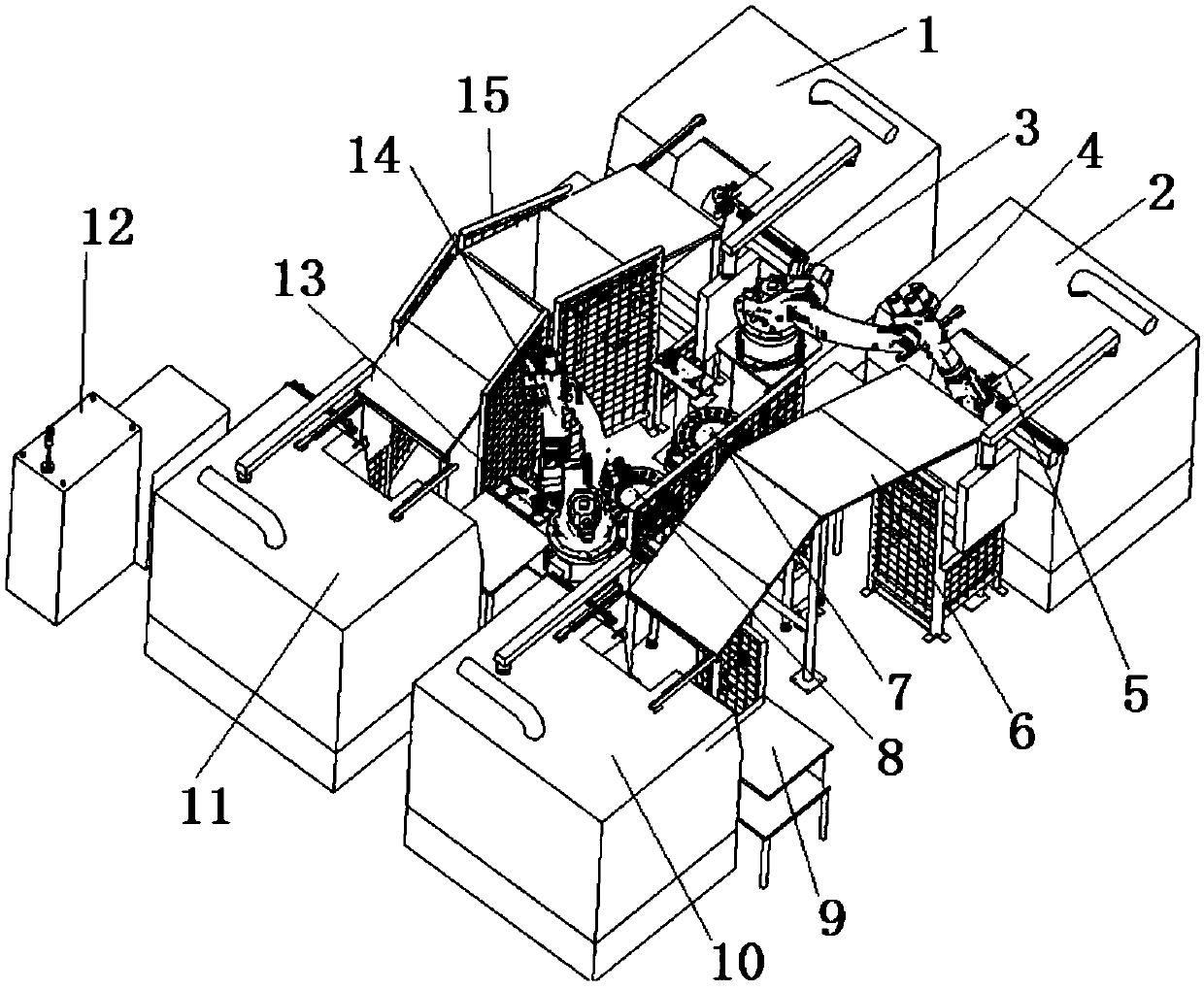

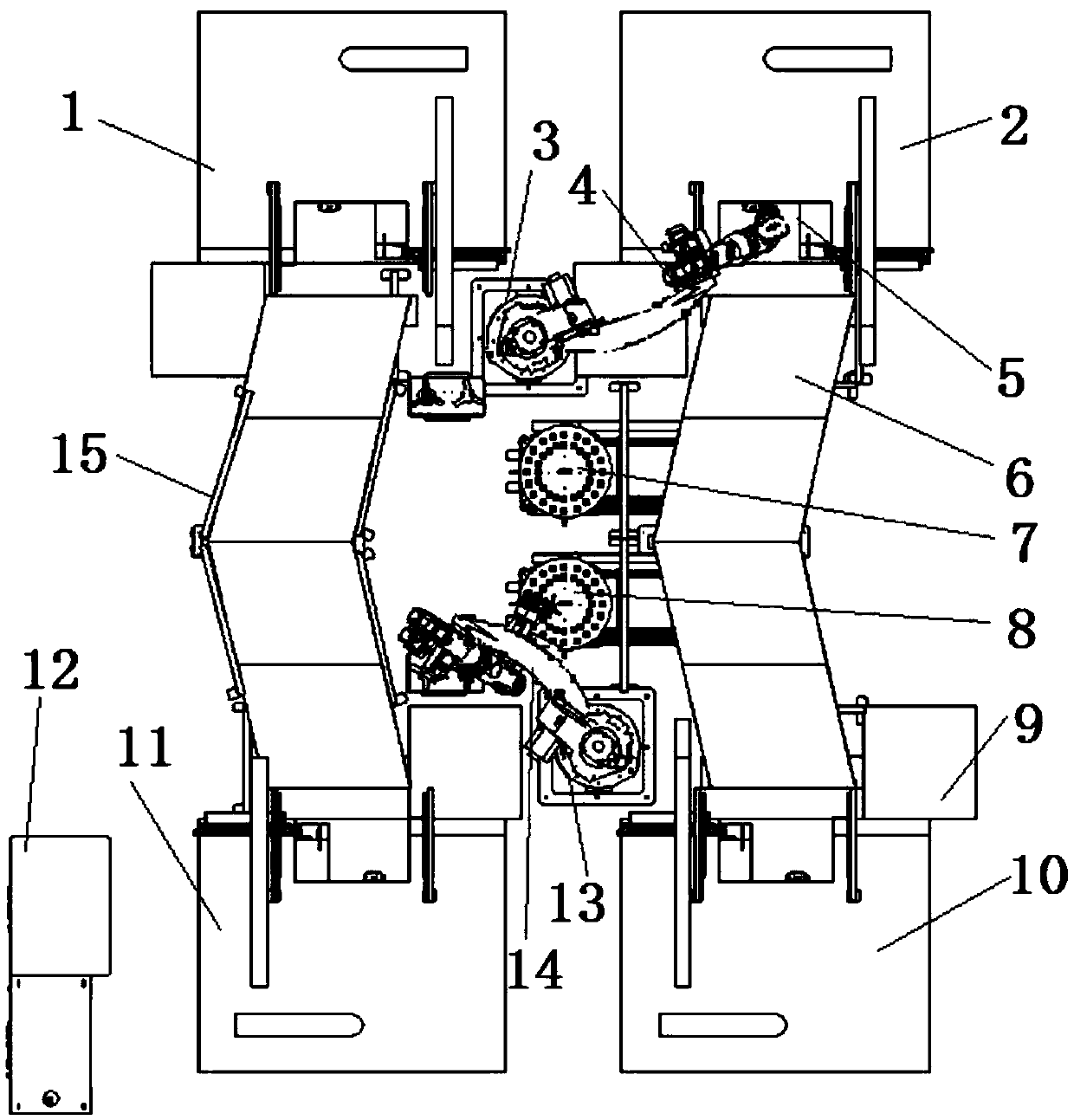

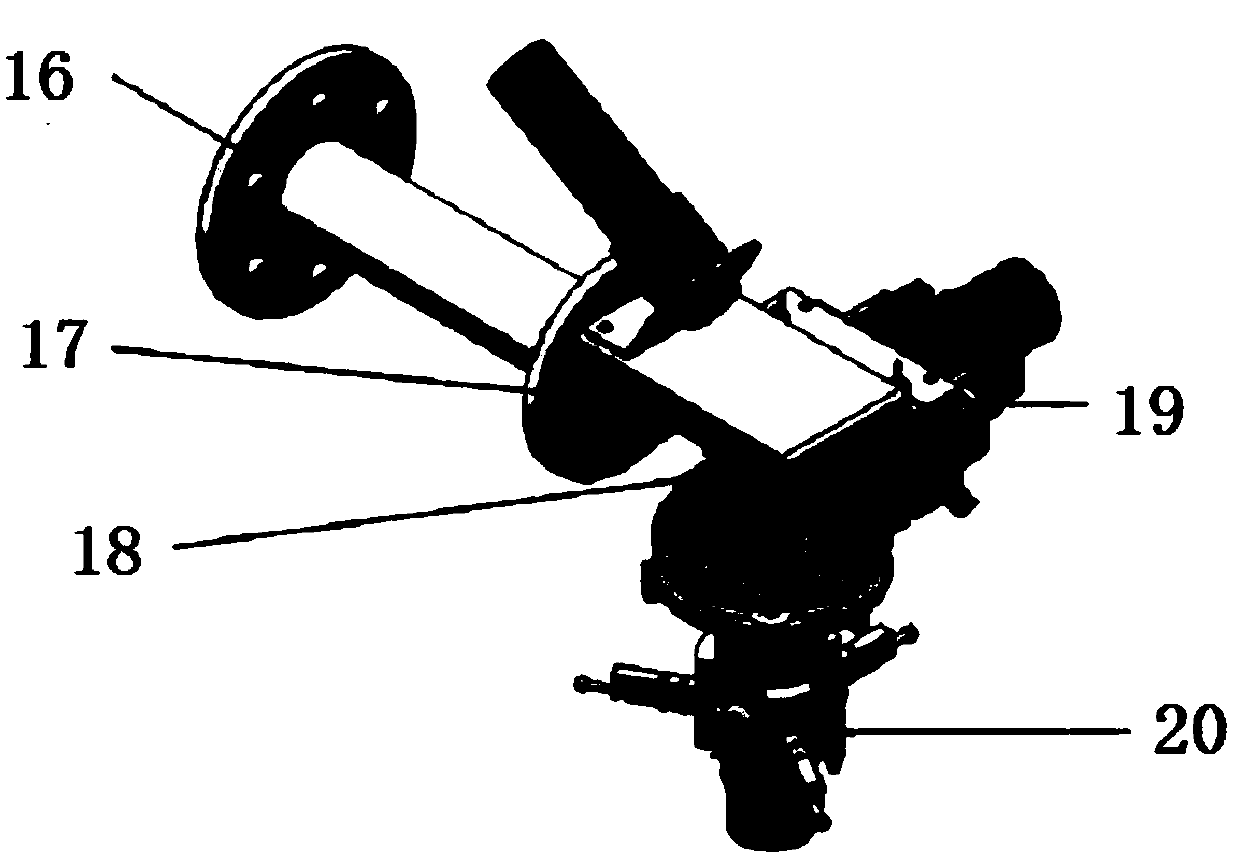

Precision internal grinding automation system for needle valve body and control method thereof

An automation system, needle valve body technology, applied in the direction of digital control, program control, electrical program control, etc., can solve the problems of low production efficiency, low automation and safety, etc., to achieve high degree of automation and safety, simple structure, low cost cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

[0055] The workflow of an implementation case is as follows:

[0056] Production preparation: download the NC code of the part to be processed to the CNC machine tool, prepare the tool, reset the parameters of the machine tool (such as the machine door is closed), and reset other equipment (material buffer table, industrial robot, feeding and discharging table) to zero;

[0057] Control cabinet setting: There are two setting methods for fully automatic operation, one is the production command issued by the upper computer, and the other is the local production setting. When the equipment is connected to the remote control, the upper computer can issue production orders, including the types of processed parts and the number of processed parts. When hitting the local area, you can also choose the type of needle valve body to process and the number of needle valve bodies to process. After all the settings are completed, you can enter the production and processing stage.

[0058] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com