Automatic feeding control method and system for waste incineration feeding

A technology of automatic feeding and waste incineration, applied in the direction of combustion method, incinerator, combustion type, etc., can solve the problems of unstable, unstable and low efficiency of boiler combustion, and achieve the best effect of boiler combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

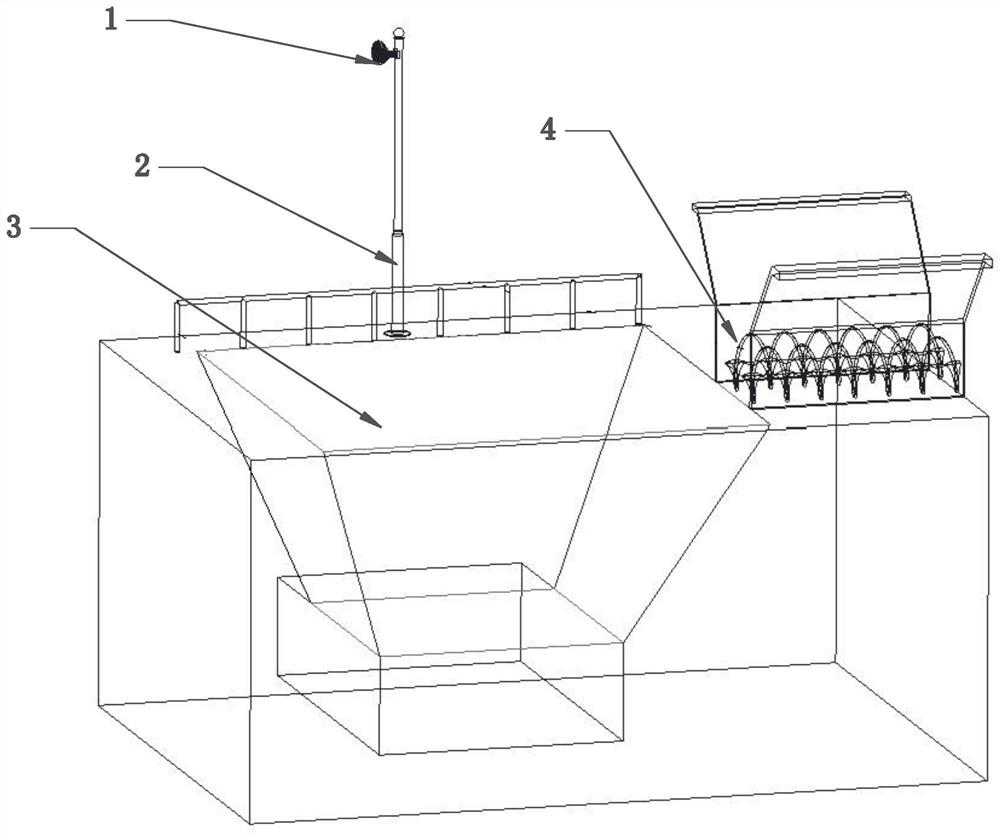

[0044] In this embodiment, a kind of automatic feeding control system for waste incineration feeding, such as figure 1 As shown, it includes a depth sensor platform 2, a depth sensor 1 and a processor. The depth sensor is connected to the processor. The depth sensor is arranged on the depth sensor platform. The reamer of the device is connected. In this embodiment, the height and angle of the depth sensor platform can be adjusted. When the depth sensor is installed, the angle and height of the depth sensor platform can be adjusted to ensure that the depth sensor can obtain the depth information of the hopper.

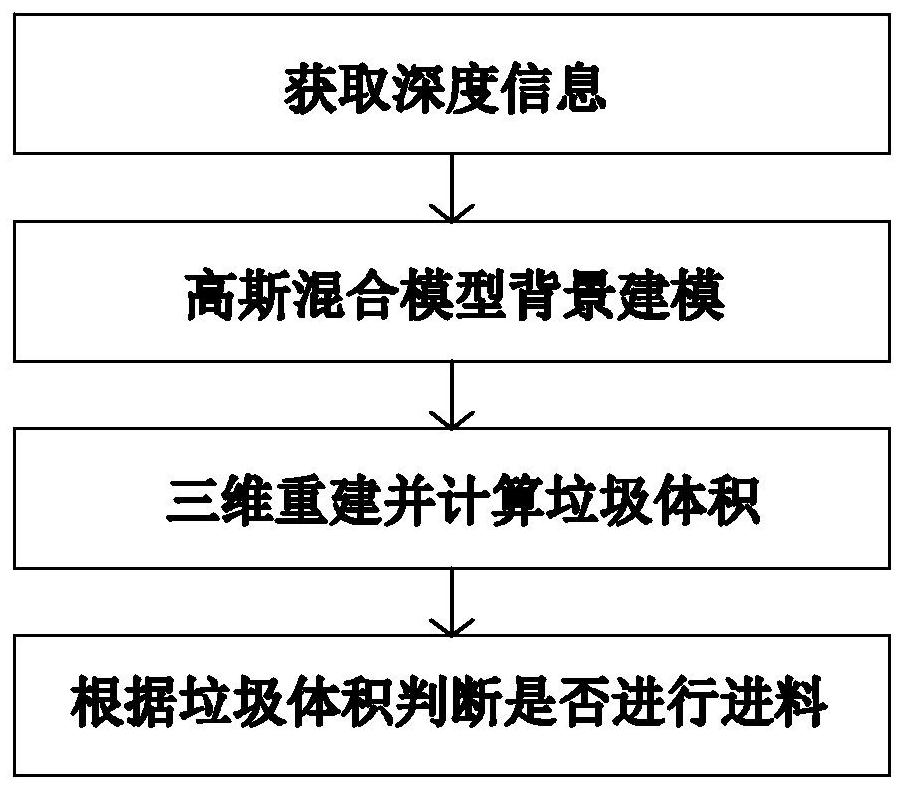

[0045] Correspondingly, this embodiment also proposes an automatic feeding control method for waste incineration feeding, such as figure 2 shown, including the following steps:

[0046] S1: Collect the image of the garbage inlet in real time, and obtain the depth information of the imaging surface.

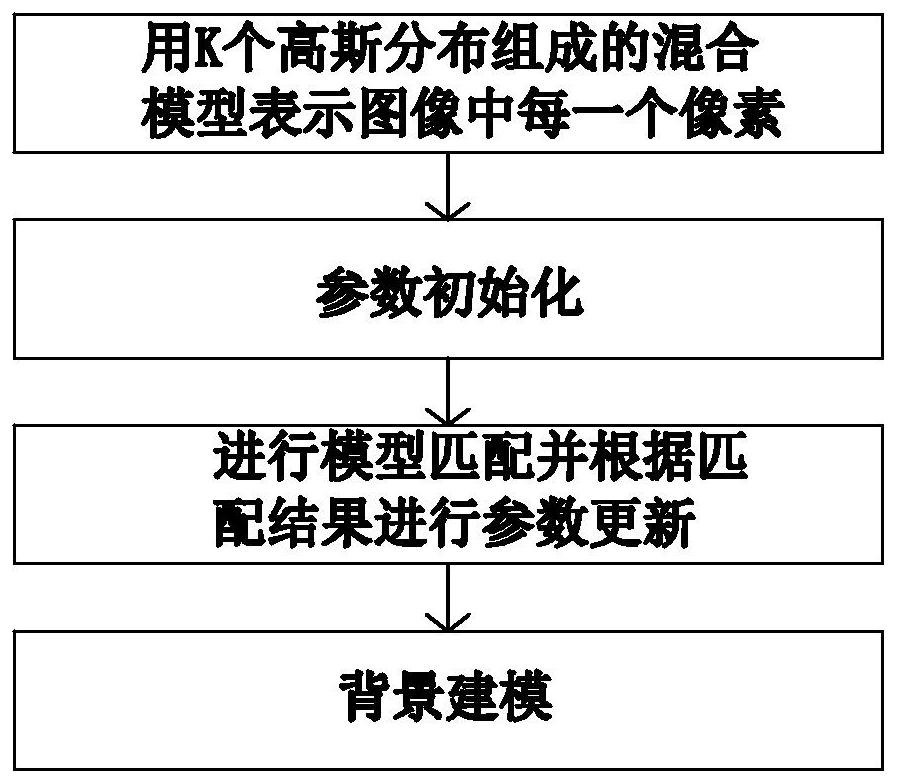

[0047] S2: Gaussian mixture model background modeling based on dep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com