Feeding mechanism of sewing machine

A feeding mechanism and sewing machine technology, applied in the field of sewing machines, can solve problems such as cumbersome processing, high labor costs, and low production efficiency, and achieve the effects of avoiding reprocessing procedures, reducing labor costs, and reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

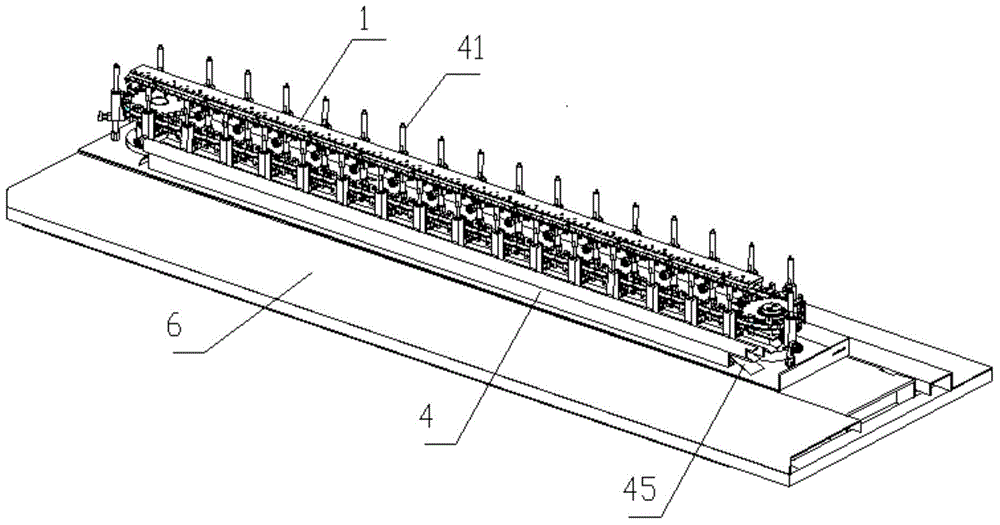

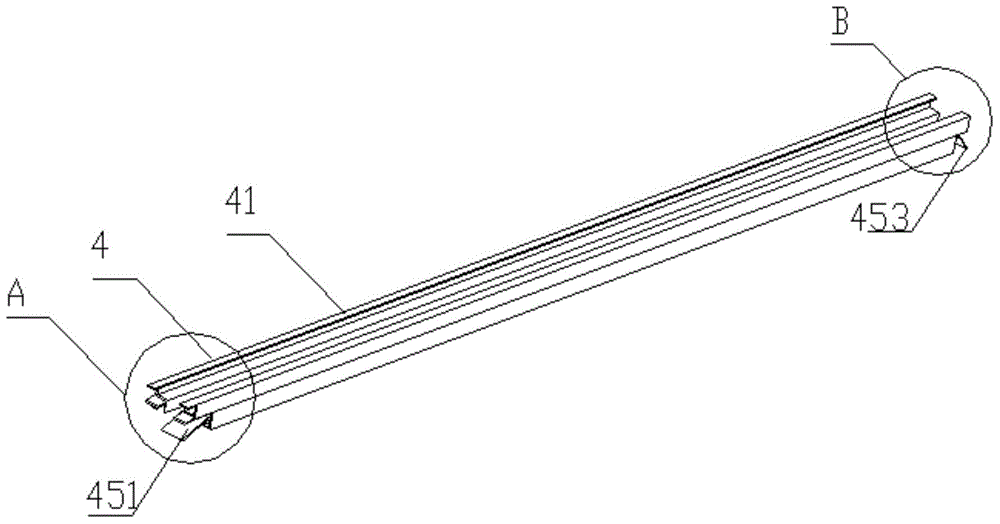

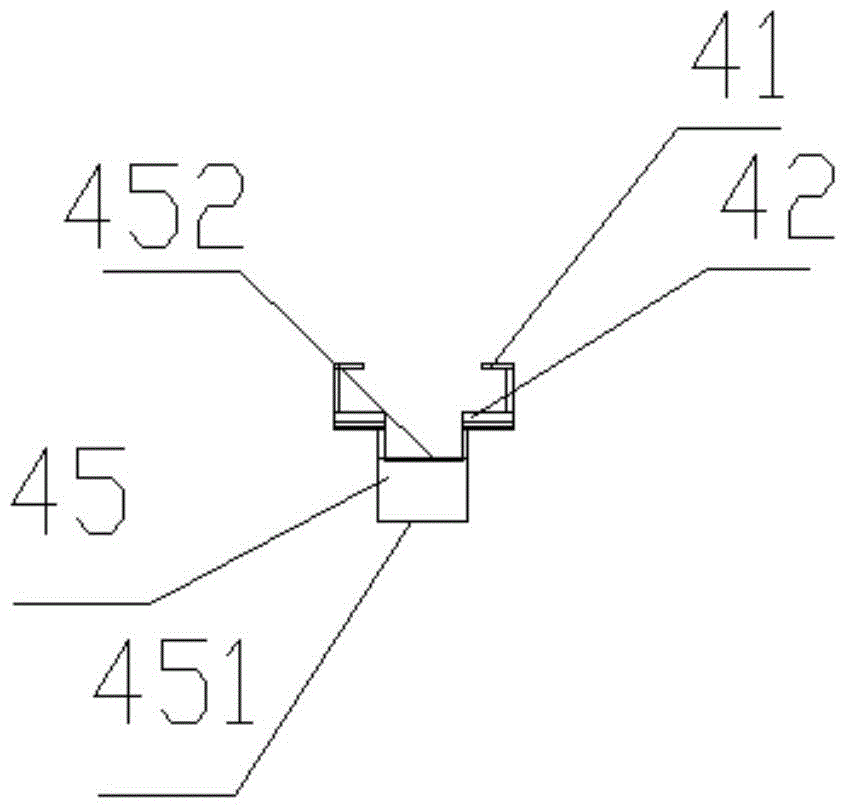

[0026] Such as figure 1 , the feeding mechanism of the sewing machine provided by the present embodiment is located on the frame, and mainly consists of frame 1, hanging cloth plate 5, transmission belt 31, limit rail 452, ramp 45, some ejector rods 2, thimble 22 And two driving rollers 3. The transmission rollers 3 are rotatably connected to the frame 1, and the two transmission rollers 3 are connected by a transmission belt 31 to form a closed-loop transmission chain. The ejector rods 2 are evenly arranged on the transmission belt 31 and move with the transmission belt 31 in a set motion track. The trajectory is determined by figure 1 It can be known as a type of ellipse, which is composed of two straight transmission paths and two semi-circular transmission paths. The high ends of the limiting rails are respectively connected with the two ramps...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com