Efficient multi-sawtooth thicknessing machine for trees

A planer, high-efficiency technology, applied in the direction of planer, wood processing equipment, processing machines for manufacturing flat surfaces, etc., can solve the problems that the cutting rollers cannot work at the same time, the cutting speed cannot be increased, and the automatic feeding of materials is inconvenient. , to achieve the effect of improving processing efficiency, shortening processing time, and avoiding manual loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

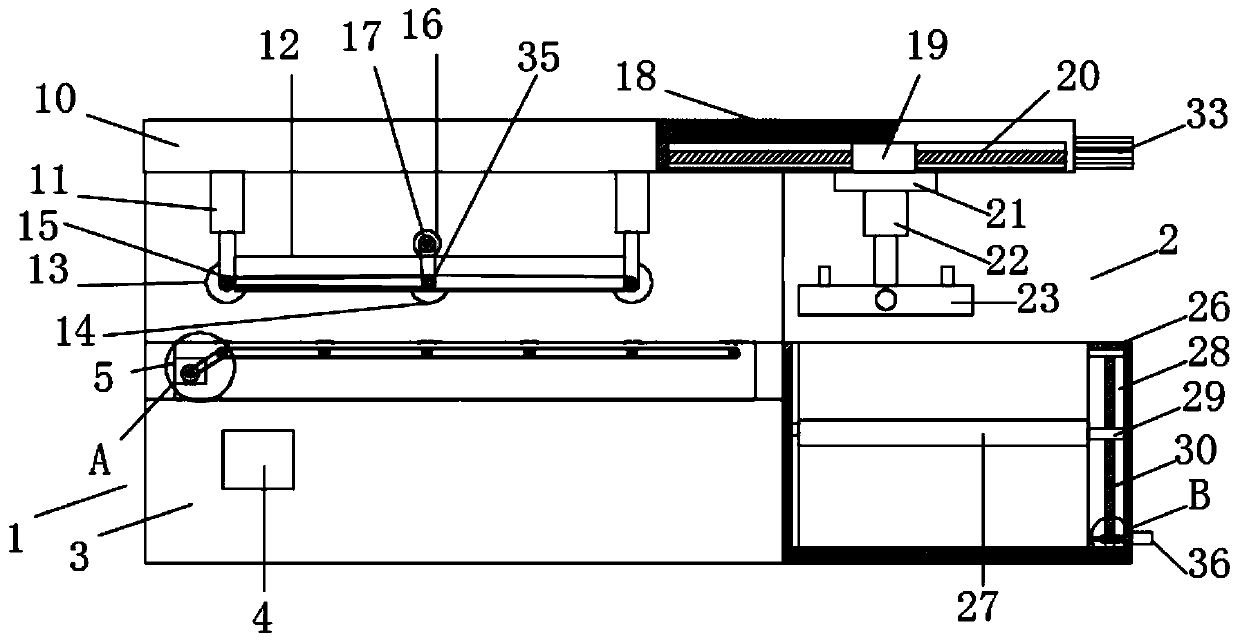

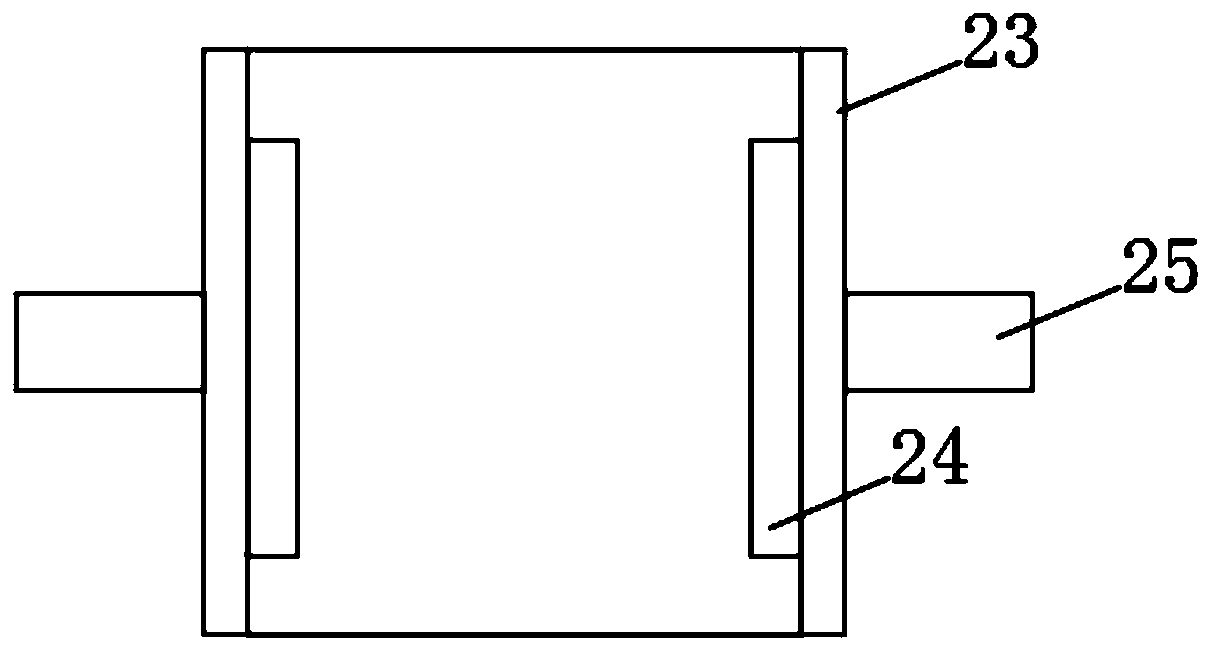

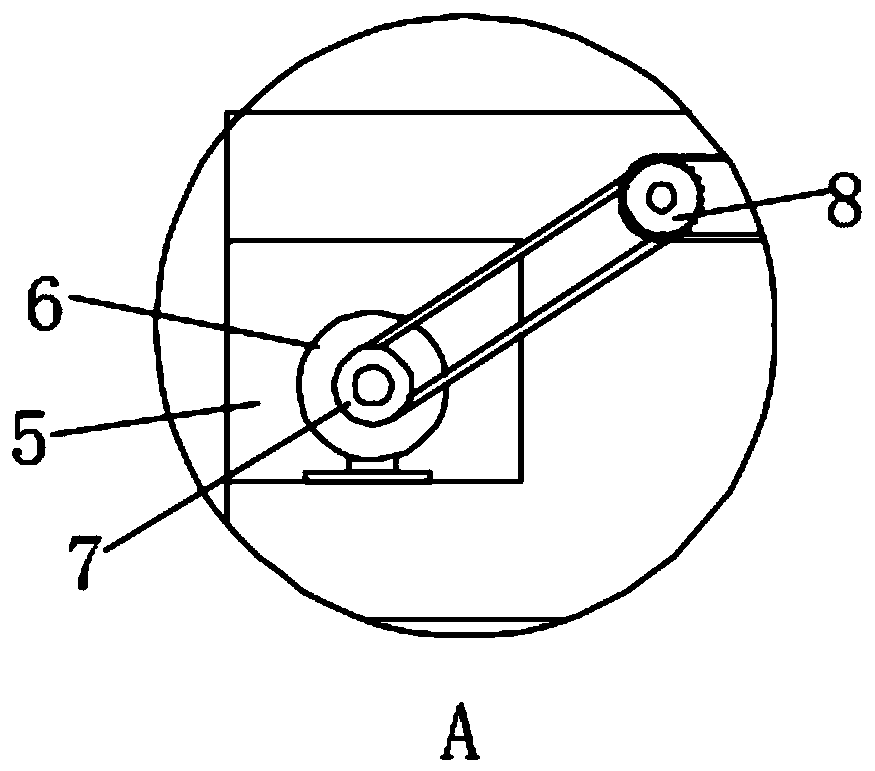

[0021] Such as Figure 1-5 As shown, the specific embodiment adopts the following technical scheme: a high-efficiency multi-blade sawtooth planer for trees, including a processing mechanism 1 and a feeding mechanism 2, and the processing mechanism 1 consists of a workbench 3, a control panel 4, and a mounting groove 5 , the first servo motor 6, the driving sprocket 7, the driven sprocket 8, the cutting roller 9, the support frame 10, the pressing cylinder 11, the fixed frame 12, the driven pressing roller 13, the active pressing roller 14, the first The driven pulley 15, the second servo motor 16 and the driving pulley 17 are formed. The top of the workbench 3 is dug with a feeding chute 34, and one end of the feeding chute 34 is connected with several cutting rollers 9 in rotation. The working An installation groove 5 is excavated at one end of the table 3, and the inside of the installation groove 5 is fixedly connected with a first servo motor 6, and the output end of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com