Phase difference calibrating system for rotating shaft

A technology for calibrating systems and rotating shafts, applied in the direction of force/torque/work measurement instrument calibration/testing, measuring devices, instruments, etc., and can solve problems such as phase difference, no standard input signal, and inability to perform calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

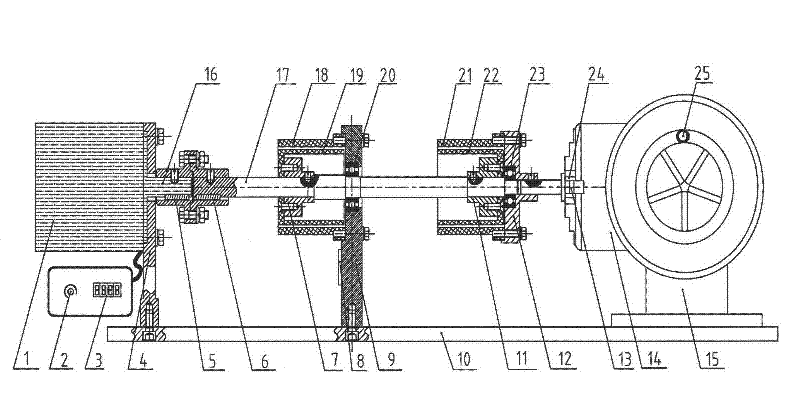

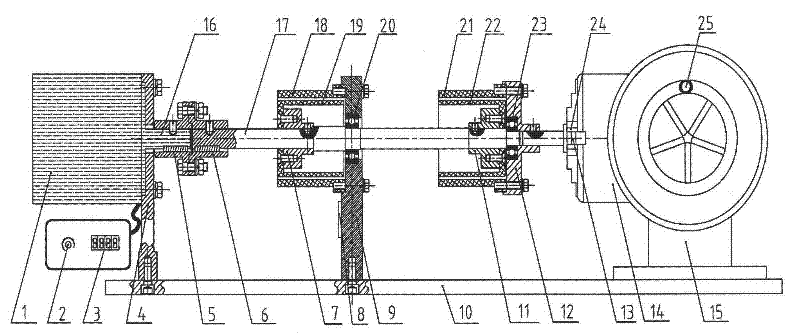

[0019] Embodiment 1. Rotary axis calibration system

[0020] This rotating shaft calibration system of this example is used to calibrate the instrument or device for measuring the rotational speed of the rotating shaft, and the specific structure of the rotating shaft rotational speed calibration system can be figure 1 As shown, the calibration system includes: a motor 1 and its driven motor shaft 16, the front end of the rotating shaft motor shaft 16 and the rotating shaft 17 are connected on the coaxial line through a coupling 5-6. The bracket 9 that fixes the rotating shaft 17, the middle part of the rotating shaft 17 is rotatably arranged or installed on the bracket 9 such as through the bearing A (20). Sleeve A is also installed on the support 9, and sleeve A is made up of the urceolus A (18) that is installed on the support 9 and the inner cylinder A (19) that is installed on the rotating shaft 17 by follower sleeve A (7). The part to be calibrated in this example is th...

Embodiment 2

[0023] Embodiment 2. Rotary axis calibration system

[0024] The structure of the rotary axis calibration system in this example can generally be used figure 1 As shown, the structure of the calibration system is as described in Embodiment 1 and will not be repeated. The difference between the rotary shaft speed calibration system of this example and the rotary shaft speed calibration system of Embodiment 1 is as follows: 1. The instrument or device for measuring the rotary shaft speed of the calibrated part of the rotary shaft speed calibration system of this example is a grating rotary shaft speed Tester, the structure of the grating rotary shaft speed tester is composed of a light source A, a grating A, a photoelectric receiving element A, a counting circuit and a display circuit. The grating A is installed on the rotating shaft 17 coaxially with the rotating shaft 17, and the light source A and the photoreceiving element A are arranged on one side of the grating A (for th...

Embodiment 3

[0025] Embodiment 3. Rotary axis calibration system

[0026] The structure of the rotary axis calibration system in this example can generally be used figure 1As shown, the structure of the calibration system is as described in Embodiment 1 and will not be repeated. The difference between the rotary shaft speed calibration system of this example and the rotary shaft speed calibration system of embodiment one and embodiment two is: 1. The instrument or device for measuring the rotary shaft speed of the calibrated part of the rotary shaft speed calibration system of this example is Hall rotary shaft speed tester, the structure of the Hall rotary shaft speed tester is composed of magnets, Hall sensors, counting circuits and display circuits and other test circuits. Stick the magnet on the rotating shaft 17, and the probe of the Hall sensor is aligned with the magnet and installed on the bracket 9. The output end of the hall sensor is connected with the input end of the counting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com