Silver nanometer wire synthesizing process

A technology of silver nanowires and synthesis methods, applied in chemical instruments and methods, crystal growth, single crystal growth, etc., can solve problems such as product quality uncertainty, unfavorable large-scale preparation, and impact on electrical conductivity, and achieve excellent dispersion , good structure and mechanical properties, and the effect of reducing reaction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

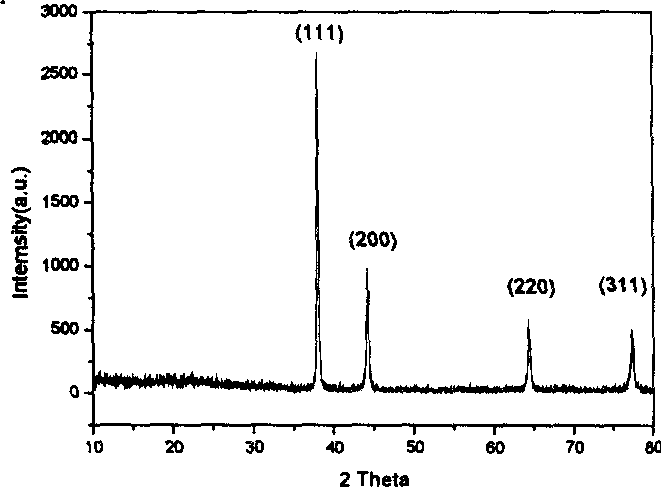

[0033] Vacuumize a closed 50ml three-neck flask equipped with a condensing reflux device and fill it with argon, and place it in an oil bath at 160°C; add 2ml of ethylene glycol, stir with a magnetic stirrer, and preheat for 10min; -4 M AgNO 3 Add 1ml of ethylene glycol solution into the three-neck flask, react for 15min; then add AgNO with a concentration of 0.1M 3 Add 5ml of ethylene glycol solution into the three-neck bottle, control the speed at 900ml / h, and add 10ml of PVP ethanol solution with a concentration of 0.15M dropwise at the same time, keep the speed at 60ml / h, and react for 6h; Add 30ml of acetone to a 100ml beaker, mix well, pour into a centrifuge tube and centrifuge at 3000rpm for 30min, remove the upper solution; then add 40ml of ethanol, ultrasonic for 1min to disperse the precipitate, then centrifuge at 3000rpm, remove the upper solution; repeat once ; Then disperse the purified silver nanowires with 5ml of ethanol, transfer them to a watch glass, and dry...

Embodiment 2

[0035] Vacuumize a closed 50ml three-neck flask equipped with a condensing reflux device and fill it with argon, and place it in an oil bath at 160°C; add 2ml of ethylene glycol, stir with a magnetic stirrer, and preheat for 10min; -4 M AgNO 3 Add 1ml of ethylene glycol solution into the three-neck flask, react for 30min; then add AgNO with a concentration of 0.1M 3Add 5ml of ethylene glycol solution into the three-necked bottle, and the speed is controlled at 1500ml / h. At the same time, 10ml of PVP ethylene glycol solution with a concentration of 0.15M is added dropwise, keeping the speed at 100ml / h, and reacting for 1h; after the reactants are naturally cooled, Pour into a 100ml beaker, add 30ml of acetone and mix evenly, pour into a centrifuge tube and centrifuge at 5000rpm for 30min, remove the upper solution; then add 40ml of ethanol, ultrasonication for 1min to disperse the precipitate, then centrifuge at 5000rpm, remove the upper solution; Repeat once; then disperse th...

Embodiment 3

[0037] Vacuumize a closed 50ml three-necked flask equipped with a condensing reflux device and fill it with argon, and place it in an oil bath at 200°C; add 2ml of ethylene glycol, stir with a magnetic stirrer, and preheat at 200°C for 10 minutes; 2×10 -4 M AgNO 3 Add 1ml of ethylene glycol solution into the three-necked flask, and react at 200°C for 30min; then lower the temperature of the oil bath to 160°C, and then add AgNO 3 Add 5ml of ethylene glycol solution into the three-necked bottle, and the speed is controlled at 2000ml / h. At the same time, 10ml of PVP ethylene glycol solution with a concentration of 0.15M is added dropwise, keeping the speed at 60ml / h, and reacting for 2h; after the reactants are naturally cooled, Pour into a 100ml beaker, add 30ml of acetone and mix evenly, pour into a centrifuge tube and centrifuge at 4000rpm for 30min, remove the upper solution; then add 40ml of ethanol, ultrasonic for 1min to disperse the precipitate, then centrifuge at 4000rp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com