Double flip bag device

A bag-turning and hopper-turning technology, which is applied in packaging, container emptying, bottle filling, etc., can solve problems such as long time for overhead cranes and ground personnel, serious damage to human body due to dust, and no recycling value, so as to improve the working environment of workers, Reduce labor intensity and realize the effect of automatic feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

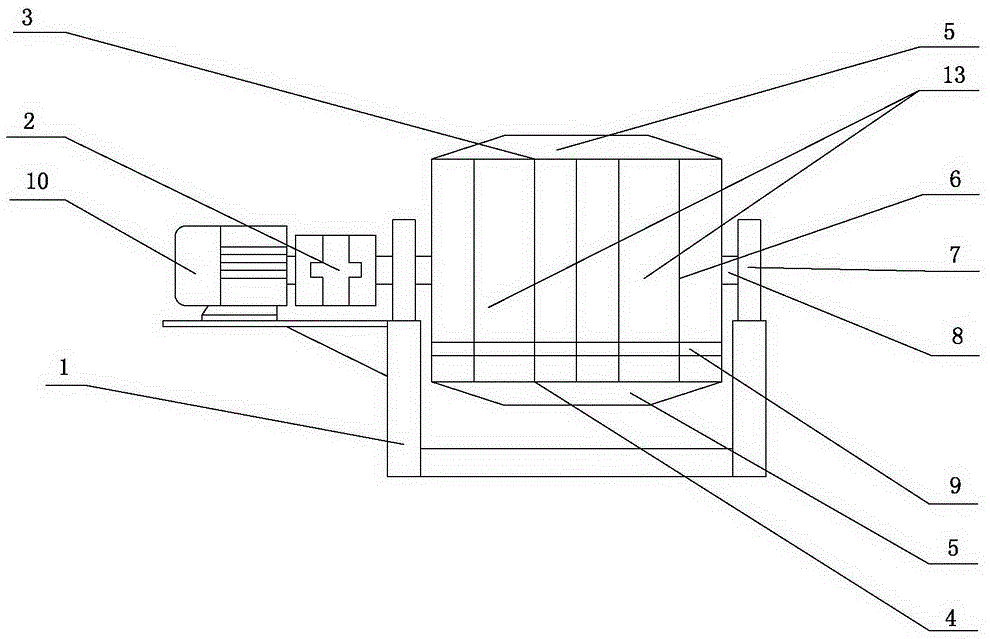

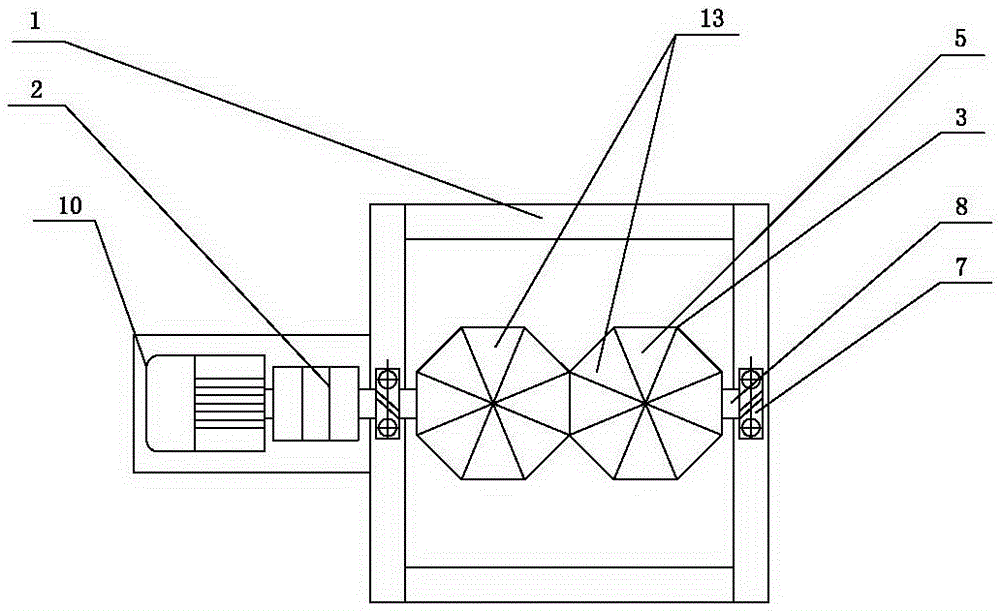

[0010] Such as figure 1 , 2 As shown, the present invention includes a support 1, and also includes a tipping hopper composed of two frames 13 connected together inside. Both sides of the tipping hopper are supported on the bracket 1 through the rotating shaft 8 and the inclined sliding bearing 7, and the rotating shaft on one side is extended to connect with the reduction motor 10 through the coupling 2, and the reduction motor 10 can drive the two frames 13 of the tipping hopper to realize 360° ° any rotation. Each frame 13 is composed of octagonal upper and lower openings 3, 4 and slideways 6 between them. All be provided with self-locking door 5 on the outer side of upper and lower mouth 3,4. Each frame 13 is provided with a sliding chassis 9 that can slide vertically through the slideway 6 .

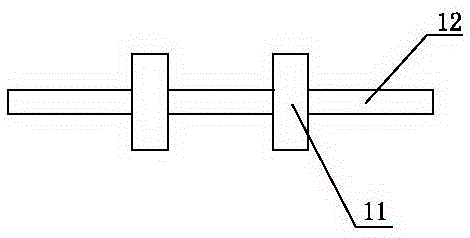

[0011] Such as image 3 , 4 As shown, the sliding chassis 9 of the present invention is composed of a chassis 12 and both sides thereof, and sliding bars 11 matched with the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com