End face machining method of bolts and end face machining machine achieving method

A technology of end face processing and bolts, which is applied in the direction of metal processing machinery parts, metal processing, metal processing equipment, etc., can solve problems such as low work efficiency, large hidden dangers of operation safety, and poor work continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further described in detail below through specific embodiments.

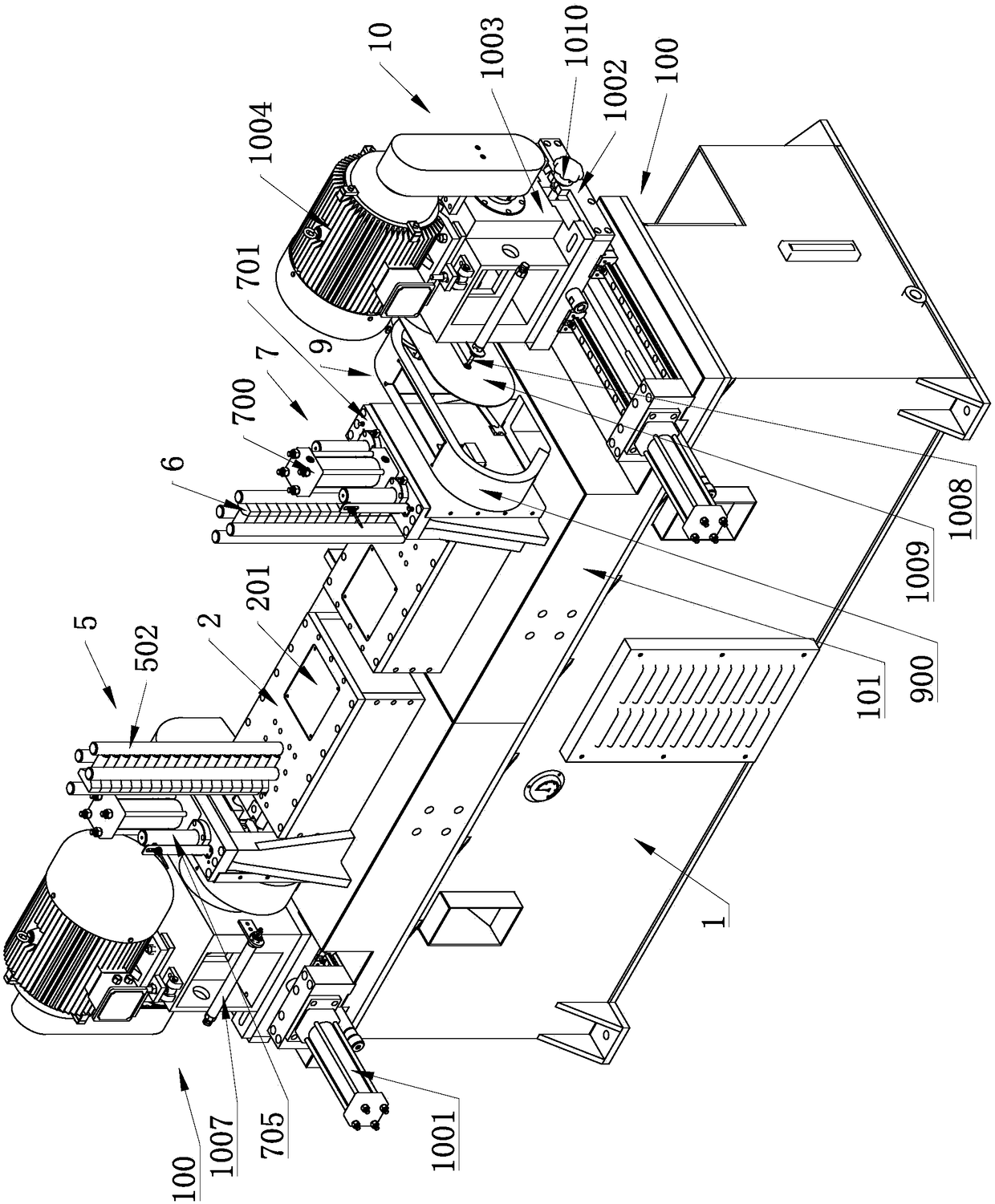

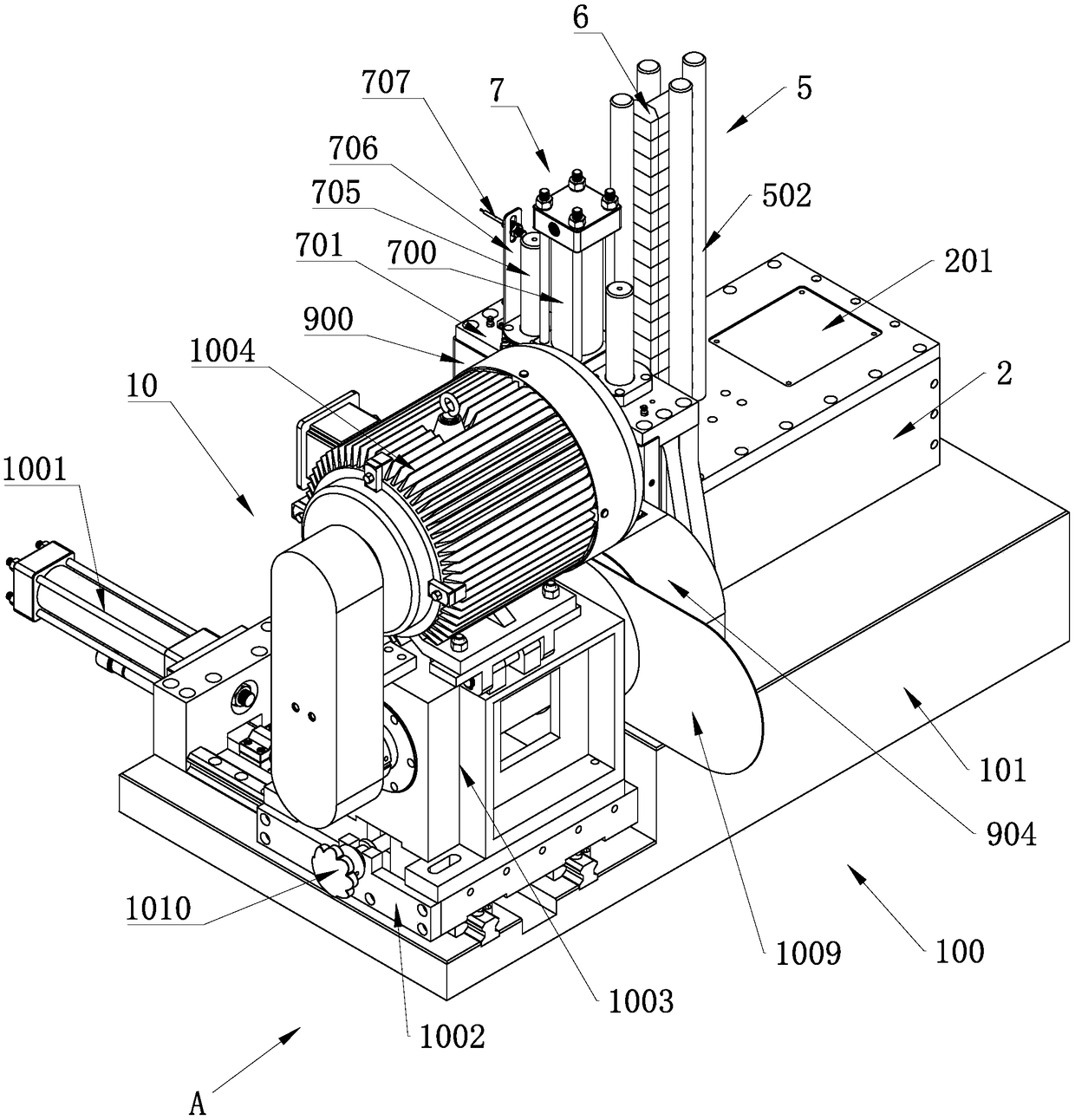

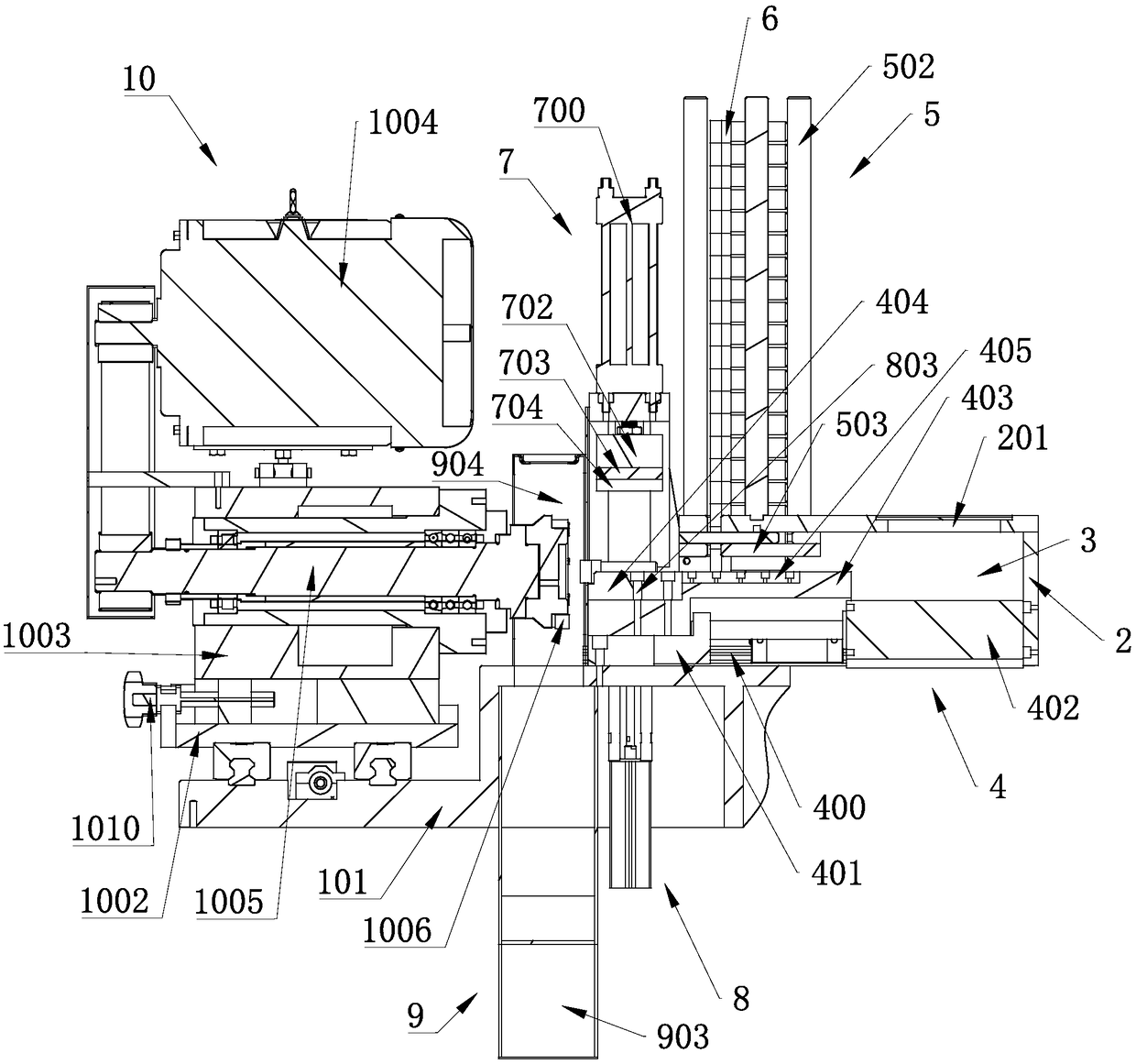

[0062] An embodiment of the present invention provides a method for machining an end face of a bolt, which includes the following steps implemented in sequence:

[0063] S1, guide the bolts 6 to be processed one by one;

[0064] S2, push the guided bolt 6 to be processed to the processing station, and in the process of pushing, the pushing mechanism 4 for pushing the bolt 6 to be processed abuts against the next bolt 6 to be processed;

[0065] S3, positioning and clamping the bolts 6 to be processed that are pushed to the processing station;

[0066] S4, perform reciprocating end face processing;

[0067] S5, reset the end face machining device 10 for end face machining and the clamping mechanism 7 for clamping the bolt 6 to be machined;

[0068] S6, push the processed bolts 6;

[0069] S7, feeding the bolts 6 after top feeding;

[0070] S8, the push mechanism 4 returns...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com