Shaft sleeve shaping machine and its working method

A technology for shaping machines and bushings, applied in manufacturing tools, metal processing equipment, feeding devices, etc., can solve problems such as inconvenience in use, and achieve the effects of easy collection of finished products, improved production efficiency, and stable working process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation of above-mentioned shaft sleeve shaping machine is as follows:

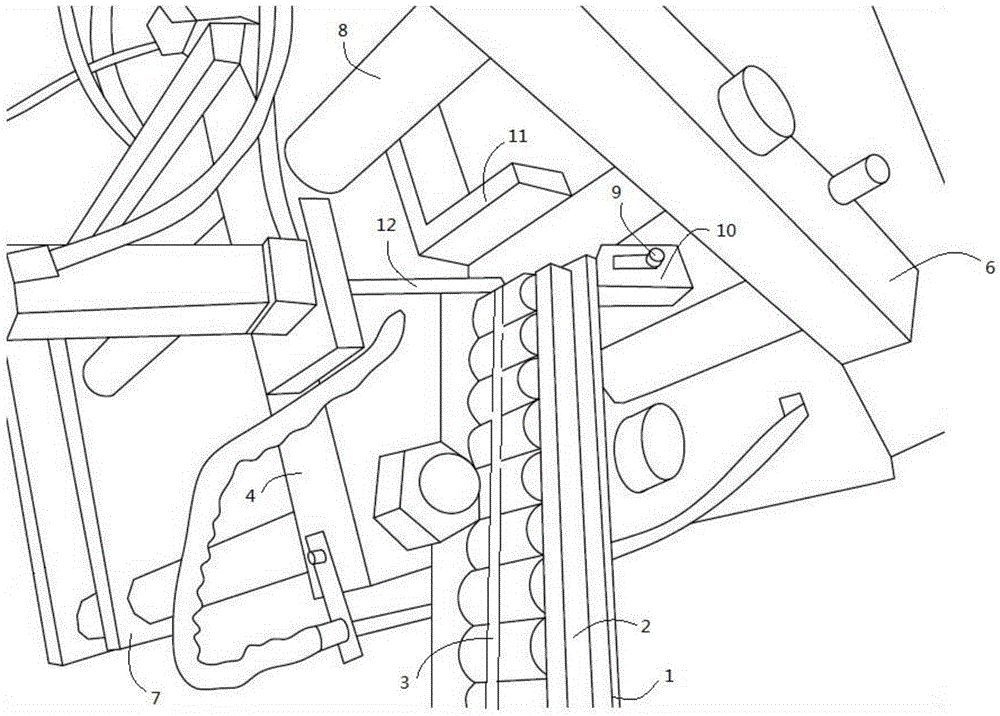

[0033] Such as figure 1 As shown, the feeding mechanism is composed of a feeding plate 1, a fixing bar 2, and a fixing rod 3; Positioning plate 10, front positioning plate 11, limit pin 12, the second column 9 form.

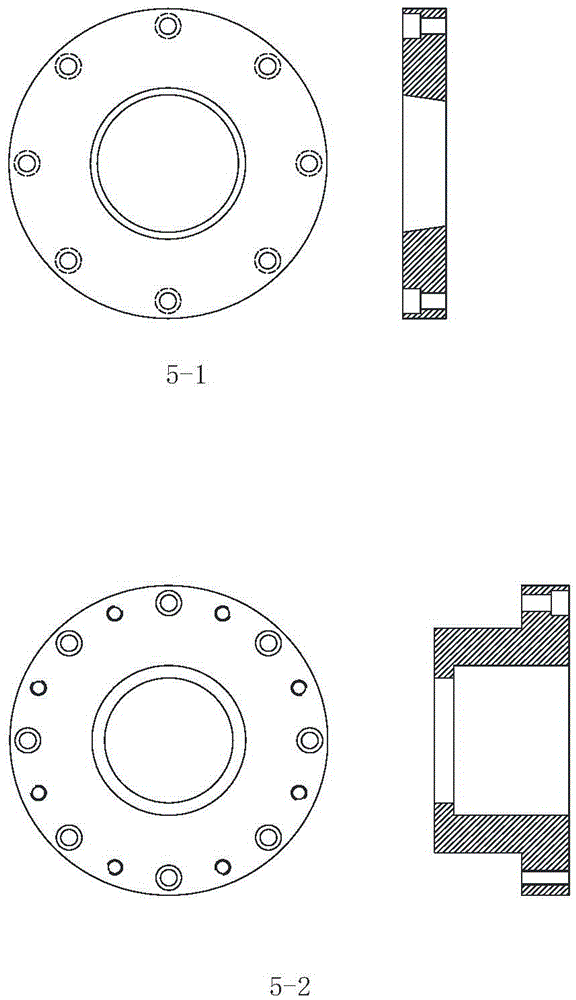

[0034] Such as image 3 As shown, the formwork mounting structure is installed by pressing plate 5-1 and inserting 5-2 cover openings.

[0035] The two ends of the feed plate 1 are fixedly connected with the fixed strip 2; the top of the fixed strip on one side is connected to the telescopic bracket, and the other end of the telescopic bracket is connected to the fixed rod 3, and the direction of the fixed rod 3 is parallel to the feed plate 1, and is located between the two fixed strips 2. between.

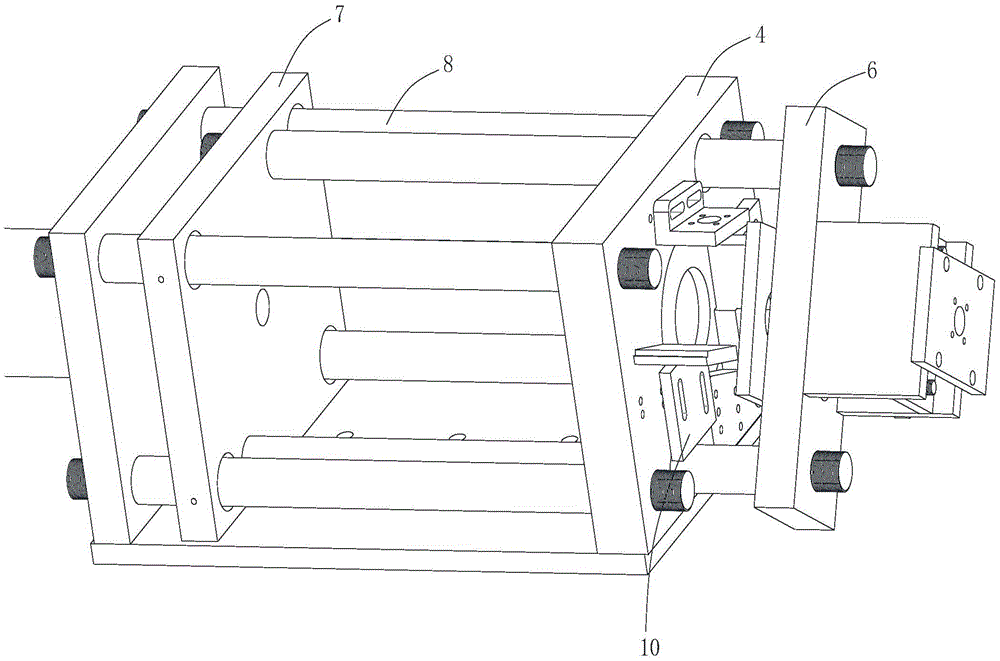

[0036] The middle part of the base 4 is open, and the surface is provided with through holes, and its left and right sides are respectively provided with a left s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com