Method for processing locating hole of product locating piece in forming mould

A processing method and a technology of positioning parts, which are applied in the direction of manufacturing tools and workshop equipment, etc., can solve problems such as waste and prolong mold repair time, and achieve the effects of improving labor productivity, avoiding returning to processing, and shortening repair time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

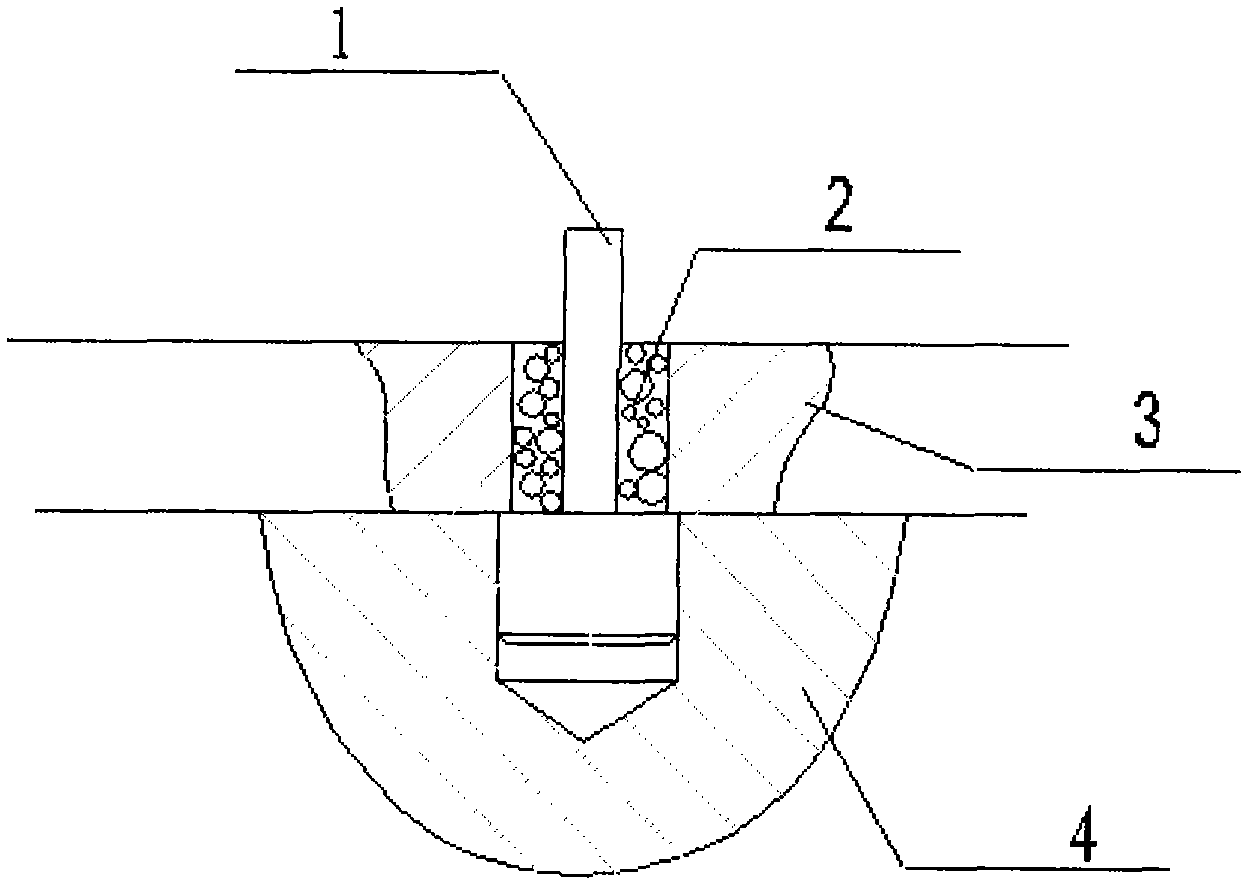

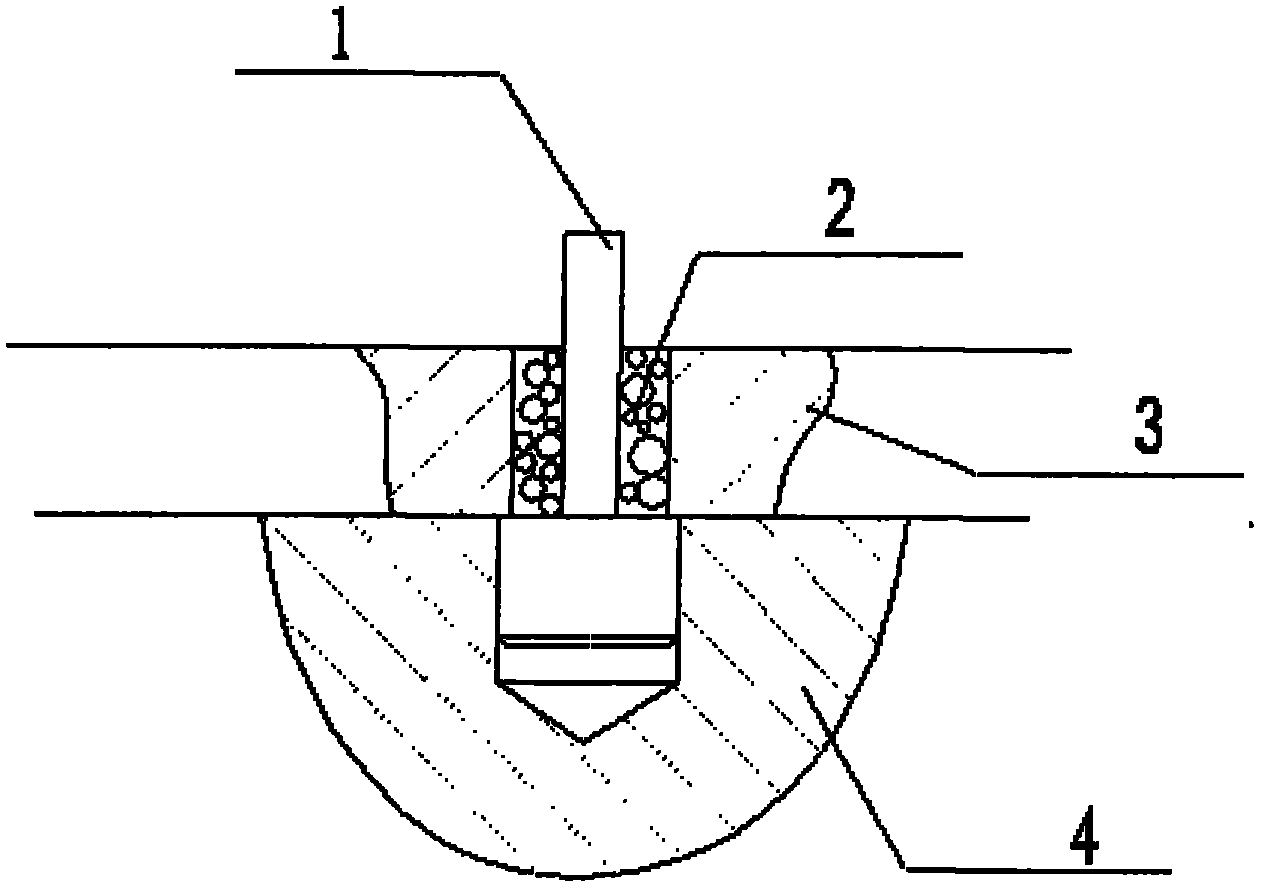

[0019] The specific implementation of this method is: first make a small hole smaller than the end hole at the approximate position of the positioning piece, then make a stepped pin and press it into the positioning hole of the mold body, then fix the positioning piece at the correct position with the connecting piece, and then Fill the gap between the positioning piece and the stepped pin with epoxy resin mixture. After the glue is completely dry, remove the positioning piece, align the hole made by the mixture, and expand and bore to the required positioning. hole. It is required that the cooperation between the pin used and the positioning hole of the mold body must be excessively matched, and the mixed glue must be fully filled.

[0020] An example of this method is as follows: For example, in the manufacturing process of the side wall positioning part of a certain model, the thickness of the positioning part is 16 mm, the width is 45 mm, and the length is 120 mm. There ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com