Patents

Literature

107results about How to "Avoid manual feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

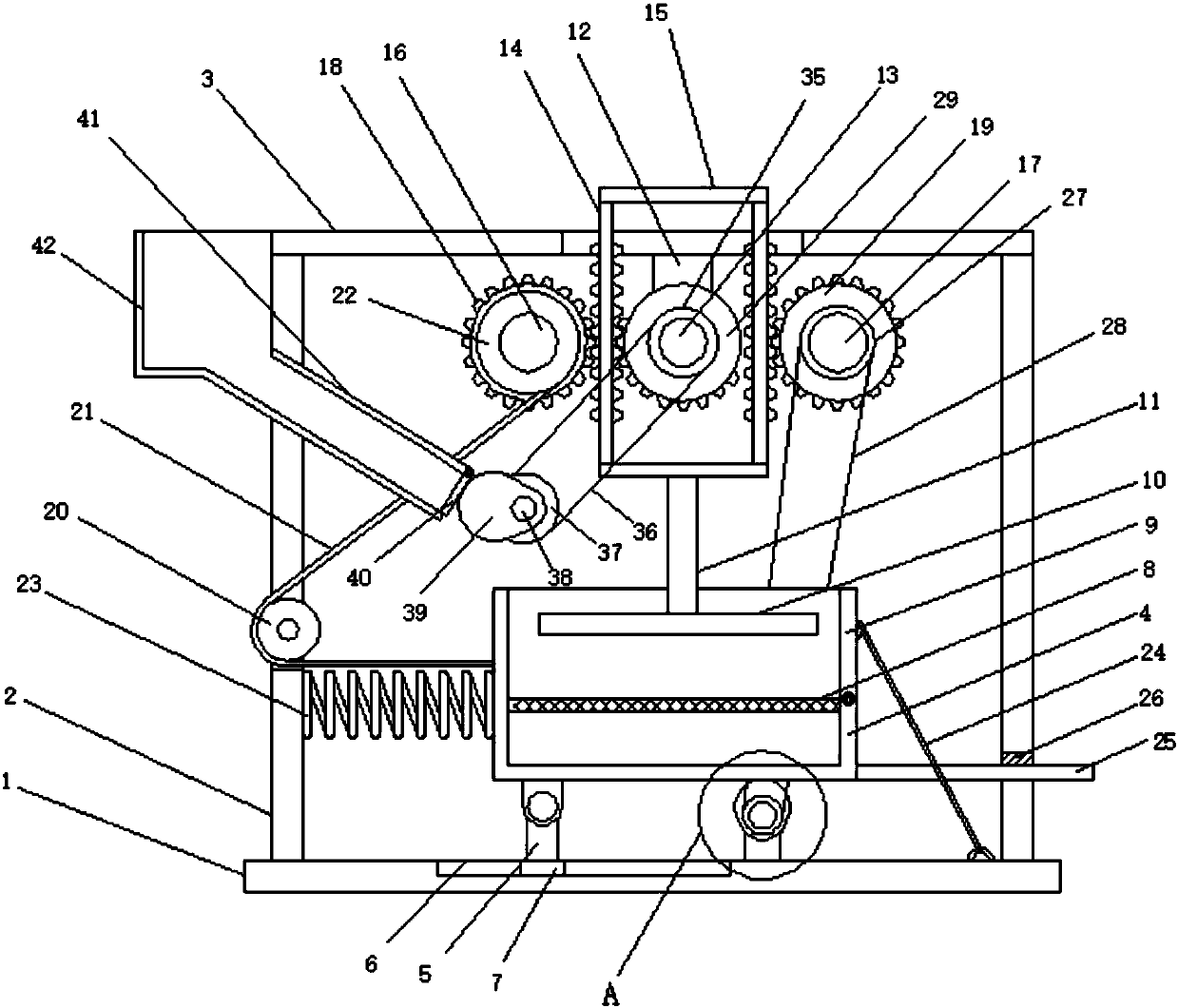

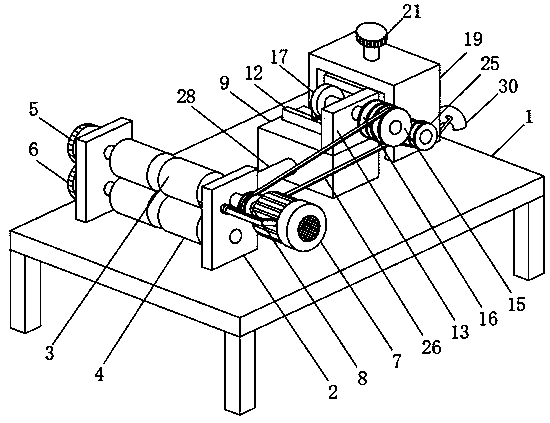

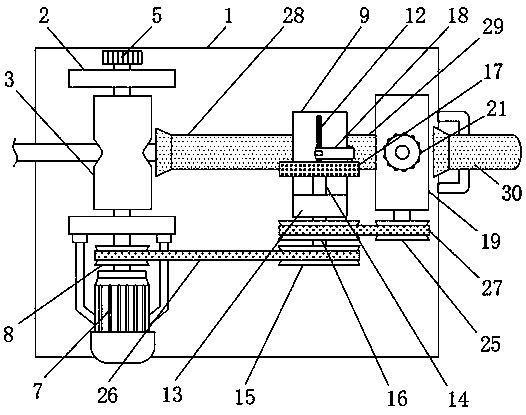

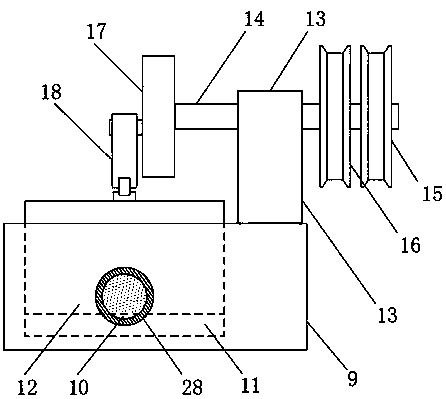

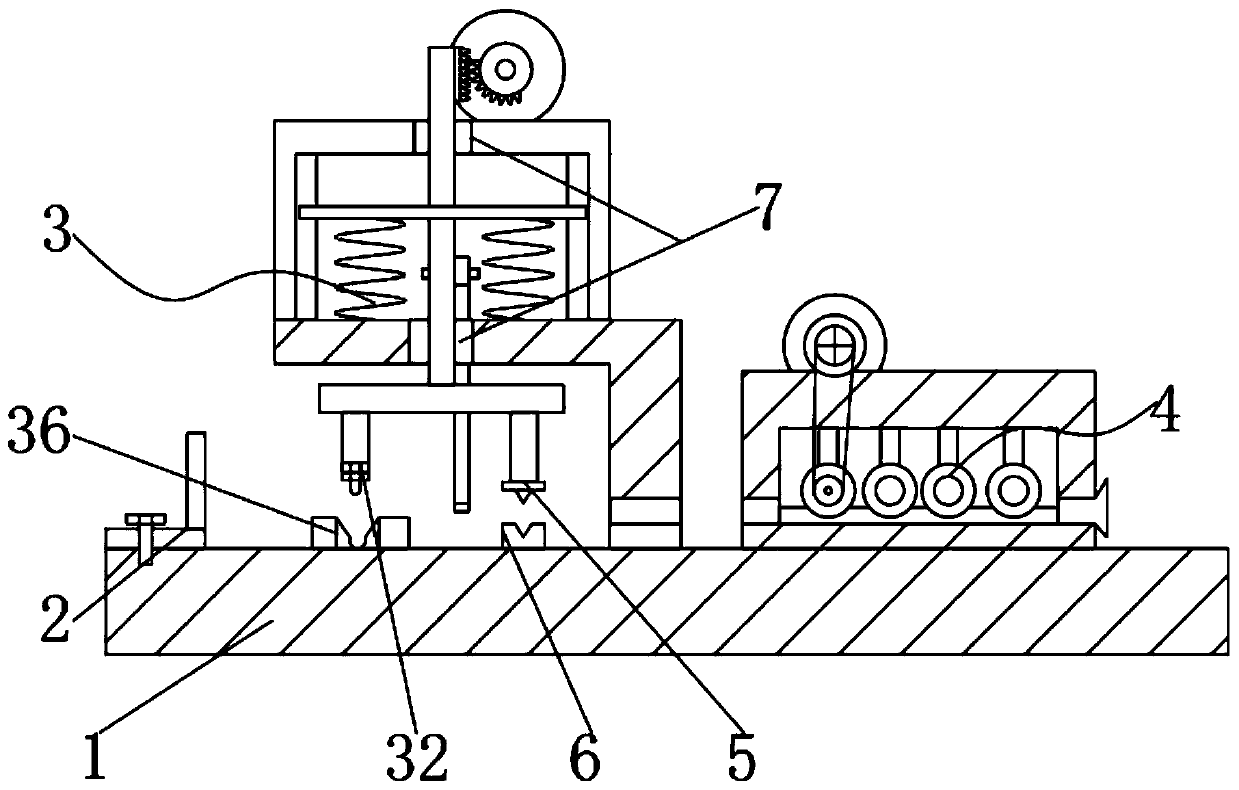

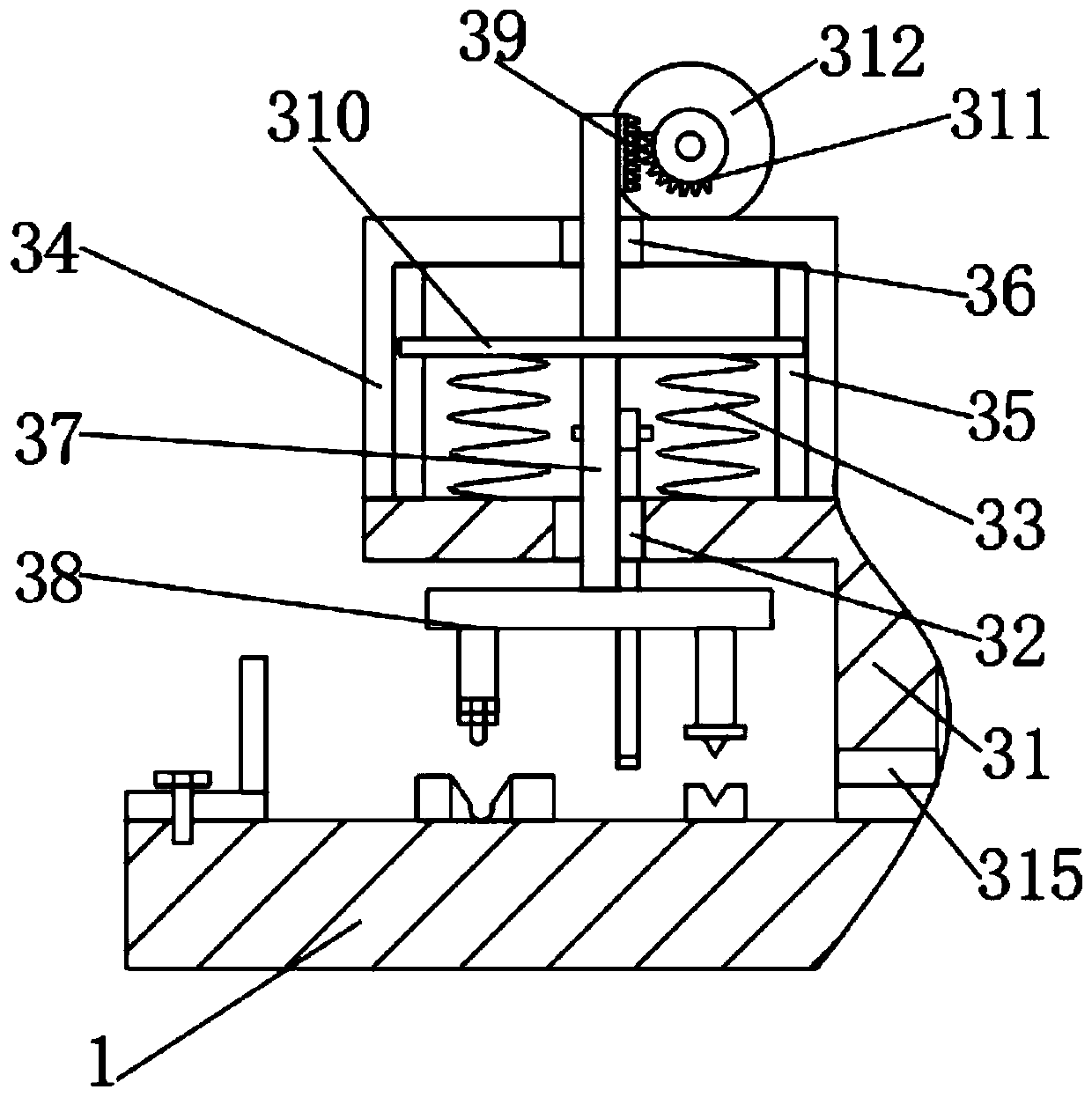

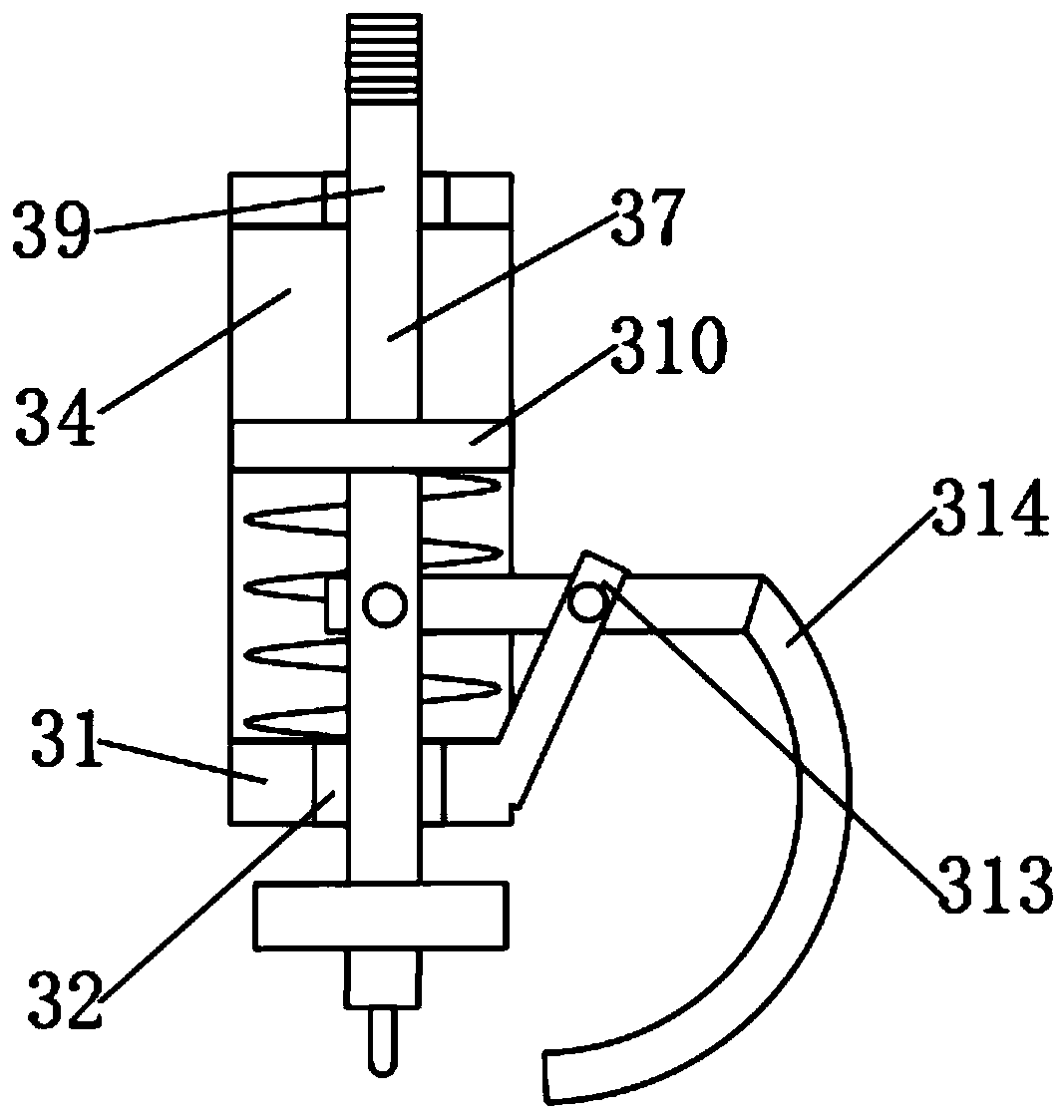

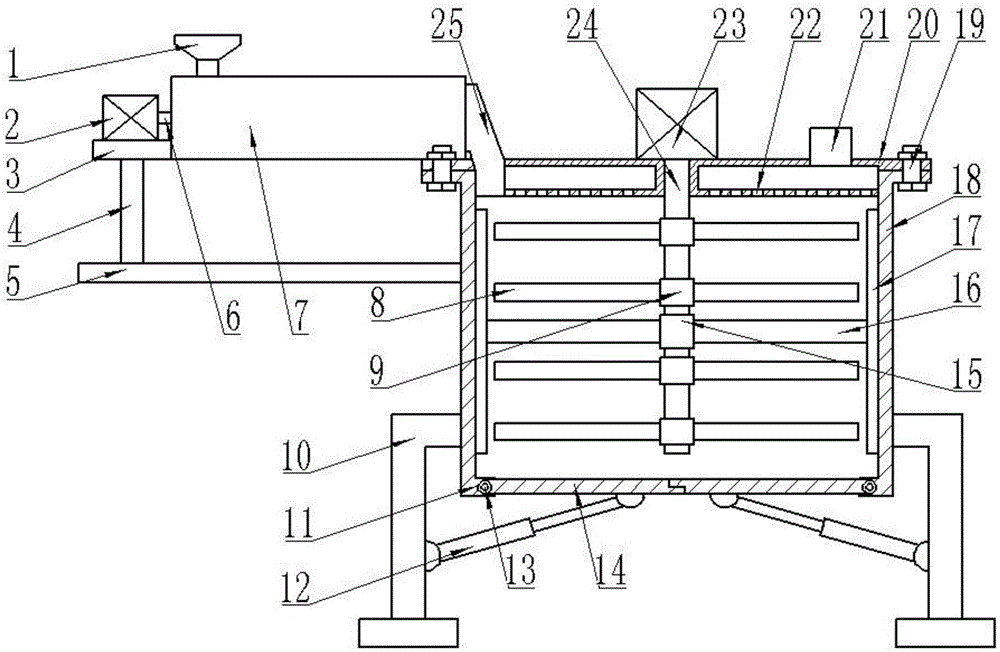

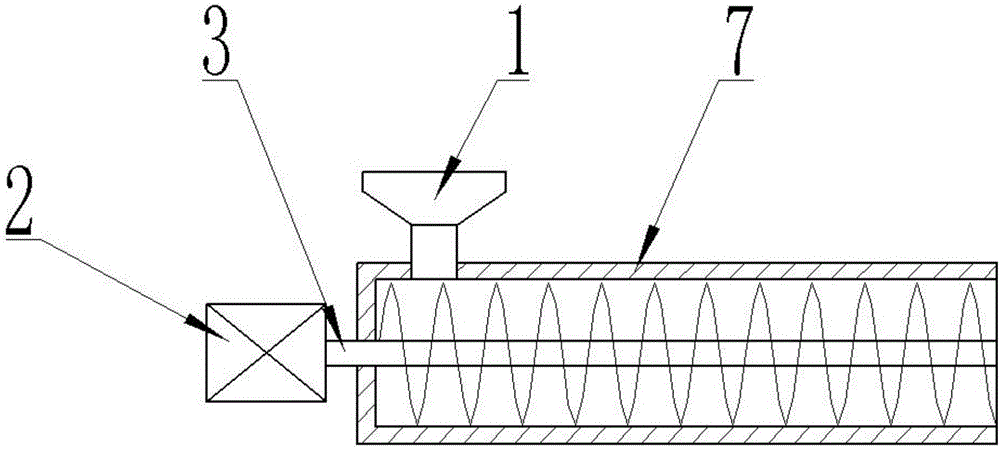

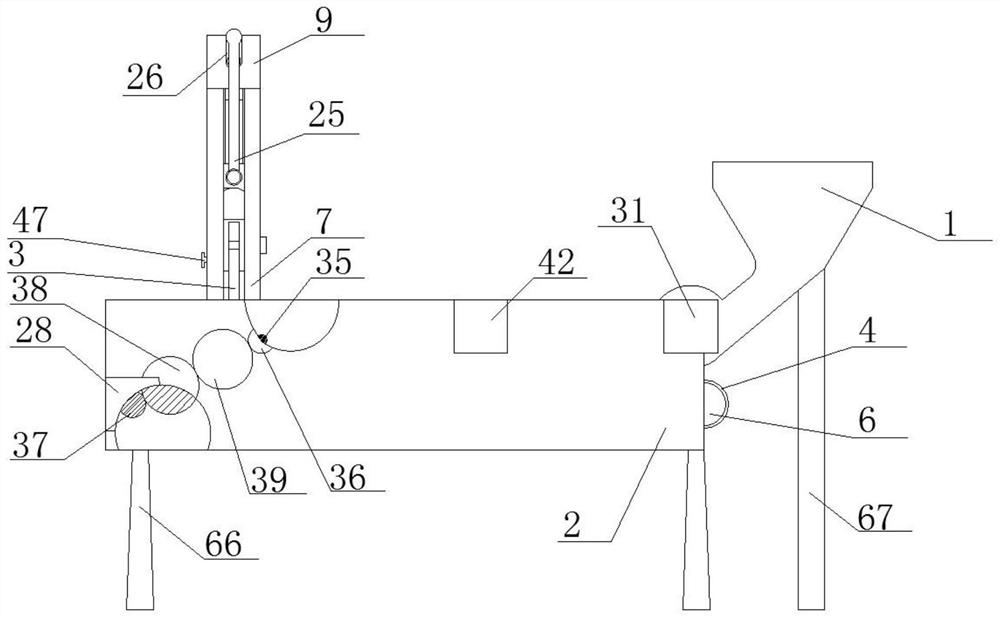

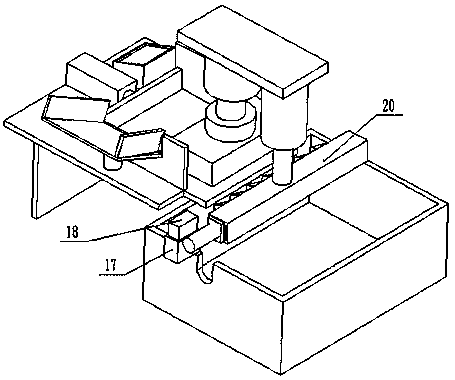

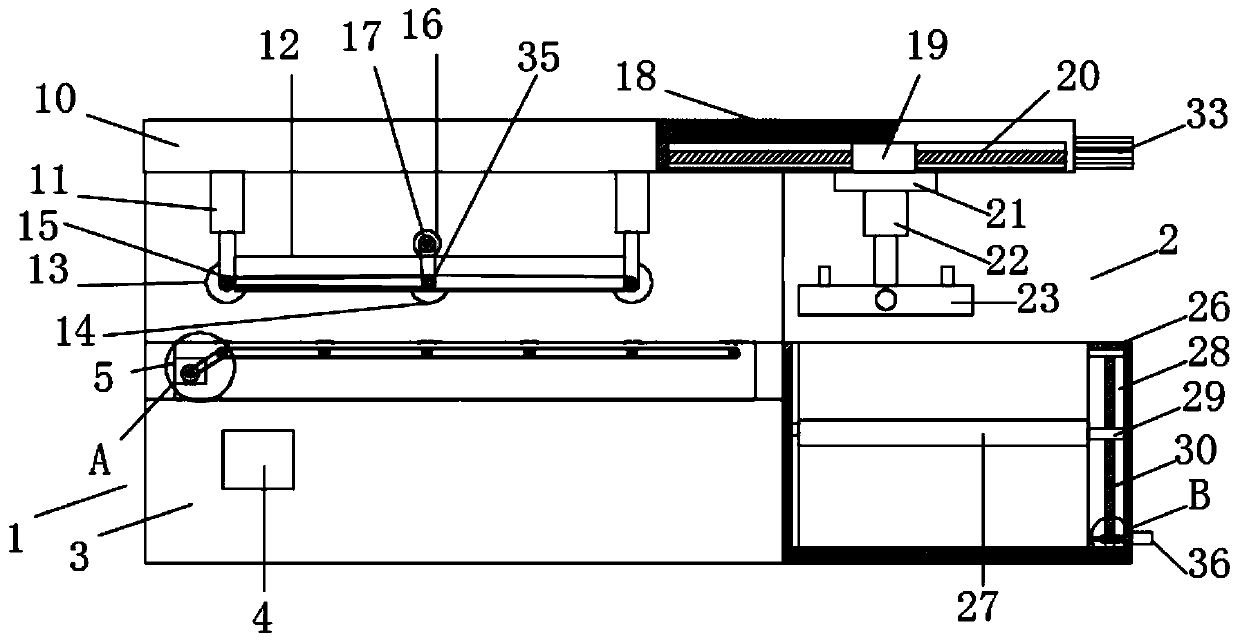

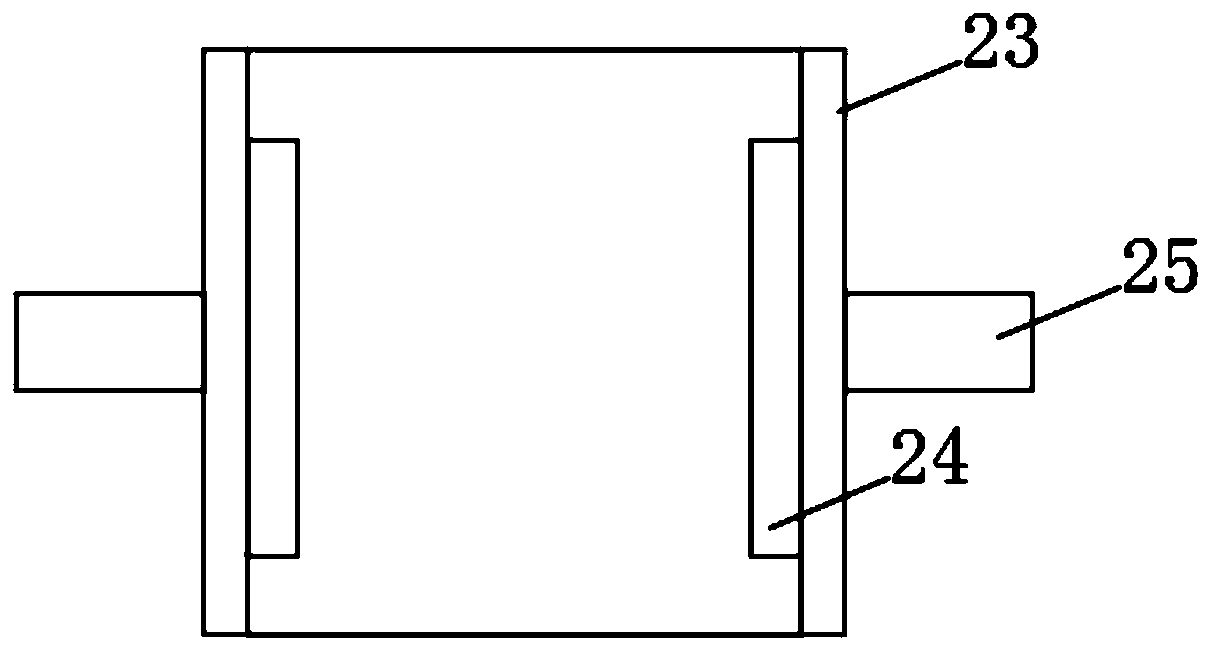

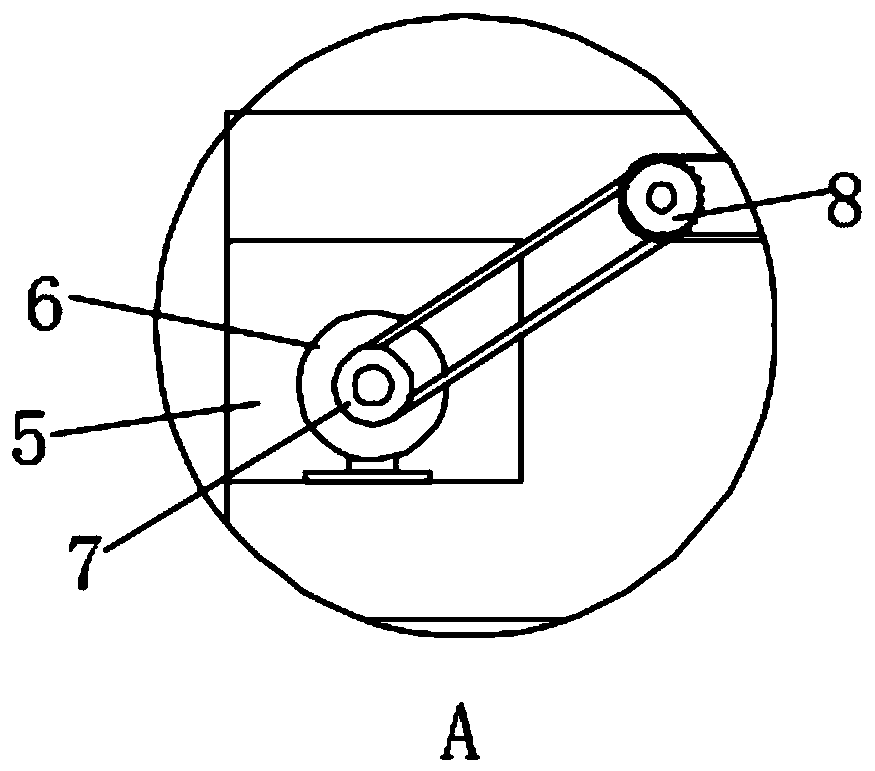

Continuous working efficient waste vegetable and fruit water removing device

InactiveCN107599474AEasy dischargeAvoid Manual FeedingPressesAgricultural engineeringLinkage concept

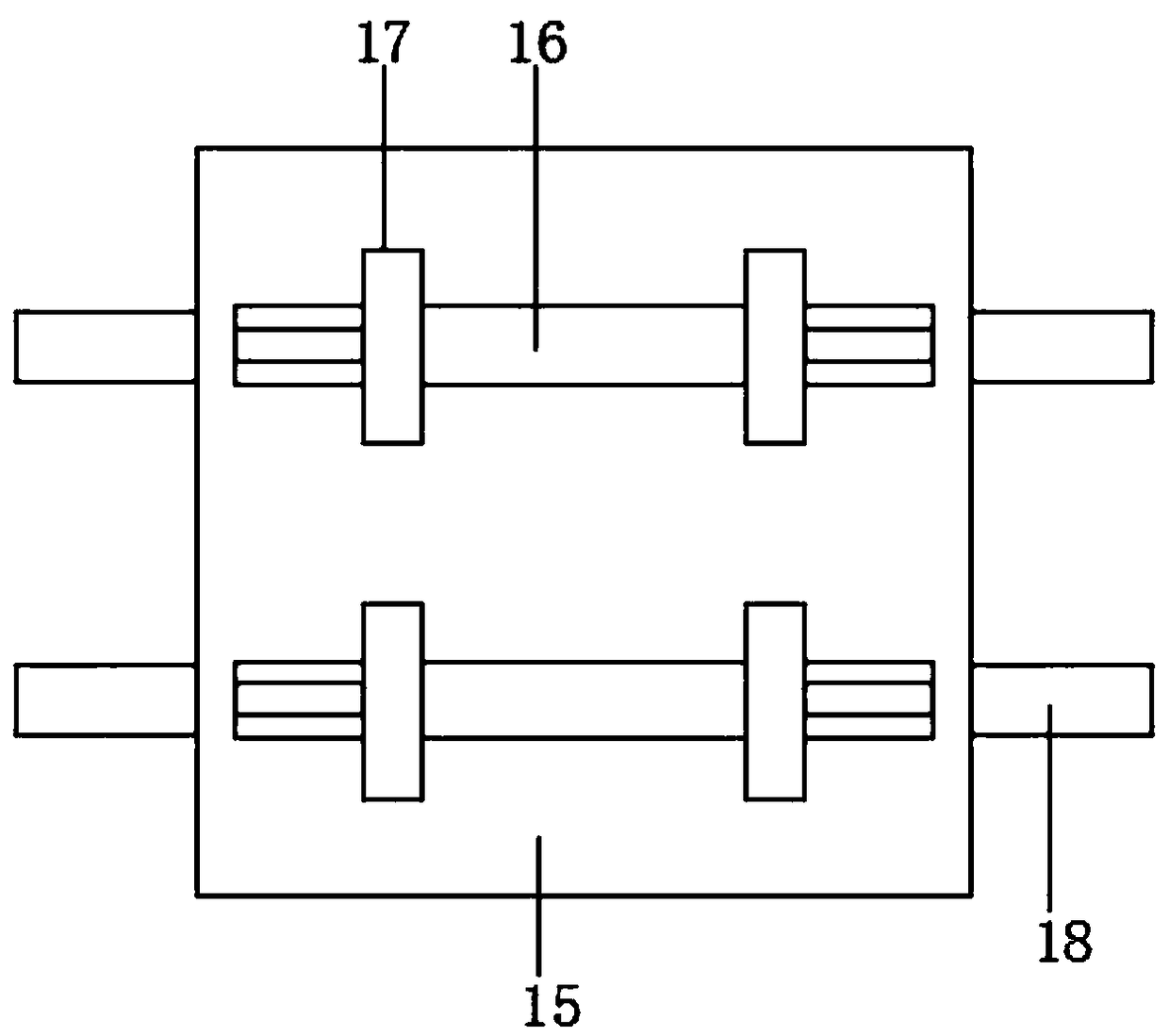

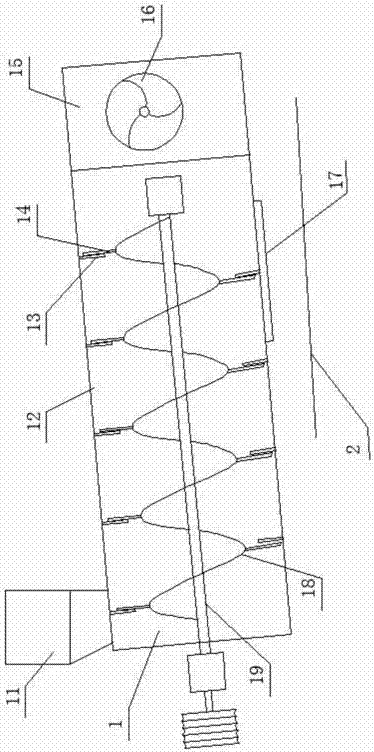

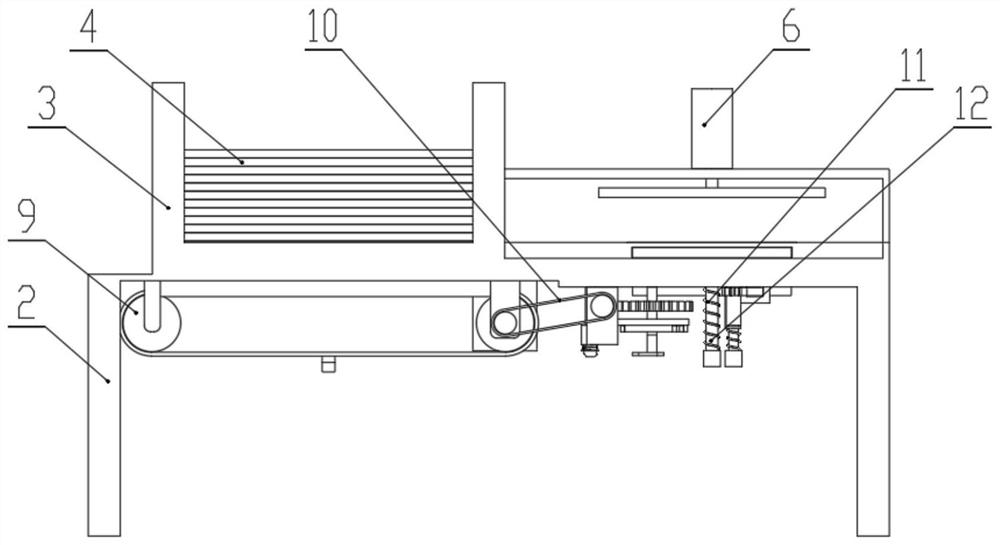

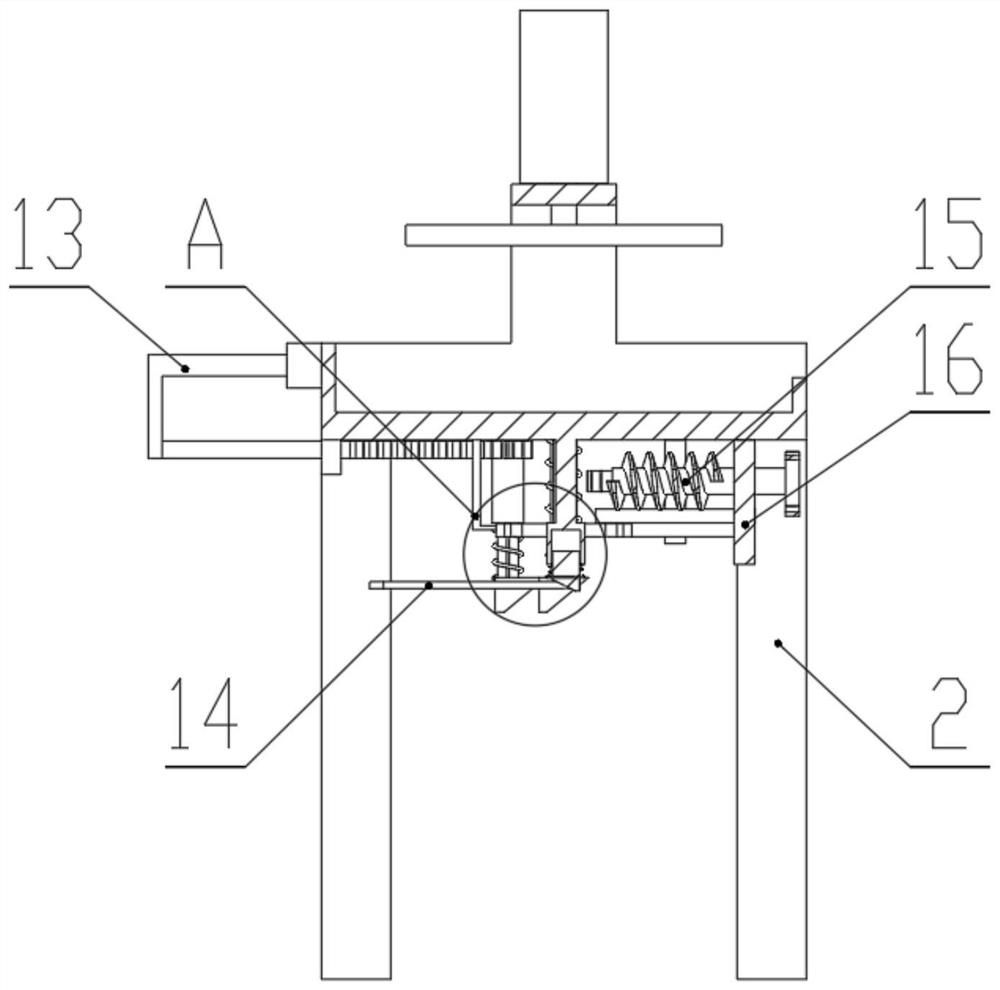

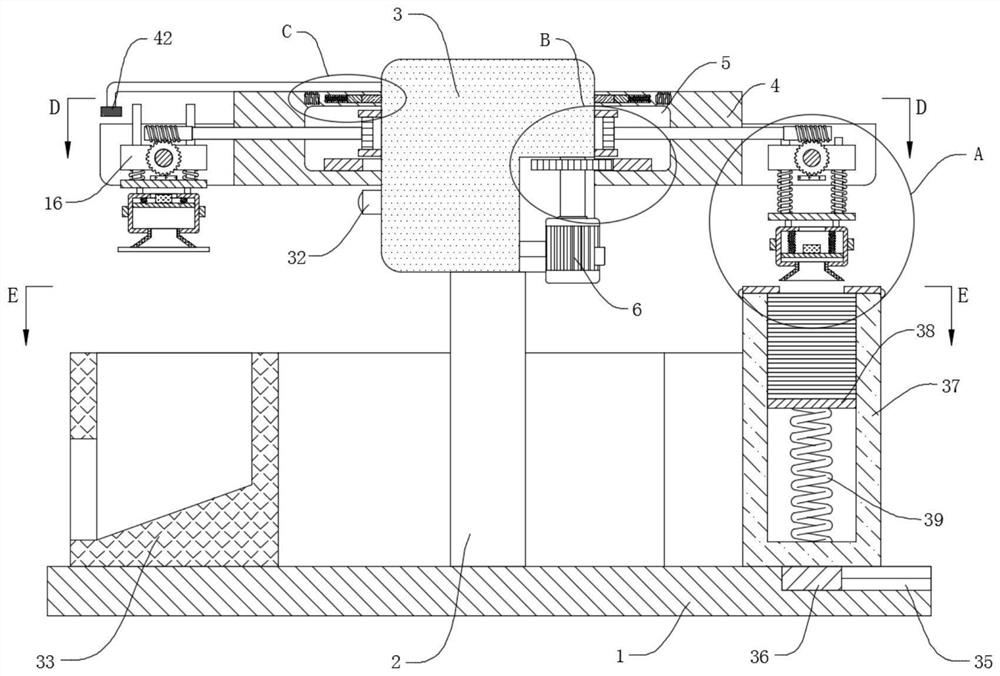

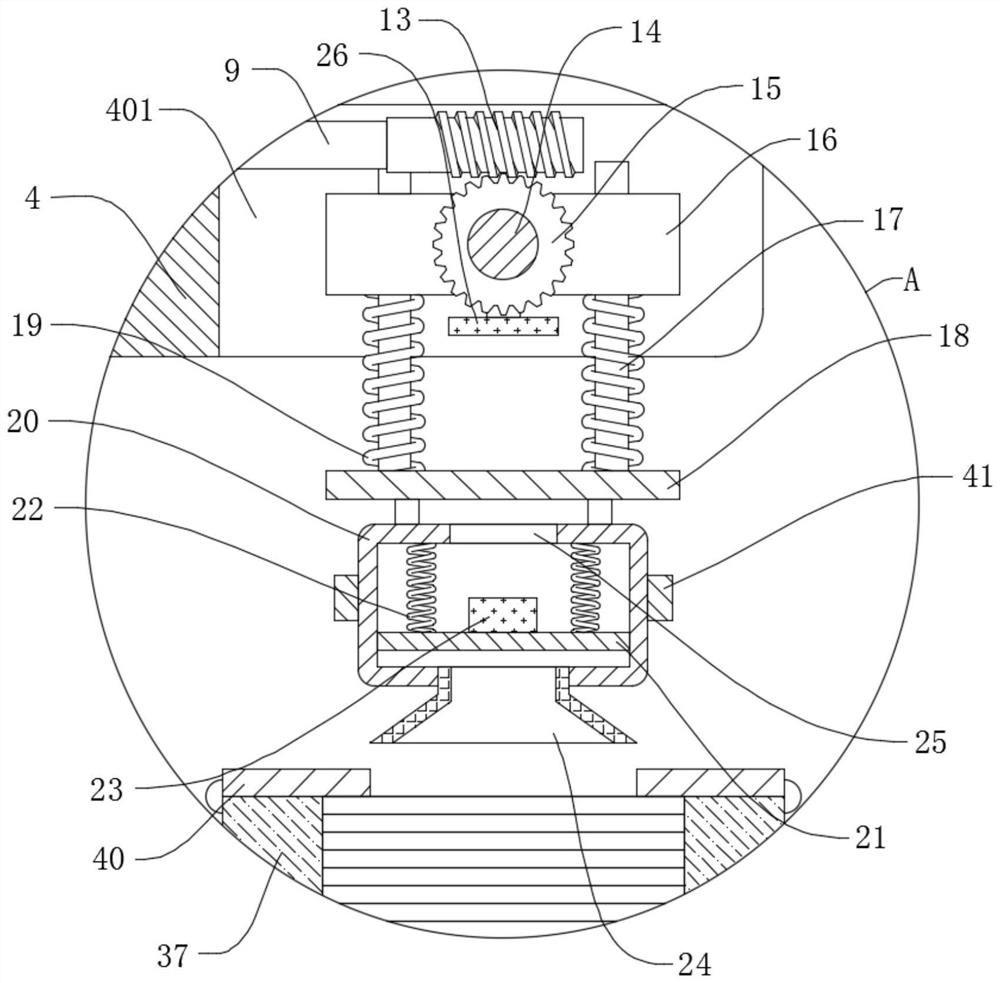

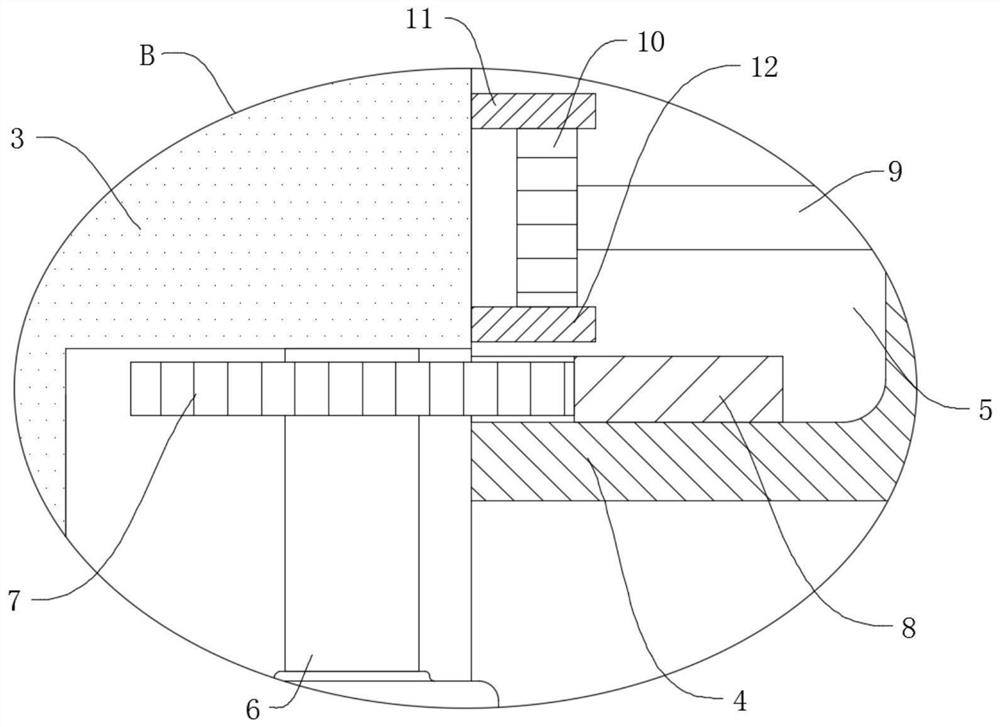

The invention discloses a continuous working efficient waste vegetable and fruit water removing device. The continuous working efficient waste vegetable and fruit water removing device comprises a bottom plate, a supporting frame and a water removing tank. The support is provided with a rotation shaft, and an eccentric wheel is arranged on the rotation shaft. A water removing net plate is arrangedin the water removing tank. A first cross shaft, a second cross shaft and a third cross shaft, all of which are parallel are arranged on the supporting frame. The first cross shaft is further provided with a semicircular-tooth gear, double-face racks are arranged on the two sides of the semicircular-tooth gear, and a push rod is arranged on the lower end face of a connecting plate at the lower ends of the double-face racks. A pressing plate is arranged at the bottom end of the push rod. The third cross shaft is connected with the rotation shaft through a chain wheel mechanism. A traction ropeis wound around winding wheels. One end of the traction rope is wound around a guiding roller and is connected with the left side wall of the water removing tank. A feeding groove is further formed in the upper end of the left side of the supporting frame. The continuous working efficient waste vegetable and fruit water removing device is simple in structure and high in linkage performance, discharging and feeding are convenient and fast, manual operation is not needed, manual labor is saved, the work efficiency is high, and practicability is high.

Owner:郑州味觉信息技术有限公司

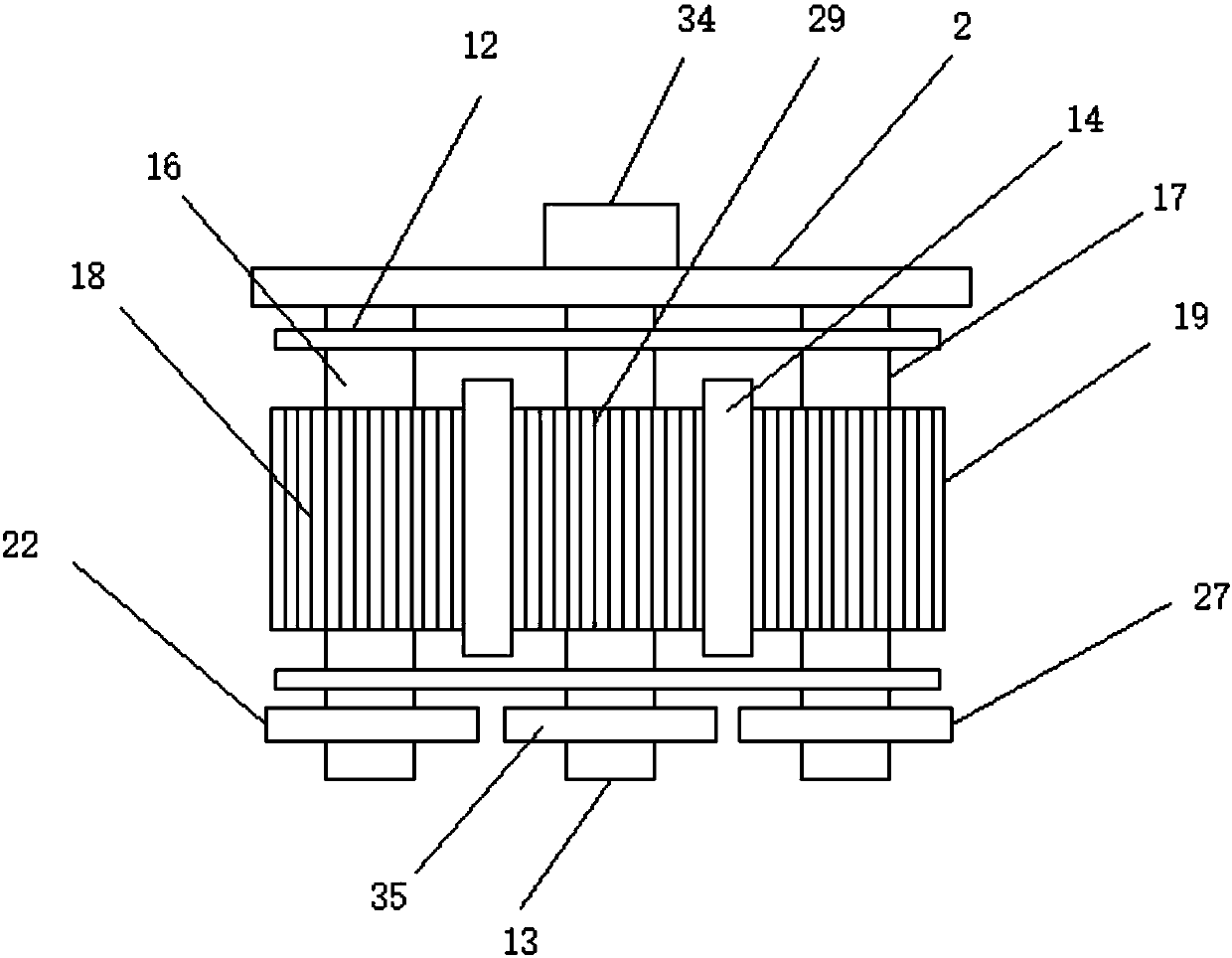

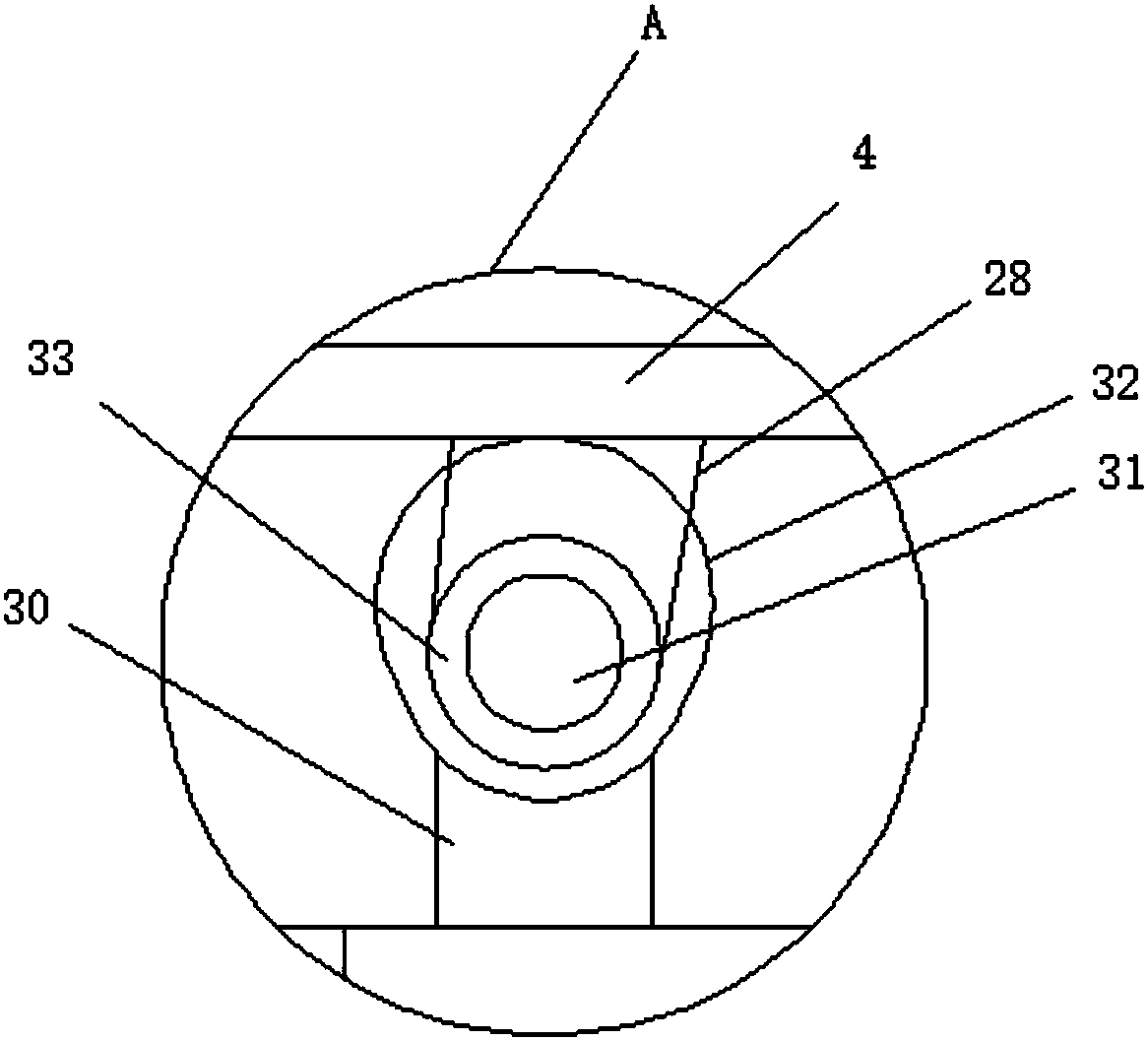

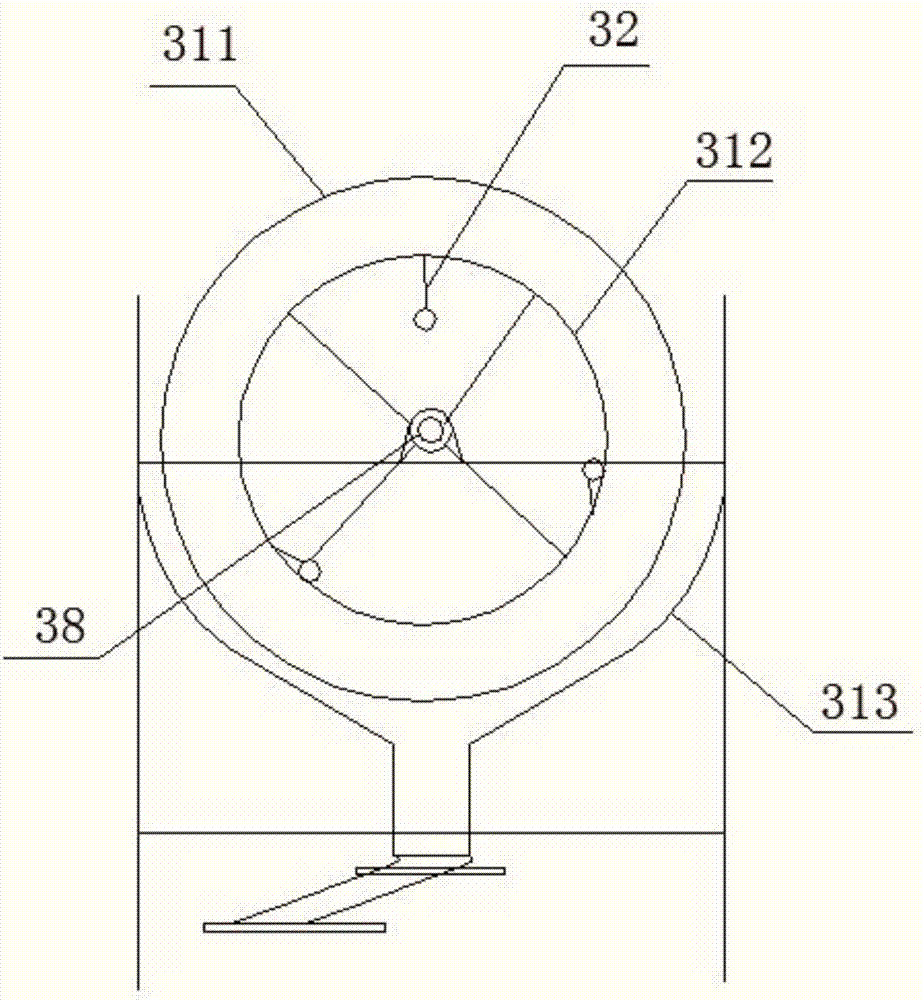

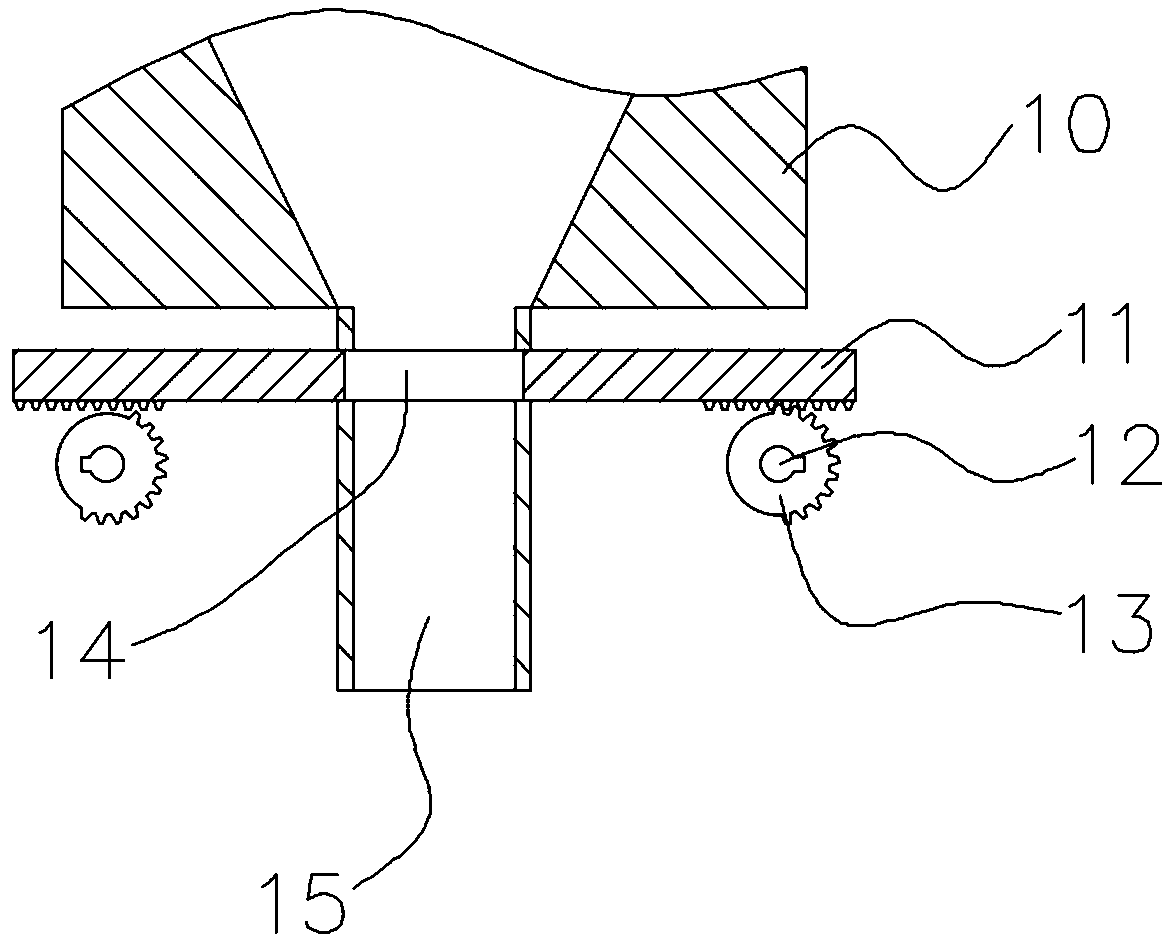

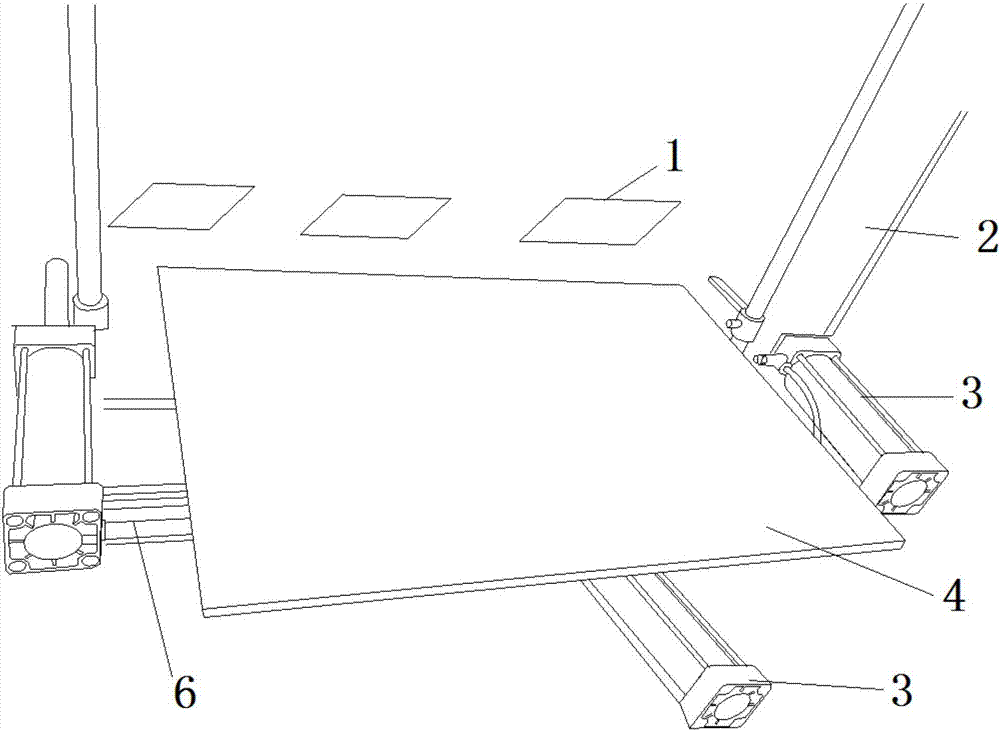

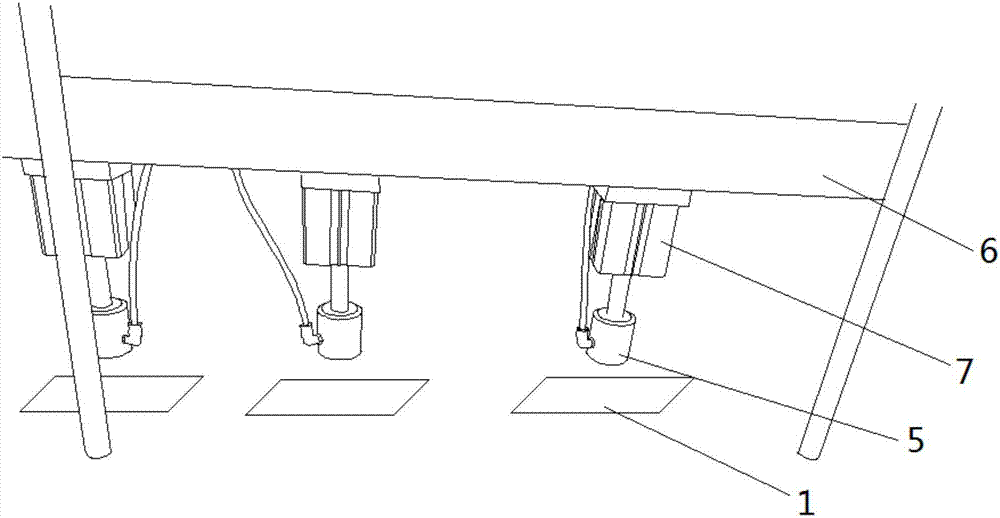

Automatic spraying device for porcelain insulator

ActiveCN109317335ASimple and flexible structureAvoid manual feedingSpray boothsMechanical engineeringUltimate tensile strength

The invention discloses an automatic spraying device for a porcelain insulator. The automatic spraying device comprises a feeding mechanism and a spraying mechanism, the feeding mechanism is composedof a material base, a first hopper, a second hopper, a supporting plate, a control panel, a conveying motor, a feeding sliding groove, a feeding screw rod, a feeding sliding block, a conveying air cylinder, a servo motor, a connecting plate, a fixing plate, clamping sliding grooves, clamping plates and clamping air cylinders, and the supporting plate is fixedly connected to one end of the materialbase. According to the automatic spraying device, in the working process, the porcelain insulator is clamped through the clamping plates and the clamping air cylinders, the angle position of the porcelain insulator is adjusted through the servo motor, so that the porcelain insulator is in a vertical state and then is conveyed to a designated position through the conveying motor, manual feeding isavoided, and therefore the labor intensity of workers is lowered, and the feeding speed is increased; and a steering motor and a lifting air cylinder are arranged, so that materials can be conveniently and continuously rotated and replaced, and therefore the clamping time is shortened, and the processing and replacing efficiency is greatly improved.

Owner:湖南兴华电瓷电器制造有限公司

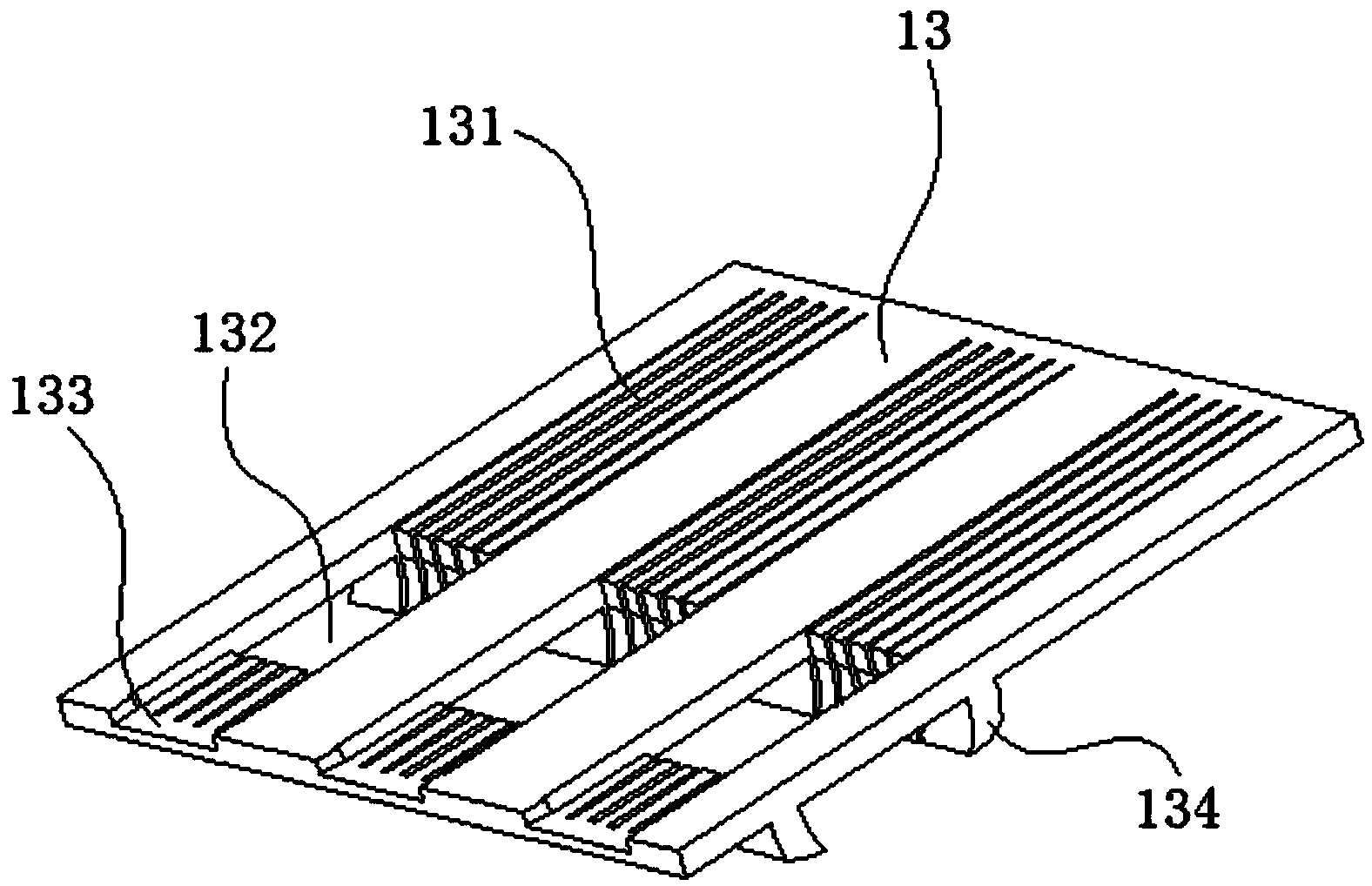

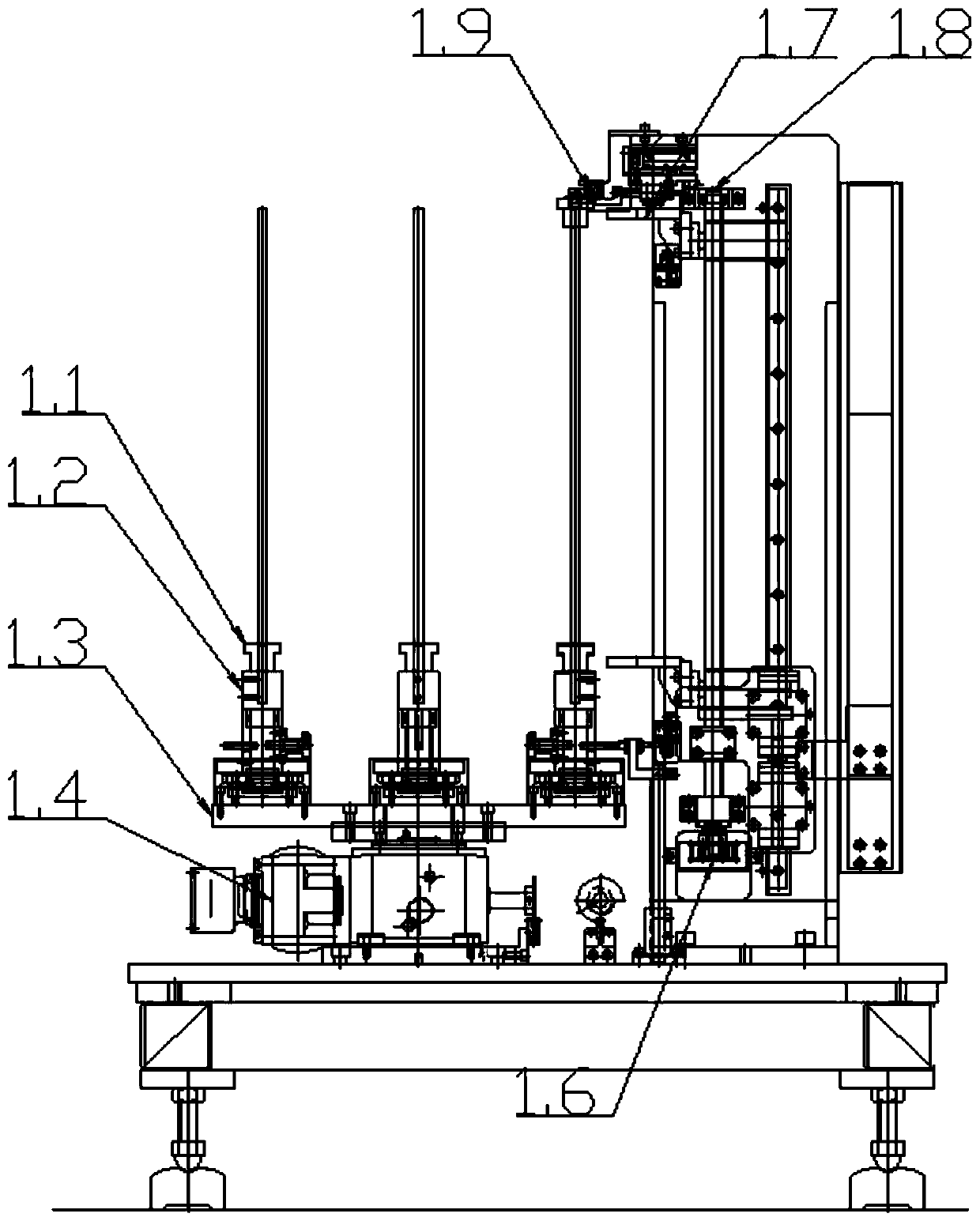

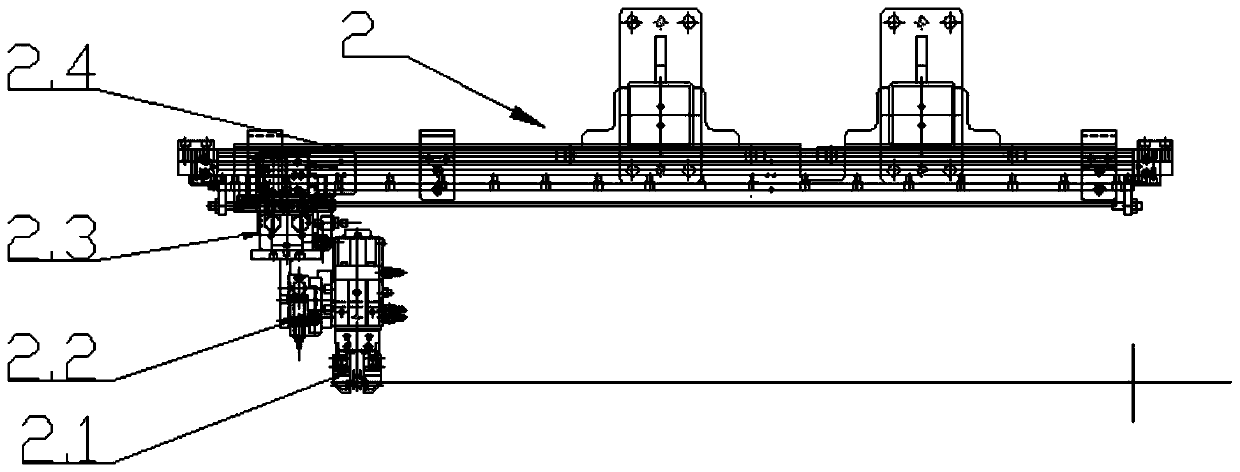

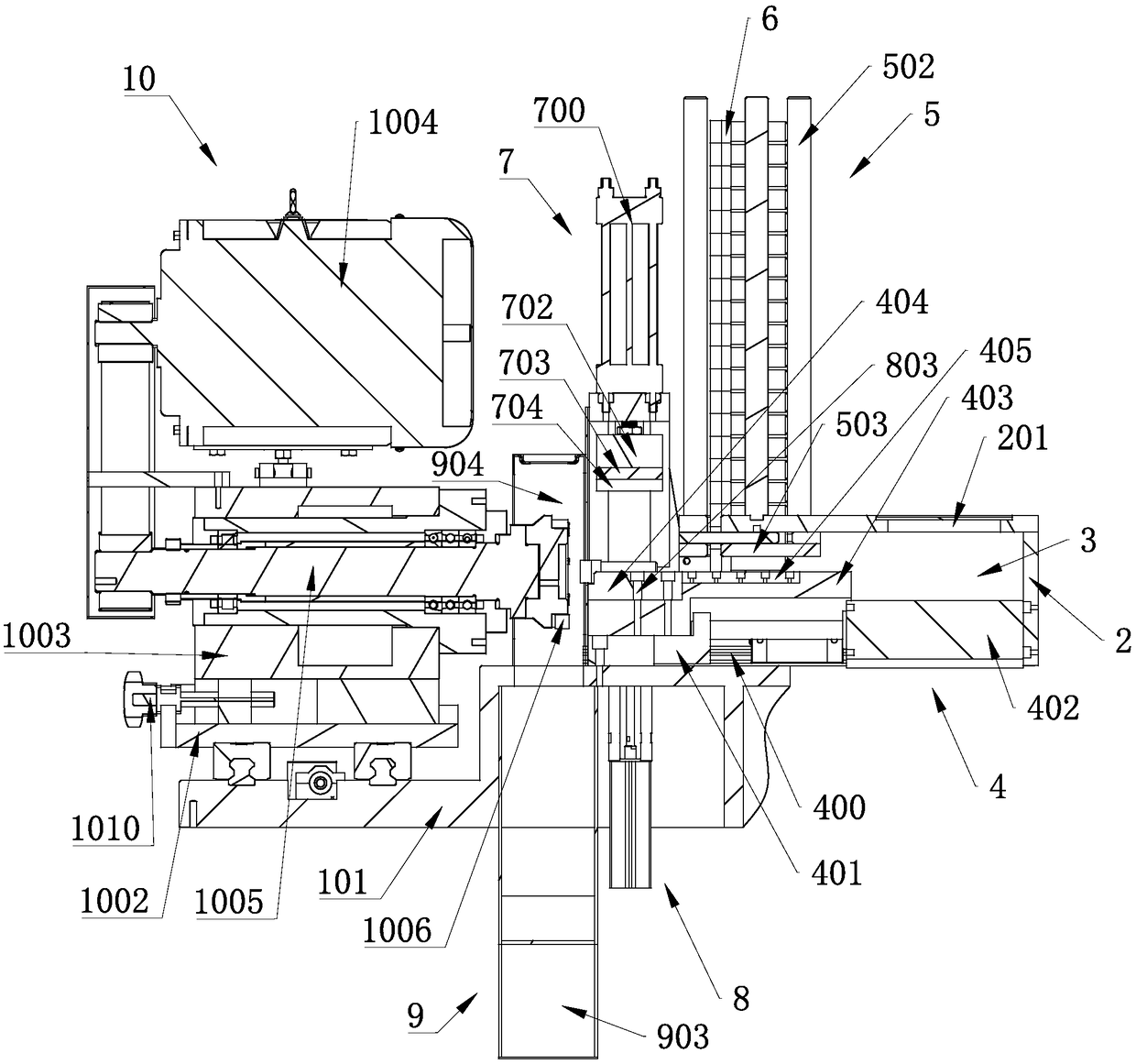

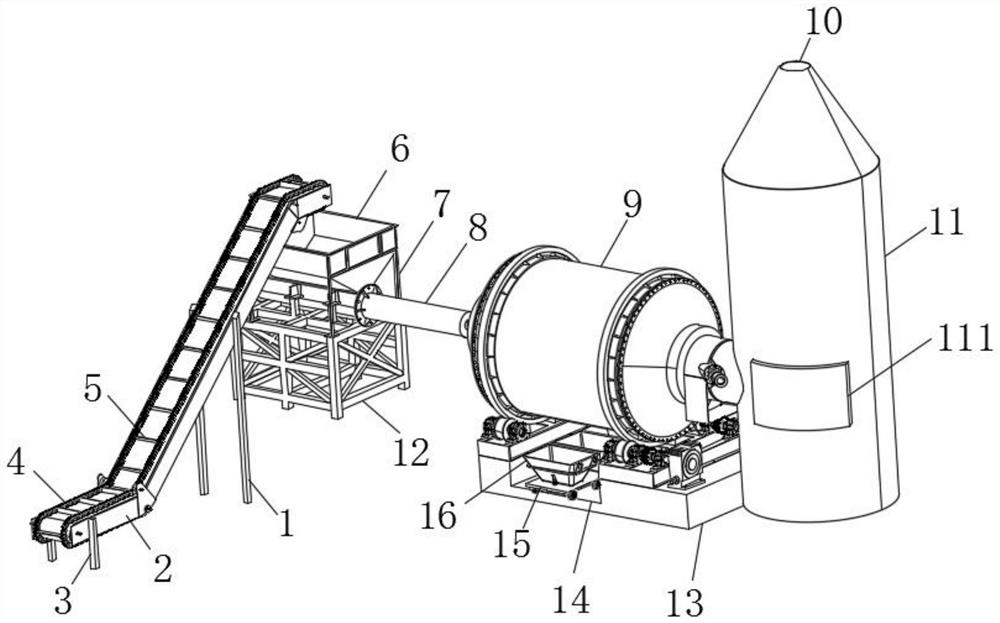

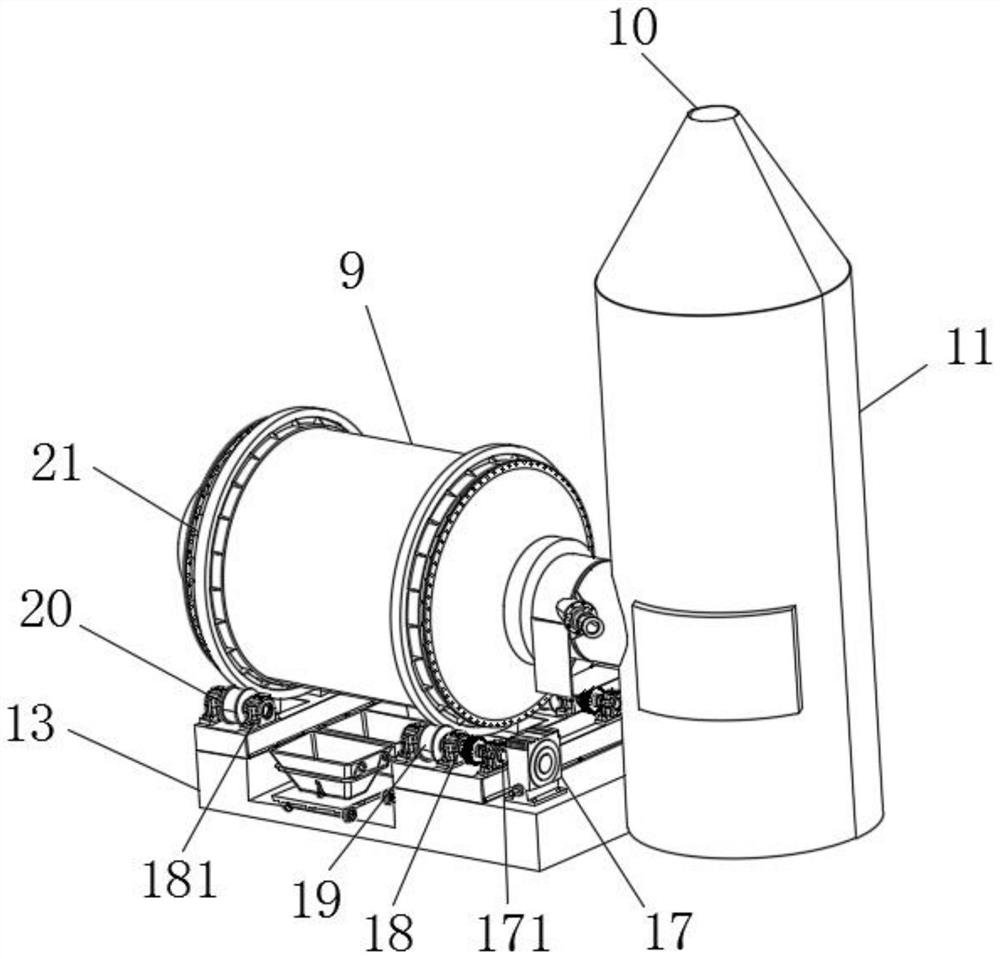

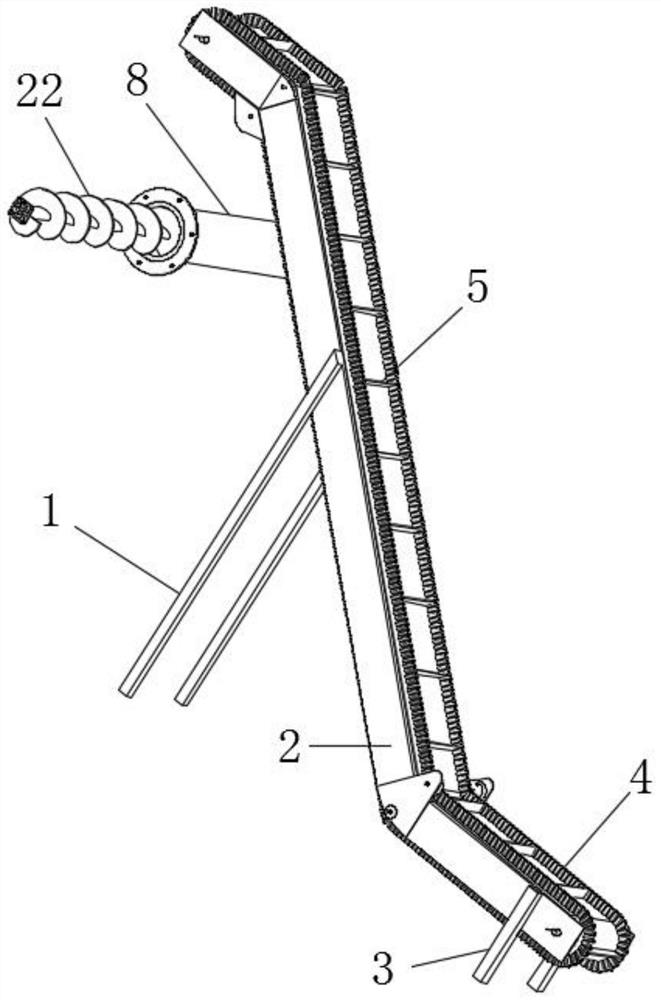

Fermented forage production system

ActiveCN106962963AExtended service lifeReduce labor intensitySievingFeeding-stuffCompression moldingAgricultural science

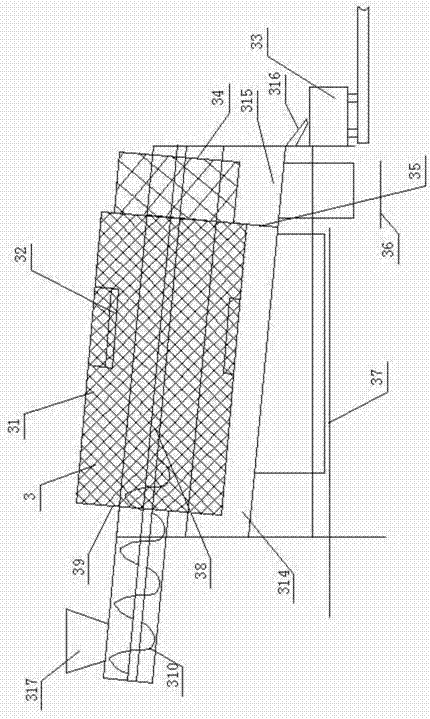

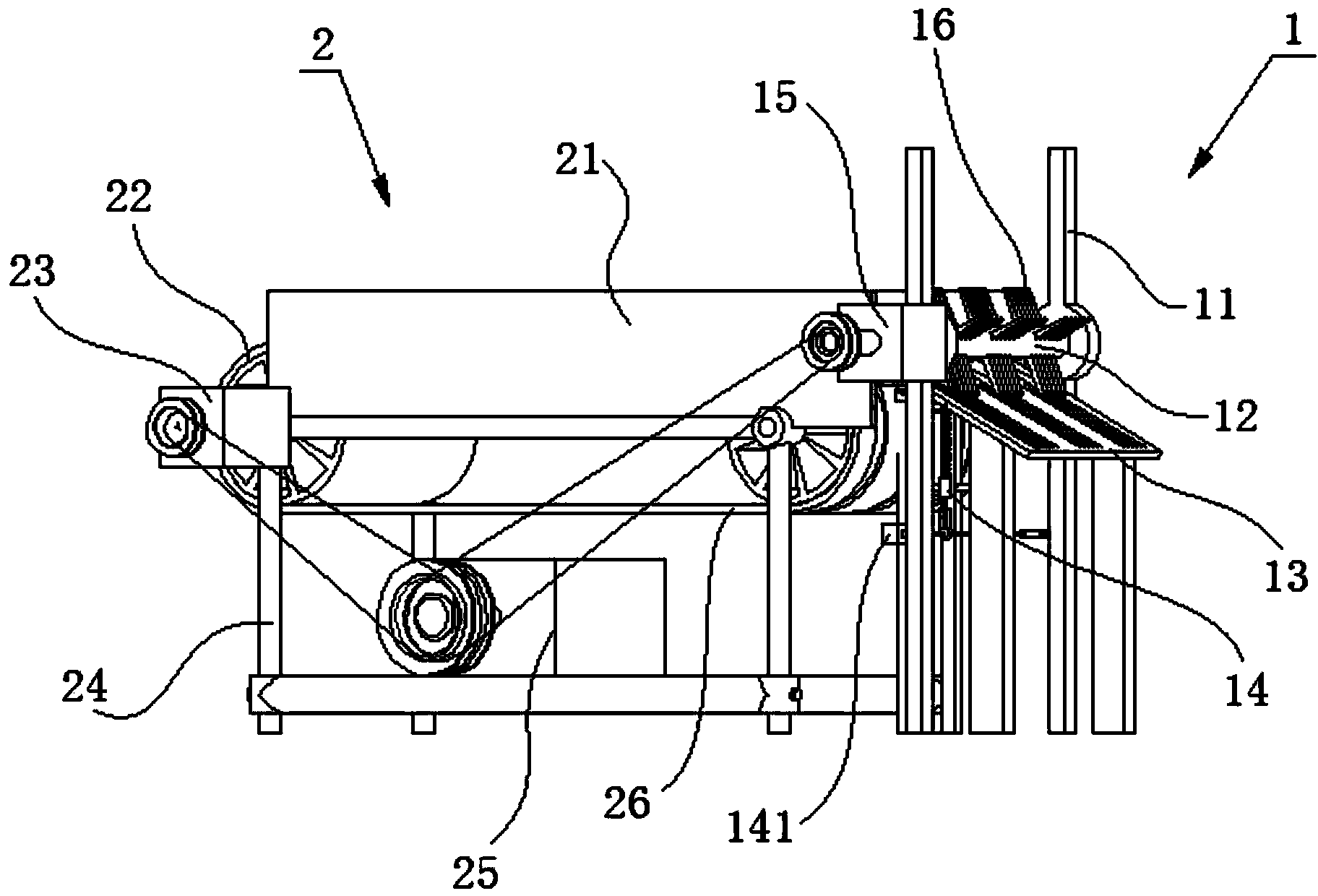

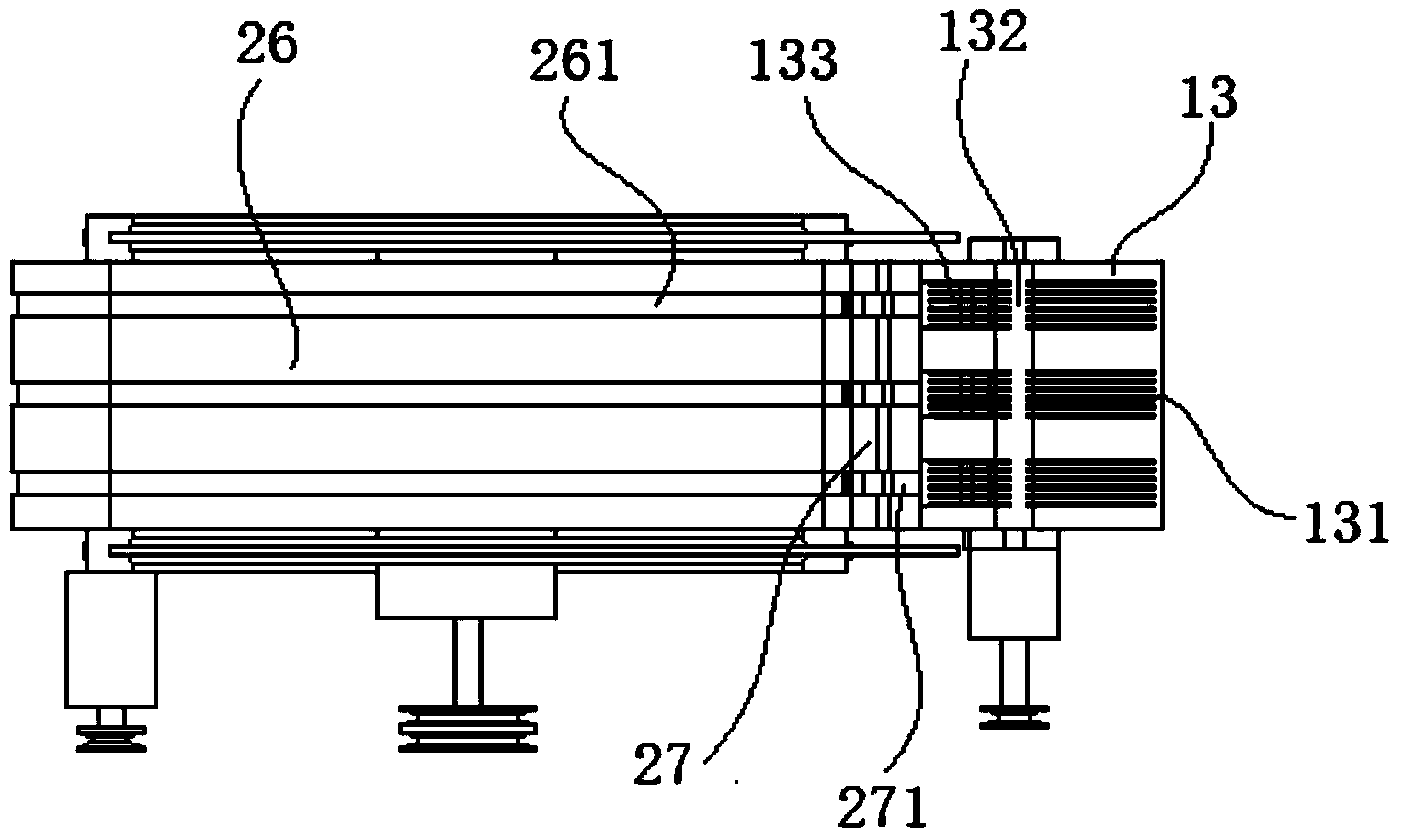

The invention provides a fermented forage production system. The production system comprises a pulverizing device, a screening device, a stirring device, a material metering mechanism, a compression molding machine and a three-dimensional film-wrapping mechanism, all are arranged sequentially along the feeding direction. The three-dimensional film-wrapping mechanism comprises an axial film-wrapping mechanism and a circumferential film-wrapping mechanism. According to the fermented forage production system, materials are pulverized through the pulverizing device; the materials are screened through the screening device and impurities are removed, then raw materials are added through the stirring device and stirred, and fermented forage obtained by processing bacterial bag waste is manufactured into a column shape through the compression molding machine so as to facilitate the sale and transportation. Thin film is wrapped around the entire outer surface of the column-shaped fermented forage by means of the arrangement of the axial wrapping mechanism and the circumferential wrapping mechanism; and the manual operation is not required in the whole process and the whole process is time-saving and labor-saving. The column-shaped fermented forage is continuously wrapped with film, thereby saving the moved time, ensuring the good effect of wrapping the film, reducing the labor strength and labor cost. The fermented forage production system has the advantages of being reasonable in design, convenient to operate, high in using efficiency and improving the process efficiency and process effect of the bacterial bag waste.

Owner:连云港瑞洋牧业有限公司

Cable stripping auxiliary tool convenient for feeding and discharging

ActiveCN111478235ASave processing time and costsAvoid manual feedingApparatus for cutting/splicing cablesApparatus for removing/armouring cablesElectric machineryEngineering

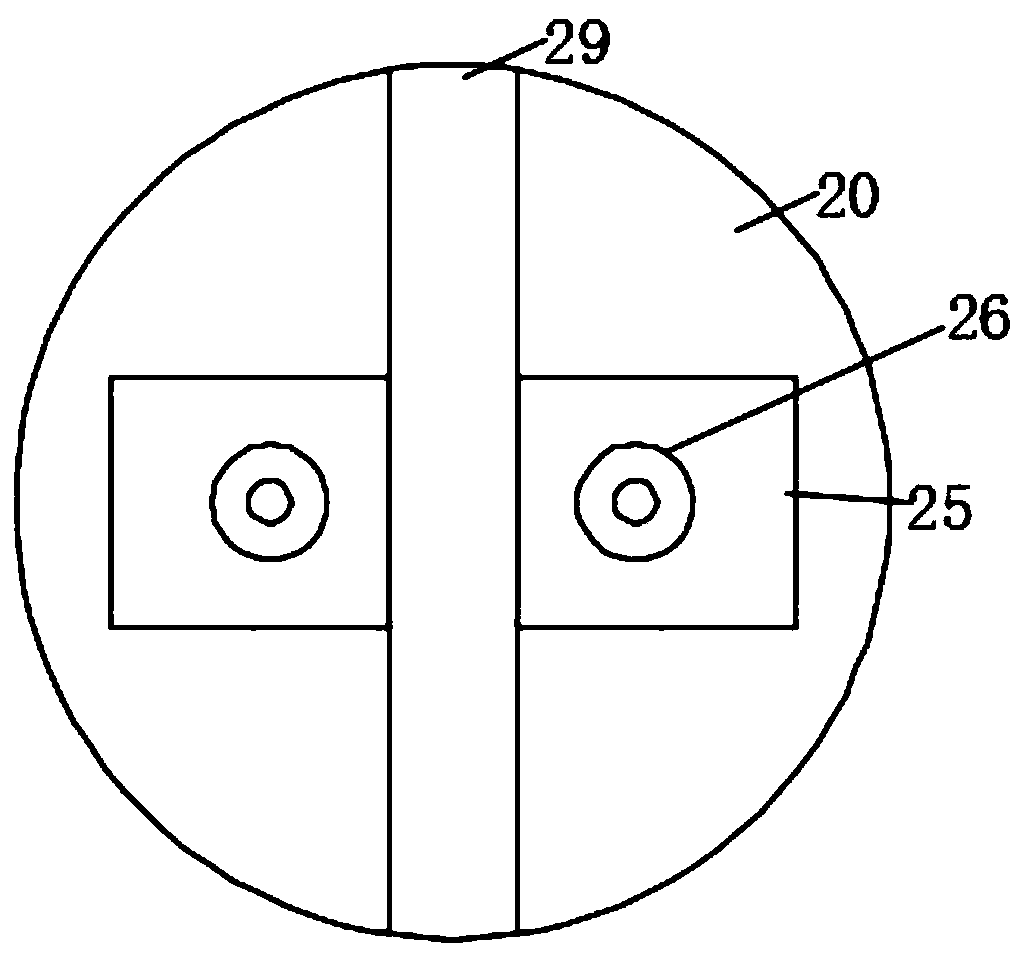

The invention relates to the technical field of cables, and discloses a cable stripping auxiliary tool convenient for feeding and discharging. The cable stripping auxiliary tool comprises a table top,a feeding mechanism, a cutting mechanism and a peeling mechanism are arranged at the top of the table top; the cutting mechanism is located between the feeding mechanism and the peeling mechanism. The feeding mechanism comprises two base plates which are distributed in a bilateral symmetry mode, a first roller and a second roller which are distributed in an up-down symmetry mode are arranged between the two base plates, the two ends of the first roller are movably connected with the two base plates respectively, and the two ends of the second roller are movably connected with the two base plates respectively. According to the cable stripping auxiliary tool facilitating feeding and discharging, the motor is arranged, the feeding mechanism, the cutting mechanism and the stripping mechanismcan be operated after the motor is started, a cutter on the cutting mechanism can intermittently move up and down, long cables can be cut at equal intervals in the stripping process, the two procedures are conducted at the same time, and the machining time and cost are saved.

Owner:周玉旗

Plate bending device for diesel generator production

InactiveCN111167893AAvoid the dangers of hand-heldReduce labor intensityMetal-working feeding devicesPositioning devicesElectric machineStructural engineering

The invention discloses a plate bending device for diesel generator production. A conveying assembly comprises a second mounting frame, a conveying wheel, a rolling wheel, a first belt wheel, a firstfeeding port, a second belt, a groove, a second rotating motor, second belt wheels and a discharging port, wherein the second mounting frame is welded to the position, corresponding to an L-shaped mounting frame, of the outer wall of the top end of a workbench; the second rotating motor is fixed to the outer wall of the top end of the second mounting frame through bolts; the second belt wheels arefixed to the outer walls of the two sides of an output shaft of the second rotating motor in a sleeving manner; and the first feeding port is formed in the outer wall of one side of the second mounting frame in a penetrating manner. The plate bending device is provided with the conveying assembly, steel can be continuously conveyed and pressed to be straight, time and labor are saved, and manualfeeding is avoided; and the plate bending device is further provided with a bending assembly, the steel can be bent, cut off and replaced, the product quality and work efficiency are improved, use isconvenient, and the labor intensity of operators is relieved.

Owner:FUAN XINGSHIDAI MOTOR

Automobile stamping mechanism capable of automatically demolding and feeding

PendingCN112620514AAvoid being inAvoid accidental injuryMetal-working feeding devicesPositioning devicesEngineeringStructural engineering

The invention discloses an automobile stamping mechanism capable of automatically demolding and feeding. The automobile stamping mechanism capable of automatically demolding and feeding comprises a supporting plate, wherein supporting legs are fixedly arranged at the four corners of the lower surface of the supporting plate correspondingly; a material frame is fixedly connected onto the supporting plate; a stamping part is placed in the material frame; a mounting plate is mounted on the supporting plate; an air cylinder is mounted on the upper surface of the mounting plate; the lower end of the air cylinder penetrates through the lower surface of the mounting plate so as to be connected with a stamping plate; a die groove is formed in the lower part of the stamping plate and is formed in the upper surface of the supporting plate; and the upper end of a limiting supporting piece is arranged in the die groove. The automobile stamping mechanism capable of automatically demolding and feeding has the functions of automatic feeding and automatic demolding and discharging, limbs of workers can be prevented from being located below a stamping structure, then the working efficiency can be improved, and the workers can be prevented from being accidentally injured.

Owner:黄浩然

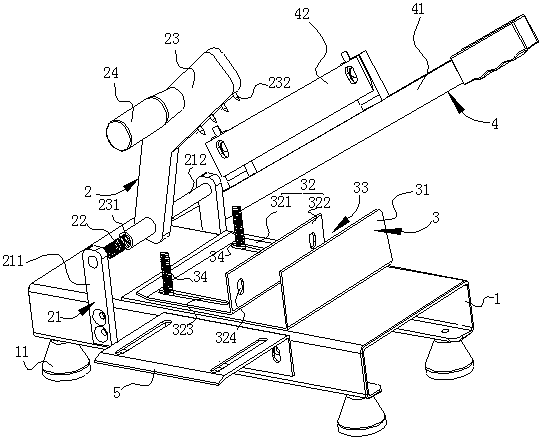

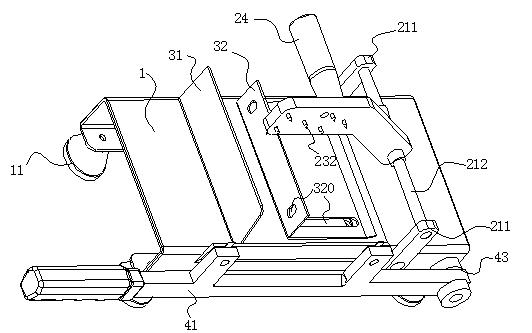

Fruit and vegetable slicing machine

InactiveCN104015218APrecise deliveryPrecise positioningMetal working apparatusSlice thicknessAgricultural engineering

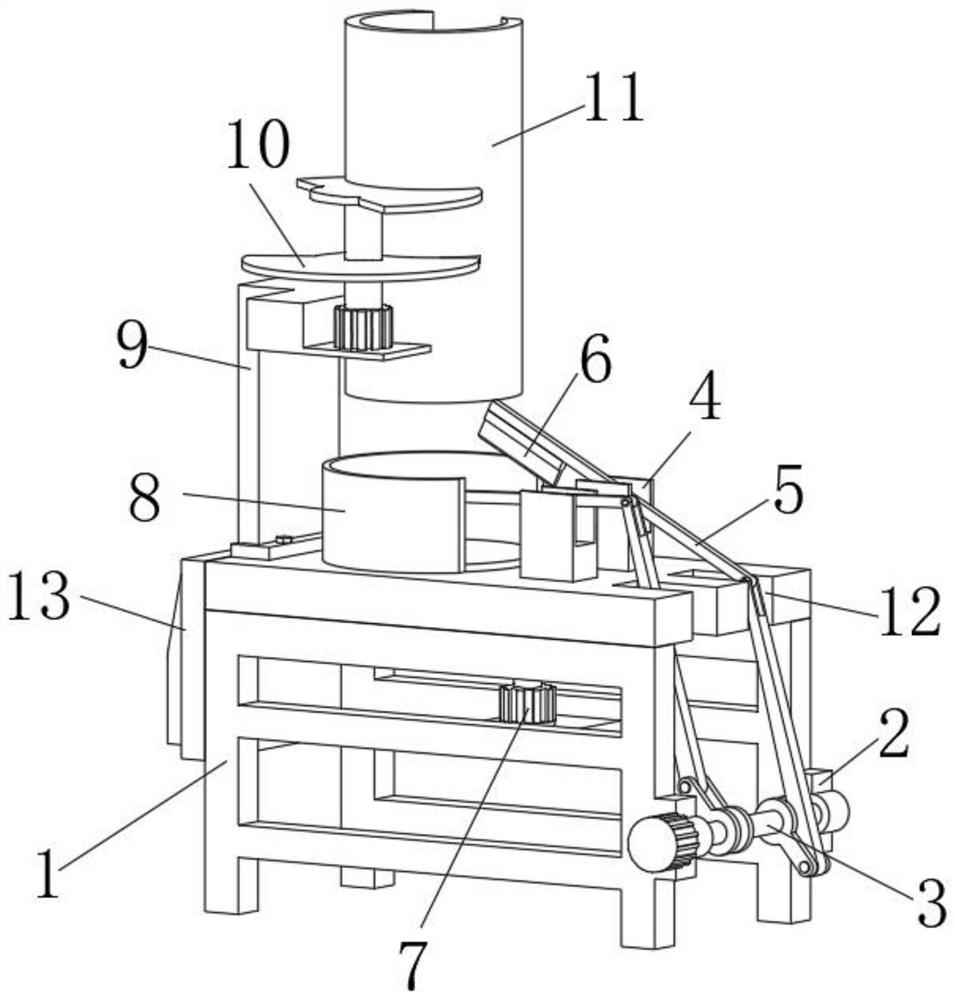

The invention discloses a fruit and vegetable slicing machine which comprises a slicing table, a slicing cutter, a first driving piece, a slicing plate and a gasket assembly, wherein the slicing cutter comprises a cutter shaft arranged on the slicing table and a plurality of slicing units arranged on the cutter shaft, the first driving piece is connected with the cutter shaft, the slicing plate is arranged on the slicing table in a slant mode and located below the slicing cutter, the slicing plate is provided with a plurality of first cutter groove sets corresponding to the slicing units in a one-to-one mode, a fruit and vegetable cavity and a first guide groove are formed in each first cutter groove set in the slicing plate, the gasket assembly comprises gaskets and a lifting mechanism, the gaskets are arranged below the slicing plate and correspond to the fruit and vegetable cavities, an upper plate faces of the gaskets are slant faces, the gaskets are provided with a plurality of second cutter groove sets corresponding to the first cutter groove sets, and the lifting mechanism is connected with the gaskets to drive the gaskets to be lifted. By means of the fruit and vegetable slicing machine, fruits and vegetables are conveniently and accurately conveyed and located, slicing sheets are even in thickness, and the fruit and vegetable slicing machine is safe and reliable.

Owner:GUANGXI UNIV

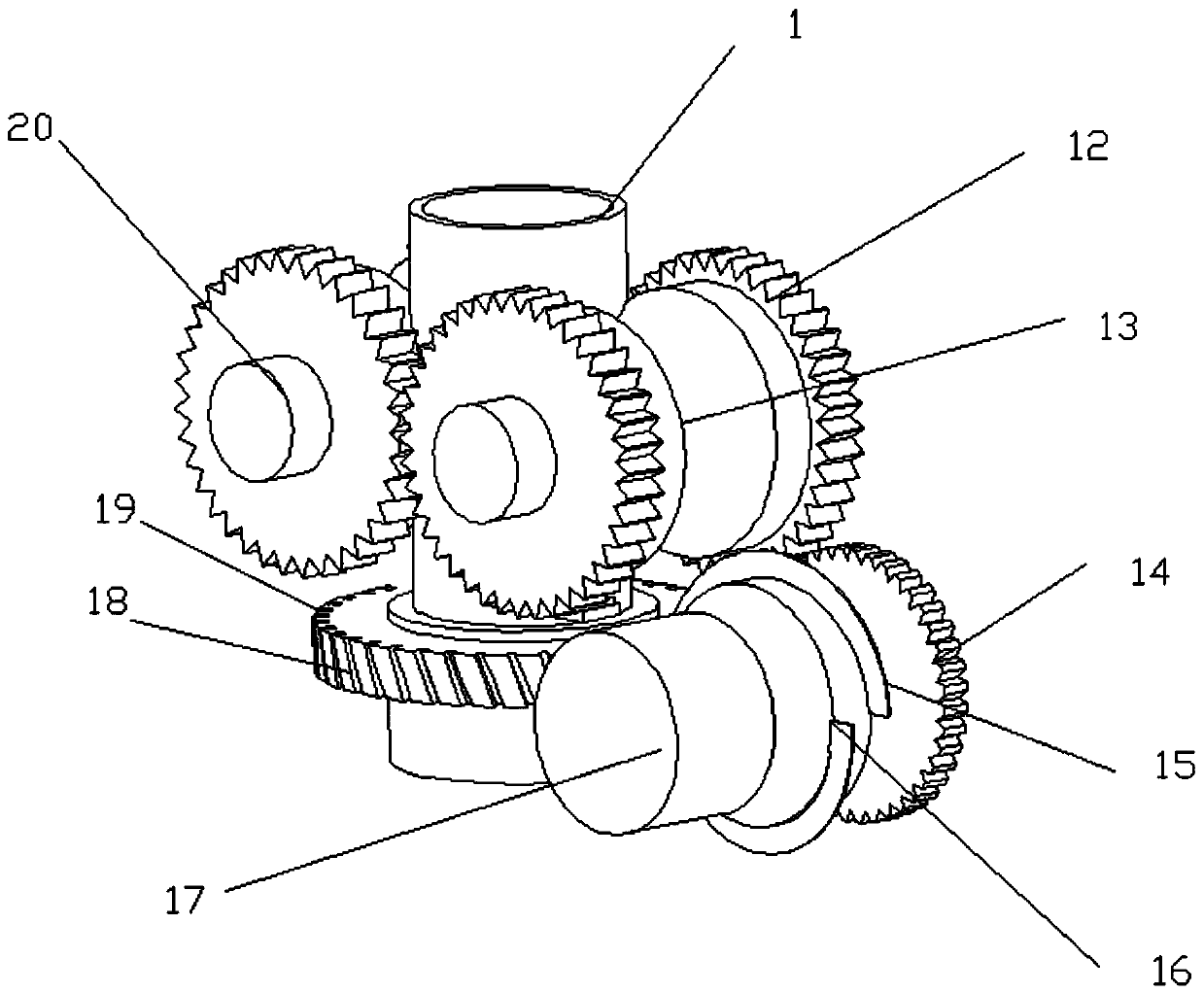

Energy-saving corn threshing machine

ActiveCN110249804AAct as a downward driveAvoid wastingSaving energy measuresThreshersDrive wheelSpiral blade

The invention relates to the technical field of agriculture, and particularly discloses an energy-saving corn threshing machine. The energy-saving corn threshing machine comprises a shell, the top of the shell is communicated with a feeding hopper, transmission pieces are rotatably arranged at the inner top of the shell, the bottom of the feeding hopper is rotatably communicated with the top of a threshing cylinder, each transmission piece comprises a transmission roller and driven gears, every two driven gears are coaxially and fixedly connected to the two ends of the corresponding transmission roller, a driven wheel is coaxially and fixedly arranged on the outer side wall of the threshing cylinder, and several slant grooves are uniformly formed in the driven wheel; a motor is installed inside the shell, a driving wheel and a driving gear are connected to the motor, and spiral blades are fixedly arranged on the outer side wall of the driving wheel, and embedded in the slant grooves; a separating piece is fixedly arranged below the threshing cylinder and communicated with a corn kernel outlet, and a material guiding piece is arranged inside the shell and communicated with a corn cob outlet. The energy-saving corn threshing machine has the advantages of being simple in structure, high in production efficiency and threshing quality, low in production cost, high in threshing recycling rate and cleanliness level, and convenient to popularize and implement.

Owner:辽宁展华实业有限公司

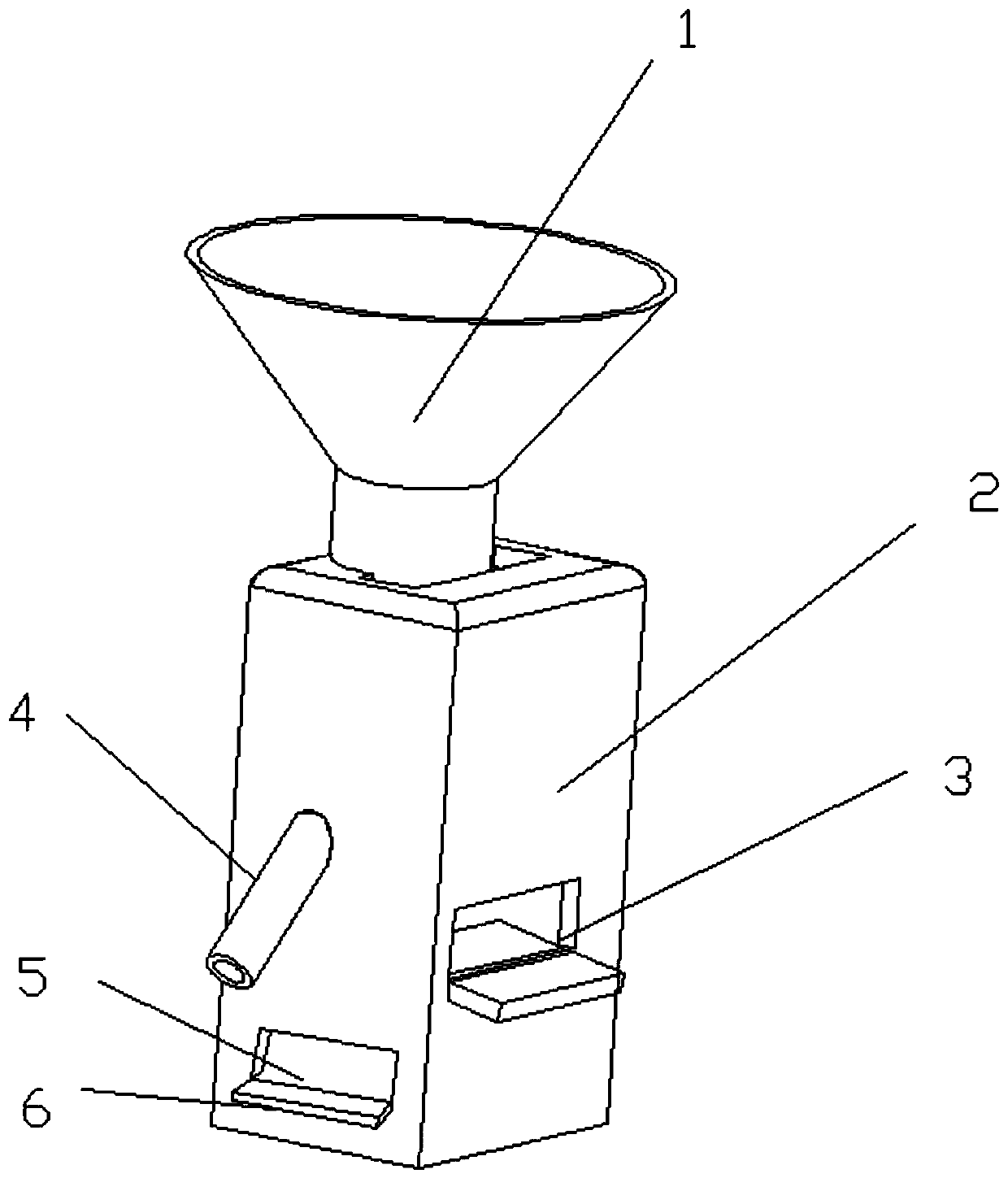

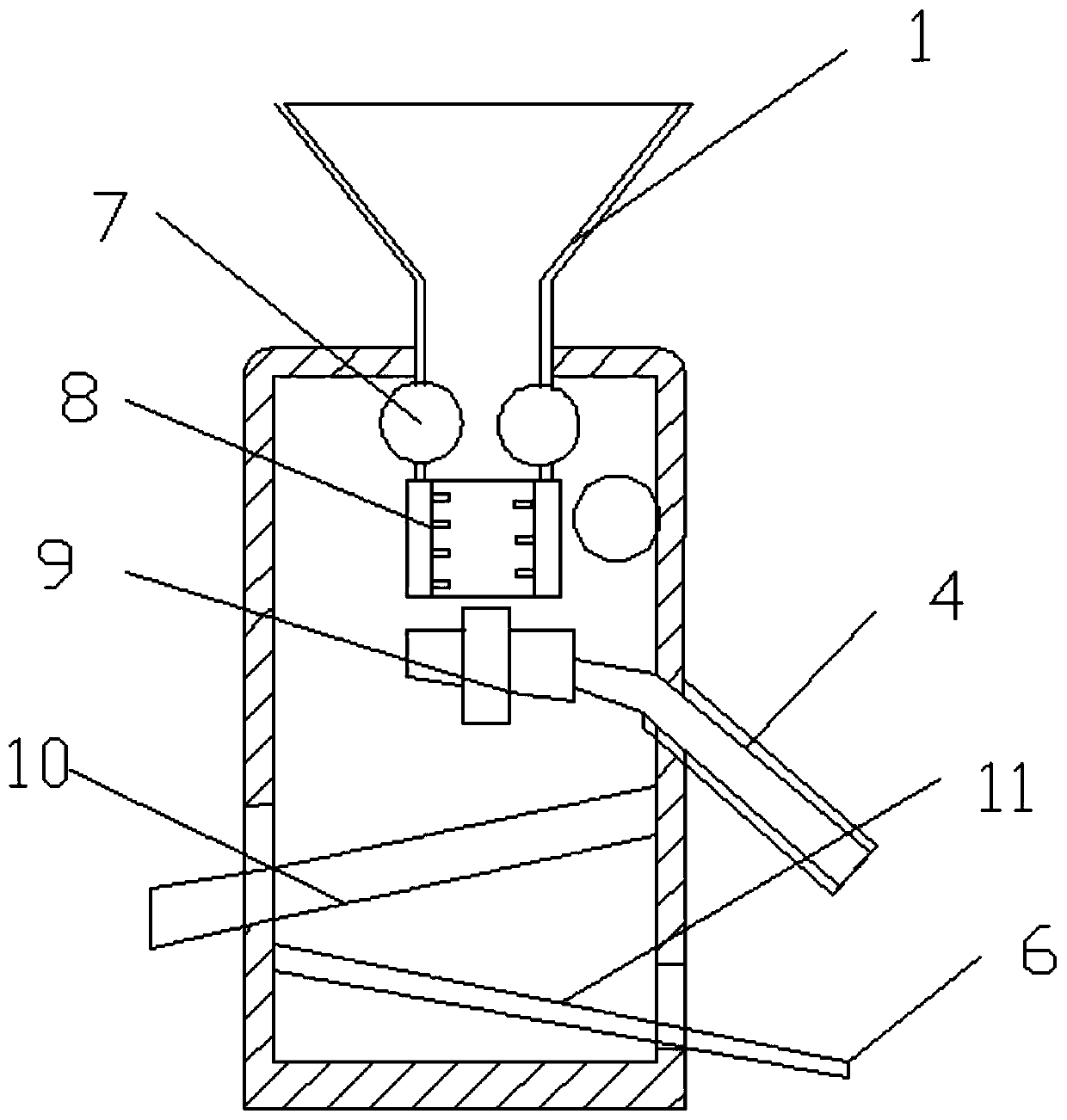

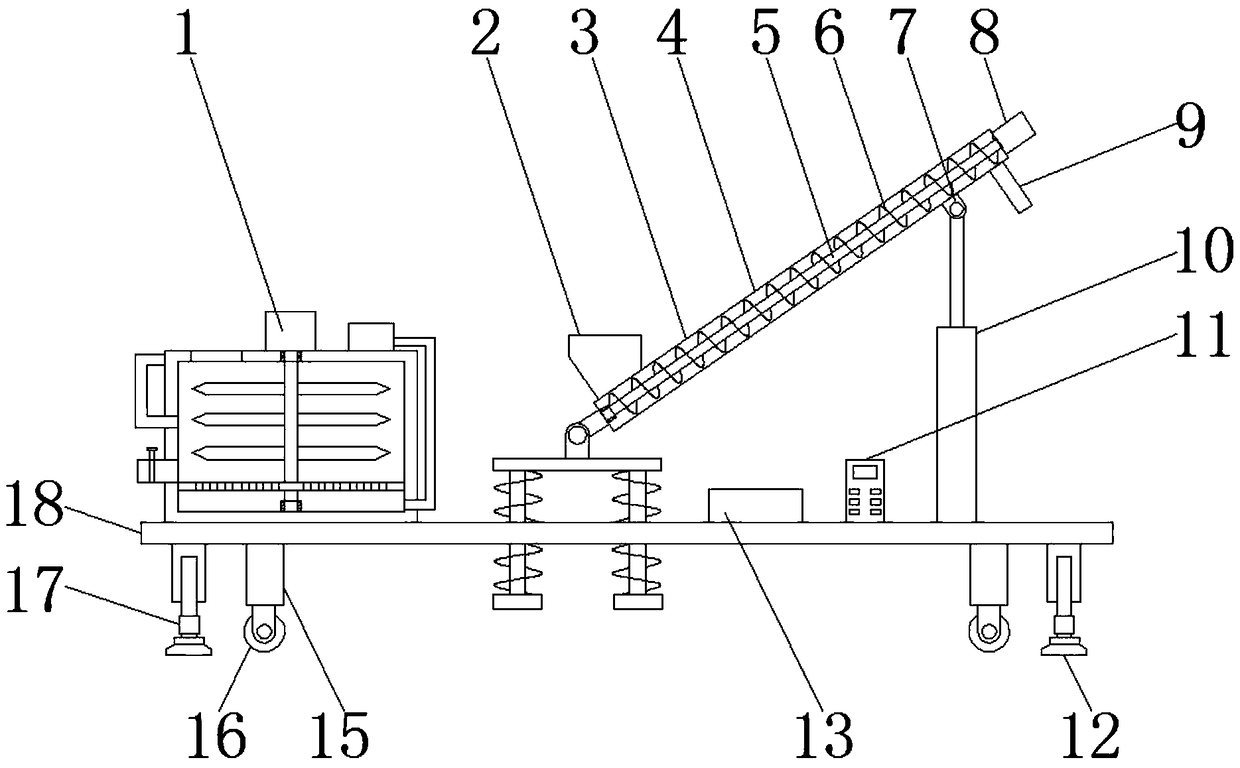

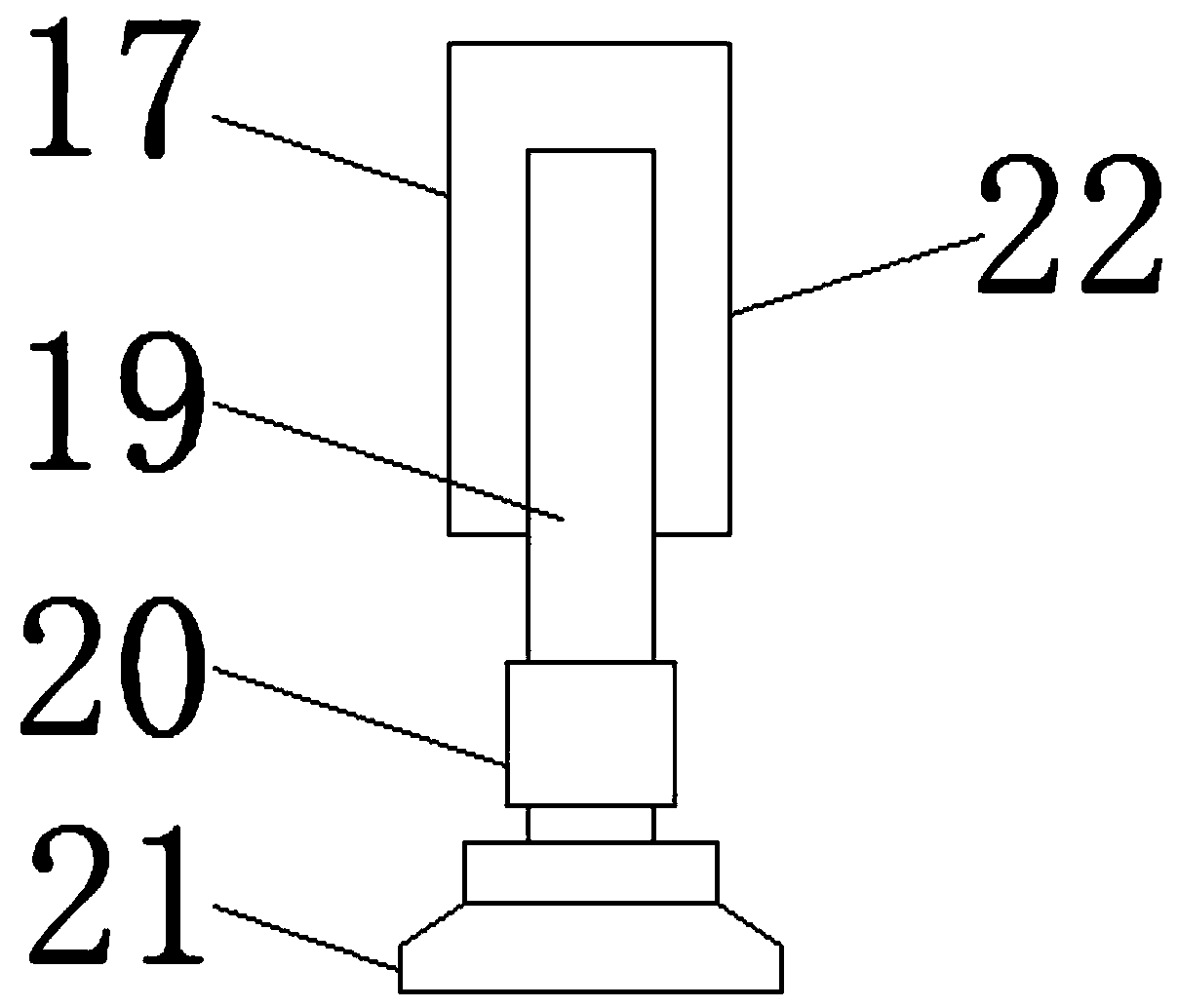

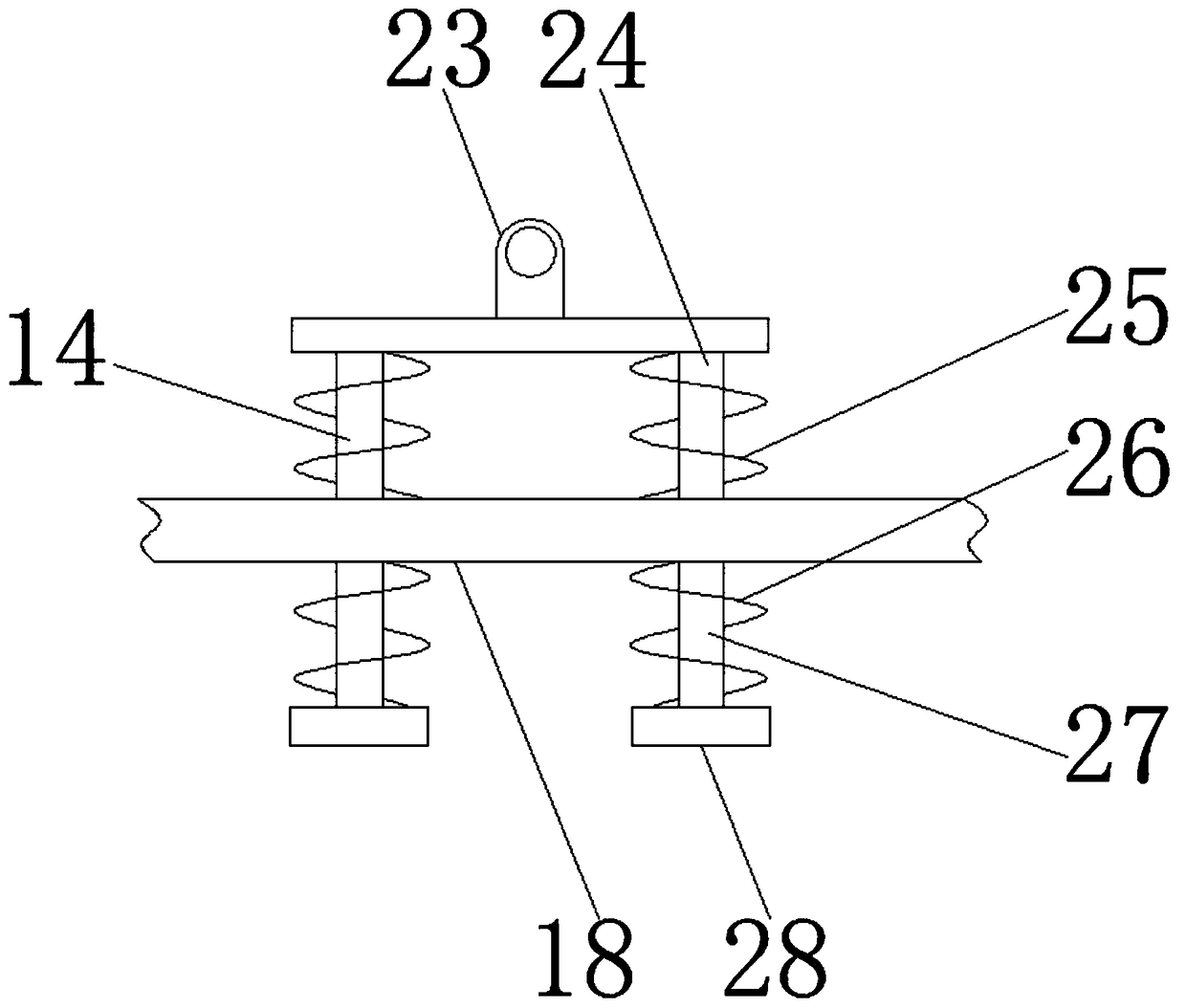

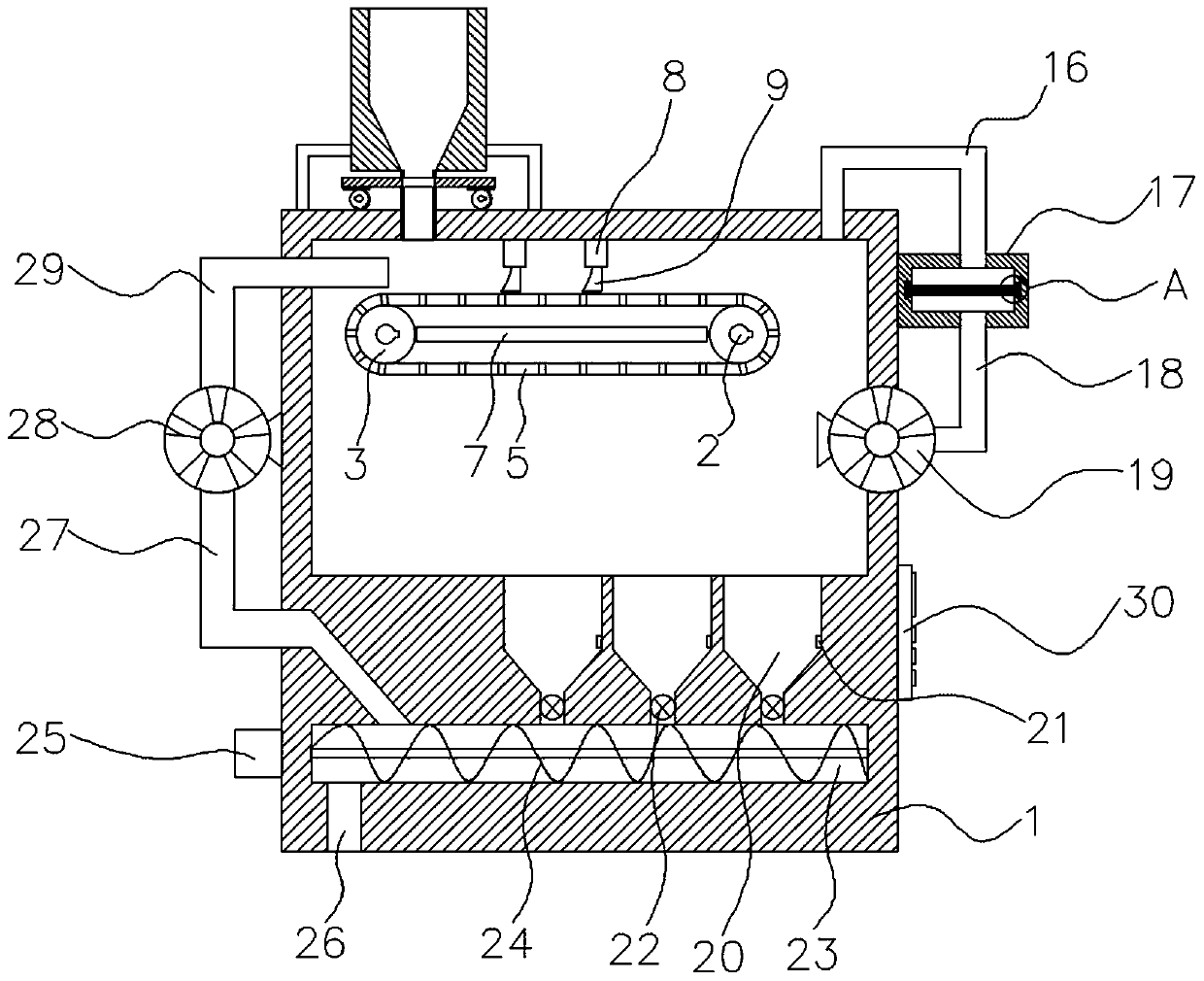

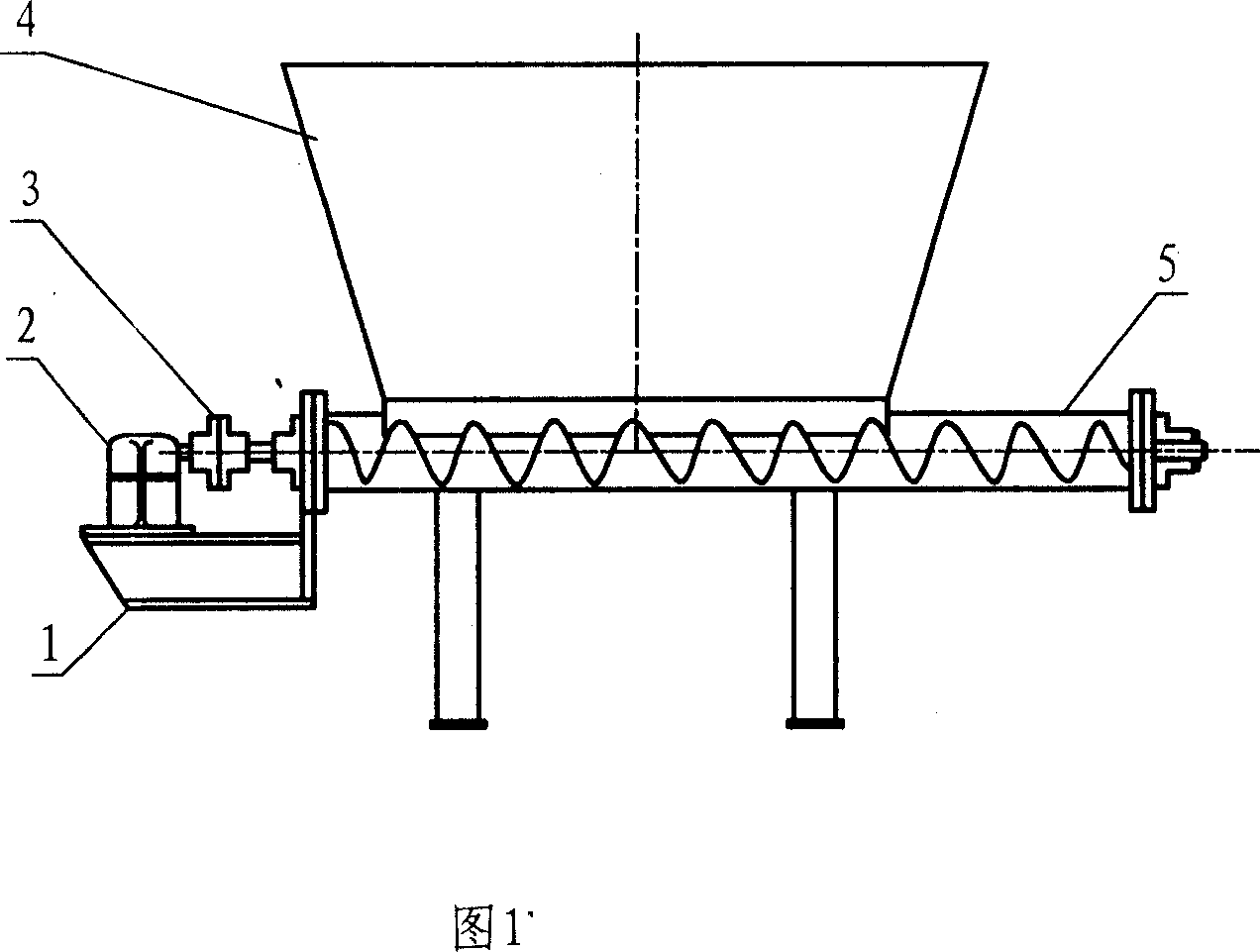

Automatic feed device with pre-processing function for forage production

InactiveCN108855534ARealize the purpose of heating and dryingRealize automatic feeding processNon-rotating vibration suppressionPackagingGround contactEngineering

The invention discloses an automatic feed device with a pre-processing function for forage production. The automatic feed device with the pre-processing function comprises a fixing sleeve, a first motor, a cylinder, a second motor and a base plate. Through the fixing sleeve, a user can conveniently rotate a screw rod to drive the base to move downwards and be contact with the ground to fix the base to the ground and achieve the aim of fixing the position of equipment, avoid moving of the equipment, and improve practicability of the equipment. Through the first motor, spiral conveying blades ata conveying rotating shaft are driven to rotate, and therefore materials are lifted to be discharged from a discharging pipe. In this way, automatic feeding is achieved, manual feeding is not required, and feeding efficiency is improved. A piston rod is driven by a cylinder to stretch out and retract back, and therefore the aim of adjusting the inclination angle of a first cylinder body is achieved, and requirements to the inclination angles of the first cylinder body under different circumstances are met.

Owner:张孝法

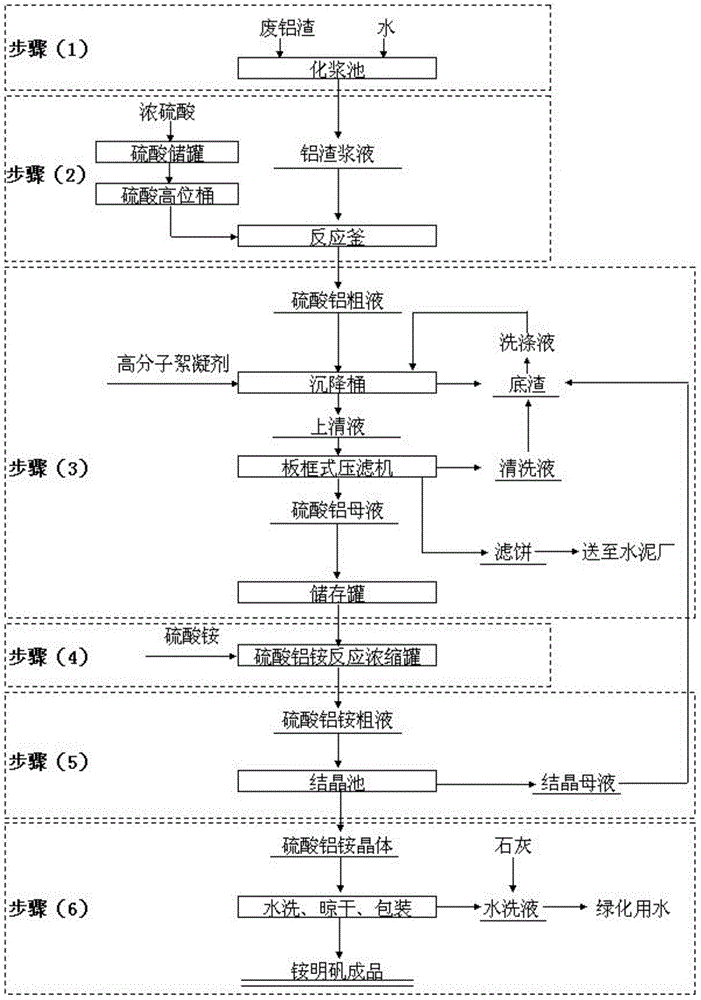

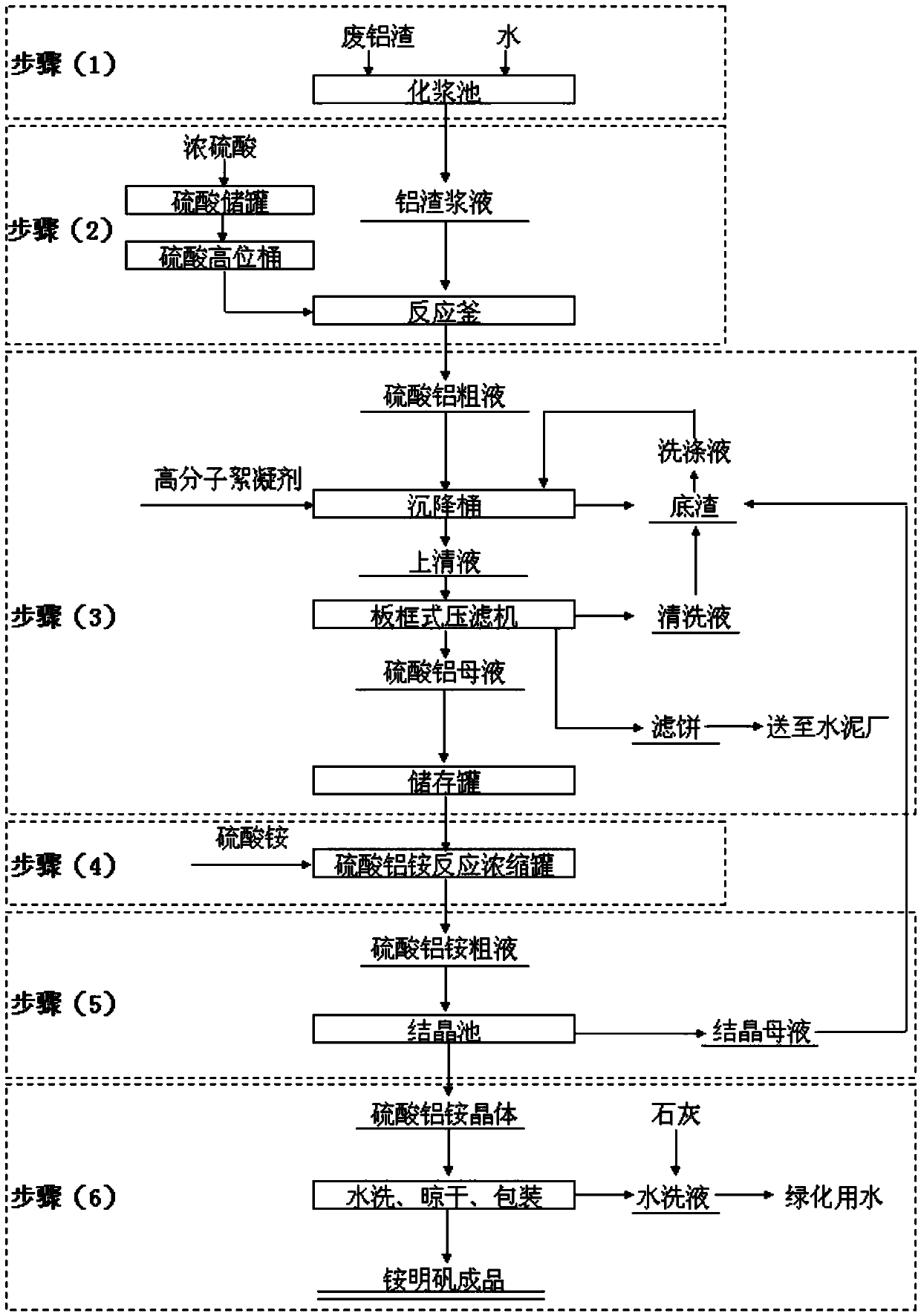

Method for producing aluminum ammonium sulfate crystal

ActiveCN104445330AEfficient use ofReduce pollutionAluminium sulfatesAluminium sulfateAluminum ammonium sulfate

The invention discloses a method for producing an aluminum ammonium sulfate crystal from an industrial waste (aluminum residue). The method for producing the aluminum ammonium sulfate from aluminum residue comprises the following steps: (1) preparing an aluminum residue slurry from aluminum residue; (2) enabling the aluminum residue slurry to react with concentrated sulfuric acid to generate a crude aluminum sulfate solution; (3) precipitating to separate the crude aluminum sulfate solution; (4) enabling aluminum sulfate to react with aluminum sulfate to generate a crude aluminum ammonium sulfate solution; (5) cooling to crystallize the crude aluminum ammonium sulfate solution; and (6) washing the aluminum ammonium sulfate crystal with water, airing, and packaging to obtain the finished product of aluminum ammonium sulfate. Because aluminum residue is used as the raw material to produce the aluminum ammonium sulfate crystal, the production cost can be reduced. A small amount of aluminum residue is used, but an additional benefit can be achieved. The wastewater can be recycled. The process for producing the aluminum ammonium sulfate crystal is simple, is convenient to operate, is highly safe, is low in production cost, consumes less energy and is suitable of large-scale production.

Owner:广西北部湾粮油技术研究有限公司

Building material feeding and stirring device

InactiveCN106738336AEasy to pourImprove practicalityDischarging apparatusMixing operation control apparatusEngineeringUltimate tensile strength

The invention provides a building material feeding and stirring device. The building material feeding and stirring device comprises a feeding device and a water adding, stirring and discharging device, wherein the feeding device comprises a first motor, a feeding box and a guiding box; the left end of the feeding box is welded on the right side surface of a fixing plate, and the right end of the feeding box is arranged above the left side of of a uniform water tank; the first motor is fixedly arranged on the fixing plate; one end of the guiding box is arranged in the right side of the feeding box, and the other end of the guiding box is arranged in a stirring box through the uniform water tank; the water adding, stirring and discharging device comprises a baffle plate, scraping plates, the stirring box and the uniform water tank; the uniform water tank is fixedly arranged on the stirring box through bolts; the scraping plates are welded on fixed links; and the baffle plate is fixedly arranged on a rotating shaft. According to the building material feeding and stirring device, manual feeding is avoided, the labor intensity is reduced, residual materials on the inner wall are removed through the scraping plates, meanwhile, mixed concrete can be conveniently poured out, and therefore, the practicability is high.

Owner:河南常青藤信息科技有限公司

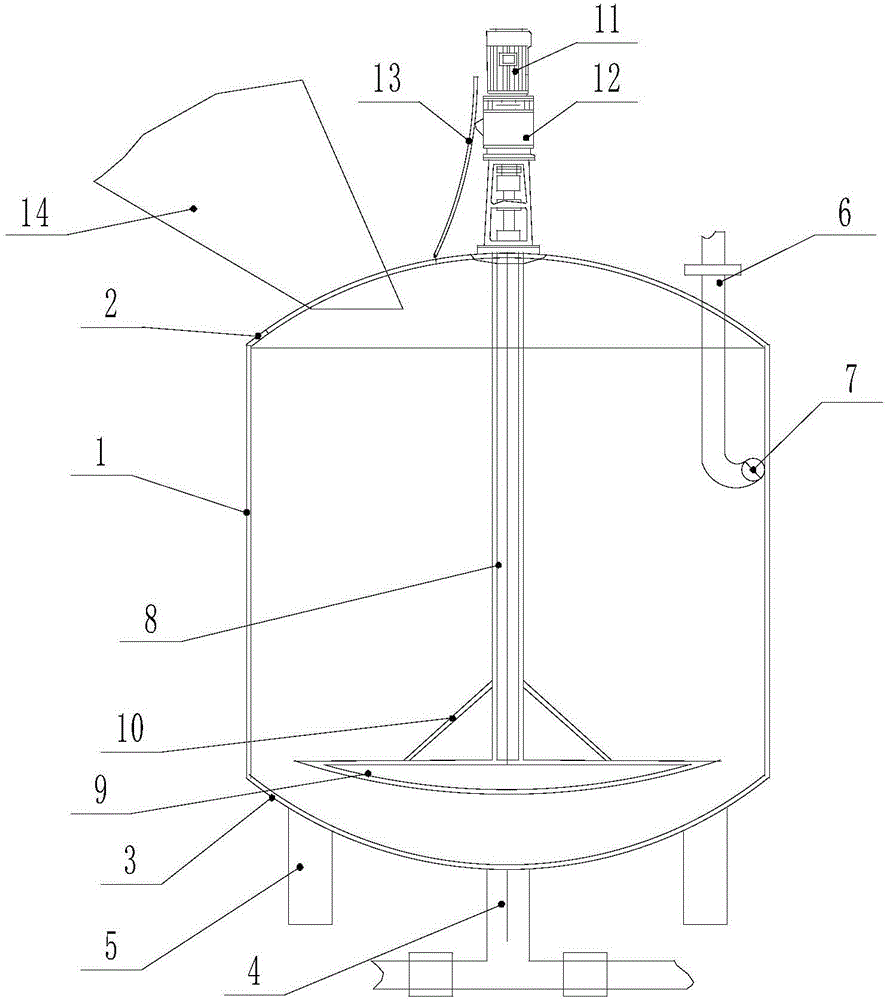

Zinc sulfate preparation reaction kettle for optical infrared imaging

ActiveCN104587941AAvoid corrosionPrevent splashZinc sulatesChemical/physical/physico-chemical stationary reactorsSulfateZinc

The invention discloses a zinc sulfate preparation reaction kettle for optical infrared imaging. The zinc sulfate preparation reaction kettle comprises a kettle body, a mixing shaft rotationally arranged on the kettle body, and a motor used for driving the mixing shaft to rotate, wherein polytetrafluoroethylene coatings are arranged on the inner wall of the kettle body and the outer surface of the mixing shaft, the kettle body comprises a kettle top, a kettle body and a kettle bottom, the kettle bottom is provided with a zinc sulfate discharging pipe, a sulfuric acid adding pipe is arranged at one side of the kettle top, an outlet end of the sulfuric acid adding pipe extends into the kettle body and is clung to the inner wall of the kettle body, the liquid discharging direction of the sulfuric acid adding pipe is tangent to the inner wall of the kettle body, a zinc oxide adding hole is formed in the other side of the kettle top, a feeding hopper is formed in the zinc oxide adding hole, and the feeding hopper is connected with a zinc oxide conveying device. According to the zinc sulfate preparation reaction kettle, sulfuric acid is not splashed when being added, and meanwhile, zinc oxide is conveniently added.

Owner:张家港汇普光学材料有限公司

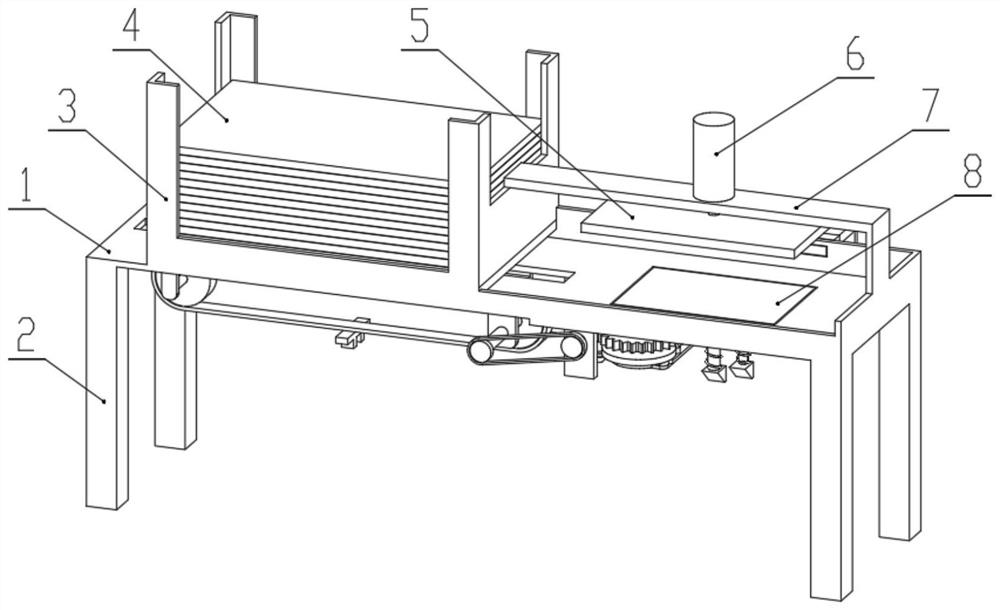

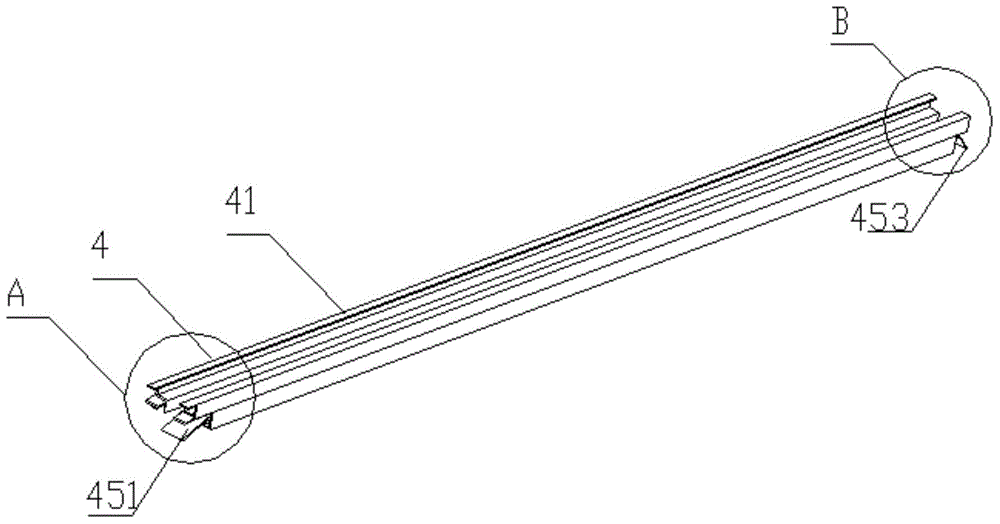

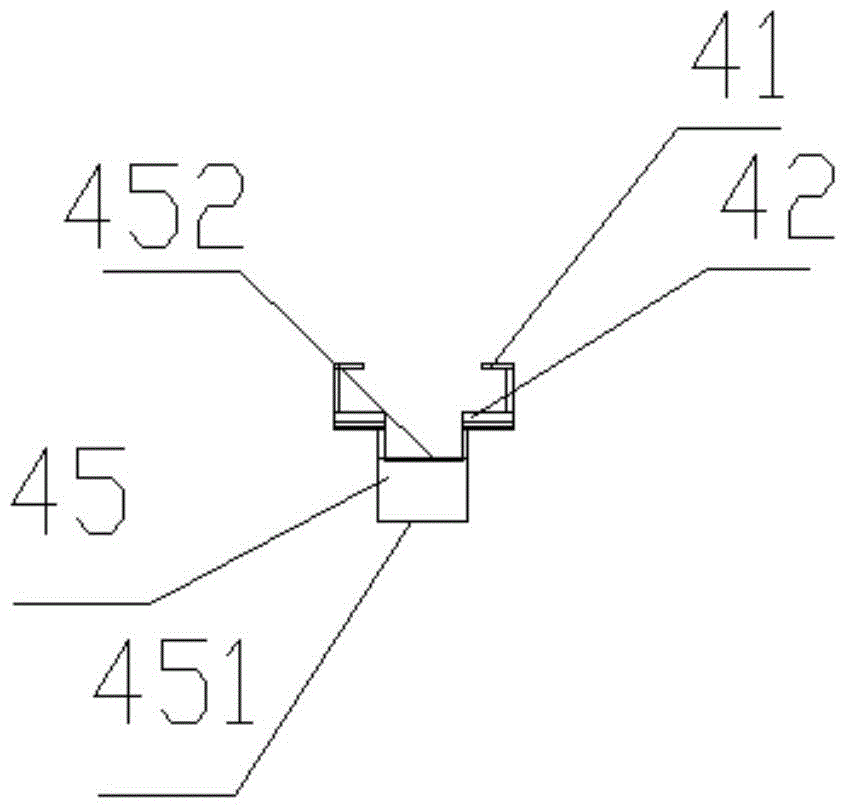

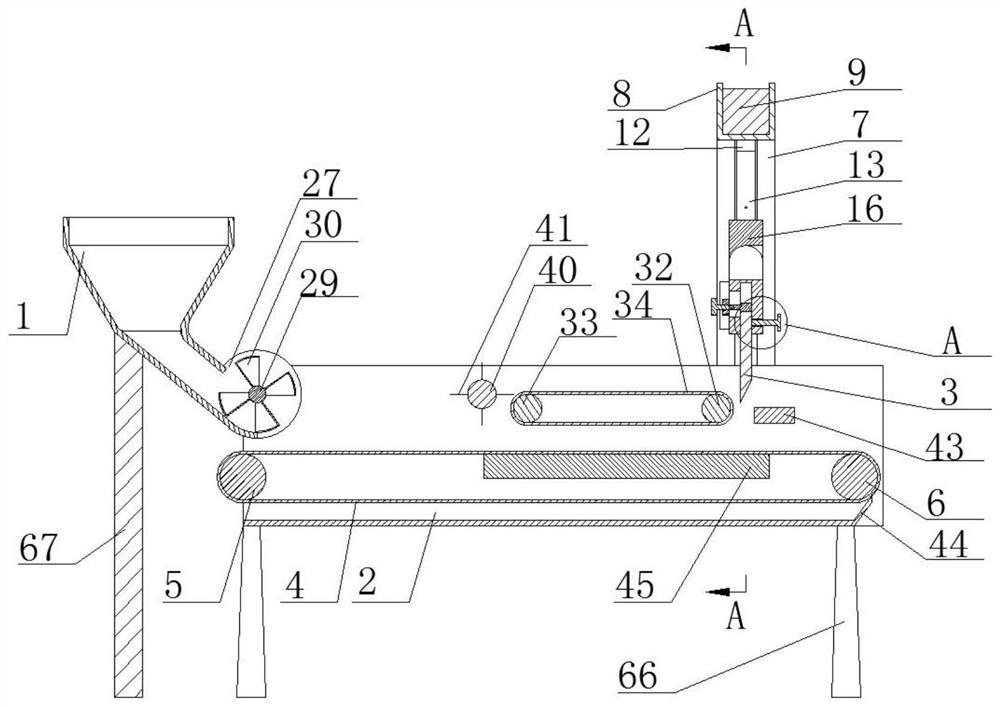

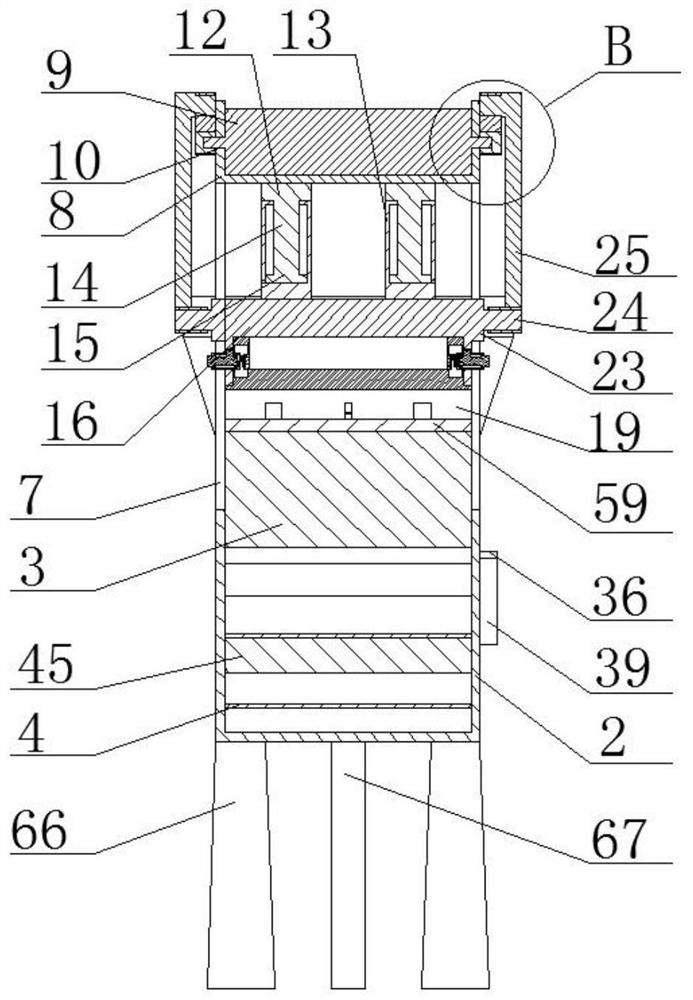

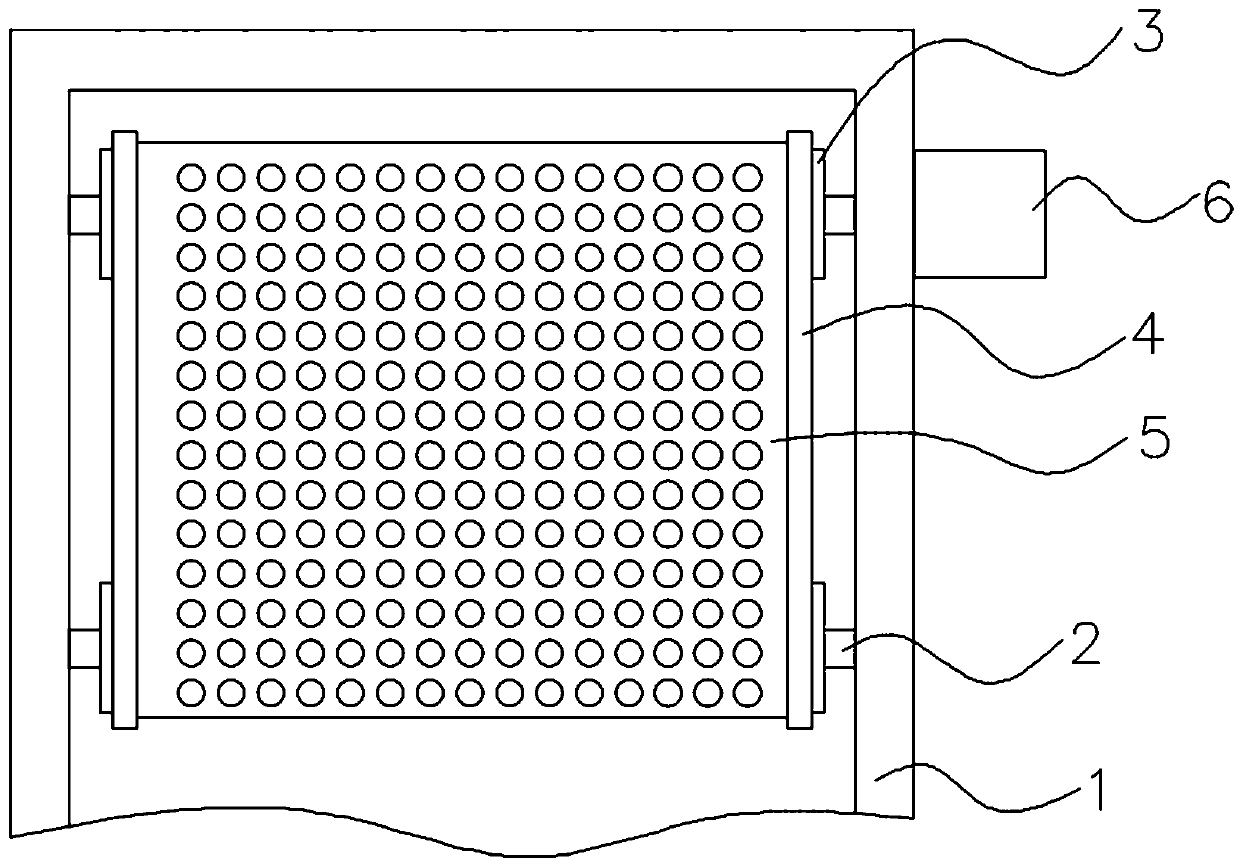

Feeding mechanism of sewing machine

ActiveCN105002664AAvoid reprocessingVersatilityWork-feeding meansEngineeringElectrical and Electronics engineering

The invention relates to a feeding mechanism of a sewing machine. The feeding mechanism comprises a rack, a cloth hanging plate, a driving belt, a limiting rail, ramps, a plurality of thimbles and two driving roller wheels. The two driving roller wheels are rotatably connected with the rack and are connected in a transmission manner through the driving belt. The limiting rail and a high end, and the ramps connected with two ends of the limiting rail, are arranged on a side of a close-loop transmission chain. The plurality of thimbles respectively slide up and down and are elastically arranged on the driving belt. The cloth hanging plate is provided with a spliced eye, and the cloth hanging plate is arranged above the driving belt. Beneficial effects are that the cloth hanging plate which is provided with cloth can be directly driven to do rectilinear motion to feed. Compared with a fell seam machine, the feeding mechanism prevents manual feeding, and positions of cloth hung on cloth hanging needles are relatively fixed, and a water gap can be controlled, and the front end and the rear end of the cloth can be effectively sewed, and a reprocessing program is prevented.

Owner:程林森

Automatic lentinus edodes pileus slicing machine and using method thereof

ActiveCN112917527AAchieve a cleansing effectPrevent jumpingCleaning using toolsMetal working apparatusRotational axisReciprocating motion

An automatic lentinus edodes pileus slicing machine comprises a feeding hopper, a box body, a slicing knife, a conveying belt, a driving belt wheel and a driven belt wheel. After lentinus edodes is manually added into the feeding hopper, a fan-shaped containing hopper on a rotating shaft at the lower end of the feeding hopper rotates clockwise, a part of pileus falling at a round discharging guide opening is scooped up to be poured onto the conveying belt, the situation that pileus is crushed during manual feeding and rotation of a common rolling shaft is avoided, completeness and attractiveness of the pileus are guaranteed, lentinus edodes is flatly laid on the conveying belt through bristles and sequentially enter a feeding conveying belt, the situation that the lentinus edodes jumps or the machine gets stuck by the lentinus edodes during slicing is avoided, meanwhile, the feeding conveying belt and the conveying belt are set to be at the same rotating speed, and the situation that one end is too high in rotating speed, the exterior of the pileus is abraded, and attractive appearance is affected are avoided. During slicing, a double-shaft motor is used for driving a rocker to rotate, a sliding block connected with the lower end of a crank slides on a guide rail, a blade achieves the telescopic effect, and the reciprocating motion of the blade is accelerated or slowed down by adjusting the rotating speed of the double-shaft motor so as to control the thickness of a pileus piece.

Owner:汤运清

Energy-saving fiveleaf gynostemma herb drying stove

InactiveCN110849133AAvoid wastingReal-time processingDrying gas arrangementsDrying solid materialsThermodynamicsElectric machinery

The invention discloses an energy-saving fiveleaf gynostemma herb drying stove, comprising a stove body. The stove body is internally provided with a drying chamber, two rotating shafts are rotatablyconnected with inner walls on both sides of the drying chamber, the two rotating shafts are correspondingly and fixedly connected with two belt wheels in a sleeved mode at corresponding positions, thetwo belt wheels respectively located on the two rotating shafts and corresponding to each other in position are jointly connected with synchronous belts in tensioned and sleeved modes, a mesh belt isfixedly connected between the two synchronous belts, one end of one of the rotating shafts penetrates through the drying chamber and is fixedly connected with a first motor, the first motor is fixedly installed on the stove body, the inner wall of the drying chamber and the inner side of the mesh belt are provided with heating plates, and the inner top wall of the drying chamber is provided withan overturning device. The energy-saving fiveleaf gynostemma herb drying stove has the advantages that heated air in the drying chamber is pumped to a dehumidification device through a material selecting fan to remove water vapor, hot air after dehumidification is used for conducting air separation for fiveleaf gynostemma herb, so as to avoid waste of resources caused by the hot air entering the atmosphere directly, and dehumidification operation is carried out automatically for the drying chamber.

Owner:竹溪众创农村电商孵化器有限公司

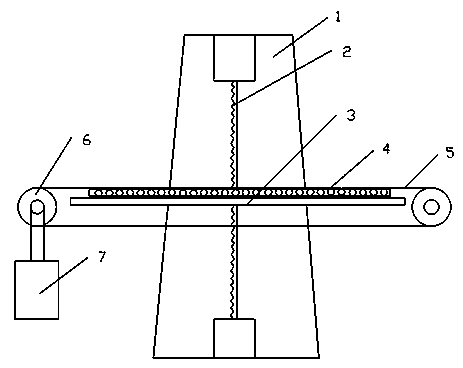

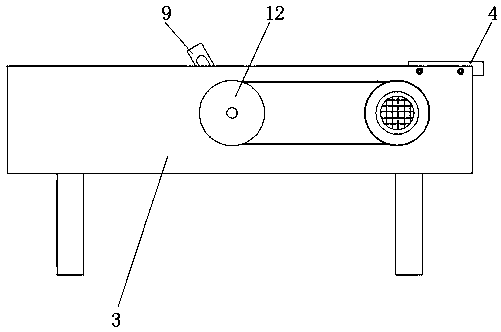

Fodder chopper equipment

InactiveCN104044172AAdjustable sizeReduce work intensityMetal working apparatusAgricultural engineeringKnife holder

The invention discloses fodder chopper equipment, which comprises a body, a feeding component, a chopping and cutting component and a fixture component, wherein the feeding component and the fixture component are arranged on the a body; the chopping and cutting component comprises a tool rest and a fodder chopper fixed on the tool rest; one end of the tool rest is hinged to one side face of the a body; the fixture component comprises a fixed fixture board and a movable fixture board; the fixed fixture board is arranged on the a body in a protruding manner; the movable fixture board is arranged on the a body in a movable manner; a groove for limiting and guiding the movements of the movable fixture board is formed in the movable fixture board; the movable fixture board and the fixed fixture board are matched, and thus a material clamping area is formed. The size of the material clamping area of the fixture component is adjustable, so the fodder chopper equipment, disclosed by the invention, has a wide application range.

Owner:钟国麟

Wood drilling equipment

PendingCN106891389AEasy to operateEasy to installStationary drilling machinesProcess engineeringWoodworking machine

The invention belongs to the technical field of woodworking machines, and particularly relates to wood drilling equipment. The wood drilling equipment is a common tool for woodworking and used for processing raw materials such as planks and square wood, and is mainly composed of a machine frame, a working table and a drilling mechanism, and during use, wood is placed on the working table, and the drilling mechanism is pushed to realize drilling operation. The wood drilling equipment is simple to operate and convenient to install, the drilling operation of the wood can be carried out quickly, the drilling dislocation is avoided, the drilling precision is improved, the defect rate is reduced, the idle waiting time is shortened, the working efficiency is improved, and meanwhile, the unpredictable safety accidents caused by manual feeding, drilling and discharging are avoided.

Owner:青岛吉森木业有限公司

Material conveying device

Owner:TIANJIN BOTIAN CHEMICAL

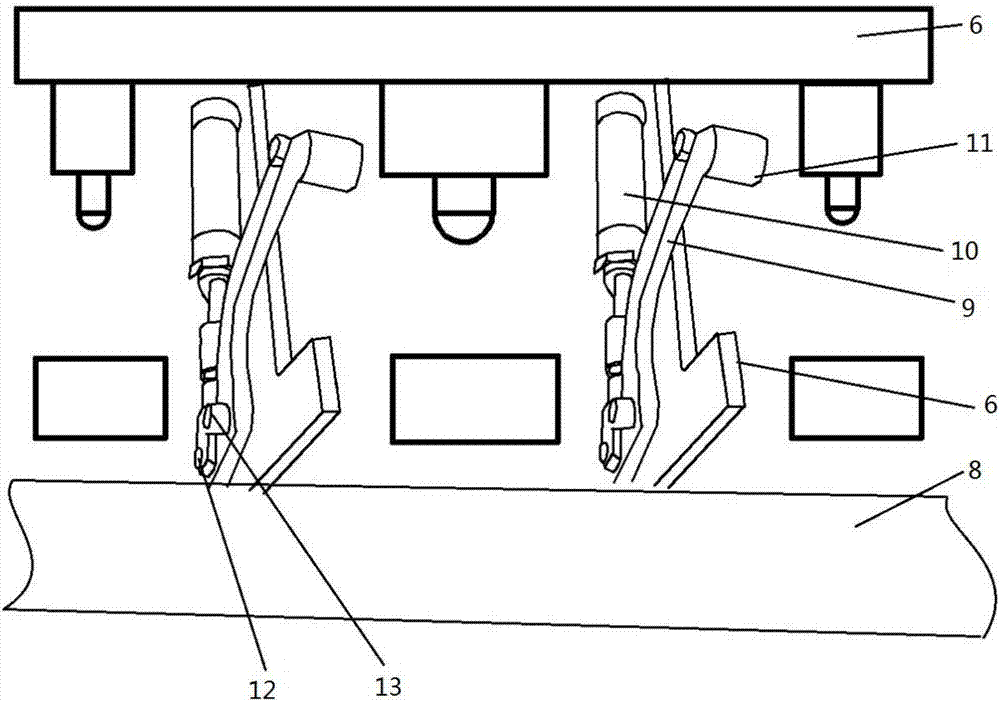

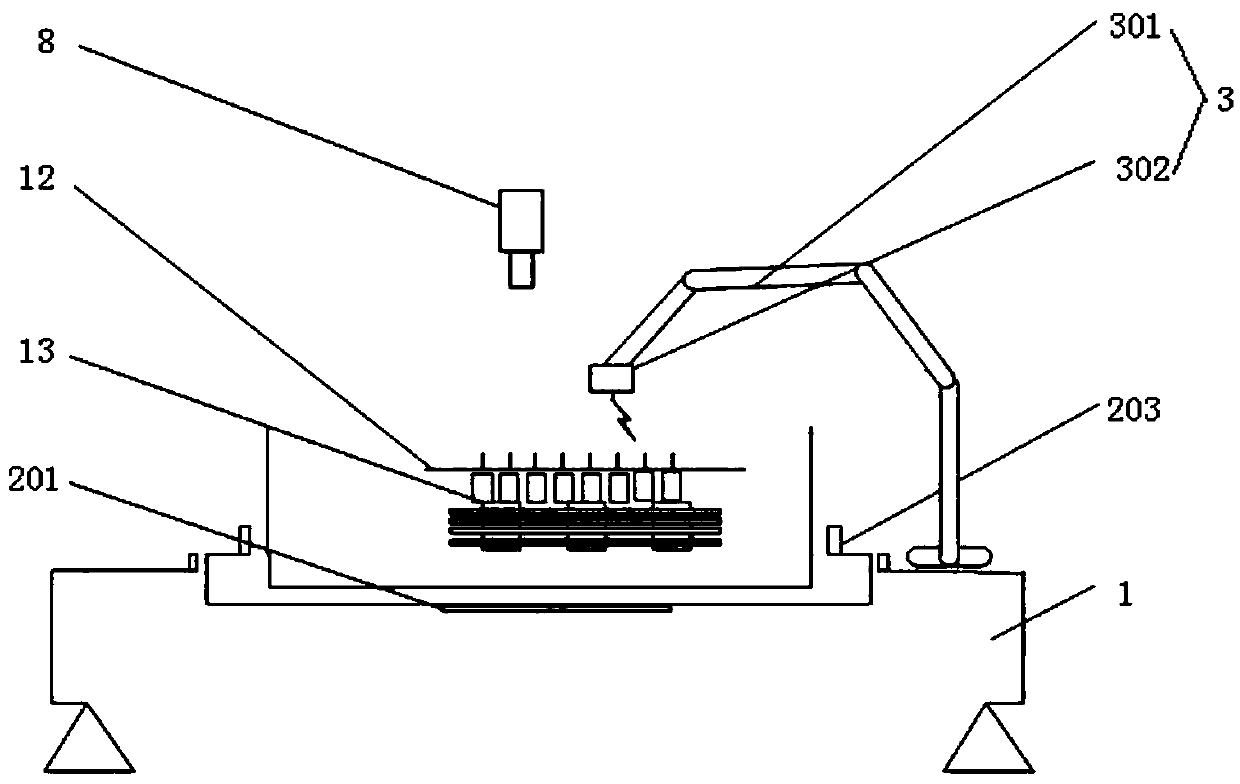

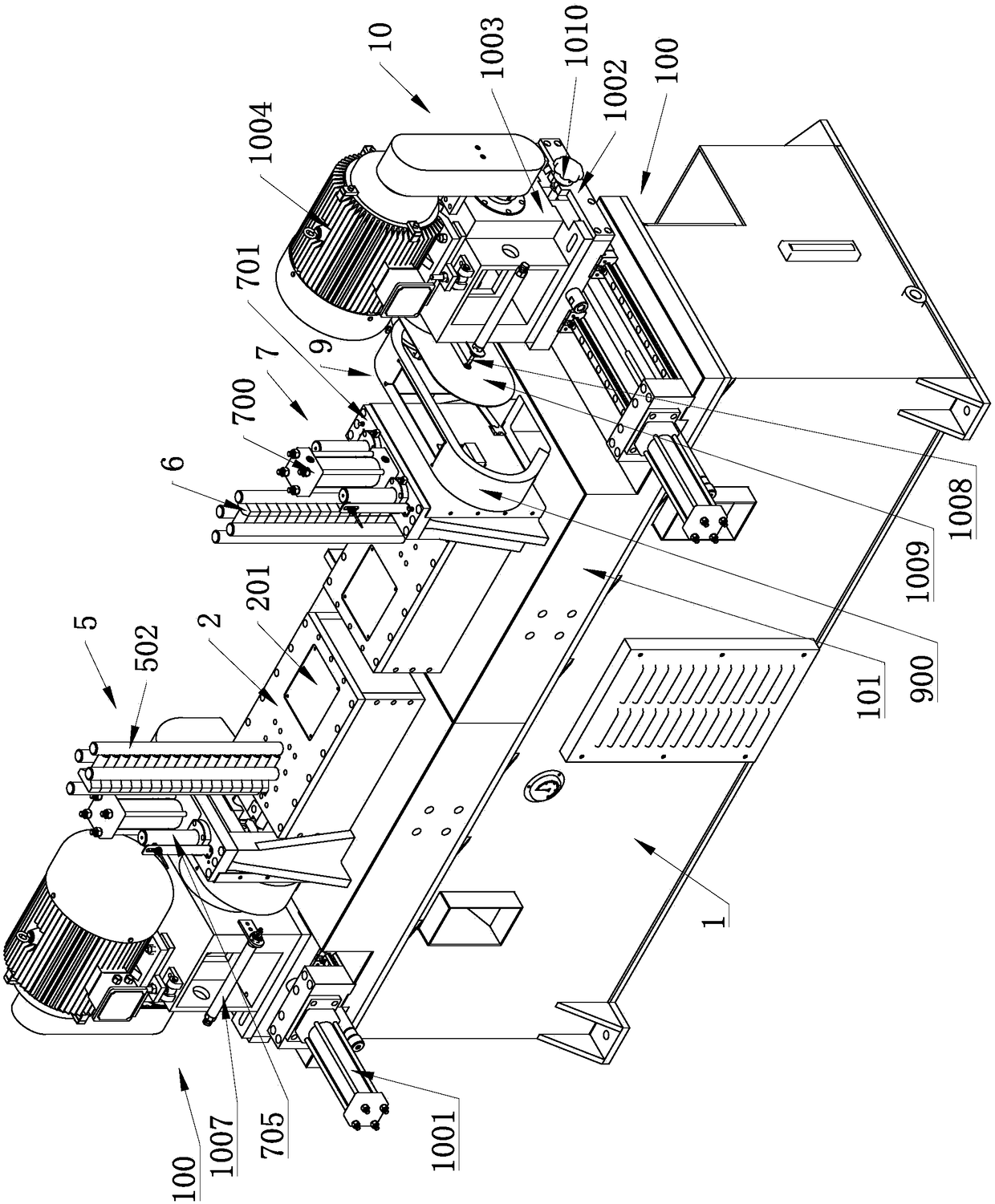

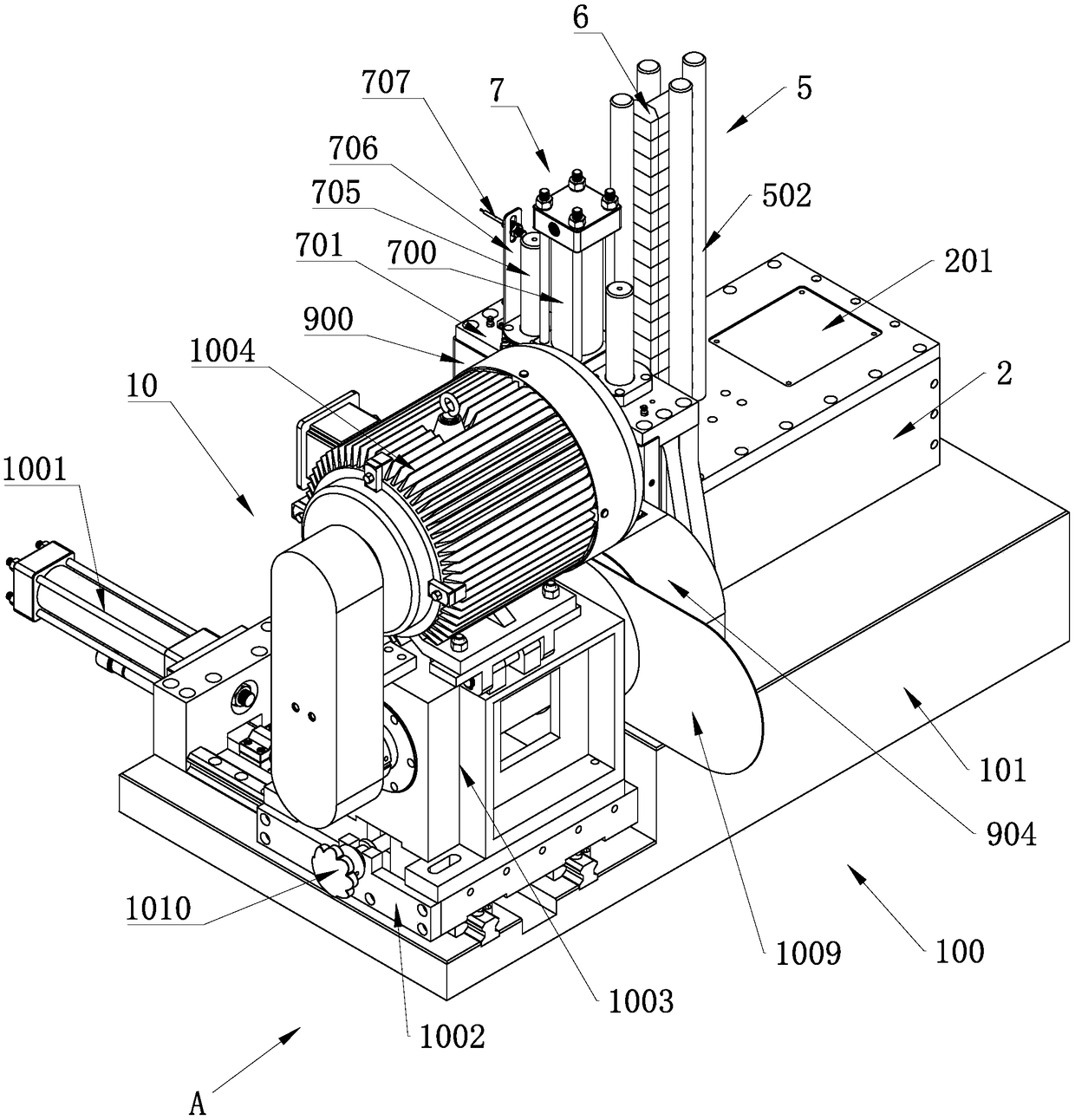

Automatic tin soldering system and control method thereof

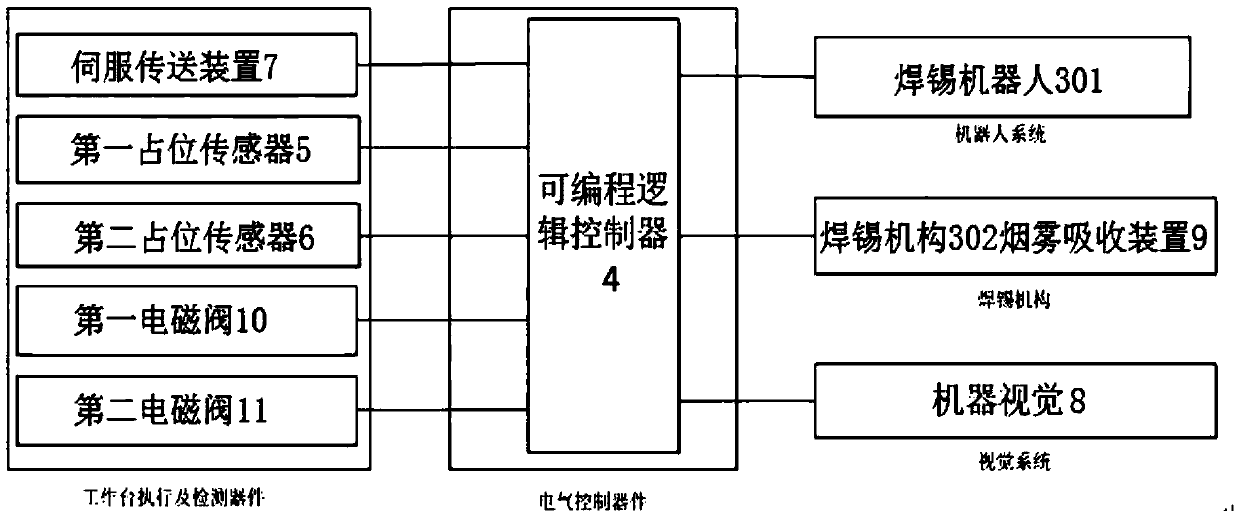

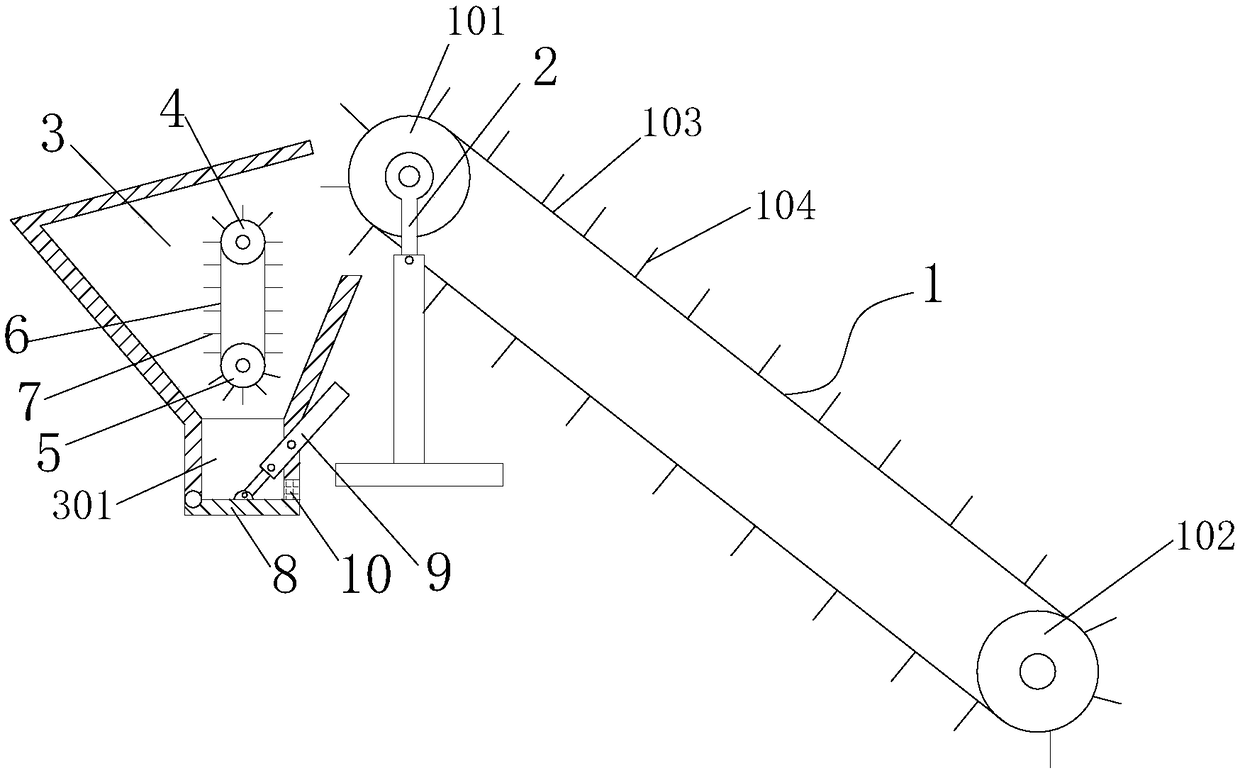

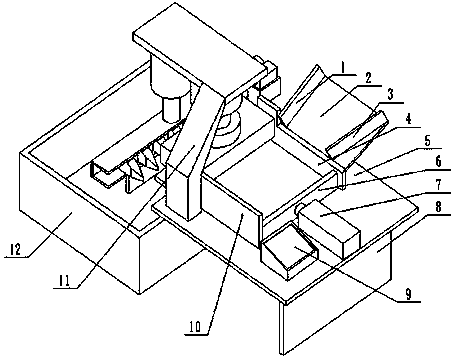

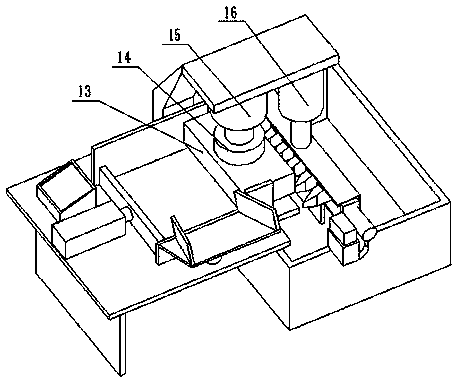

InactiveCN105364250AImprove positioning accuracy and production efficiencyReduced variety and accuracy requirementsWelding/soldering/cutting articlesMetal working apparatusElectricityWorking environment

The invention provides an automatic tin soldering system which comprises a workbench, a conveying device, a welding device and a controller. The workbench is divided into a welding waiting area and a welding area, and the welding waiting area is provided with a first occupying sensor. The conveying device comprises a bracket and a sliding rail. A second occupying sensor and a servo conveying device are arranged on the bracket. The welding device comprises a tin soldering robot arranged in the welding area and tin soldering mechanisms arranged on the arms of the tin soldering robot. The first occupying sensor and the second occupying sensor are electrically connected with the controller, and the controller is electrically connected with the servo conveying device. The tin soldering robot and the tin soldering mechanisms are all electrically connected with the controller. The invention further provides a control method of the automatic tin soldering system. By means of the system, the quality of the tin soldering process is improved, tin soldering automation and intelligence are achieved, and the problems that the technical demands of manual welding are high, the work environment is bad, fluctuation of the welding process is great, control over the auxiliary material cost is poor, and efficiency cannot be quantized are effectively solved.

Owner:WISDRI WUHAN AUTOMATION

Fertilizer maker workshop instrument

InactiveCN108146985AAvoid manual feedingImprove feeding effectConveyorsEngineeringUltimate tensile strength

The invention relates to a fertilizer maker workshop instrument. The fertilizer maker workshop instrument comprises a conveying component and is characterized in that the conveying component is connected with a regulating rod, one side of the conveying component is connected with a feeding box, a feeding roller A and a feeding roller B are arranged inside the feeding box, a conveying belt winds the feeding roller A and the feeding roller B, a plurality of discharge blades are arranged on the outer side of the conveying belt, a discharge plate is arranged at the bottom of the feeding box and connected with the end of a support rod, and the end of the discharge plate contacts with a damping pad. When the fertilizer maker workshop instrument is used and crop recycling is needed, the feeding roller A and the feeding roller B rotate to drive the discharge blades to feed the crops into the feeding box, manual feeding is avoided, a good feeding effect is achieved, labor intensity is lowered,and recycling efficiency is increased.

Owner:赵济彦

Engineering waste board crushing device

The invention discloses an engineering waste board crushing device, and belongs to the field of construction engineering equipment. A slide plate is mounted on the upper edge of a first limiting plate; a push plate is mounted on a first hydraulic cylinder; a controller is mounted on a worktable, and is positioned on the left side of the first hydraulic cylinder; a storage box is mounted rightly below a cutting device; a pressure block is mounted below a pressure sensor, and is from the worktable by a certain distance; a pressure sensor is mounted below the axis of a second hydraulic cylinder;an ultrasonic sensor is mounted on an ultrasonic sensor base, and is positioned between the edge of the worktable and the cutting device; and the cutting device is mounted below a third hydraulic cylinder. Boards are forwards pushed through the push plate, and are cut to narrow strips through the cutting device, so that combustion and reutilization are achieved, labors are saved, the working efficiency is improved, and the energy is saved.

Owner:浙江金果知识产权有限公司

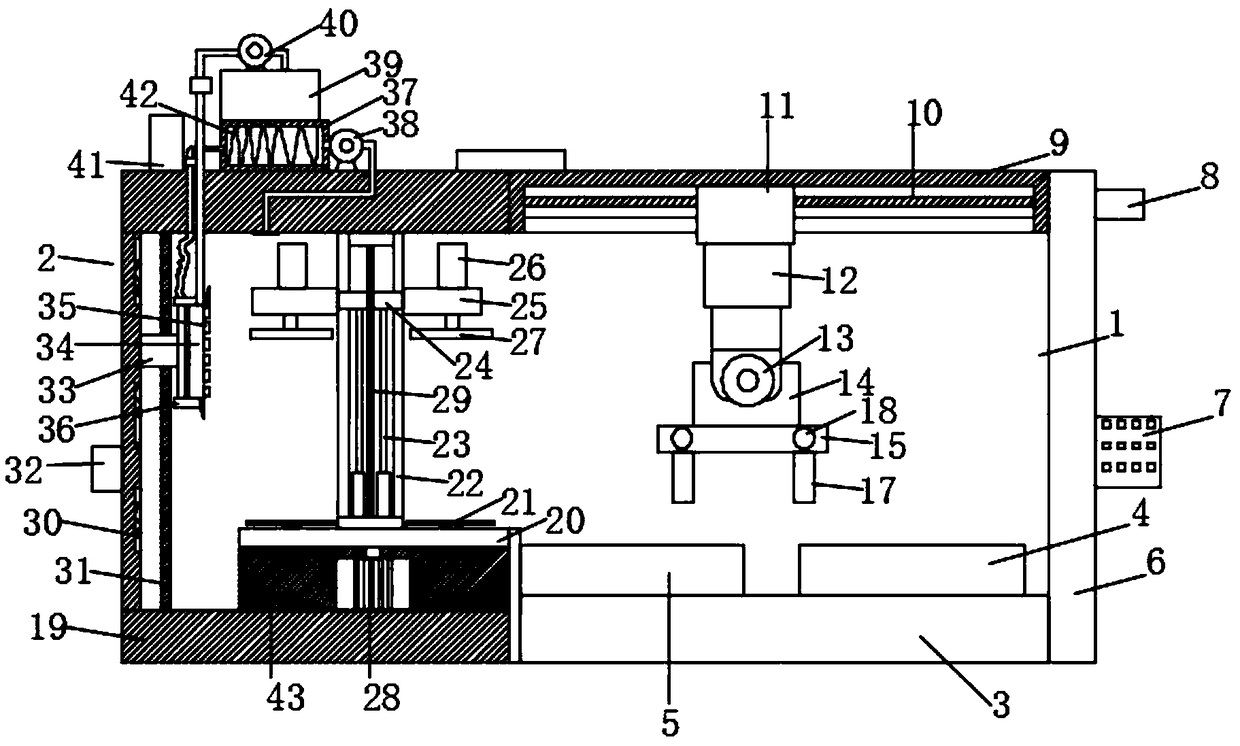

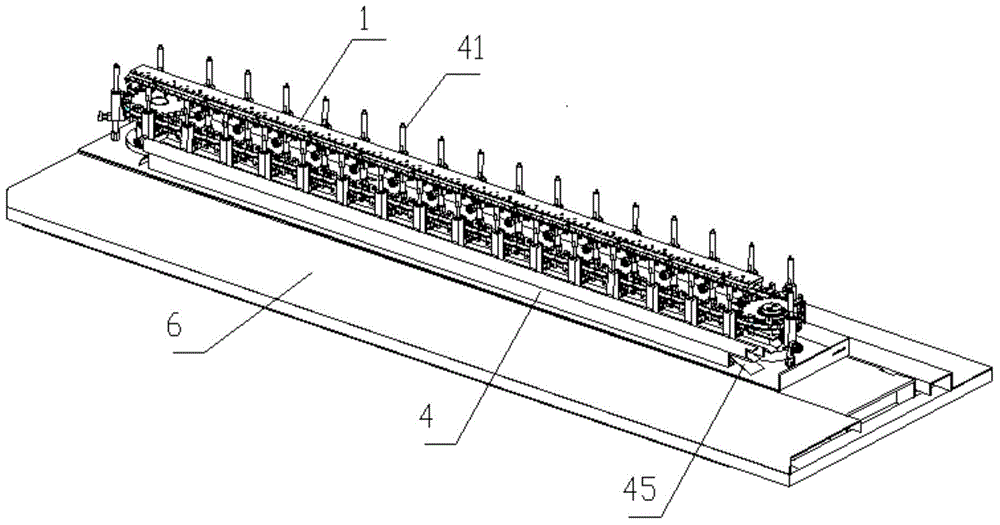

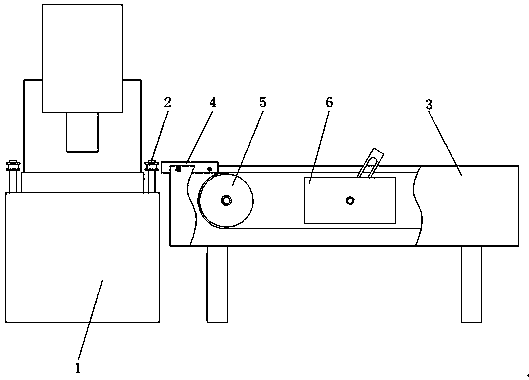

Efficient multi-sawtooth thicknessing machine for trees

InactiveCN111391026AEasy for automatic loadingReduce labor intensityThicknessing machinesElectric machineryEngineering

The invention discloses an efficient multi-sawtooth thicknessing machine for trees. The efficient multi-sawtooth thicknessing machine comprises a machining mechanism and a feeding mechanism, the machining mechanism is composed of a workbench, a control panel, a mounting groove, a first servo motor, a driving chain wheel, a driven chain wheel, cutting rollers, a supporting frame, a pressing air cylinder, a fixing frame, a driven pressing roller, a driving pressing roller, a first driven belt wheel, a second servo motor and a driving belt wheel, and a material conveying groove is formed in the top of the workbench. According to the efficient multi-sawtooth thicknessing machine for the trees, the structure is simple and flexible; through the arrangement of a feeding motor and a conveying motor, during work, automatically feeding on materials can be conveniently carried out through a clamping plate and a lifting electric telescopic rod, manual feeding is avoided, the labor intensity of workers is reduced, the feeding speed is increased; and through the arrangement of the pressing rollers and the plurality of cutting rollers, under the condition that the plurality of cutting rollers work at the same time, the cutting speed is greatly increased, the machining time is shortened, and the machining efficiency is greatly improved.

Owner:WENZHOU CHUYING TECH CO LTD

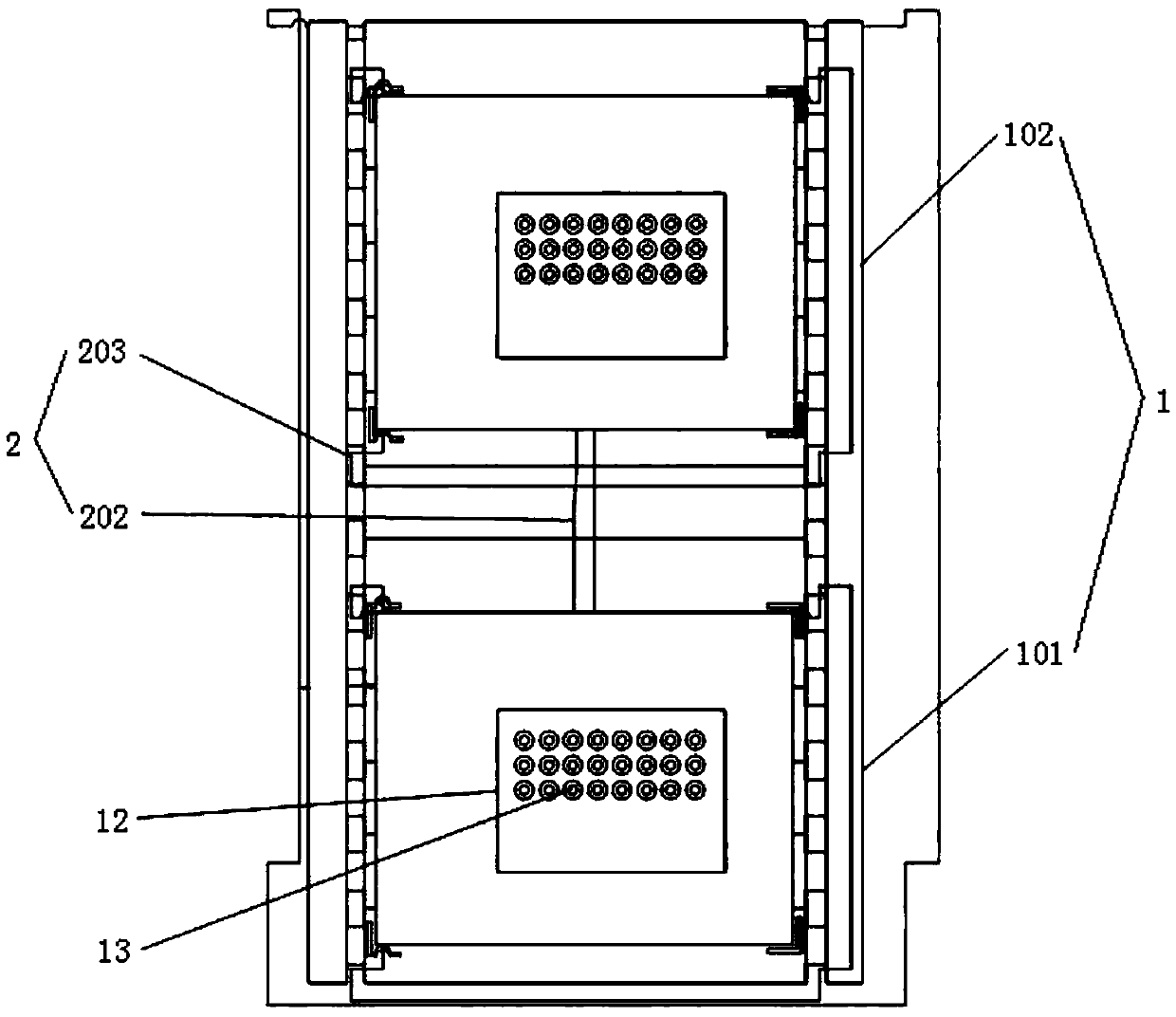

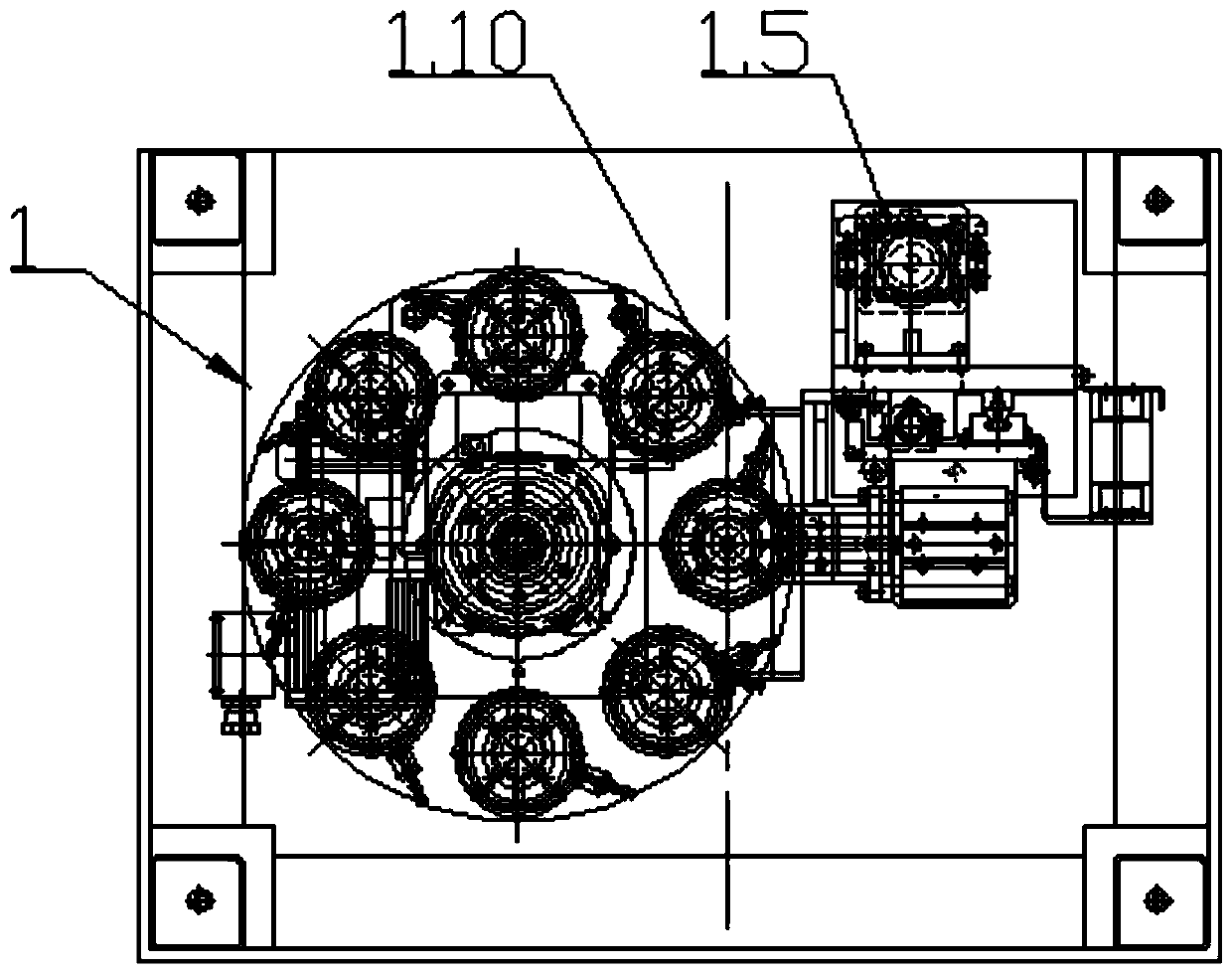

Integrated circuit chip flatness detection device and method

An integrated circuit chip flatness detection device disclosed by the present invention comprises a machine base, a stand column is welded on the upper surface of the machine base, the stand column is fixedly connected with a fixed block, the side wall of the fixed block is fixedly connected with a plurality of detectors, and the fixed block is rotatably connected with a rotating block through a bearing in a penetrating manner. A detection mechanism for flatness detection is arranged in the rotating block; the detection mechanism comprises a mounting groove formed in the inner side wall of the rotating block, the inner bottom wall of the mounting groove is fixedly connected with an inner gear ring, the inner side wall of the fixed block is fixedly connected with a servo motor through a support, an output shaft of the servo motor is in interference fit with a first gear, and the first gear is meshed with the inner gear ring; the rotating block is provided with eight functional grooves. Compared with the prior art, the chip detection device has the advantages that chips can be continuously and automatically detected, feeding, discharging and classification can be automatically carried out, and therefore the detection efficiency is greatly improved, and meanwhile the equipment cost and the labor cost are reduced.

Owner:深圳市通恒伟创科技有限公司

Automatic mechanical meat chopping equipment

InactiveCN112189703AAvoid manual feedingReduce labor intensityMeat packaging/handling/transportingMeat shaping/cuttingBiotechnologyAnimal science

The invention discloses automatic mechanical meat chopping equipment. The automatic mechanical meat chopping equipment comprises an operation table; the right ends of two supporting legs on the rightside of the operation table are each fixedly connected with a fixing base; a driving mechanism is jointly and movably connected between the two fixing bases; two limiting bases are fixedly welded to the upper end of the operation table; a limiting rod is fixedly connected into each limiting base; the middle of each limiting rod is sleeved with a meat chopping mechanism; the lower portion of each meat chopping mechanism is in transmission connection with the driving mechanism; two transmission grooves with the right ends penetrating through are formed in the right portion of the upper end of the operation table; a meat chopping knife is detachably installed at the left end of each meat chopping mechanism; a meat turning mechanism is connected to the left portion of the upper end of the operation table in a penetrating mode; a protective cover is fixedly connected to the upper end of the operation table; and a meat guide mechanism and a meat storage barrel are fixedly connected to the right end of a supporting frame. The automatic mechanical meat chopping equipment is compact in structure, short in meat chopping time, high in processing efficiency, low in labor intensity and high inautomation degree.

Owner:徐忠林

A kind of production method of ammonium alum

ActiveCN104445330BEfficient use ofReduce pollutionAluminium sulfatesSlurryAmmonium aluminium sulfate

Owner:广西北部湾粮油技术研究有限公司

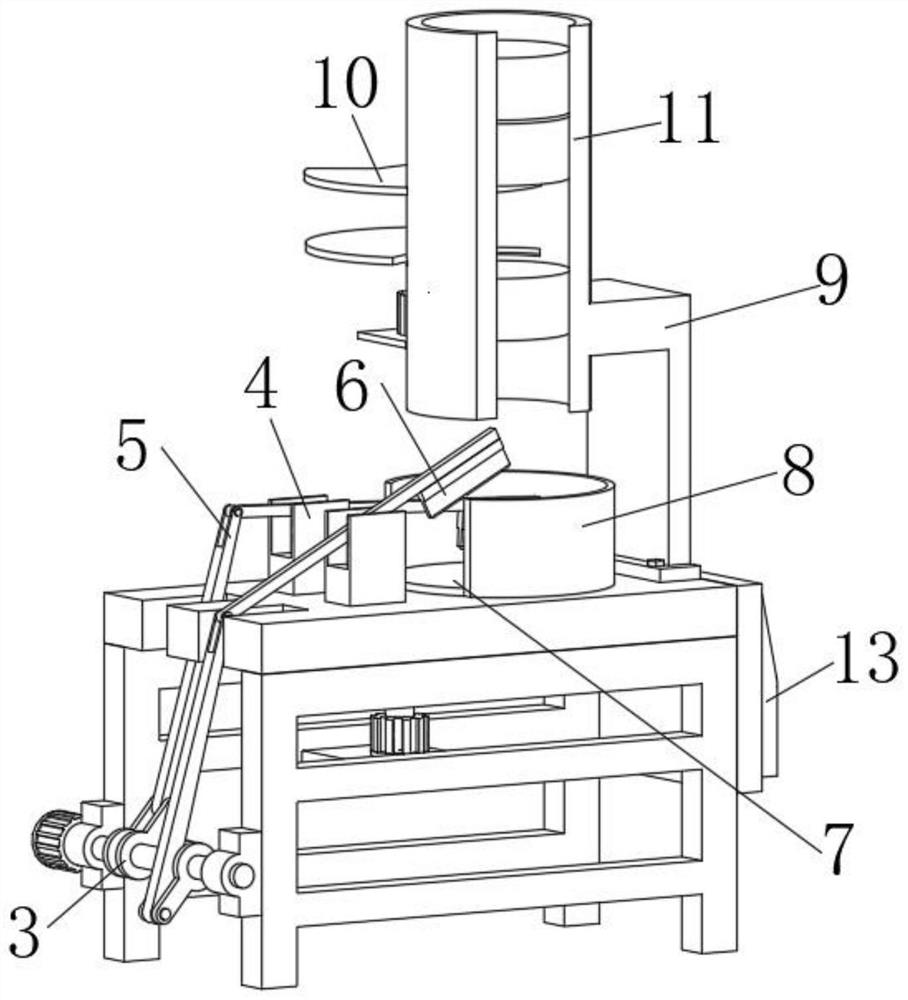

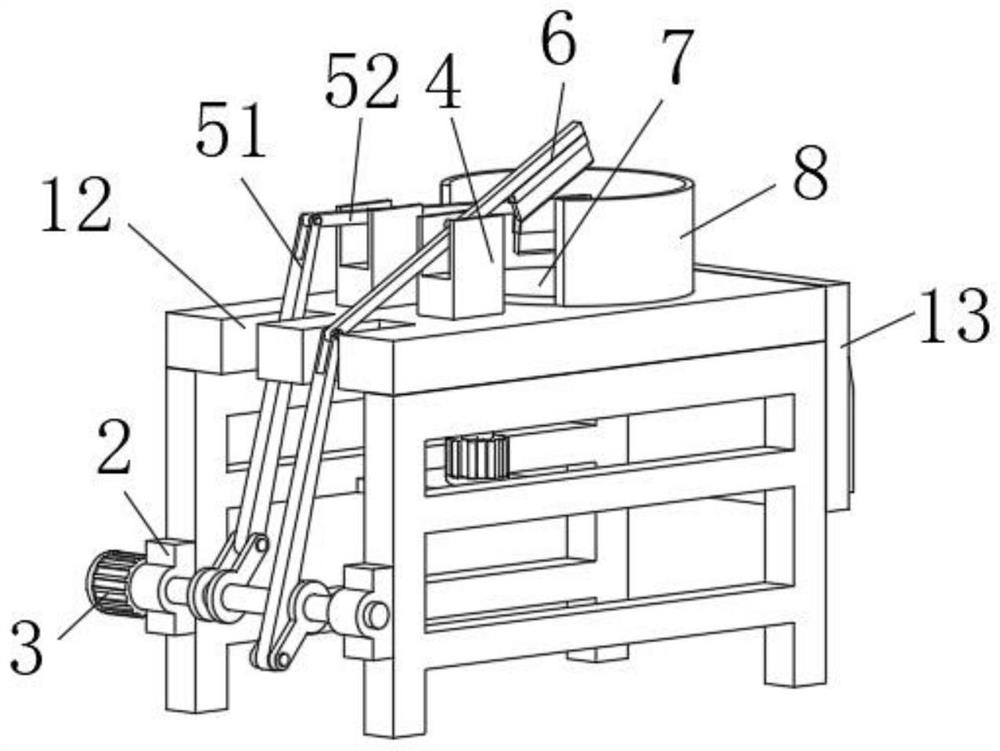

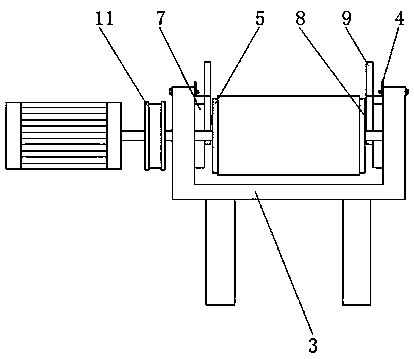

Automatic bushing assembling equipment

PendingCN110744280AImprove assembly efficiency and assembly qualityAvoid manual feedingMetal working apparatusTransfer mechanismStructural engineering

The invention discloses automatic bushing assembling equipment. The automatic bushing assembling equipment comprises an automatic bushing conveying mechanism, a bushing transferring mechanism and a bushing press-fitting mechanism, wherein the automatic bushing conveying mechanism comprises a rotating disc, a plurality of material collecting mechanisms, a carrying guide sleeve and a carrying ascending mechanism, the material collecting mechanisms are uniformly mounted on the rotating disc in the circumferential direction, and the rotating disc is driven by a rotating air cylinder to rotate fora fixed angle; bushings are fetched from the automatic bushing conveying mechanism and transferred to press-fitting positions by the bushing transferring mechanism; and the bushing press-fitting mechanism comprises a linear driver and a presser head and grip jaw assembly, the presser head and grip jaw assembly comprises presser heads and grip jaws, the grip jaws are used for clamping the bushings,the presser heads are used for pressing the bushings, and the presser head and the grip jaw assembly is driven by the linear driver to move upwards and downwards. The automatic bushing assembling equipment realizes the automatic conveying and press-fitting of bushing class accessories and can increase the assembling efficiency and improve the assembling quality.

Owner:ZHEJIANG ASIA PACIFIC MECHANICAL & ELECTRONICS

End face machining method of bolts and end face machining machine achieving method

PendingCN109352044AImprove push effectEasy to replaceMilling equipment detailsMetal working apparatusEngineeringOperation safety

The invention discloses an end face machining method of bolts and an end face machining machine achieving the method. The method comprises the following steps that bolts to be machined are guided andconveyed one by one; the guided and conveyed bolts to be machined are pushed to the machining station, and in the pushing process, a pushing mechanism used for pushing the bolts to be machined to abutagainst next bolts to be machined; the to-be-machined bolts pushed to the machining station are located and clamped; composite end face machining is carried out; an end face machining device used formachining the end face and a clamping mechanism used for clamping are reset; the machined bolts are conveyed in an ejected manner; the bolts conveyed in an ejected manner are conveyed; and the pushing mechanism is reset to push the next bolts to be machined. According to the method, assembly automatic guiding, conveying, pushing, clamping, locating and machining of the bolts, and ejected conveying and outputting of the machined bolts are achieved, the potential safety hazards in the operation of the bolt clamping process and labor intensity of personnel are reduced, and meanwhile the work continuity and the working efficiency are improved greatly.

Owner:张家港市润泰机械有限公司

Crude lead refining process for lead-acid battery recovery

ActiveCN111996549AAchieve rotationImprove running stabilityPhotography auxillary processesWaste accumulators reclaimingElectrolytic agentElectrical battery

The invention discloses a crude lead refining process for lead-acid battery recovery. The crude lead refining process comprises the following steps: stirring and dissolving at normal temperature to prepare a mixed solution, adding lead oxide powder and an additive into the mixed solution, stirring and dissolving at the temperature of 80-100 DEG C and the stirring speed of 800-1000r / min for 5-7 hours, and filtering to obtain an electrolyte; carrying out fire refining on crude lead through a refining device, and respectively casting the crude lead subjected to fire refining and electrodepositedrefined lead in a molten state into a crude lead anode and an electrodeposited lead cathode; and adding the prepared electrolyte into an electrolytic cell, introducing direct current for electrolysis,melting and casting the electrolytic lead obtained by cathode electrodeposition to obtain a pure lead ingot, washing and filter-pressing anode mud, and then sending the anode mud to a noble metal extraction process for treatment. The crude lead refining process disclosed by the invention improves the direct recovery rate of lead in the refining process and the comprehensive recovery rate of various valuable metals, and the electrolytic lead is higher in purity and lower in production cost.

Owner:太和县大华能源科技有限公司

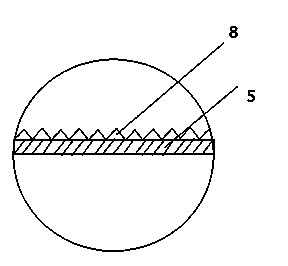

Automatic feeding band-sawing machine with sliding device

InactiveCN103846972AReduce frictional resistanceReduce lossFeeding devicesBand sawsGear wheelElectric power

The invention relates to an automatic feeding band-sawing machine with a sliding device. The automatic feeding band-sawing machine comprises a host, a saw blade, a workbench, annular crawlers, crawler wheels, a motor and a sliding pallet, wherein two annular crawlers are laid on the surface of the workbench at the two sides of the saw blade in parallel, and are both connected to one group of crawler wheels, the annular crawlers are connected to the motor for providing the power through gears or belt pulleys, the sliding pallet is formed by arranging one group of rotating slide bars, and the sliding pallet is positioned between the workbench and the annular crawlers. According to the automatic feeding band-sawing machine, manual feeding is avoided, electric automatic feeding is realized, occurrence of safety accidents is effectively prevented and avoided, and the production efficiency is greatly improved.

Owner:XINGHUA DONGXU MACHINERY

Stamping device for casting machining

PendingCN109433944ASolve the problem of manual feeding and low efficiencyAvoid manual feedingMetal-working feeding devicesPositioning devicesDrive wheelElectric machinery

The invention discloses a stamping device for casting machining. The following scheme is provided aiming at the problems that manual feeding is needed for existing stamping equipment, the efficiency is low, and a certain risk exists. The scheme of the stamping device comprises a stamping equipment main body, wherein guide wheels are installed on the top wall of the base of the stamping equipment main body, and the left side of the stamping equipment main body is provided with a conveying device; the conveying device comprises a shell, angle irons are arranged on the left side of the top of thefront inner side wall and the left side of the top of the rear inner side wall of the shell respectively, two symmetrically distributed rollers are arranged on the left side and the right side of theshell body, and a boosting device is arranged between the two rollers; the boosting device comprises a groove body, a groove is formed in the inner wall of the groove body, a short shaft is arrangedin the groove in a sliding mode, and the other end of the short shaft is provided with a rotating rod in a sleeve mode; and a motor is arranged outside the back side of the shell, an output shaft of the motor is connected to a driving wheel, and the driving wheel is connected to a driven wheel through a belt. According to the stamping device, the labor intensity is reduced, the danger is reduced,and the working efficiency is improved.

Owner:阜宁隆德机械制造有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com