Automatic tin soldering system and control method thereof

An automatic welding and soldering technology, applied in manufacturing tools, welding equipment, welding/welding/cutting items, etc., can solve problems such as poor control of welding accessories cost, large fluctuation of welding process quality, and inability to quantify welding efficiency. It has the effect of good controllability of welding efficiency, improving positioning accuracy and production efficiency, and saving production and safety costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The automatic soldering system and its control method provided by the present invention will be further described below in conjunction with specific embodiments.

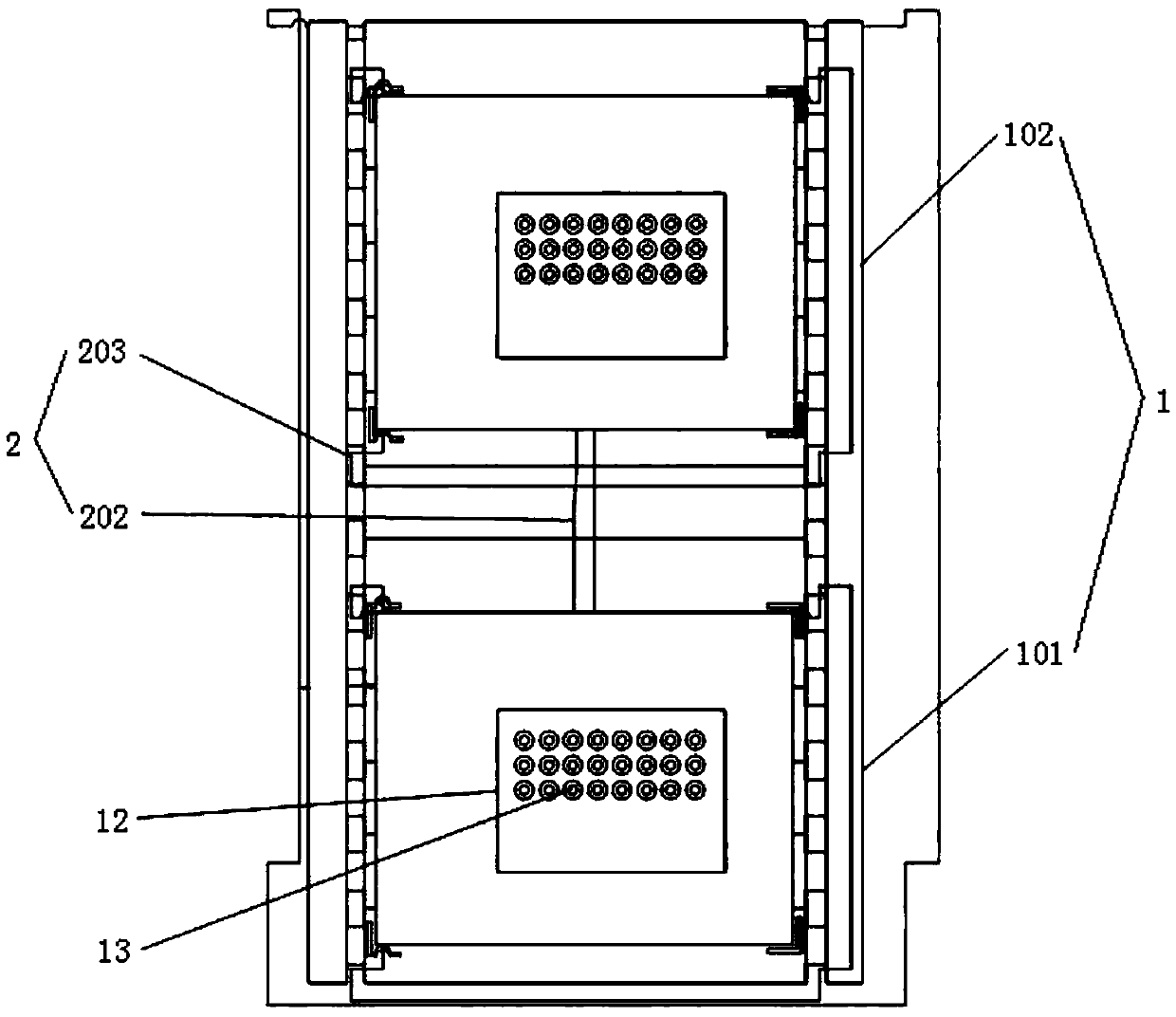

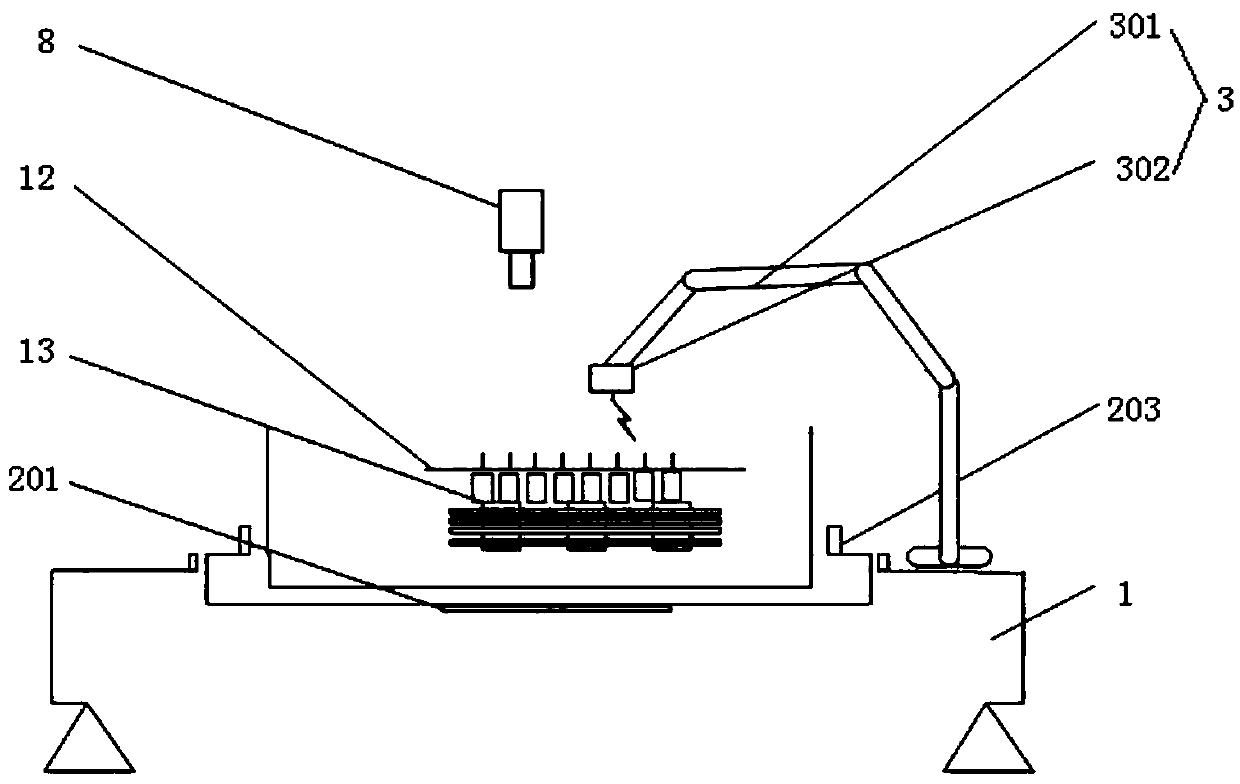

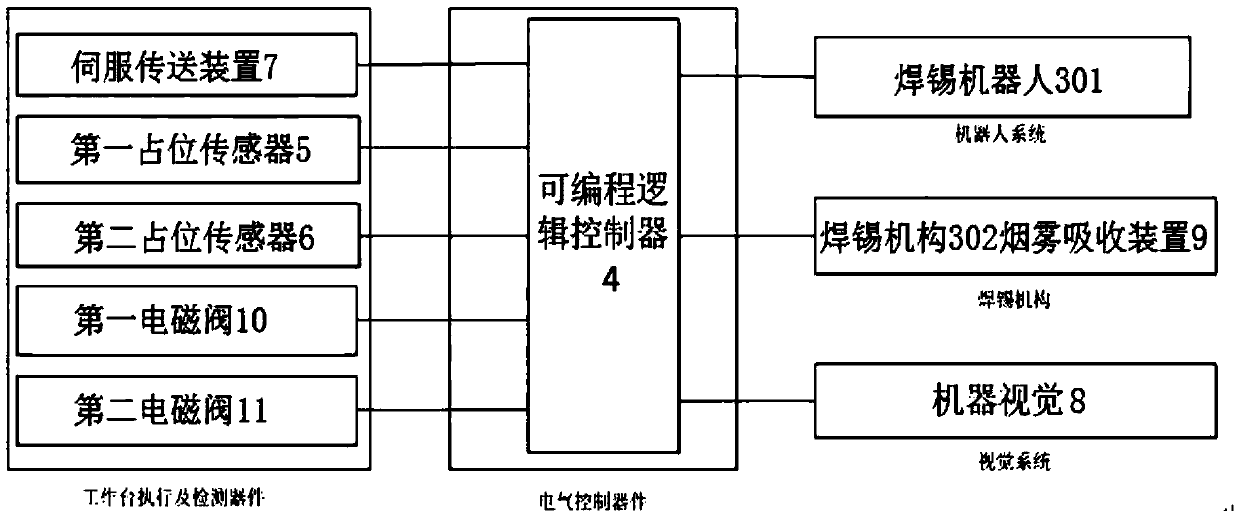

[0029] An automatic soldering system includes: a workbench 1 and a conveying device 2, a welding device 3, and a controller 4 arranged on the workbench.

[0030] The workbench 1 is divided into a welding waiting area 101 and a welding area 102. The welding waiting area 101 is provided with a first occupancy sensor 5.

[0031] The conveying device 2 includes a bracket 201 and a slide rail 202. The slide rail 202 is set on the workbench 1. The two ends of the slide rail 202 are respectively connected to the welding waiting area 101 and the welding area 102. The bracket 201 is installed on the On the sliding rail 202, a second occupancy sensor 6 and a servo transmission device 7 are provided on the bracket 201. The servo transmission device 7 includes a servo motor.

[0032] The welding device 3 includes a soldering ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com