Fodder chopper equipment

A guillotine and equipment technology, applied in the field of guillotine equipment, can solve the problems of super-long materials without support, low applicability of guillotine equipment, and no feeding mechanism, etc., to achieve the effect of supporting, avoiding manual feeding, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

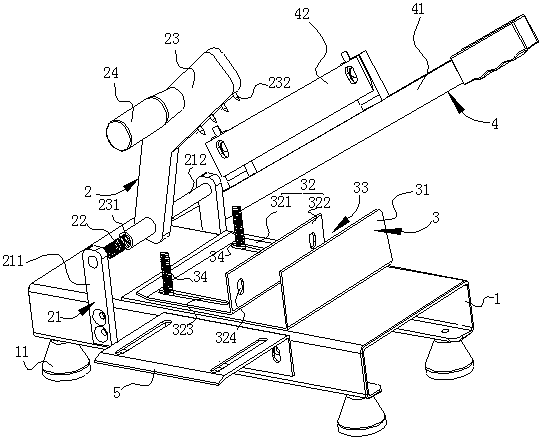

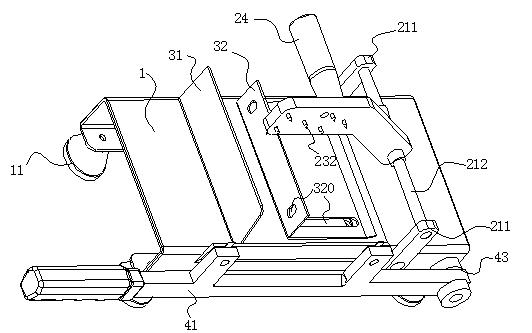

[0029] refer to figure 1 and figure 2 , a guillotine device described in this embodiment includes a machine body 1 , a feeding assembly 2 , a clamp assembly 3 and a guillotine cutting assembly 4 . Both the feed assembly 2 and the clamp assembly 3 are installed on the body 1, the guillotine cutting assembly 4 includes a knife rest 41 and a guillotine 42 fixed on the knife rest 41, one end of the knife rest 41 is connected to the body 1 One side is hinged, and the other end can be rotated at the hinge 43 between the knife rest 41 and the body 1 .

[0030] Preferably, the body 1 can be made of stainless steel, and the lower surface of the body 1 is provided with a number of feet 11 , and the number of feet 11 in this embodiment is four. The guillotine 42 is an alloy blade.

[0031] The feeding assembly 2 includes a mounting frame 21 , a spring 22 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com