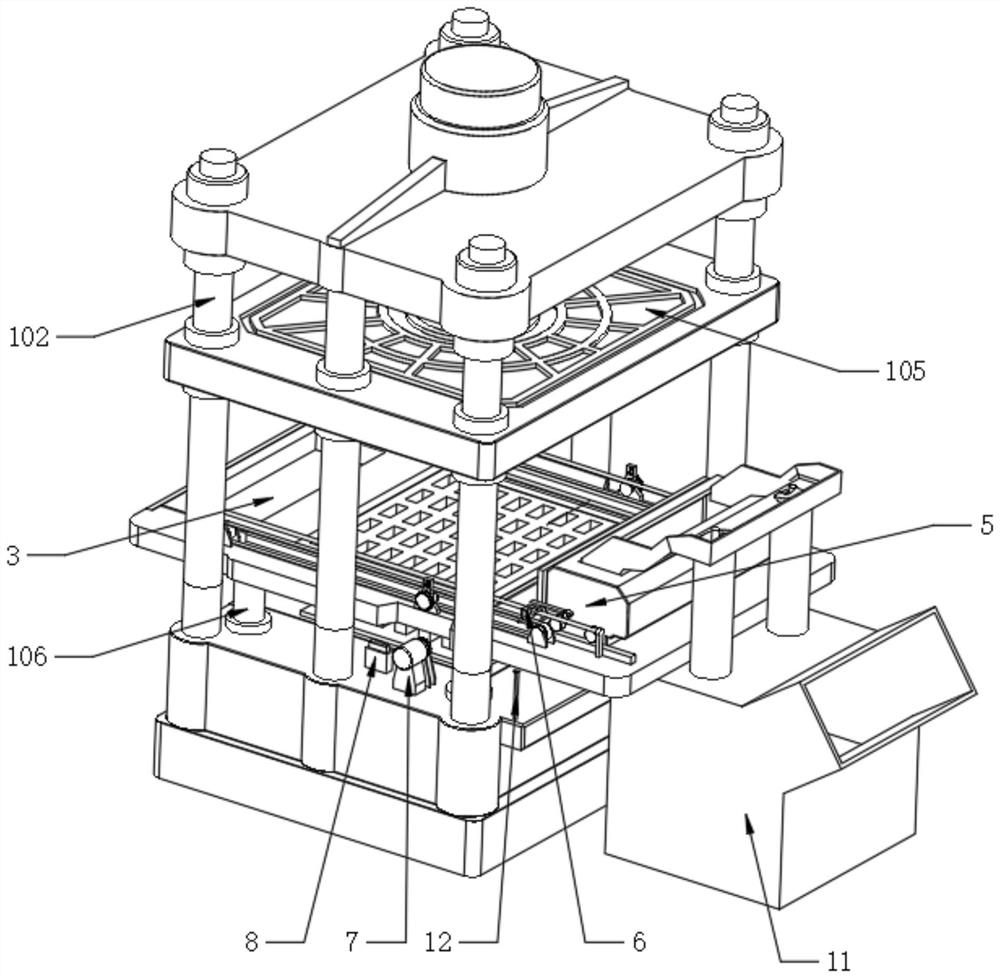

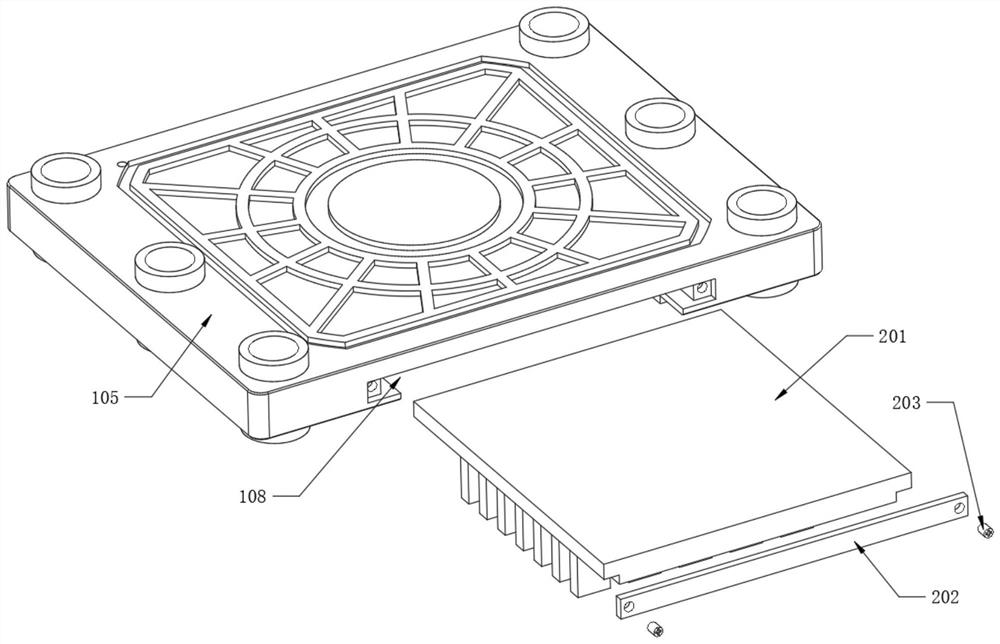

Pressing device applied to multi-specification activated carbon

InactiveCN114559695AFunction increaseConvenience to workChemical industryPressesHydraulic cylinderActivated carbon

The invention belongs to the technical field of activated carbon forming equipment, and particularly relates to a pressing device applied to multi-specification activated carbon, which comprises a pressing machine, a bottom supporting seat is arranged at the bottom of the pressing machine, a pressing plate is fixedly assembled at the output end of a main hydraulic cylinder, and auxiliary hydraulic cylinders are fixedly mounted at four corners in the bottom supporting seat; an auxiliary plate is fixedly assembled at the output end of the auxiliary hydraulic cylinder, a material supplementing structure is assembled at one end of the upper surface of the auxiliary plate in a sliding mode through the wheel rail, a piece conveying mechanism is fixedly arranged on the upper surface of the auxiliary plate, and a finished product conveying assembly is movably assembled on the portion, located under the discharging opening, of one side of the bottom supporting base. And a feeding mechanism is fixedly assembled on the other side of the bottom supporting seat. The multi-specification extrusion forming effect can be achieved, a traditional single-shape forming machining mode is changed, powder filling, powder supplementing and discharging work can be automatically achieved, finished product conveying work is facilitated, manpower is saved, and meanwhile the product production efficiency is greatly improved.

Owner:谢美霞

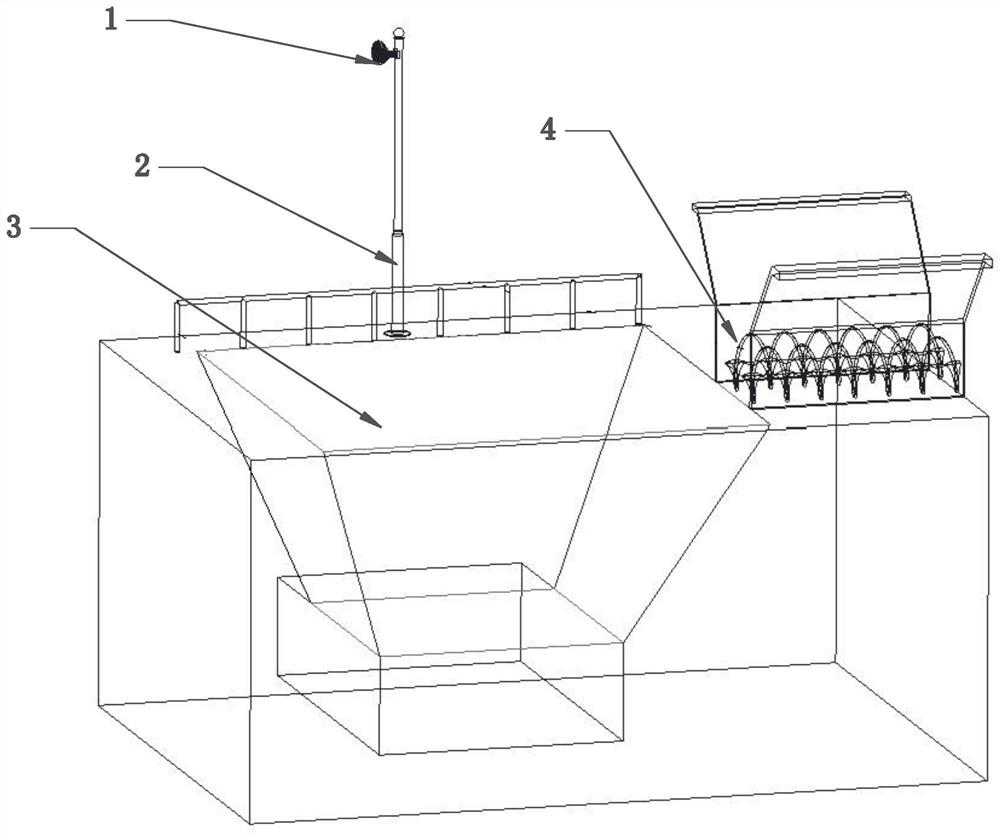

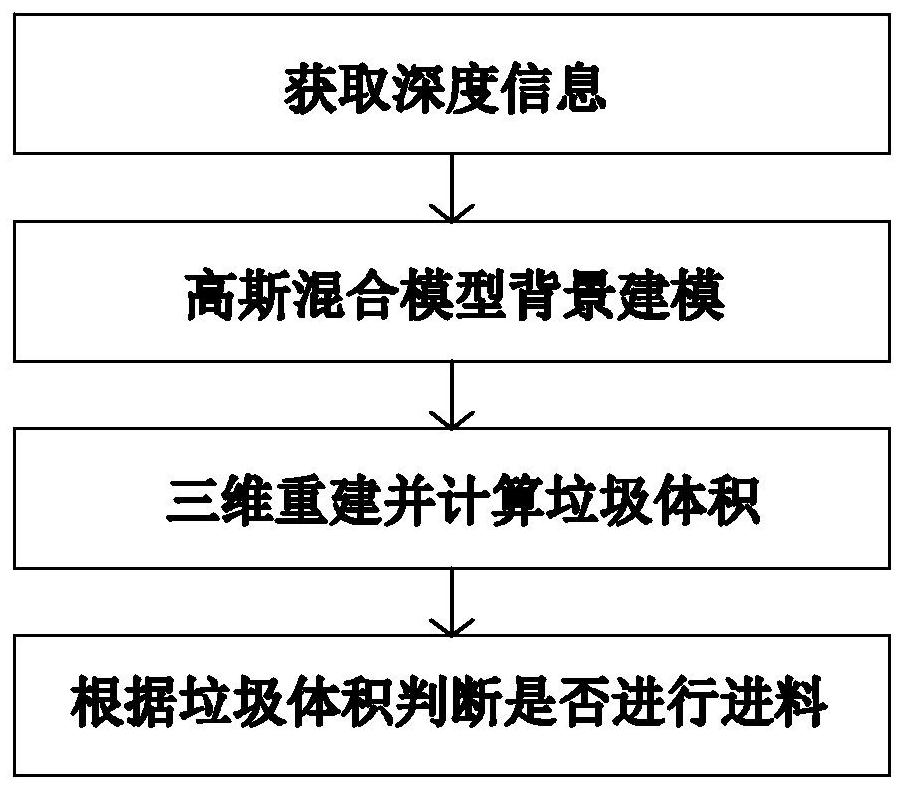

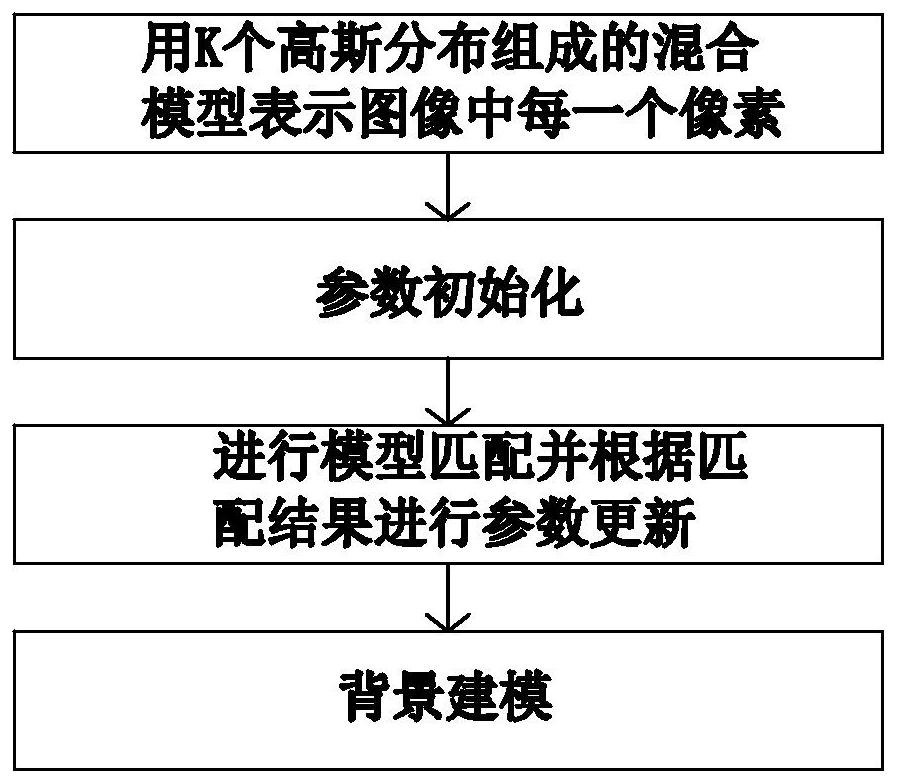

Automatic feeding control method and system for waste incineration feeding

PendingCN112097272AImprove combustion efficiencyRealize feeding automationIncinerator apparatus3D modellingProcess engineeringEnvironmental engineering

The invention relates to an automatic feeding control method and system for waste incineration feeding. The method comprises the steps of acquiring an image of a waste feeding port in real time, and acquiring the depth information of an imaging plane; carrying out Gaussian mixture model background modeling according to the depth information; carrying out three-dimensional reconstruction accordingto the Gaussian mixture model background modeling to calculate the volume of waste; and judging whether feeding needs to be carried out or not according to the volume of the waste. The system comprises a depth sensor platform, a depth sensor and a processor. The depth sensor is connected with the processor, the depth sensor is arranged on the depth sensor platform, the detection surface of the depth sensor covers the feeding port, and the processor is further connected with a reamer of a waste incineration device. The system has the advantages that the volume of the waste at the feeding port is monitored in the whole process, feeding automation is achieved without manual work, and the combustion efficiency of a boiler can be kept the best.

Owner:杭州科晟能源技术有限公司 +1

Double flip bag device

Owner:FUSHUN ALUMINUM

A powder mill for cosmetic production

The invention discloses a pulverizer used for cosmetic production. The pulverizer comprises a base. A buffering and damping device is arranged on the lower surface of the base. A grinding box is arranged on the upper surface of the base and internally provided with a primary grinding mechanism, a deep grinding mechanism and a conveying mechanism. The deep grinding mechanism is jointly composed of a feeding tube connected with the primary grinding mechanism, a conveying auger arranged in the feeding tube, a deep grinding box connected with the other end of the feeding tube, a trapezoidal groove formed in the upper surface of the deep grinding box, a rotary motor arranged on the upper surface of the deep grinding box, an oscillating rod arranged at the rotating end of the rotary motor in a sleeving mode, a grinding ball arranged at the other end of the oscillating rod, and a plurality of fine leaking holes formed in the lower surface of the deep grinding box. A cosmetic production management system is arranged in a cosmetic production management office and is electrically connected with the primary grinding mechanism, the deep grinding mechanism and the conveying mechanism. The pulverizer used for cosmetic production has the beneficial effects that grinding is complete, and the automation degree is high.

Owner:广州市康乃馨生物有限公司

Shaft sleeve shaping machine and its working method

InactiveCN104190748BFully automated collectionRealize feeding automationMetal-working feeding devicesStripping-off devicesEngineeringSlide plate

The invention discloses a working method of a shaft sleeve shaping machine, which is composed of a feeding mechanism, a shaping mechanism, a connecting mechanism and a motor. Opening, the surface is provided with a through hole, and its left and right sides are respectively provided with a left sliding plate and a right sliding plate, and the left sliding plate and the right sliding plate are connected by the first column passing through the through hole on the surface of the base; the motor is the right sliding plate Provide traction; the middle part of the right sliding plate is equipped with a shaping thimble, and the middle part of the left sliding plate is equipped with a stripping thimble; the connecting mechanism includes a lower positioning plate, a front positioning plate, and a limit pin. The side of the front positioning plate is L-shaped, and the upright part is fixedly connected On the base, the raised part is connected to the top of the through hole of the pressure plate; the lower positioning plate is driven by the cylinder and connected to the base through the second column, and a bracket is provided on the slope; the middle part of the bracket is inclined, and the bottom and top extend horizontally to one side.

Owner:嘉善新易能精密机械设备厂

Feeding device for cooking equipment

ActiveCN107960873BRealize feeding automationReduce labor workloadCooking-vessel lids/coversCooking vessel constructionsProcess engineeringSmart kitchen

Owner:李亚锐

Crusher provided with automatic feeding component

InactiveCN109174312AEfficient collectionImprove filtering effectDirt cleaningGrain treatmentsClosed chamberEngineering

The invention relates to a crusher provided with an automatic feeding component. The crusher comprises a frame component, a power component, a crushing component and the feeding component; the frame component is fixed onto the ground; the power component is arranged at the right side of the frame component; the crushing component is arranged in the frame component; the feeding component is arranged above the frame component; the frame component comprises an upper shell, a lower shell, a feeding hopper and a discharge hopper; the upper shell is arranged above the lower shell, the upper shell and the lower shell are connected tightly to form a processing closed chamber, and a fastening piece is installed at the joint of the upper shell and the lower shell; the feeding hopper is arranged on the upper shell; and the discharge hopper is arranged on the lower shell.

Owner:南京途酷信息科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com