Automatic spraying device for porcelain insulator

A technology of automatic spraying and porcelain insulators, applied in spraying devices, spray booths, etc., can solve the problems of inconvenient continuous rotation and replacement of materials, inability to improve processing efficiency, and inability to improve feeding speed, etc., to shorten the clamping time and avoid manual labor. The effect of feeding, simple and flexible structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

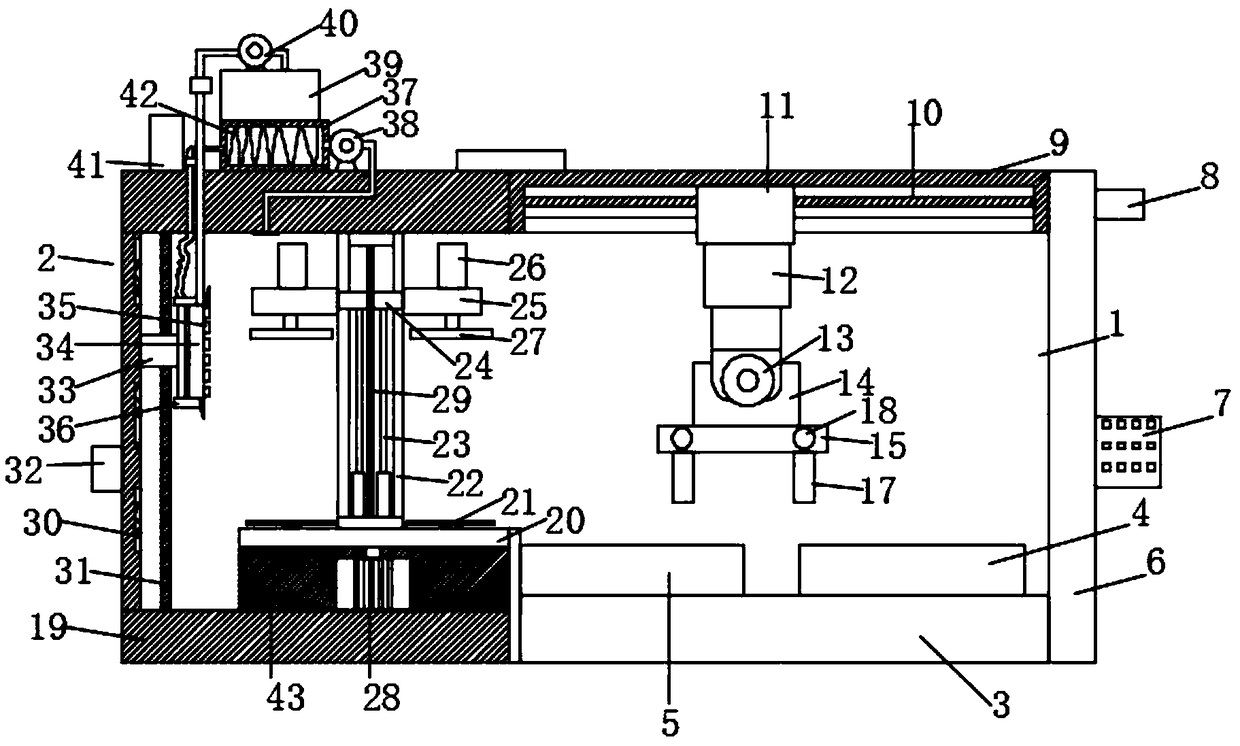

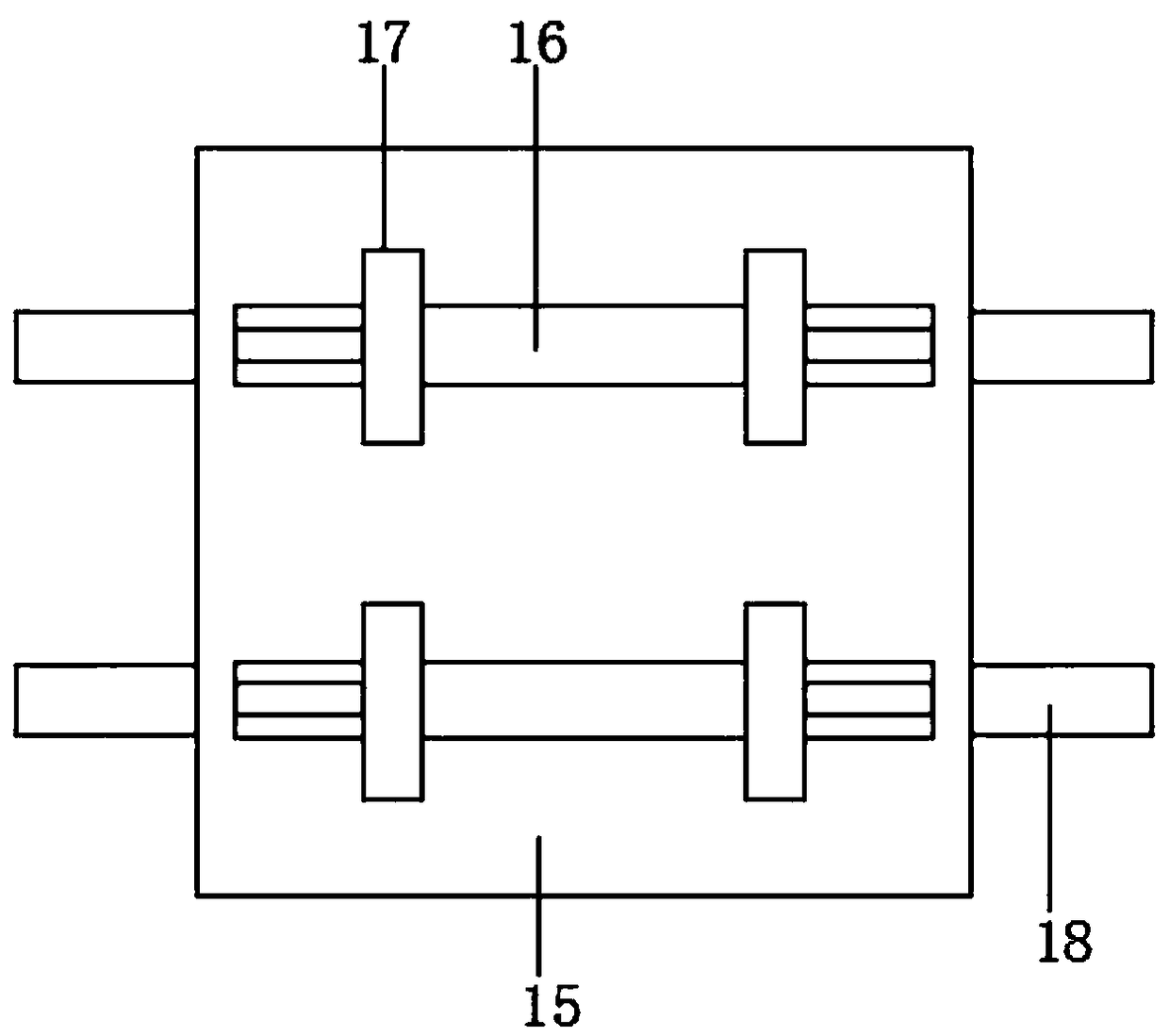

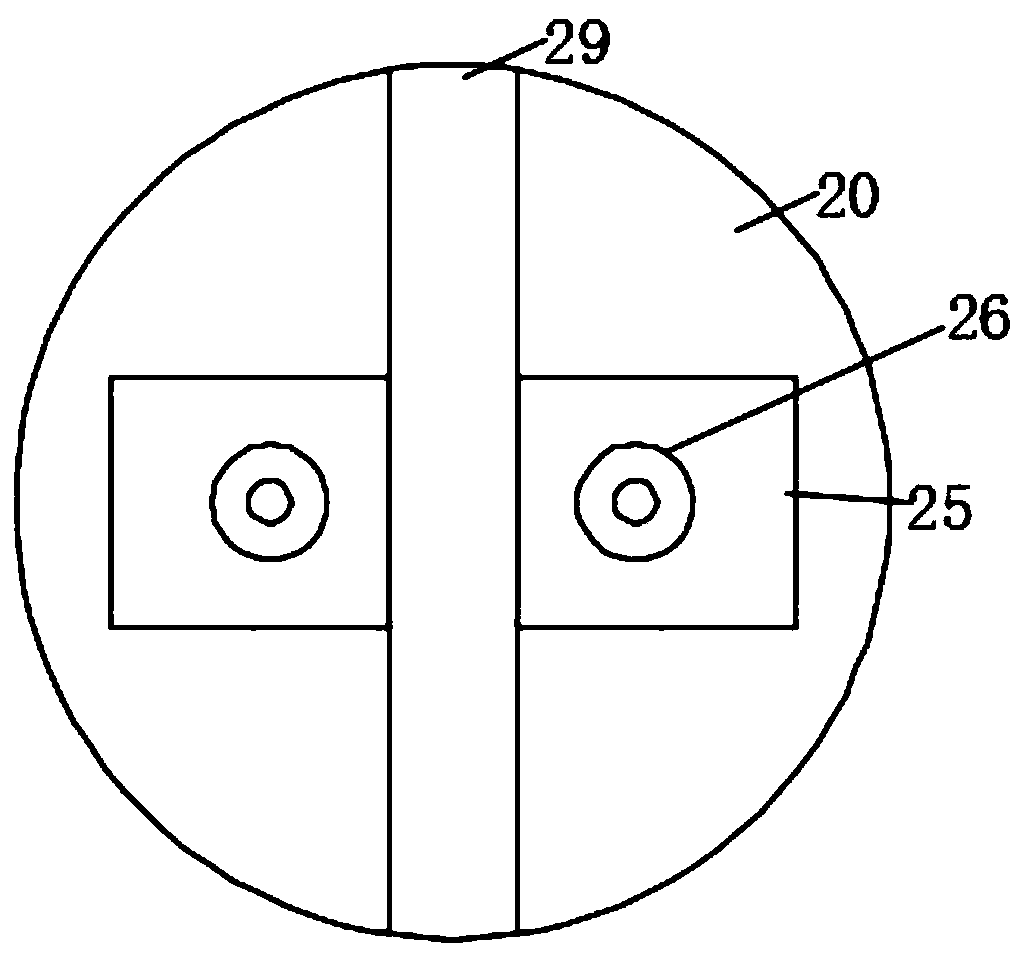

[0019] Such as Figure 1-3 As shown, this specific embodiment adopts the following technical scheme: an automatic spraying device for porcelain insulators, including a feeding mechanism 1 and a spraying mechanism 2, and the feeding mechanism 1 is composed of a material base 3, a first hopper 4, a second Hopper 5, support plate 6, control panel 7, feeding motor 8, feeding chute 9, feeding screw rod 10, feeding slider 11, feeding cylinder 12, servo motor 13, connecting plate 14, fixing plate 15, clip Holding chute 16, clamping plate 17 and clamping cylinder 18, one end of the material base 3 is fixedly connected with a support plate 6, and the top of the support plate 6 is fixedly connected with a feeding chute 9, the feeding The inside of the chute 9 is slidingly connected with a feeding slider 11, and the inside of the feeding chute 9 is rotatably connected with a feeding screw 10, and the feeding screw 10 is threadedly connected with the feeding slider 11. The side of the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com