Patents

Literature

72 results about "Ammonium aluminium sulfate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ammonium aluminium sulfate, also known as ammonium alum or just alum (though there are many different substances also called "alum"), is a white crystalline double sulfate usually encountered as the dodecahydrate, formula (NH₄)Al(SO₄)₂·12H₂O. It is used in small amounts in a variety of niche applications. The dodecahydrate occurs naturally as the rare mineral tschermigite.

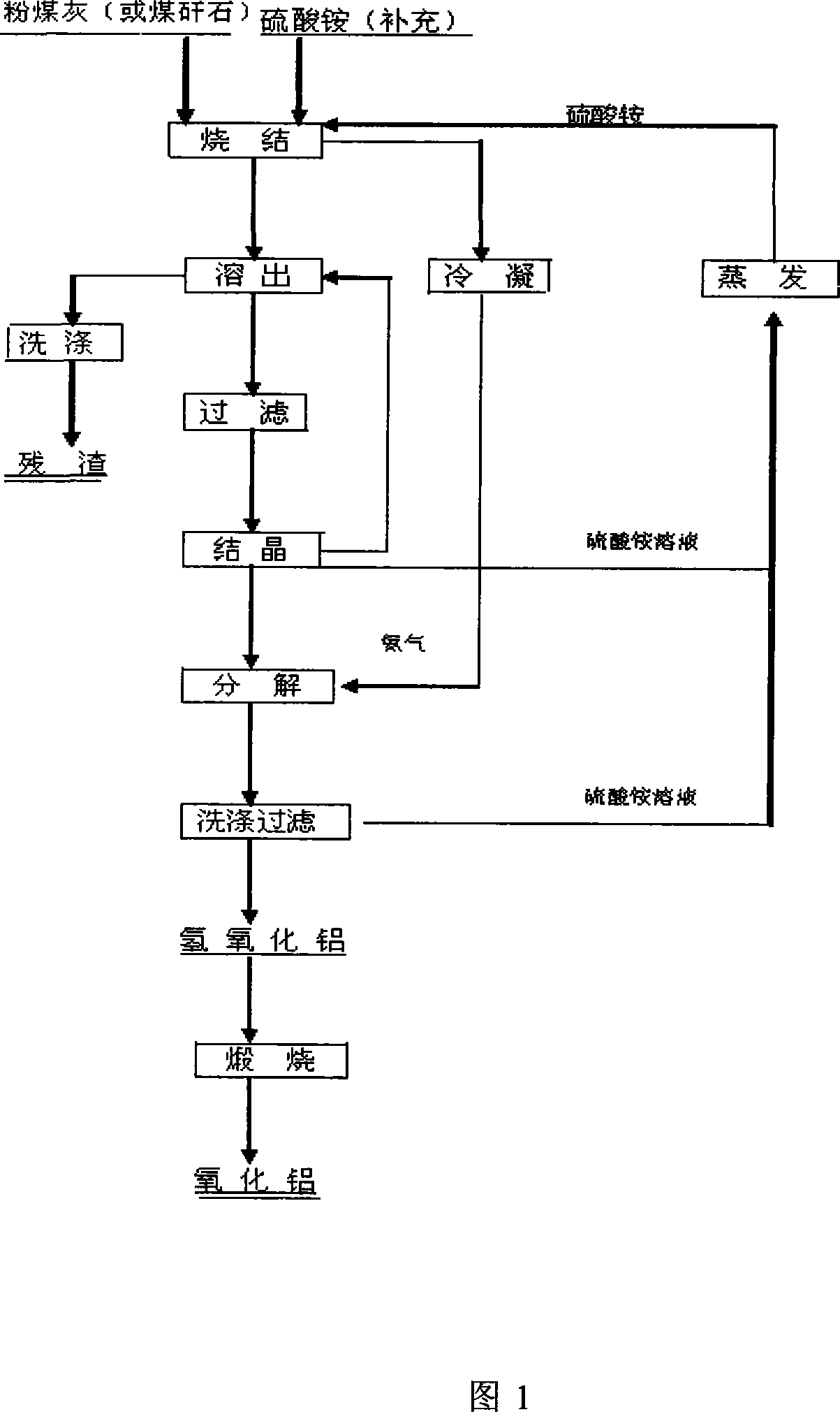

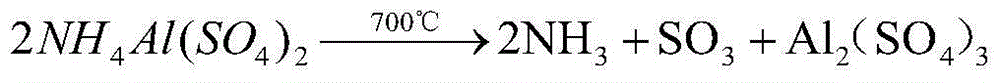

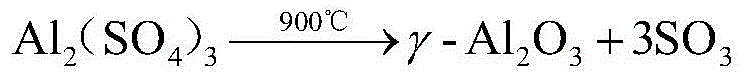

Method for extracting aluminium oxide from coal ash

ActiveCN101117228AEfficient use ofLess corrosiveAluminium oxide/hydroxide preparationAluminium oxides/hydroxidesAluminium hydroxideAmmonium aluminium sulfate

The invention provides a method to extract aluminum oxide from a fly ash, and relates to a technological method which is to extract aluminum oxide from the fly ash and comprehensively utilize the residue after extracting aluminum oxide. The invention is characterized in the method which is as follows: ammonium sulfate is mixed into the fly ash to sintering, and the solid is dissolved to obtain the solution containing aluminum-ammonium sulfate; the solution is crystallized to form solid aluminium-ammonium sulfate; solid aluminium-ammonium sulfate reacts with ammonia gas to obtain aluminium hydroxide and ammonium sulfate, and aluminium hydroxide and ammonium sulfate are washed and filtrated to obtain solid aluminium hydroxide; solid aluminium hydroxide is calcined to obtain aluminum oxide; ammonium sulfate can be circularly used after being evaporated in the liquid phase. The ammonium sulfate which is used by the method of the invention is weak acidic, the corrosiveness on the equipment is small, and the ammonium sulfate can be used circularly. The whole process is easy to industrial application. The requirement of the corrosion resistance on the equipment is low. The amount of the residue is small which is beneficial to the comprehensive utilization of the residue after extracting the aluminum oxide.

Owner:河南华慧有色工程设计有限公司 +1

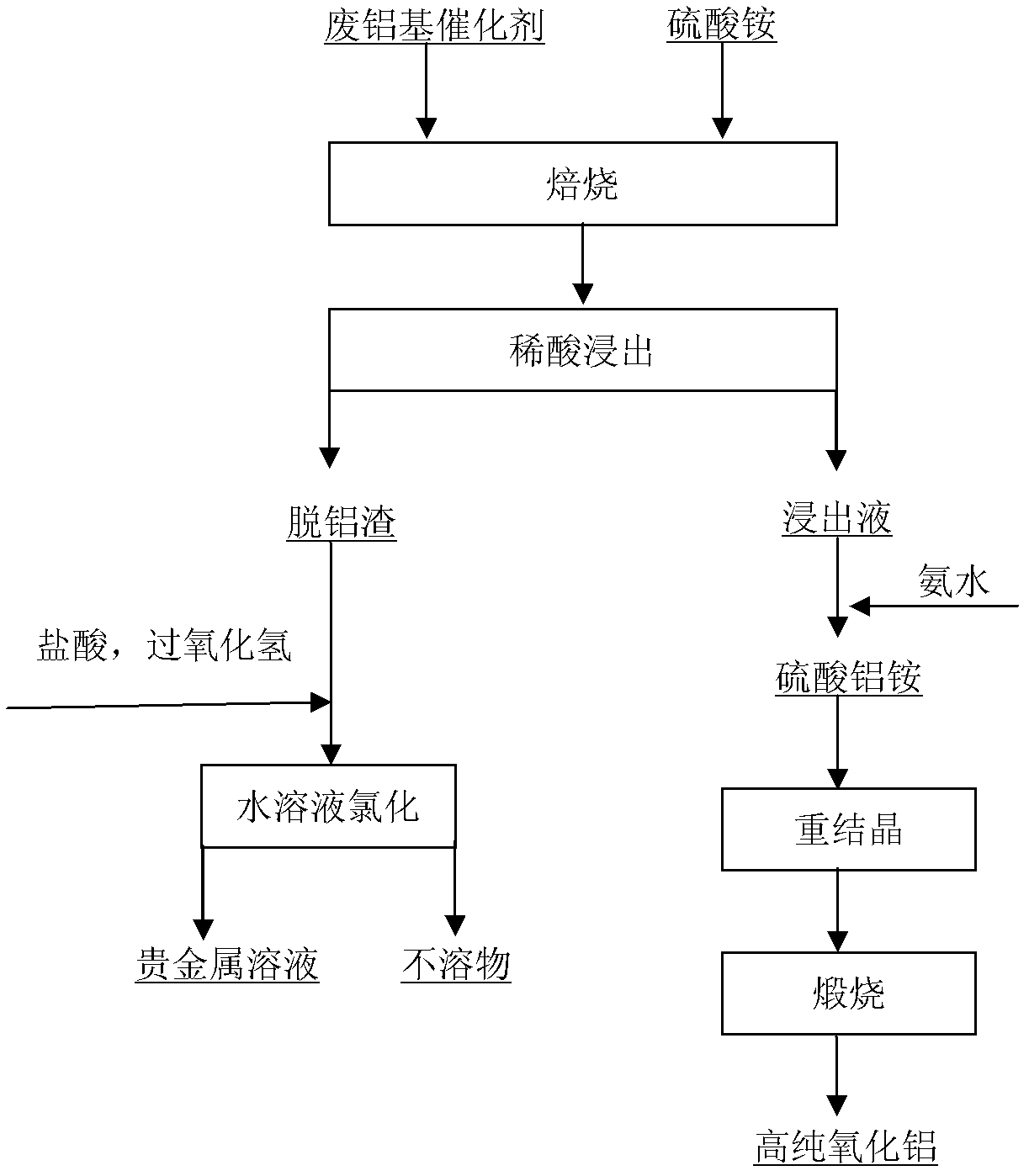

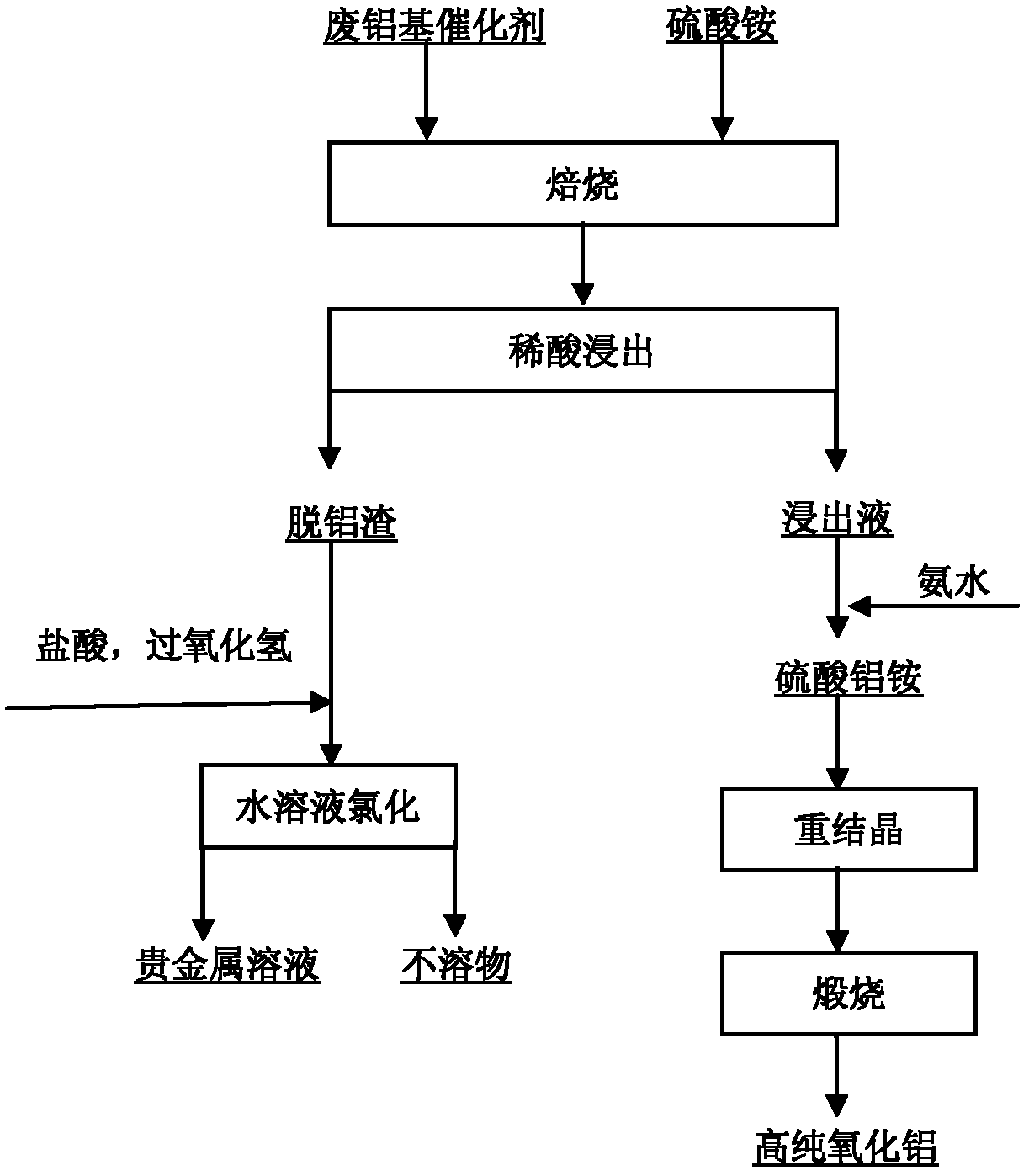

Method for recovering precious metal from waste aluminum-based catalyst and preparing high-purity alumina

InactiveCN102560129AAchieve recyclingReasonable processProcess efficiency improvementSlagAmmonium aluminium sulfate

The invention discloses a method for recovering precious metal from a waste aluminum-based catalyst and preparing high-purity alumina. The method mainly comprises the processes of: roasting, leaching to remove aluminum by using dilute sulfuric acid, recovering the precious metal from slag from which the aluminum is removed by an aqueous solution chlorination method, adding ammonia water into leachate to precipitate an ammonium aluminum sulfate coarse crystal, recrystallizing, and calcining and decomposing to prepare the high-purity alumina. The method specifically comprises the following steps of: mixing the finely ground waste aluminum-based catalyst (40mu m) and ammonium sulfate in a weight ratio of 1:(1.3-1.5), roasting at the temperature of between 300 and 500 DEG C for 2 to 4 hours, performing fluidization leaching on a roasting product by using 1mol / L dilute sulfuric acid for 2 hours, performing solid-liquid separation, and recovering the precious metal from the slag from which the aluminum is removed by the traditional aqueous solution chlorination method, wherein the recovery rate of the precious metal is over 99 percent; and adding the ammonia water into the leachate to regulate the pH value and precipitate the ammonium aluminum sulfate coarse crystal, recrystallizing, and calcining and decomposing to prepare the high-purity alumina, wherein the purity is over 99.99 percent, and the recovery rate is over 95 percent. The invention has the advantages that: the process is reasonable, the method is easy to operate, the added value of a product is high, pollution is light, mass production is convenient to implement, and the like.

Owner:KUNMING INST OF PRECIOUS METALS

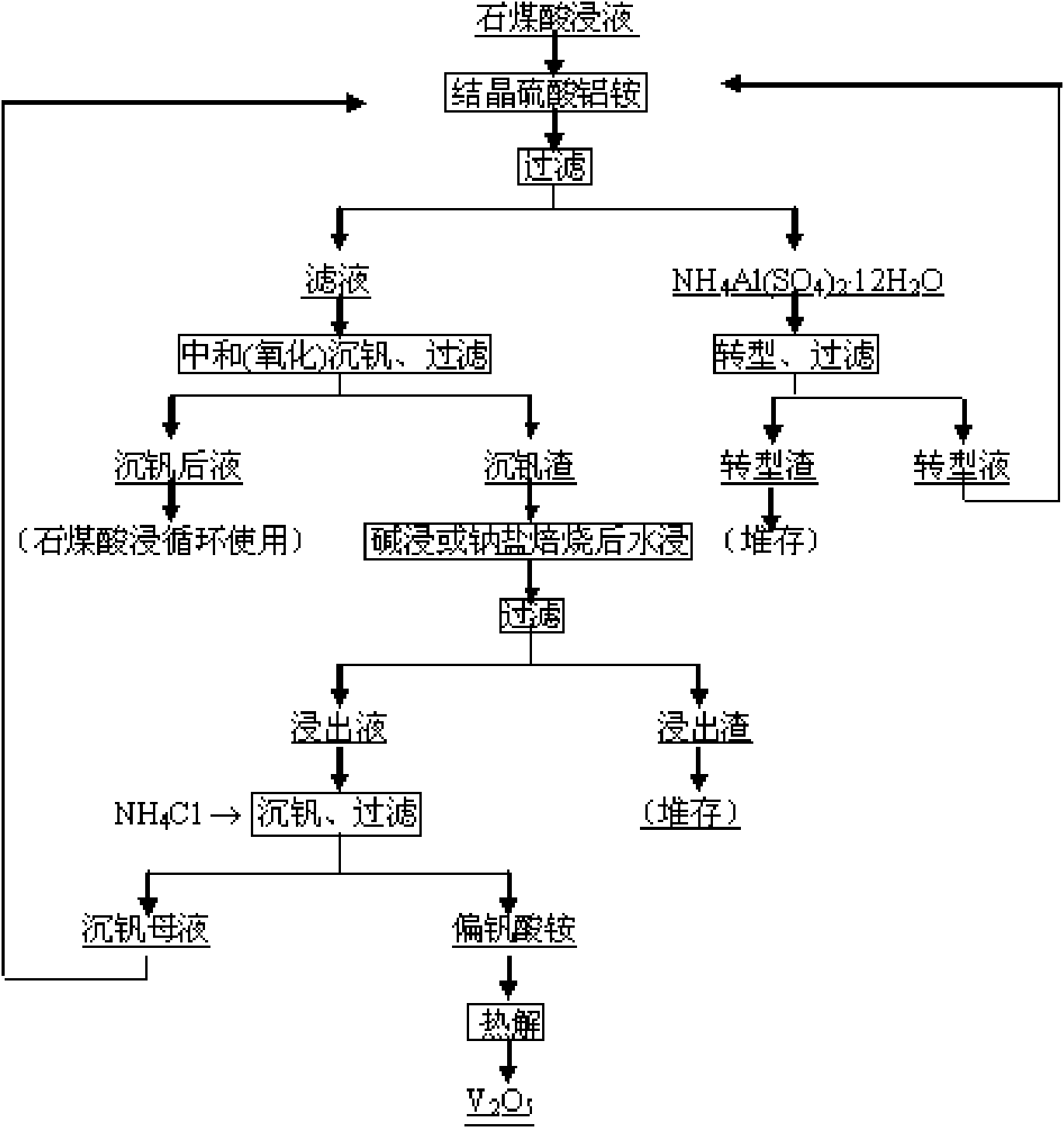

Comprehensive recovery method for extracting ferrovanadium from stone coal acid immersion liquid

InactiveCN102127657AEasy to separateEasy to recycleProcess efficiency improvementRecovery methodSlag

The invention relates to a comprehensive recovery method for extracting ferrovanadium from stone coal acid leaching liquid. The process mainly comprises the following steps of: crystallizing a stone coal sulfuric acid leaching liquid into ammonium aluminum alum sulfate and adding a pH value regulator to the crystallized liquid at a room temperature; oxidizing, precipitating and separating out crystallized liquid into a mixture containing ammonium jarosite and ammoniojarosite, leaching the vanadium-contained mixture separated from the precipitate in alkaline to obtain alkaline leaching liquid and alkaline leaching slag; adding sulphuric acid to the alkaline leaching liquid to acidify and precipitate vanadium pentoxide, calcining, washing and drying the vanadium pentoxide to obtain a refined vanadium product, calcining the alkaline leaching slag to obtain ferric oxide or adding sulphuric acid to dissolve, concentrate and crystallize to obtain polymerase ferric sulfate; and transforming the ammonium aluminum alum sulfate and regenerating vanadium precipitation mother liquor alkali, and the like. The invention has the advantages of good product quality, less reagent amount, low production cost, environmental protection, and the like.

Owner:CENT SOUTH UNIV

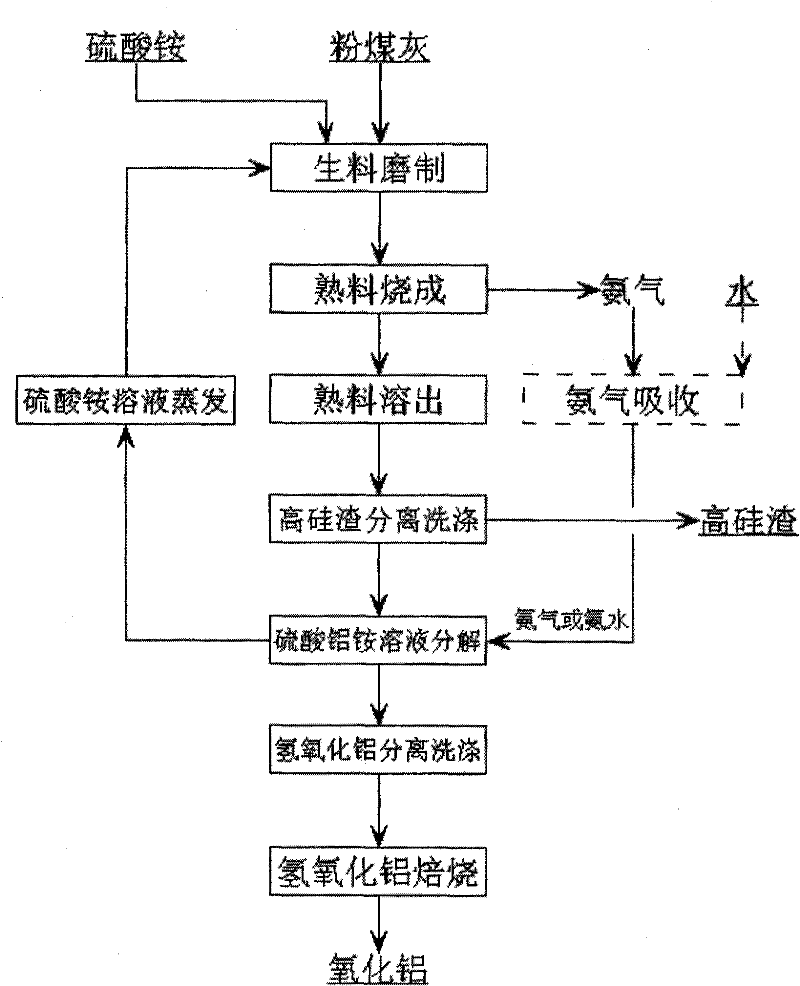

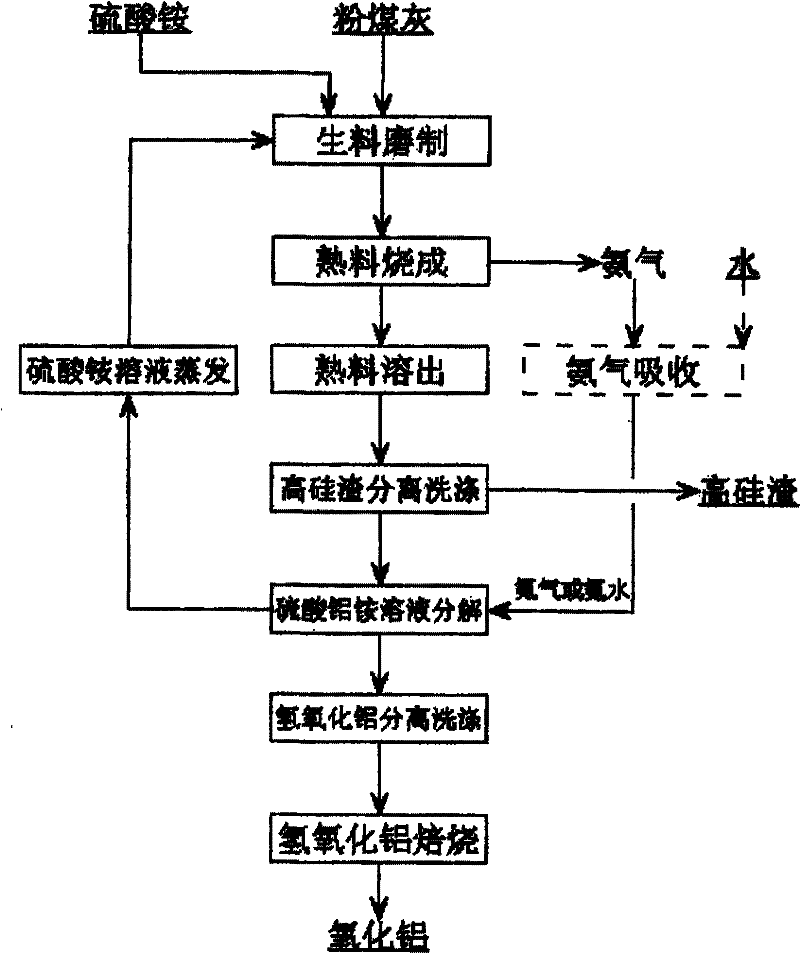

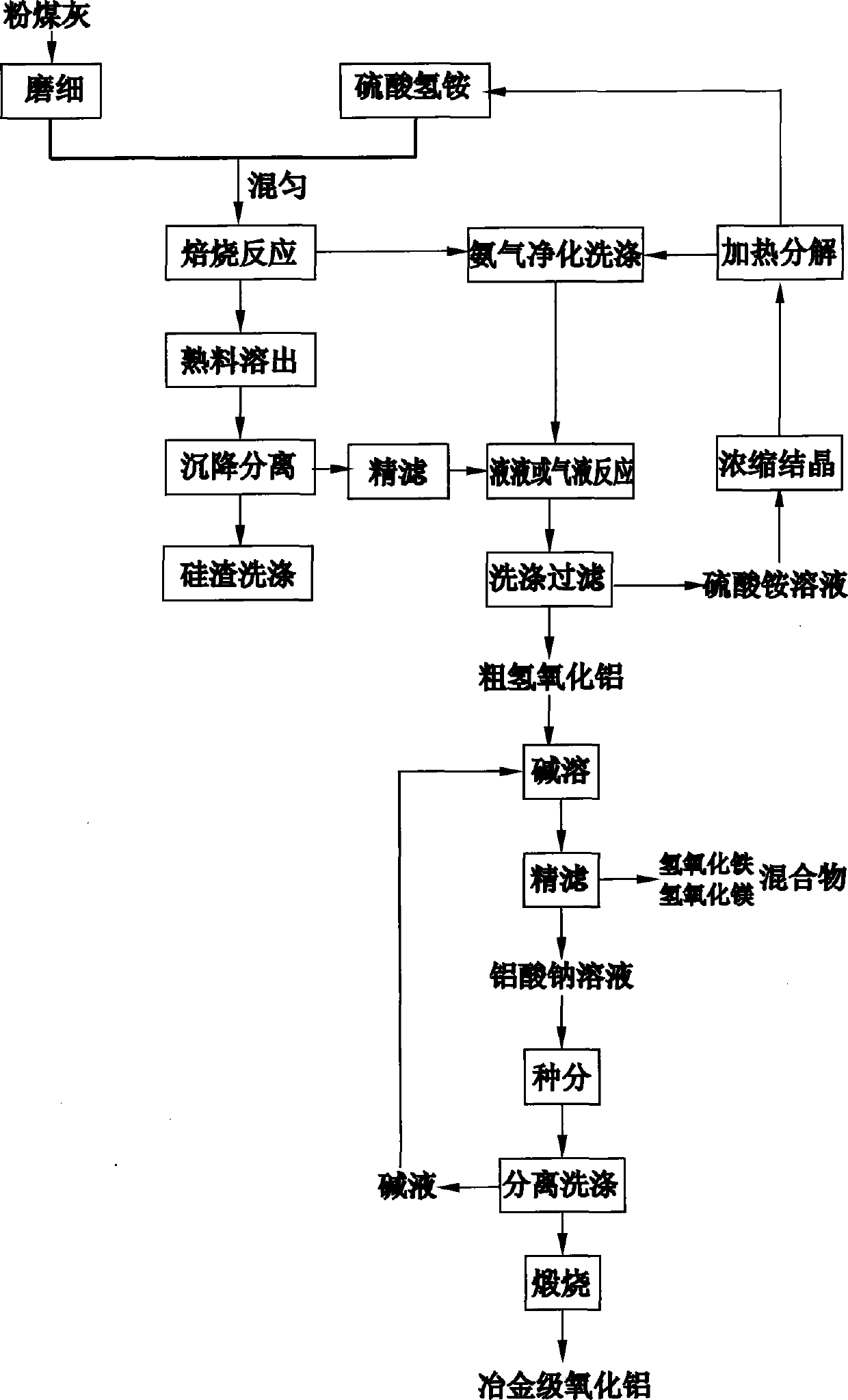

Method for preparing alumina from fly ash

InactiveCN102344155AEfficient use ofEasy to industrializeSolid waste disposalAluminium oxides/hydroxidesSlagAluminium hydroxide

The invention discloses a method for preparing alumina through industrial solid waste treatment and utilization, and specially, relates to a method for preparing alumina from fly ash. The method for preparing alumina from fly ash comprises the following steps of grinding raw materials, calcining the grinded raw materials into clinker, carrying out separation and washing to obtain high-silicon content slag, decomposing an ammonium aluminum sulfate solution, separating and washing aluminum hydroxide obtained by the previous step, carrying out calcination of aluminium hydroxide obtained by the previous step to obtain alumina as a product, evaporating an ammonium sulfate solution and the like. The method for preparing alumina from fly ash does not adopt any auxiliary agent. Through the method for preparing alumina from fly ash, alumina can be extracted effectively from fly ash, wherein an extraction rate of alumina reaches above 90%.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

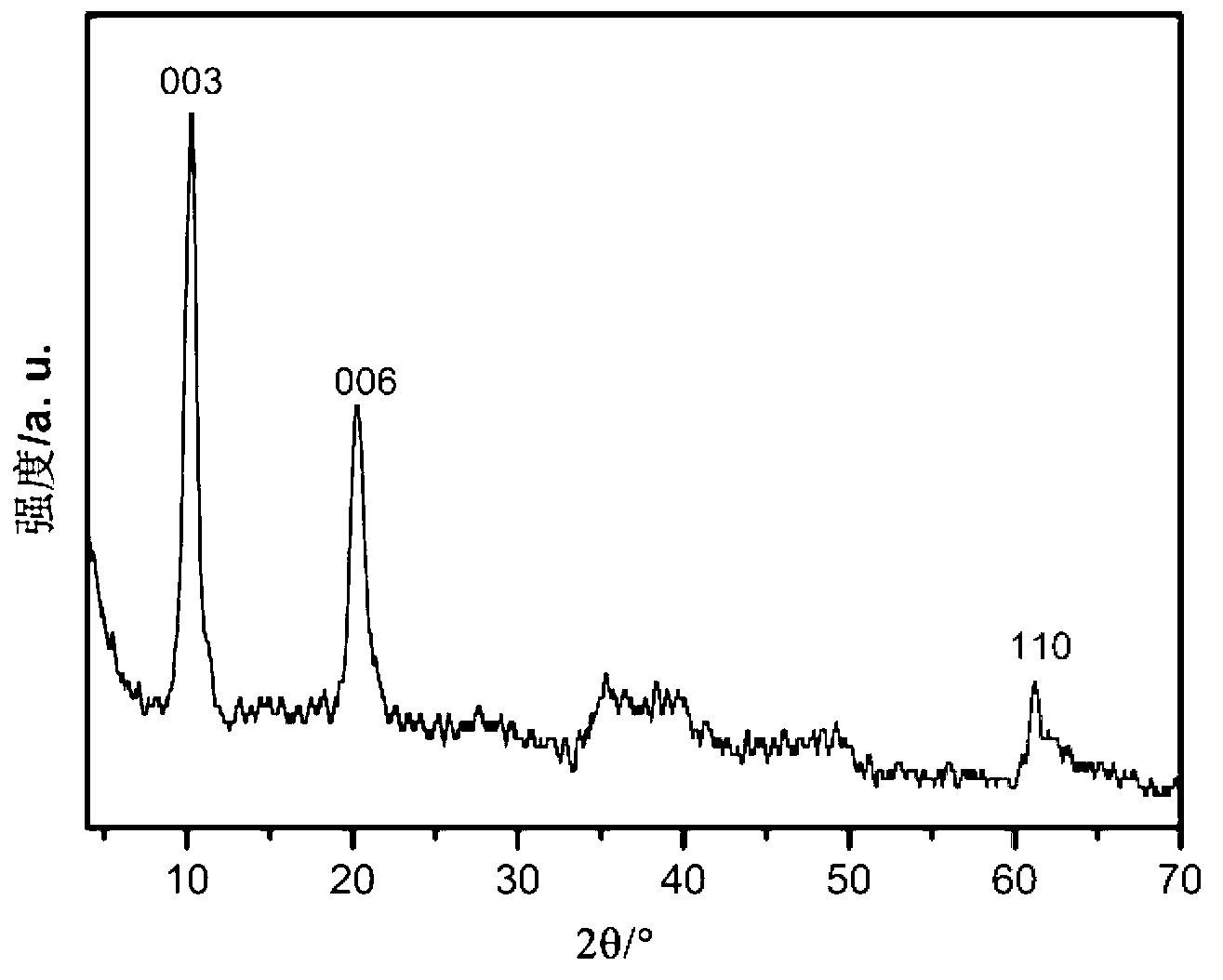

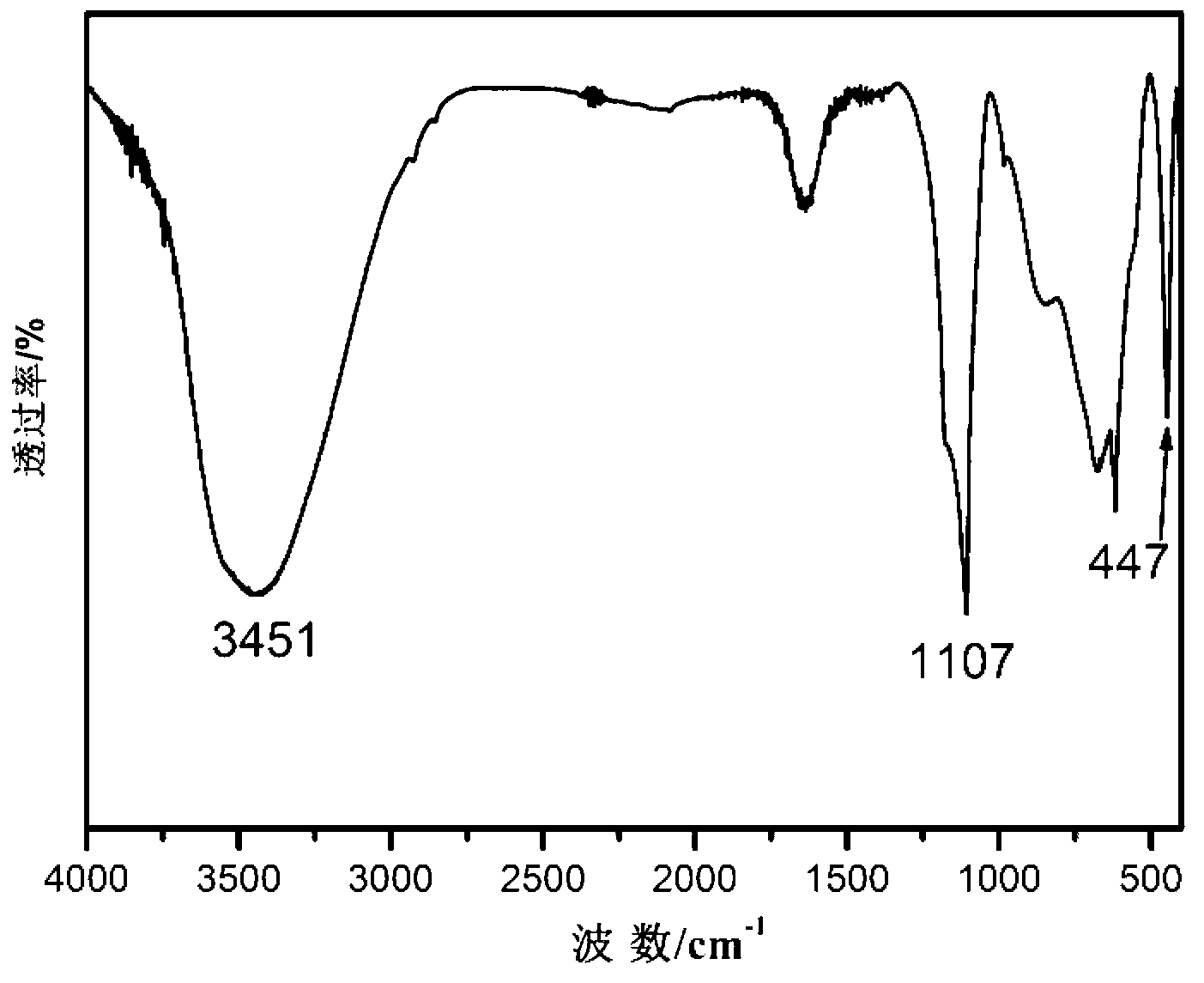

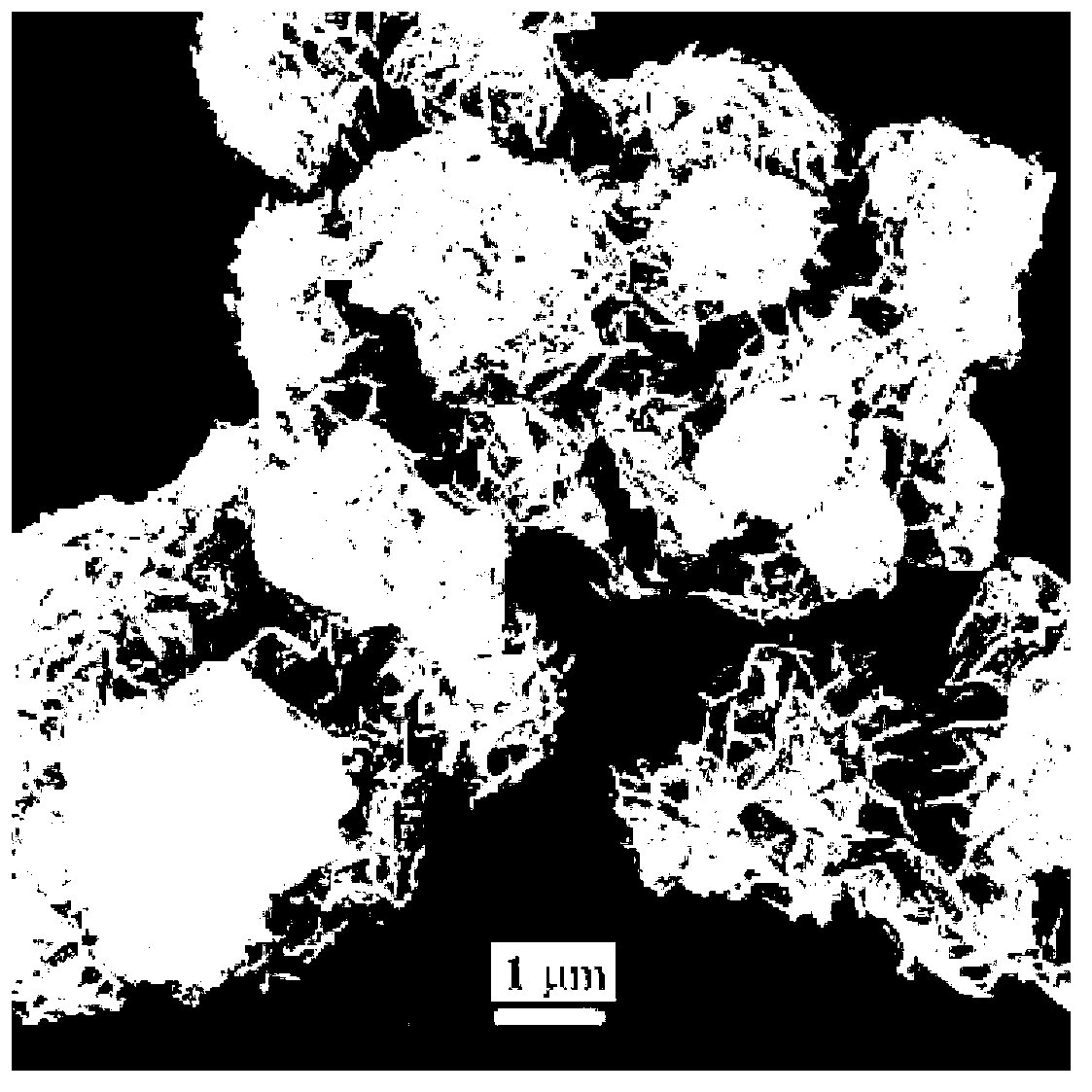

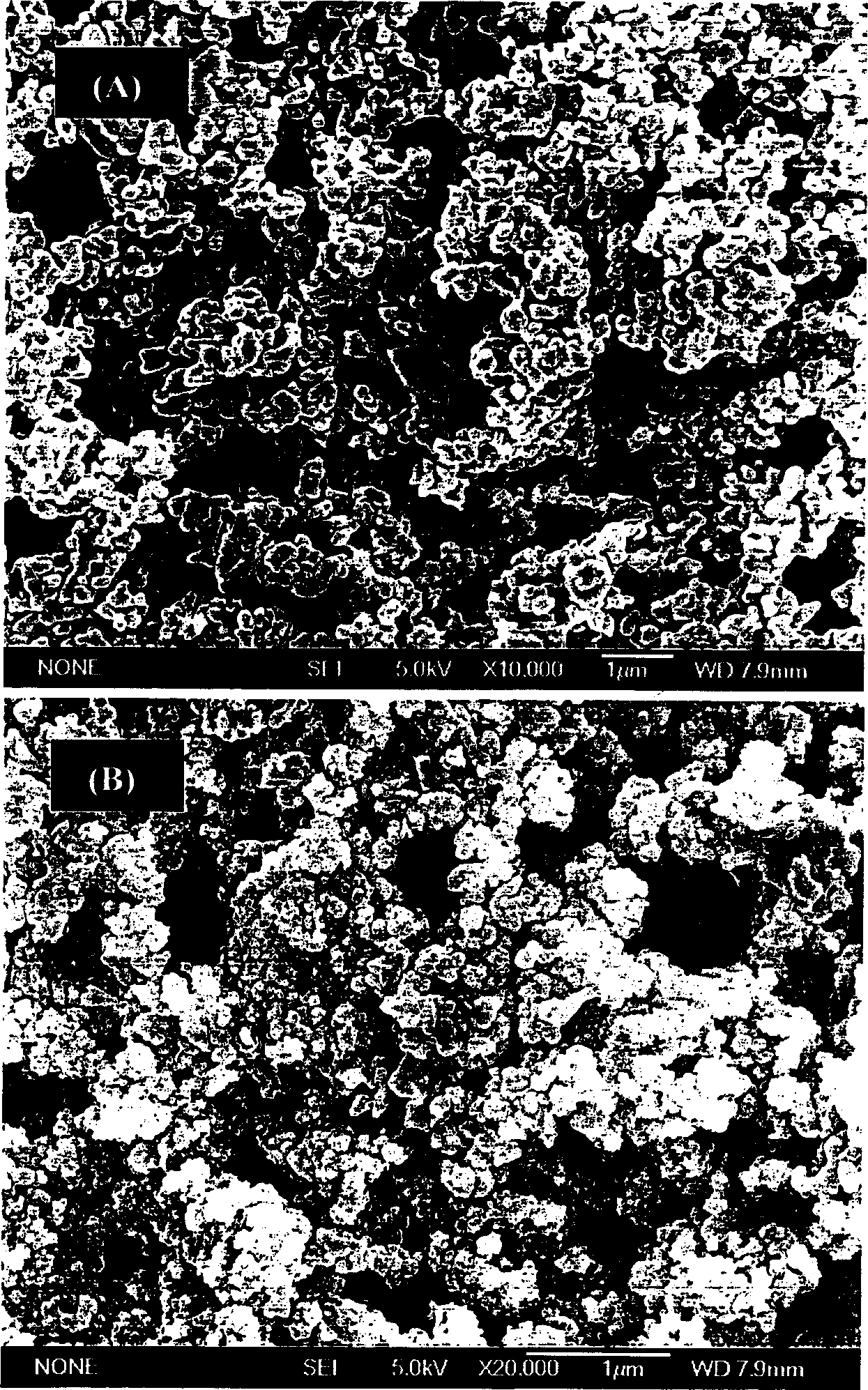

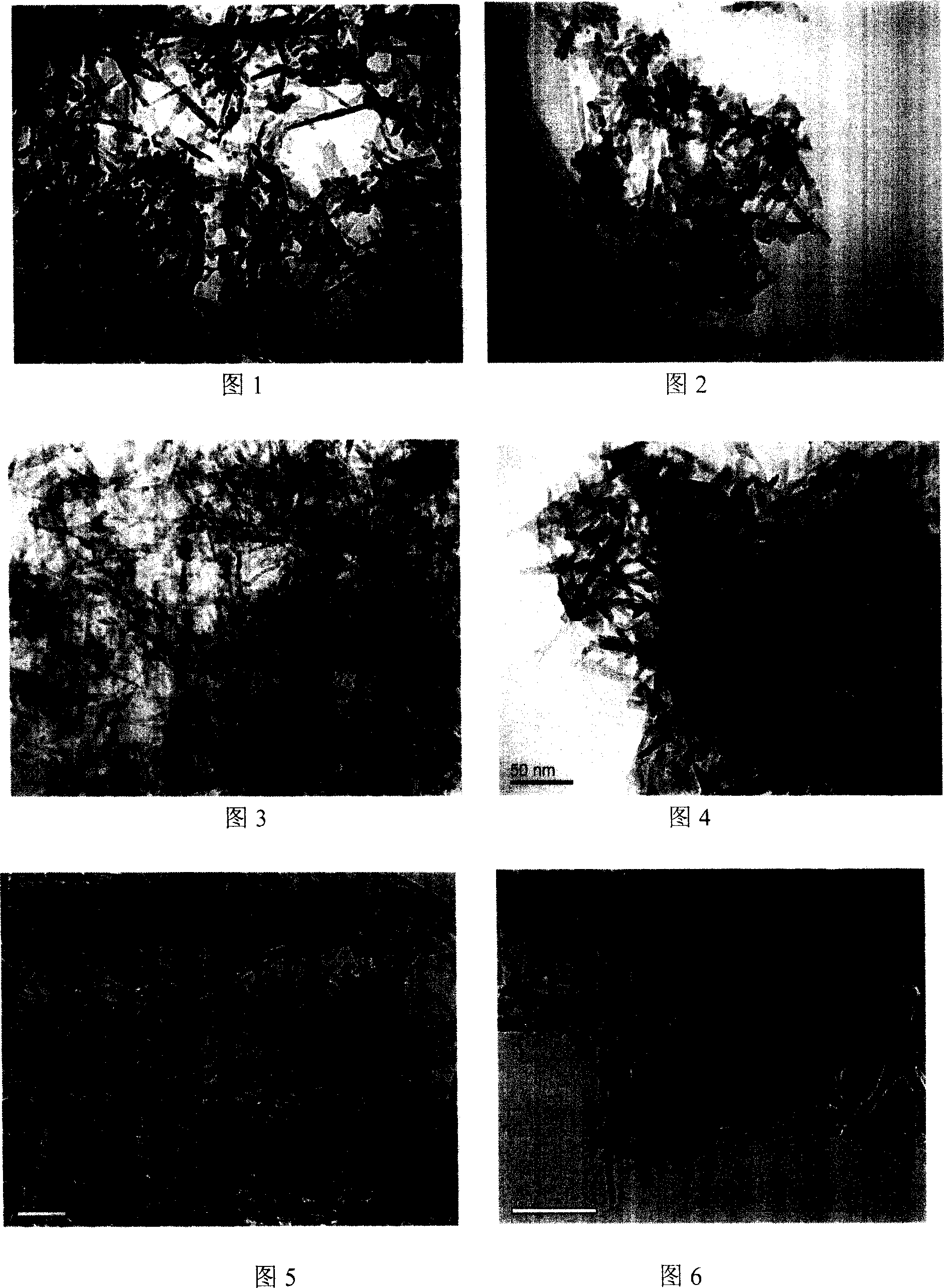

Three-dimensional flower-like layered double hydroxide and preparation method thereof

InactiveCN103274437AThree-dimensional flower-like structureEasy to prepareZinc oxides/hydroxidesNickel oxides/hydroxidesAluminium hydroxideHigh pressure

The invention provides a three-dimensional flower-like layered double hydroxide and a preparation method thereof. In the preparation of the three-dimensional flower-like layered double hydroxide, aluminum sulfate or aluminum ammonium sulfate, soluble divalent metal salt and alkali are used as raw materials; the characteristic that sphere-like micron-sized aluminium hydroxide particles can be rapidly formed by solution of aluminum sulfate and aluminum ammonium sulfate, of which the pH value is 3.7 to 4, under a temperature of 95 to 100 DEG C is utilized; after being prepared, the micron-sized particles react with the divalent metal salt and the alkali, so that a great amount of LDH (Layered Double Hydroxide) crystal nuclei can be rapidly formed on the surface of aluminium hydroxide; and finally, three-dimensional flower-like structure LDH are formed. A prepared LDH laminate has a thickness of about 10 to 20nm; and the BET (Brunauer-Emmett-Teller) specific surface area of the prepared LDH laminate is greater than 140 m<2> / g and is much greater than that of common LDH. The preparation method disclosed by the invention is simple, is simple and convenient to operate, does not require high temperature and high pressure, does not need to use an organic solvent and a surfactant and is low in cost. The three-dimensional flower-like layered double hydroxide can be widely applied to the fields of adsorption separation, catalysis, high polymer materials and the like.

Owner:BEIJING UNIV OF CHEM TECH

Process for preparing alumina powder with high sinter activity

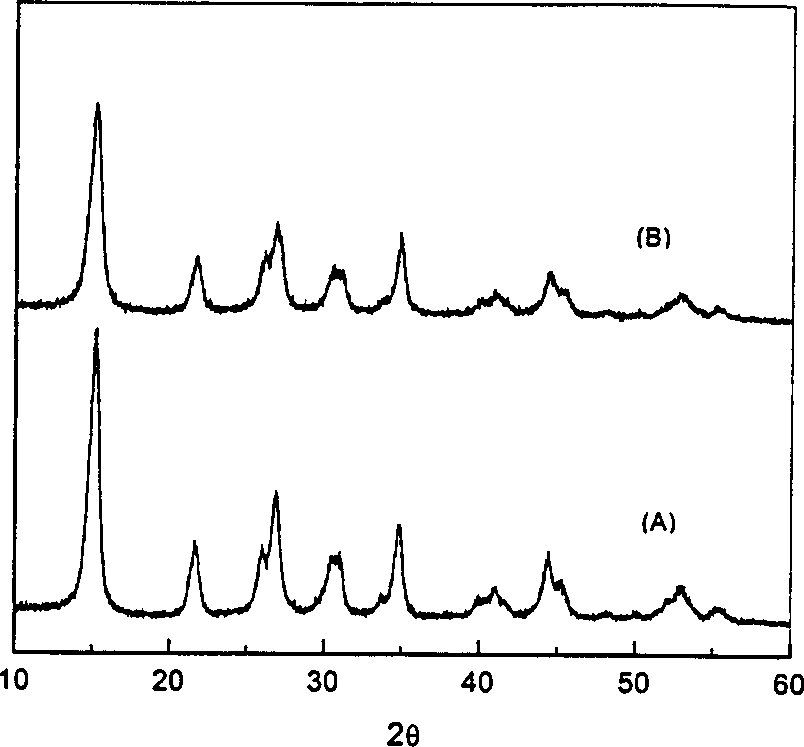

InactiveCN1369434AImprove sintering performanceLow costAluminium hydroxide preparationAluminium chlorideInorganic salts

A process for preparing alumine powder with high sinter activity includes reaction of Al-contained inorganic salt chosen from aluminium nitrate, aluminium chloride and aluminium ammonium sulfate on ammonium bicarbonate at 5-50 deg.C to generate NH4Al(OH)2CO3, depositing and ageing for 2-24 hrs, washing with deionized water, baking at 50-150 deg.C and sintering at 1100-1200 deg.C to obtain alpha-Al2O3 particles less than 400 nm.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Inorganic hydrated salt phase change energy storage microcapsule and preparation method thereof

InactiveCN106244117AIncrease coverageSimple processHeat-exchange elementsCalcium Chloride HexahydratePotassium fluoride

Belonging to preparation methods of energy storage microcapsule materials, the invention provides an inorganic hydrated salt phase change energy storage microcapsule and a preparation method thereof. The energy storage microcapsule includes an inorganic hydrated salt serving as the core material and an inorganic material serving as the wall material. The core material is one or more of potassium fluoride dehydrate, sodium acetate trihydrate, sodium thiosulfate pentahydrate, calcium chloride hexahydrate, magnesium sulfate heptahydrate, barium hydroxide octahydrate, sodium sulfate decahydrate, sodium sulfate decahydrate, disodium hydrogen phosphate dodecahydrate, ammonium aluminium sulfate dodecahydrate, aluminum potassium sulfate dodecahydrate, and aluminum sulphate ocatadecahydrate. The wall material is one or more of silicon dioxide, calcium carbonate, alumina and titanium dioxide. The core material accounts for 30%-80% of the mass of the microcapsule composite material, and the wall material accounts for 20%-70% of the mass of the microcapsule energy storage material. The prepared phase change energy storage microcapsule material has a phase transition temperature of 25-100DEG C and a diameter of 0.1-50 micrometers. The phase change energy storage microcapsule has the advantages of high encapsulation rate, good sealing performance, large phase change potential heat value, and simple preparation method, and has great industrial application prospect.

Owner:CHINA UNIV OF MINING & TECH

Method for extracting vanadium by stone coal through acid leaching

InactiveCN101597698AImprove reuse rateReduce the amount requiredProcess efficiency improvementAmmonium metavanadateSodium salt

The invention discloses a method for extracting vanadium by stone coal through acid leaching, which mainly comprises process steps of: crystallizing vanadium ammonium aluminum sulfate by stone coal acid leaching solution; performing neutralization or oxidation neutralization on a liquid after the crystallization to precipitate the vanadium; performing water leaching on vanadium precipitation residue after the alkaline leaching or the roasting by sodium salt; performing vanadium precipitation by ammonium salt on vanadium leaching solution; pyrolyzing ammonium metavanadate; transforming the vanadium ammonium aluminum sulfate and the like. The method has the advantages of less reagent consumption, low production cost, good product quality, high comprehensive utilization rate of resources, less produced waste, environmental protection and the like.

Owner:CENT SOUTH UNIV

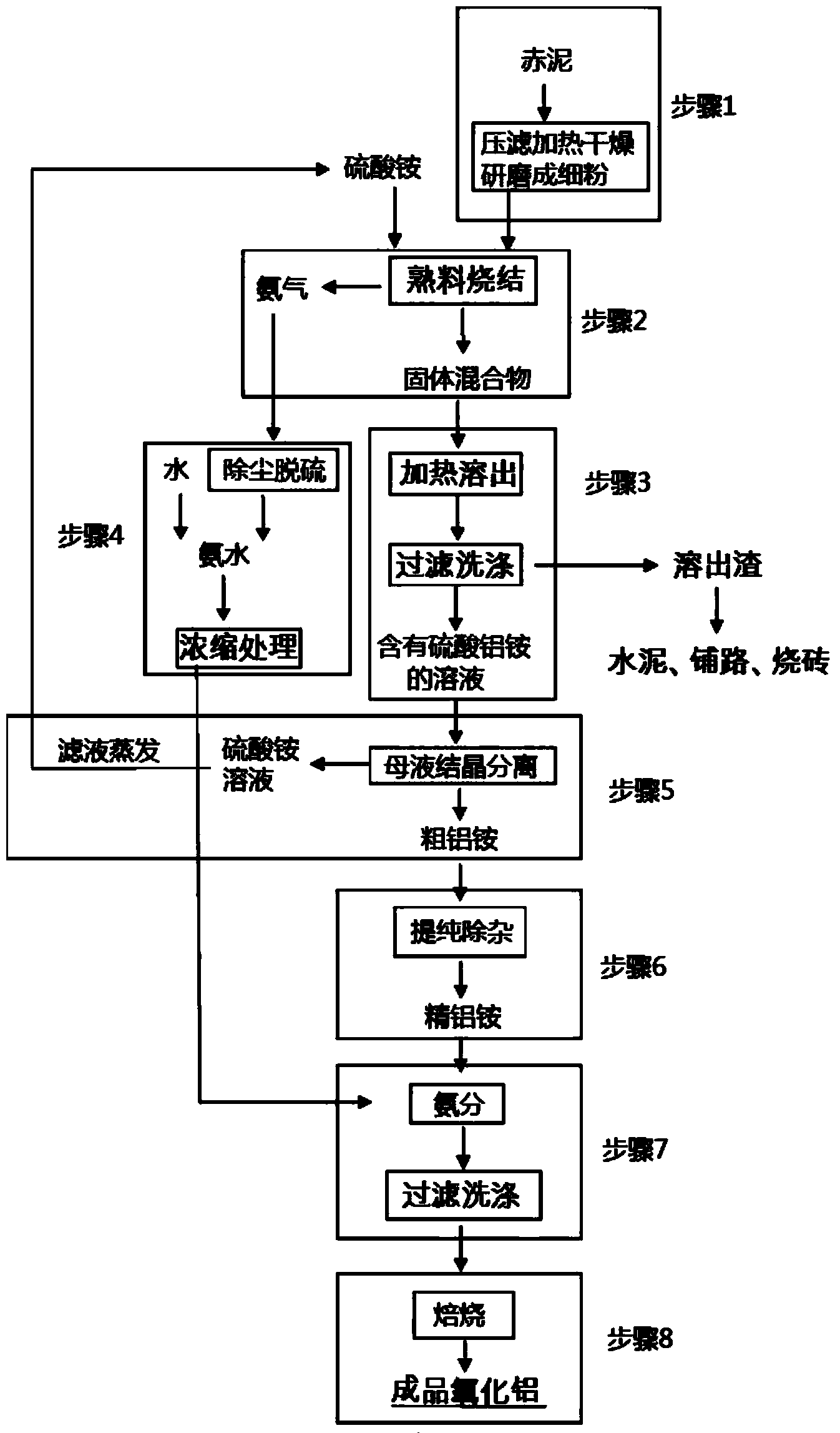

Method for recycling aluminum oxide from red mud

ActiveCN103626213AParticle size range controllableHigh purityAluminium oxides/hydroxidesAluminium hydroxideRed mud

The invention relates to a method for recycling aluminum oxide from red mud. The method comprises the following steps: filtering the red mud by pressing, drying by heating, and grinding the red mud into fine powder; mixing the ground red mud with ammonium sulfate, and sintering to obtain a solid mixture and ammonia gas; pouring the solid mixture into water so as to dissolve out by heating, and separating by filtering to obtain a solution containing ammonium aluminum sulfate; dedusting and desulfurizing the ammonia gas, and absorbing the ammonia gas by water to obtain ammonia water; crystallizing the salt solution containing ammonium aluminum sulfate to obtain crude ammonium aluminum sulfate; dissolving the solid ammonium aluminum sulfate into hot water, cooling, crystallizing, and removing impurity; dissolving the fine ammonium aluminum sulfate obtained after secondary crystallization into water, and reacting with the ammonia water to obtain aluminum hydroxide and ammonium sulfate; calcinating the aluminum hydroxide to obtain the aluminum oxide. In the method for recycling the aluminum oxide from the red mud, the ammonia gas and the ammonium sulfate are recycled, therefore, the cost and byproducts are reduced greatly.

Owner:北京世纪地和控股有限公司

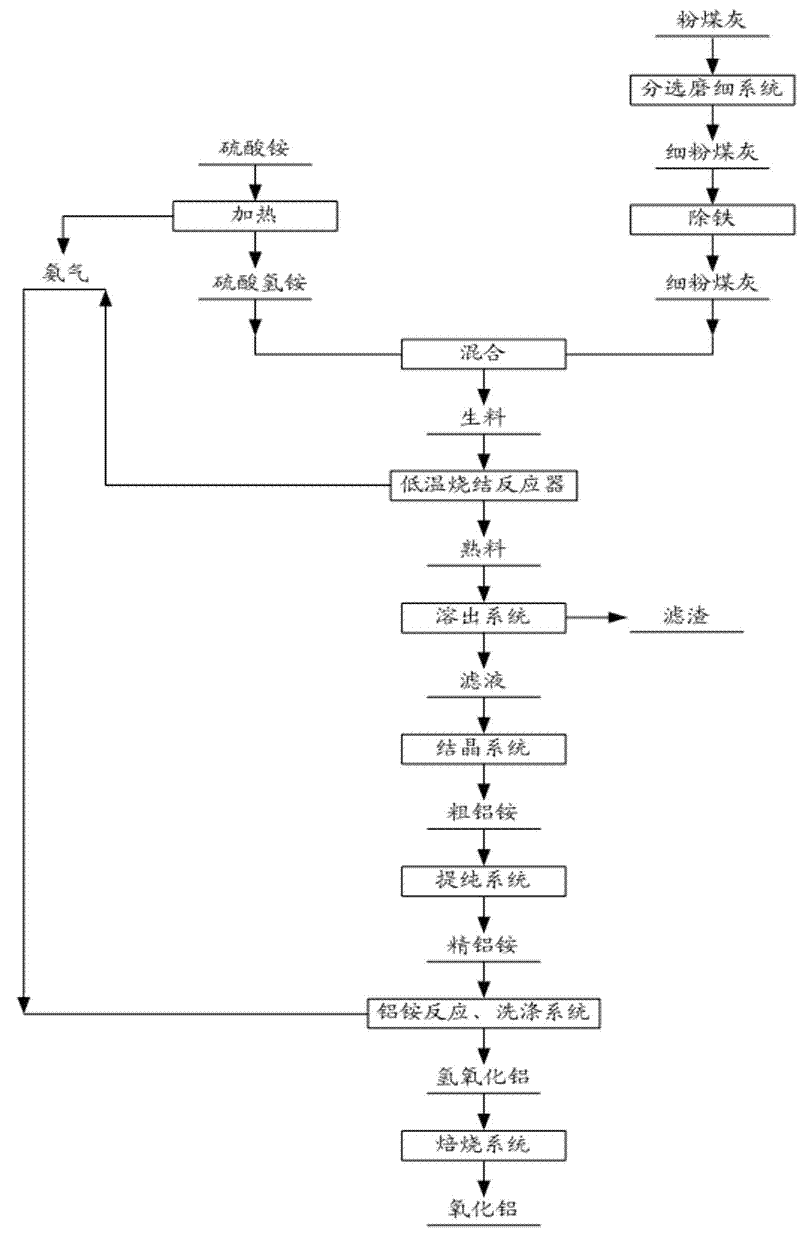

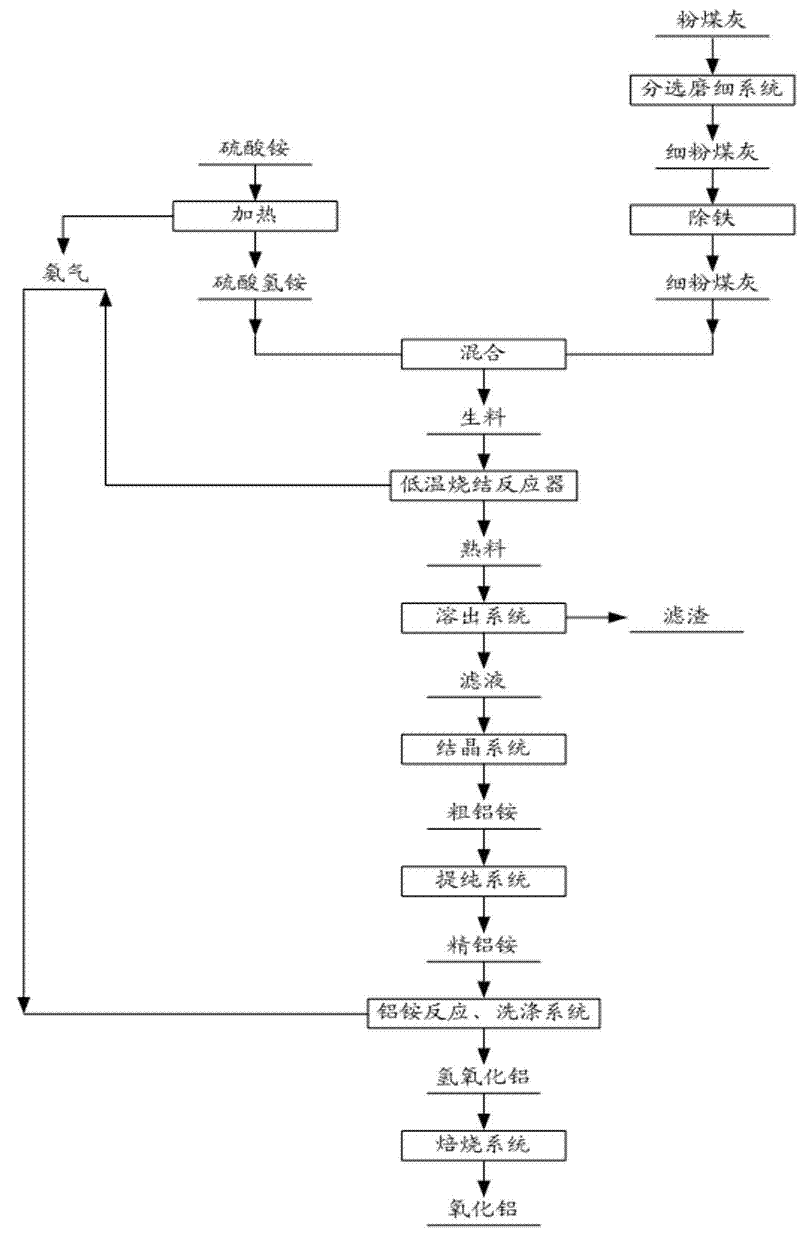

Method for extracting aluminium oxide from pulverized fuel ash

ActiveCN102381723AParticle size range controllableHigh purityAluminium oxide/hydroxide preparationAluminium hydroxidePulverized fuel ash

The invention relates to a method for extracting aluminium oxide from pulverized fuel ash. The method comprises the following steps of: finely grinding the pulverized fuel ash, and then carrying out deferrization treatment; carrying out pyrolysis on ammonium sulphate to prepare ammonium bisulfate and ammonia gas; dissolving out a solid generated after sintering, and then obtaining a solution containing ammonium aluminum sulfate; crystallizing the solution containing the ammonium aluminum sulfate to obtain solid ammonium aluminum sulfate; dissolving the solid ammonium aluminum sulfate and thenpreparing the dissolved solid ammonium aluminum sulfate into a solution reacting with the ammonia gas or ammonia water to generate trihydrate alumina or ammonium sulfate; and roasting the trihydrate alumina to obtain the aluminium oxide. By using the method for extracting aluminium oxide from pulverized fuel ash in the invention, ammonium bisulfate is prepared and the ammonia gas is coproduced, thus, the reaction between the ammonium sulfate and the pulverized fuel ash is convenient to control; and the method is simple, few in side products and easy to realize industrial application.

Owner:北京世纪地和控股有限公司

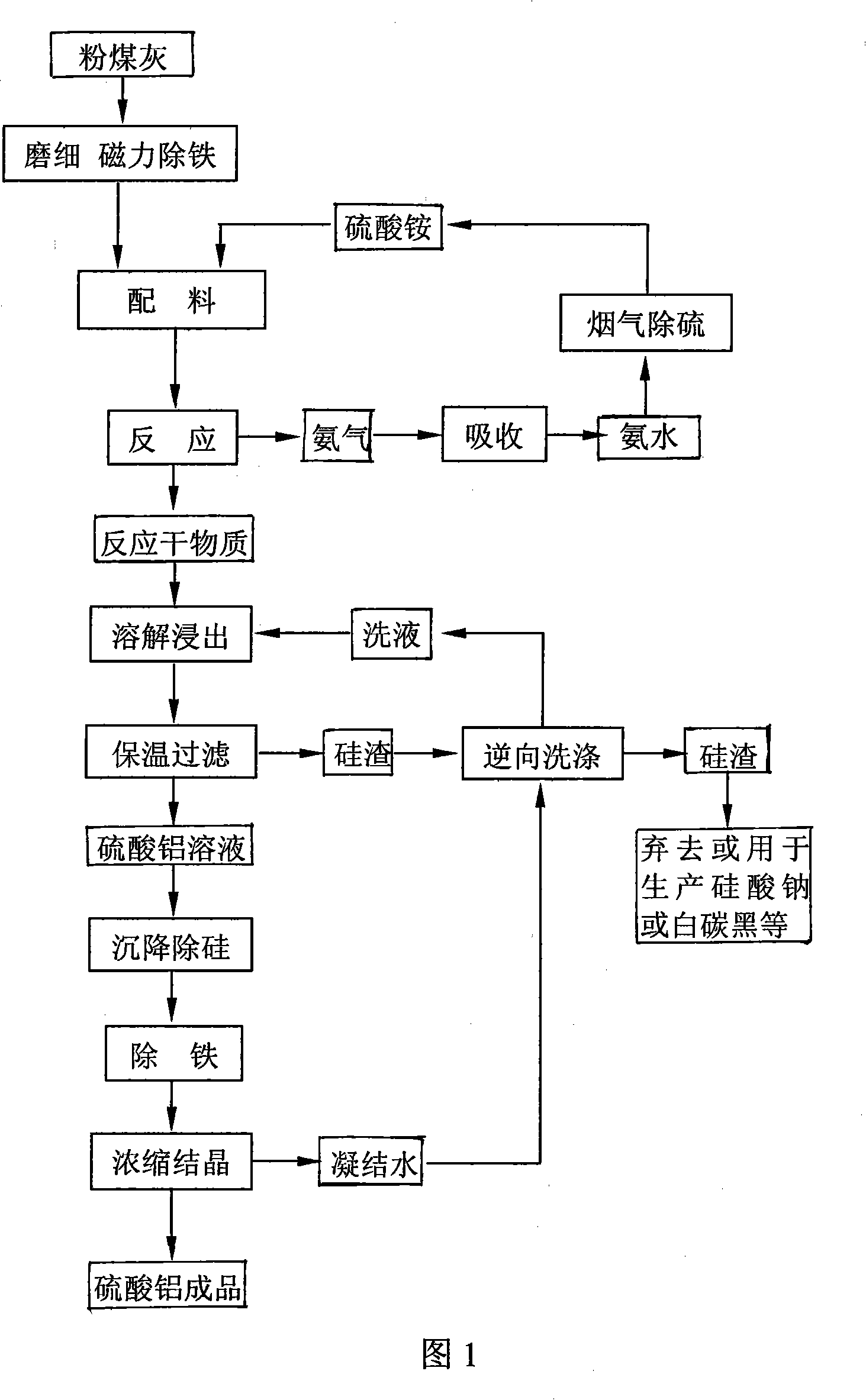

Comprehensive utilization method of ammonium sulfate and pulverized coal ash produced by thermal power plant ammonia process

InactiveCN101157456AAchieve recyclingEmission reductionAmmonia preparation/separationAluminium sulfatesChemical industryPulverized fuel ash

The invention relates to a processing technic for emission produced during burning coal in a heat-engine plant, in particular to a multipurpose use method of ammonium sulphate and pulverized fuel ash produced during the ammonia process of desulfurization in the heat-engine plant. The invention solves the problems that evacuated rejectamenta produced in the heat-engine plant pollutes the environment in the prior art. The invention has the following steps: the pulverized fuel ash is milled and activated, proportioning feeding and action are performed, ammonia gas is recycled and lixiviated, silicon is removed from filtrate, and pearl alum and / or aluminium ammonium sulfate are / is produced after being crystallized. The invention has the fundamental principle that the ammonium sulphate produced by the ammonia process of desulfurization is mixed with the pulverized fuel ash, the ammonium sulphate and the pulverized fuel ash perform a solid state reaction to produce the pearl alum and release the ammonia gas. The pearl alum is used as a commodity to sale, the ammonia gas returns to a stack gas desulfurization process for periodic duty. The stack gas desulfurization and the multipurpose use method of the pulverized fuel ash are combined with each other, basic products of the chemical industry such as the pearl alum and the aluminium ammonium sulfate is produced, thereby realizing the periodic duty of the ammonia gas and the multipurpose use of the pulverized fuel ash, effectively reducing the discharging of the injurant produced in a coal-fired power plant, and having obvious economic benefit and social benefit.

Owner:李禹

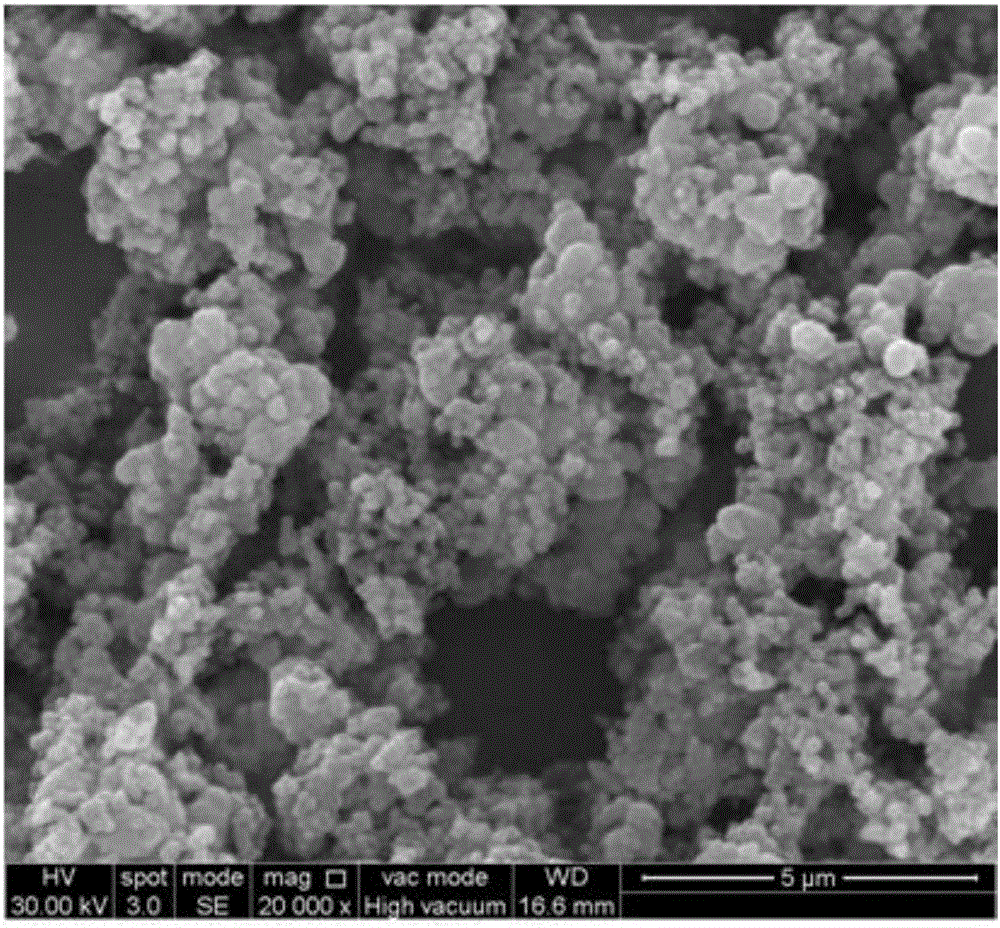

Preparation and application of adsorbing agent of pseudo-boehmite and gamma-Al*O* hollow microspheres

InactiveCN101618312AReduce concentrationControllable grain sizeOther chemical processesMicroballoon preparationCongo redOrganic dye

The invention discloses a preparation method and an application of an adsorbing agent of pseudo-boehmite and gamma-Al2O3 (nuclear shell) hollow microspheres. The method comprises the following steps: dissolving aluminum sulfate, ammonium alum and aluminum potassium sulfate or a mixture thereof in an arbitrary proportion in distilled water; then respectively adding a certain quantity of urea and sodium tartrate; after the mixture is stirred uniformly, transferring the mixture into a hydrothermal kettle to carry out hydrothermal processing; and respectively obtaining the pseudo-boehmite and the gamma-Al2O3 (nuclear shell) hollow microsphere products after hydrothermal products are naturally cooled, filtered, washed, dried in vacuum and roasted. The method has simple process, moderate condition and good ruggedness of the (nuclear shell) hollow microsphere structure. The prepared pseudo-boehmite / gamma-Al2O3 hollow microspheres have excellent adsorption performance, particularly have good adsorption and purification effects on organic dye such as Congo red in waste water, and the like and hard degraded organic matters such as phenol, and the like and can be regenerated and recycled for many times, and regenerated products have the performance of adsorbing organic pollutants.

Owner:WUHAN UNIV OF TECH

Method for preparing Nano powder of alumina from industrial waste

A process for preparing the aluminium oxide nanoparticles from the industrial waste (used Al catalyst or rejected A-alloy) includes grinding, reacting on fused ammonium hydrogen sulfate or its solution, filtering, thermal concentrating, recrystallzing to obtain ammonium aluminium sulfate crystals, preparing its solution, dripping it in the solution of ammonium dicarbonate containing polyethanediol to generate alkaline ammonium aluminium carbonate, drying, and burning.

Owner:SHANGHAI UNIV

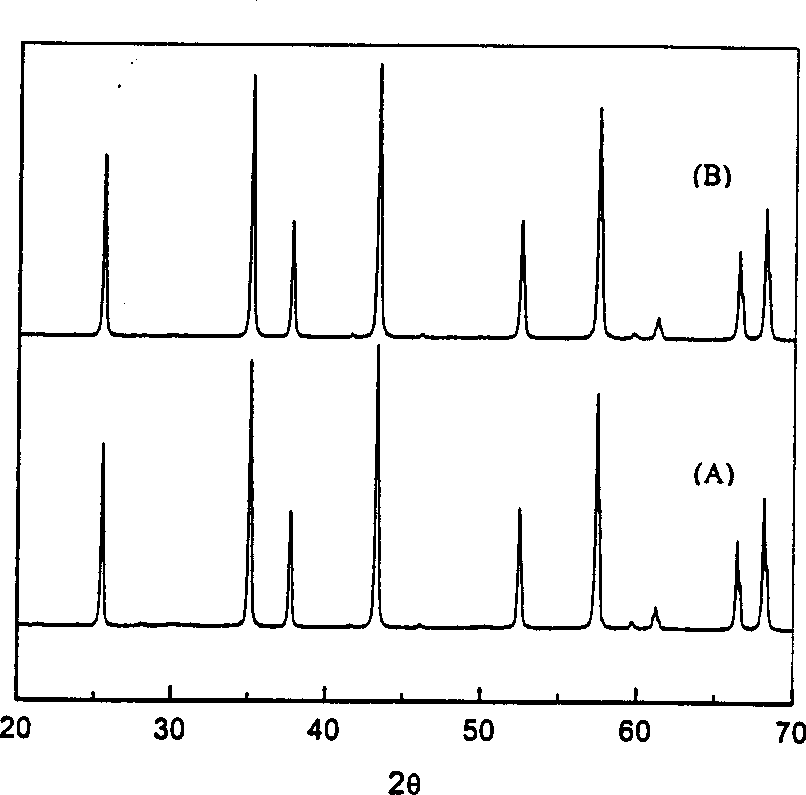

Preparing process fibrous nano alumina powder

InactiveCN1986408ALarge specific surface areaLow costNanostructure manufactureAluminium oxide/hydroxide preparationNano al2o3Polyethylene glycol

The process of preparing fibrous nanometer alumina powder includes the following steps: dissolving ammonium aluminum sulfate and ammonium bicarbonate separately in double distilled water to compound solutions; adding polyglycol into the ammonium aluminum sulfate solution to prepare solution A of ammonium aluminum sulfate containing polyglycol, adding Span-80 into the ammonium bicarbonate solution to prepare solution B of ammonium bicarbonate containing Span-80 and regulating pH value, adding the solution A into the solution B via stirring, centrifuging, washing, azeotropic distillation to dewatering, and calcining at 850-900 deg.c or 1100-1150 deg.c to nanometer fibrous gamma-Al2O3 powder or nanometer fibrous alpha-Al2O3 powder. The process is simple and low in cost, and the prepared fibrous product with high specific surface area may be used in ceramic material, nanometer composite material, etc in different fields.

Owner:WUHAN UNIV

Flocculating agent

InactiveCN101497468AReduce usageWaste water treatment from food industryWater/sewage treatment by flocculation/precipitationSodium sulfateAmmonium aluminium sulfate

The invention relates to a flocculating agent; the usage amount of the flocculating agent is less than that of the marketing products; and the flocculated deposits can be chemical substances for executing refuse treatment; the treated drain satisfies the environmental standard (BOD and COD). The flocculating agent is characterized by comprising 1 to 3 weight % of natural organic acids, 40 to 55 weight % of ammonium aluminum sulfate, 7 to 10 weight % of aluminum sodium sulfate, 8 to 15 weight % of acrylamide polymer with average molecular weight being 9 million to 10 million, 20 to 25 weight % of sodium carbonate (treated pH being set between 6.71 to 7.70); wherein, the natural organic acids are selected from natural organic acids of citric acid, lactic acid and ferrous lactate.

Owner:TECH CORPORATION CO LTD

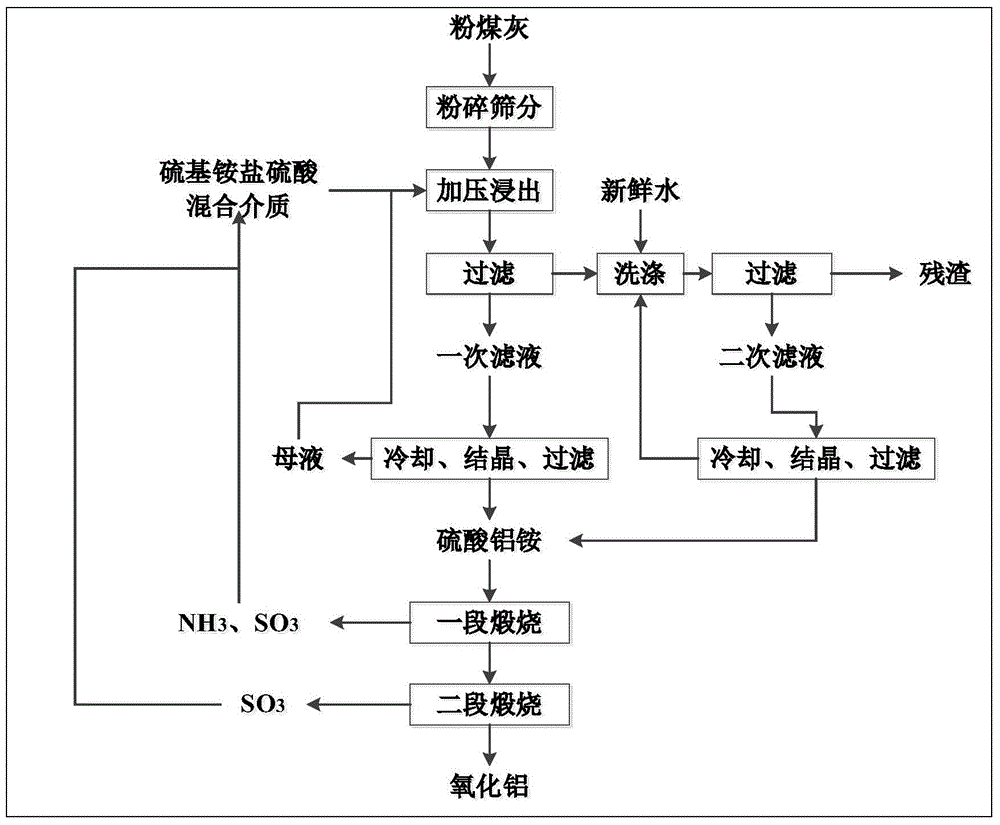

Method for extracting alumina from fly ash through sulfo ammonium salt mixing medium system

ActiveCN104860338AAvoid the energy-intensive process of evaporative concentrationEfficient use ofAluminium oxides/hydroxidesSolubilityFiltration

The invention relates to a method for extracting alumina from fly ash through a sulfo ammonium salt mixing medium system. The method comprises: adopting solid waste fly ash discharged from coal-fired power plant or boiler as a raw material, and carrying out strengthening leaching in a sulfo ammonium salt mixing medium system at a high temperature of 120-240 DEG C, wherein the leaching time is 0.5-6 h; maintaining the system at a temperature of 75-95 DEG C after the leaching, and filtering to obtain the primary filtrate and the primary filtration residue; cooling the primary filtrate to a temperature of 10-30 DEG C by using the characteristic of the large change of the ammonium aluminum sulfate solubility along with the temperature change so as to precipitate the ammonium aluminum sulfate solid; washing the primary filtration residue at a temperature of 85-95 DEG C, and filtering to obtain the secondary filtrate and the secondary filtration residue; carrying out evaporation concentration on the secondary filtrate, and cooling to a temperature of 10-30 DEG C so as to precipitate the ammonium aluminum sulfate solid; and carrying out sectional high-temperature calcination (600-800 DEG C and 1000-1200 DEG C) on the obtained ammonium aluminum sulfate solid so as to obtain the white alumina powder, and recovering the sulfo ammonium salt mixing medium. With the method of the present invention, the efficient cleaning extraction of the alumina from the fly ash can be achieved, the impurity is easily removed, and good economic benefits and broad industrial application prospects are provided.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for extracting aluminum oxide from low grade bauxite

The invention discloses a method to extract aluminum oxide from low-grade alumyte, which comprises the following steps: allocating ammonia sulfate; caking with low-grade alumyte; getting clinker; dissolving out; getting ammonia alum solution; crystallizing; getting solid ammonia alum; reacting with ammonia gas; getting aluminum hydroxide and ammonia sulfate; washing; filtering; getting solid aluminum hydroxide; caking; getting aluminum oxide product; entering into liquid phase ammonia sulfate; evaporating; cycling. This method possesses little residue, which takes the advantage of comprehensive utilization.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Powder leakage type fresh keeping powder and preparation method thereof

InactiveCN108902920ARipening controlImprove qualityMulti-step food processesFood ingredient as mouthfeel improving agentToughnessAmmonium aluminium sulfate

The invention discloses powder leakage type fresh keeping powder and a preparation method thereof. The powder leakage type fresh keeping powder is prepared from mixed starch, edible salt, sodium dehydroacetate, ammonium aluminum sulfate and water through thickening, powder mixing, powder leaking, aging, retrogradation, freezing, powder opening, acid soaking, packaging and sterilization. The prepared fresh keeping powder has the advantages that the curing degree is proper; the toughness is good; strip breaking cannot easily occur; segmented freezing aging is used for treating bean vermicelli; starch molecules can be effectively enabled to have time for directional arrangement; the mouthfeel and the smooth degree of the bean vermicelli are maintained; through powder opening treatment, the vermicelli can be separated; meanwhile, the adhesion occurring during the later-period packaging sterilization is effectively prevented; the product quality is ensured; the shelf life is prolonged; experiments prove that the loss rate of used additives in the preparation process is high; the residual quantity is in a national safety standard range.

Owner:SICHUAN PROVINCE DANDAN CONDIMENT

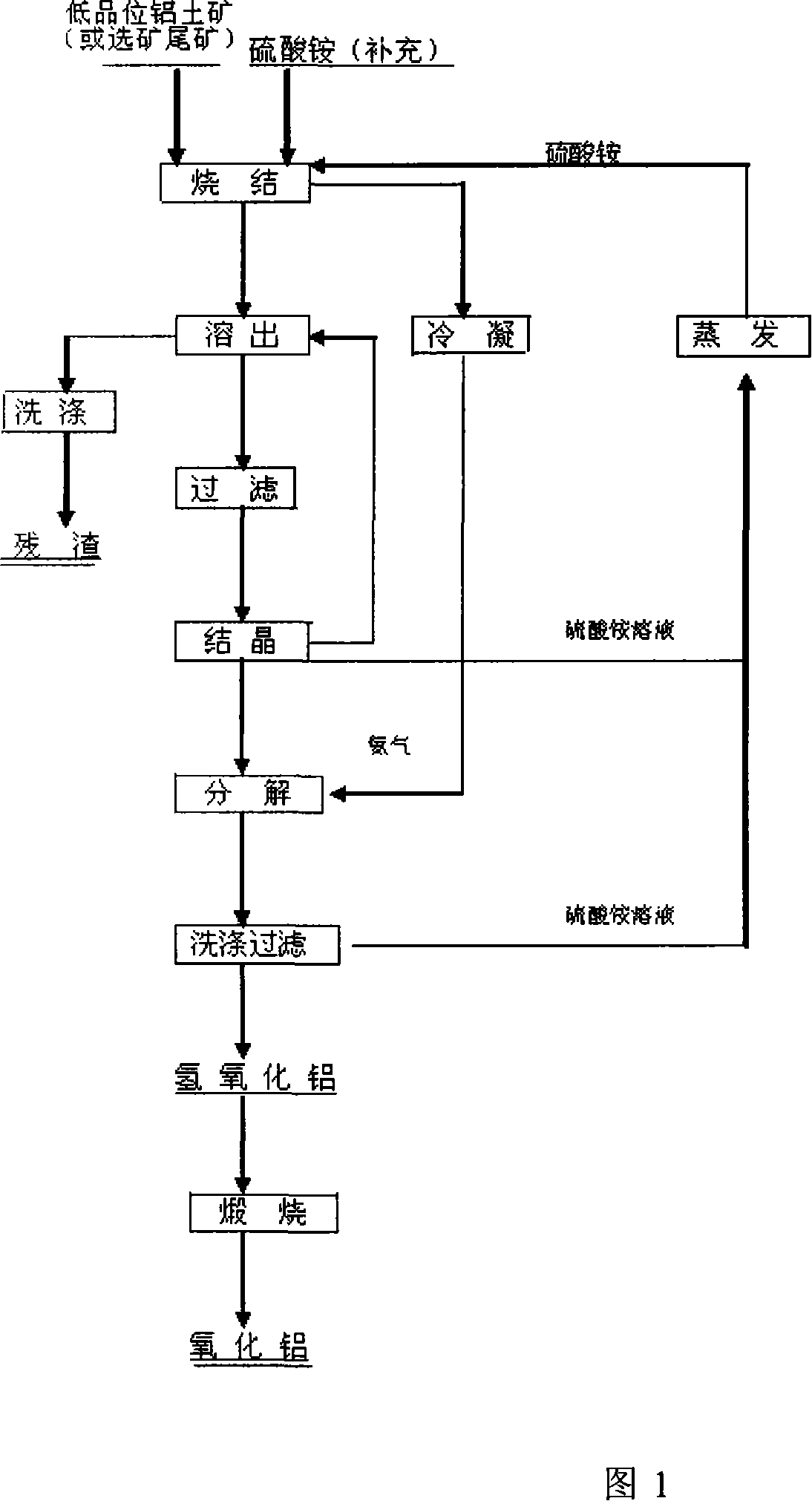

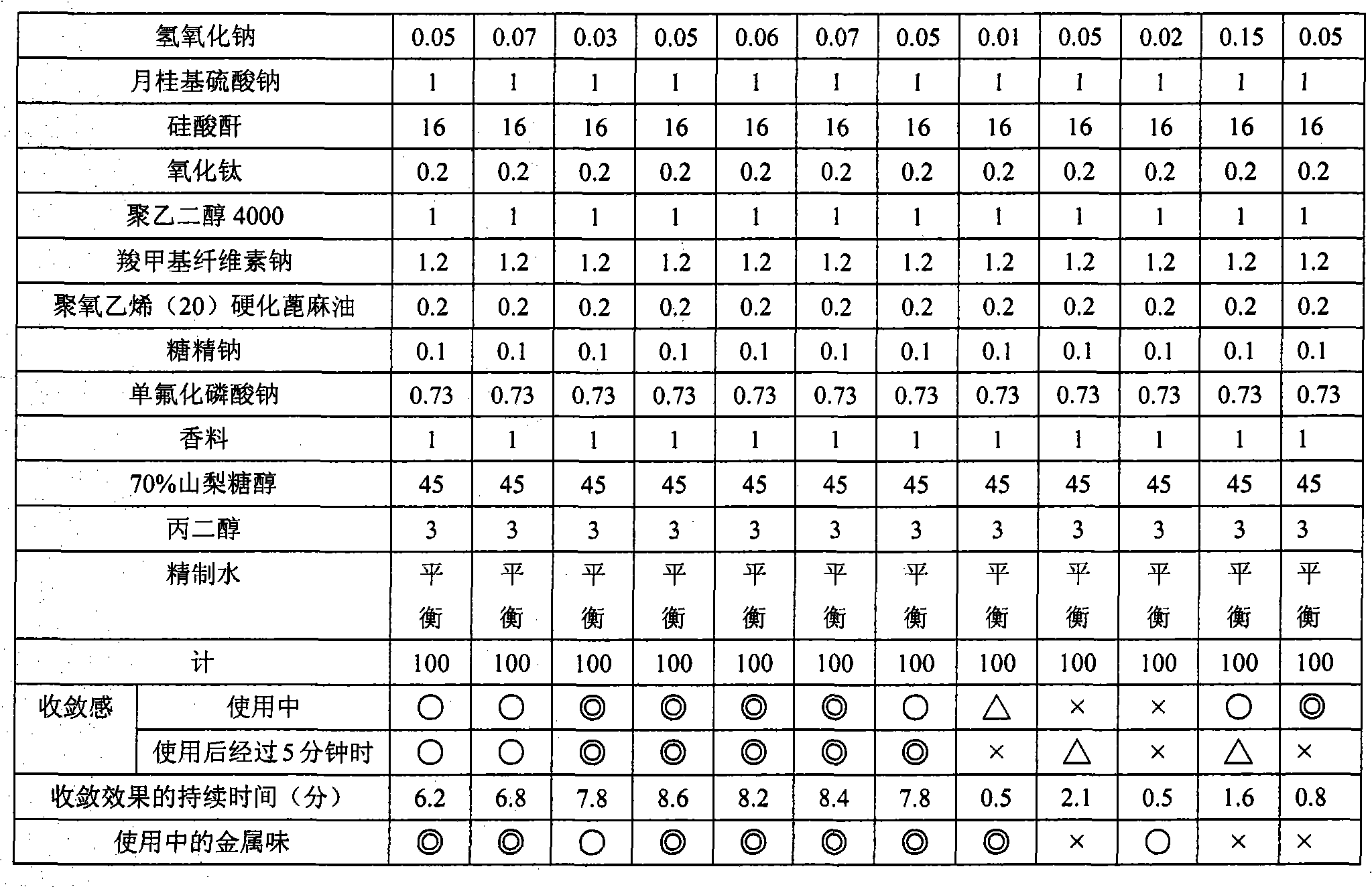

Oral composition and method of improving astringency of oral composition

ActiveCN101801334AFast convergenceEasy to useCosmetic preparationsToilet preparationsAdditive ingredientMedicine

One or more aluminum compounds (a) selected among potassium aluminum sulfate, anhydrous potassium aluminum sulfate, and ammonium aluminum sulfate and sodium chloride (b) are incorporated into an oral composition, the amount of the ingredient (a) being 0.2-3 mass%. By the method of improving the astringency of an oral composition, an oral composition can be obtained which has a high astringent effect in the oral cavity at the time of use and retains therein the high astringent effect even after use. This oral composition does not have a metallic taste attributable to a polyvalent metal, and has excellent suitability for use and satisfactory safety.

Owner:LION CORP

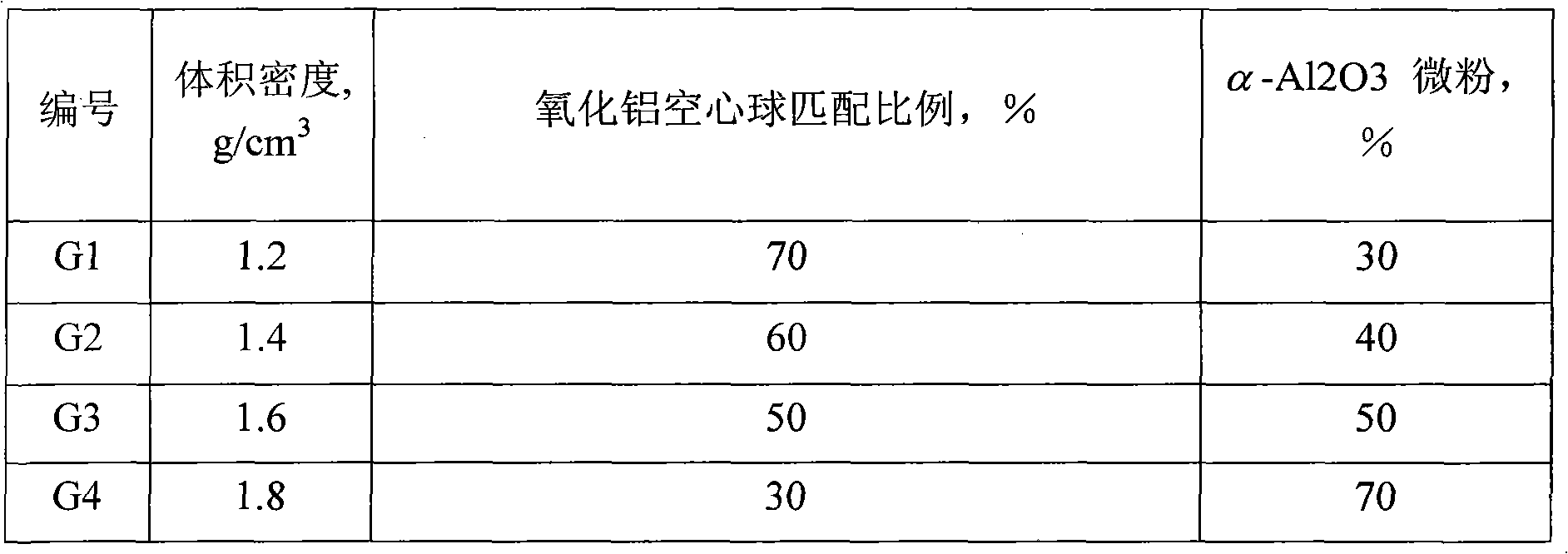

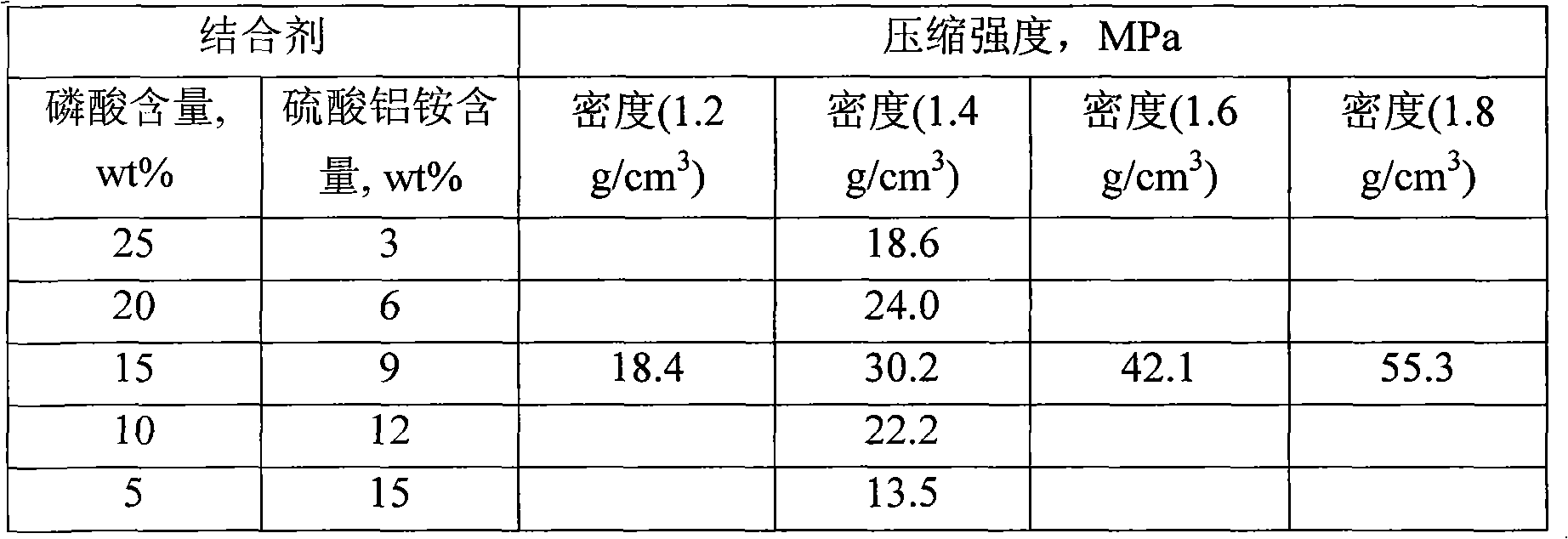

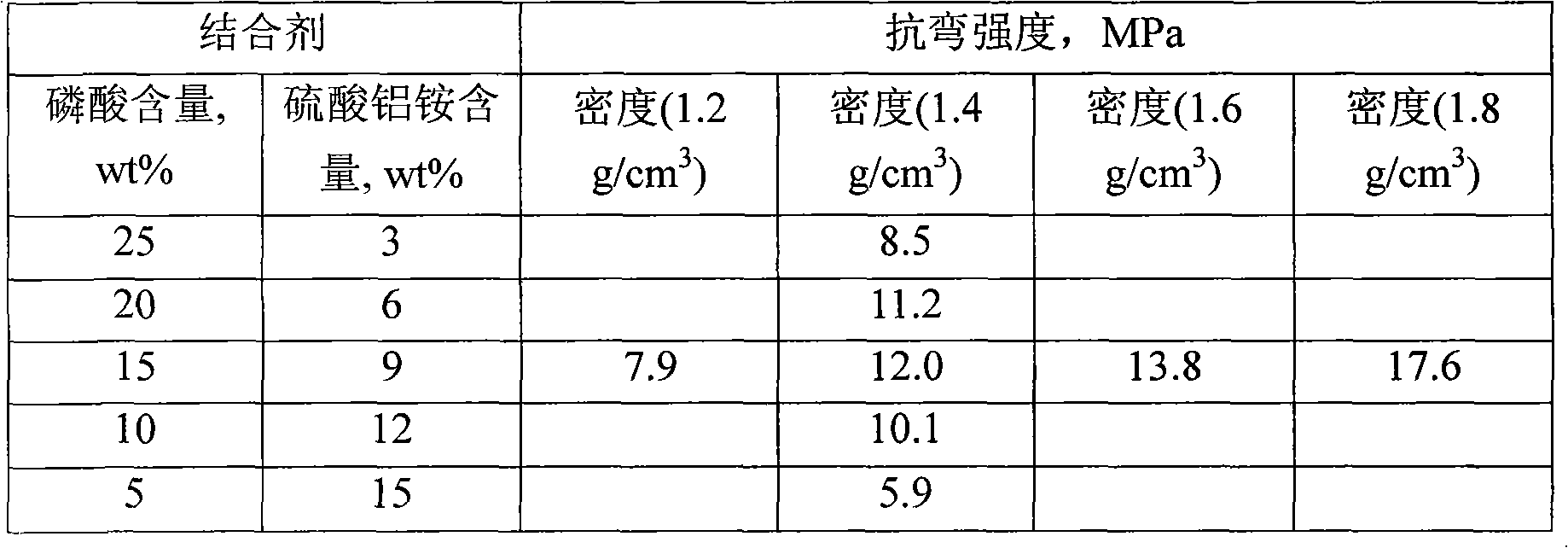

Structural-thermal-insulation integrated and high-strength alumina bubble ceramic and preparation method thereof

The invention discloses a structural-thermal-insulation integrated and high-strength alumina bubble ceramic and a preparation method thereof. The preparation method in which 30-70 wt% of the alumina bubble with a grain diameter of 0.2-5 mm is taken as aggregate comprises the following steps: adding a complex aqueous solution of phosphoric acid and aluminium ammonium sulfate with uniform stirring, wherein in the aqueous solution, the content of the phosphoric acid is 5-25 wt% and the content of the aluminium ammonium sulfate is 3-15 wt%, and the use level of the complex aqueous solution is 25-35 wt% of alpha-Al2O3 micro powder; stirring, adding 30-70 wt% of alpha-Al2O3 micro powder and stirring uniformly, preparing shaped bricks and special-shaped bricks in a vibrating manner under pressure, and finally using the bricks directly for masonry after oven drying at 200 DEG C, or after igniting and keeping a temperature at 1500-1700 DEG C for 4-10 hours. Compared with dense fire-proof materials, the ceramic disclosed by the invention has characteristics of low density and lightweight, thermal shock resistance, good heat preservation performance, low thermal capacity and the like. Compared with common thermal insulation materials, the ceramic disclosed by the invention has characteristics of high compression strength, high refractoriness under load, low linear shrinkage rate on reheating and the like. The ceramic can not only be used as thermal insulation layers, but also directly contact with flame, and thereby being an ideal inner lining construction material for an ultra-high-temperature furnace with a lightweight structure.

Owner:ZHEJIANG UNIV

Preparation method of active nano-aluminium oxide for coating

InactiveCN1752007AEfficient removalEliminate hard agglomerationAluminium oxide/hydroxide preparationNanoparticleNano al2o3

A process for preparing the active aluminium oxide nanoparticles used for coating includes such steps as proportionally and respectively dissolving ammonium aluminium sulfate and ammonium carbonate in secondary water, respectively adding them to polyethanediol to obtain two kinds of solution, regulating pH, mixing them together, stirring, centrifugal separation, washing, drying, dewatering by azeotropic distilling and high-temp calcining.

Owner:WUHAN UNIV

Method for producing metallurgical grade alumina by using fly ash

The invention relates to a method for producing metallurgical grade alumina by using fly ash. The method is characterized by comprising the following steps: uniformly mixing and roasting a raw material fly ash and a circulating medium ammonium hydrogen sulfate; dissolving out an obtained clinker to prepare an aluminium ammonium sulfate solution; subjecting the solution with ammonia or ammonia liquid to liquid-liquid or liquid-gas replacement reaction to obtain a product of a mixture containing aluminium hydroxide and ammonium sulfate; washing and filtering the mixture to obtain coarse aluminum hydroxide; subjecting the ammonium sulfate in the washing liquid to evaporative crystallization and pyrolysis deamination to generate ammonium hydrogen sulfate; returning the ammonium hydrogen sulfate to a roasting process; and subjecting the coarse aluminum hydroxide to impurity removal by alkali dissolution, carbon separation or grade separation to prepare metallurgical grade alumina. Compared with the existing method, the method using ammonium hydrogen sulfate as the circulating medium to produce aluminum alumina has the advantages of extraction rate of aluminum increased by 8%-15% in the roasting process, short roasting time, low roasting temperature and improved efficiency, and is easy for scale production.

Owner:NORTH UNITED POWER CO LTD

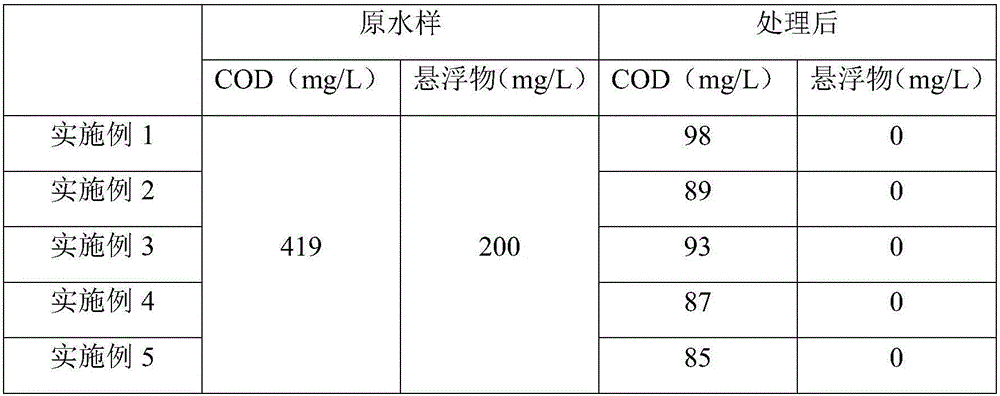

Highly-efficient water-pollution treating agent

InactiveCN105417599AQuick removalPrevent eutrophicationWater/sewage treatmentParticulatesEutrophication

The invention provides a highly-efficient water-pollution treating agent. The water-pollution treating agent is composed of the following components by weight: 10 to 16% of a cationic flocculant, 5 to 8% of ammonium aluminium sulfate, 6 to 10% of sodium alkyl ethoxy carboxylate, 8 to 12% of polyferric sulfate, 1 to 2% of starch, 2 to 6% of active carbon, 9 to 12% of acrylic acid-acrylate-sulfonate terpolymer and 6 to 8% of sodium lauroyl sarcosinate, with the balance being water. The highly-efficient water-pollution treating agent provided by the invention can rapidly remove particulate matters and heavy metals in water, has biodegradability, can avoid water eutrophication and emission secondary pollution, and is capable of improving sewage treatment efficiency and treatment quality.

Owner:TIANJIN OUPAN TECH DEV CO LTD

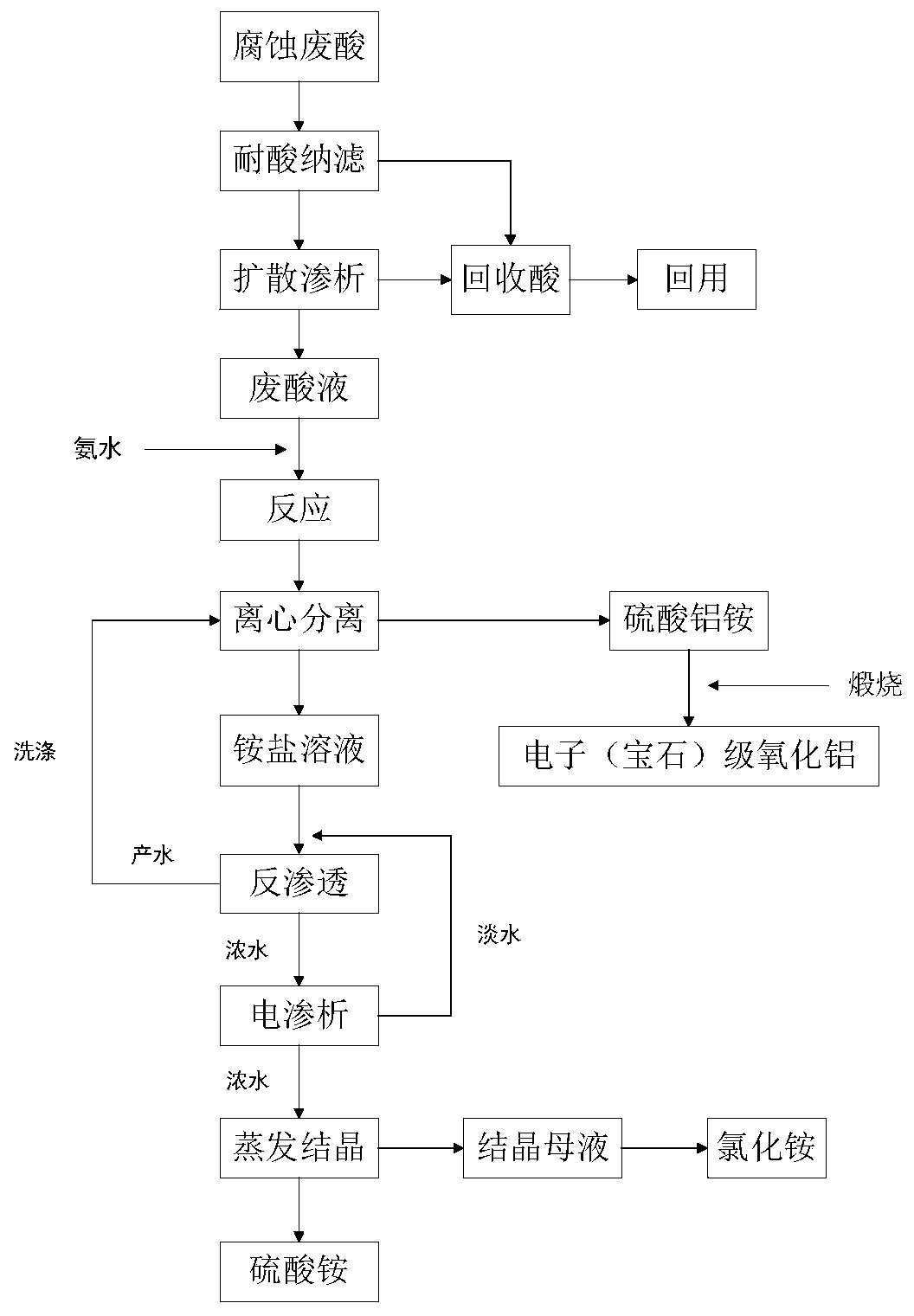

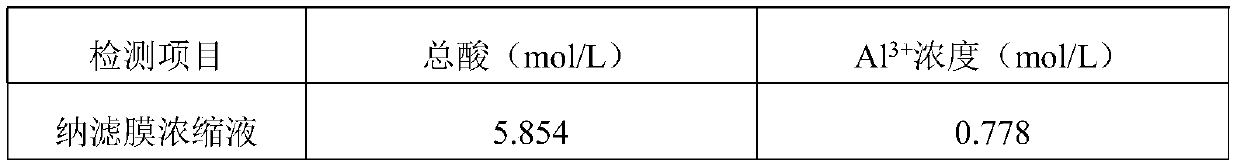

Resourceful treatment process of waste acid

ActiveCN110217931AAchieve recyclingAchieving zero emissionsWater/sewage treatment by centrifugal separationMultistage water/sewage treatmentReverse osmosisEvaporation

The invention discloses a resourceful treatment process of a waste acid. The resourceful treatment process comprises the following steps: I, carrying out treatment with an acid-resistant nanofiltration process+diffusion dialysis process, and carrying out acid recycling; II, adding an ammonium hydroxide solution into a dialysis raffinate of the diffusion dialysis process, carrying out a sufficientreaction so as to obtain ammonium aluminum sulfate precipitate and an ammonium salt solution with mixed ammonium sulfate and ammonium chloride, and carrying out a centrifugal separation process to separate the ammonium aluminum sulfate precipitate from the ammonium salt solution; III, carrying out washing, drying and calcining processes on the ammonium aluminum sulfate precipitate so as to obtainelectron (gemstone)-grade aluminum oxide; IV, treating the electron (gemstone)-grade aluminum oxide by using a reverse osmosis+electrodialysis process; and IV, treating concentrated water generated inthe electrodialysis process by using an evaporation crystallization technique, so as to obtain a product of ammonium sulfate and ammonium chloride. By adopting the resourceful treatment process, circulation use of 90% or greater of acids in a waste acid liquid can be achieved, meanwhile, the electron (gemstone)-grade aluminum oxide can be prepared, and very high values can be made.

Owner:苏州富淼膜科技有限公司

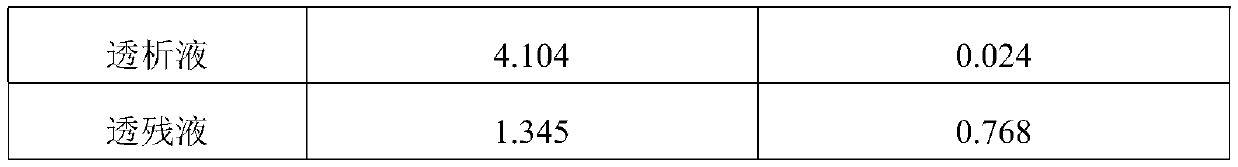

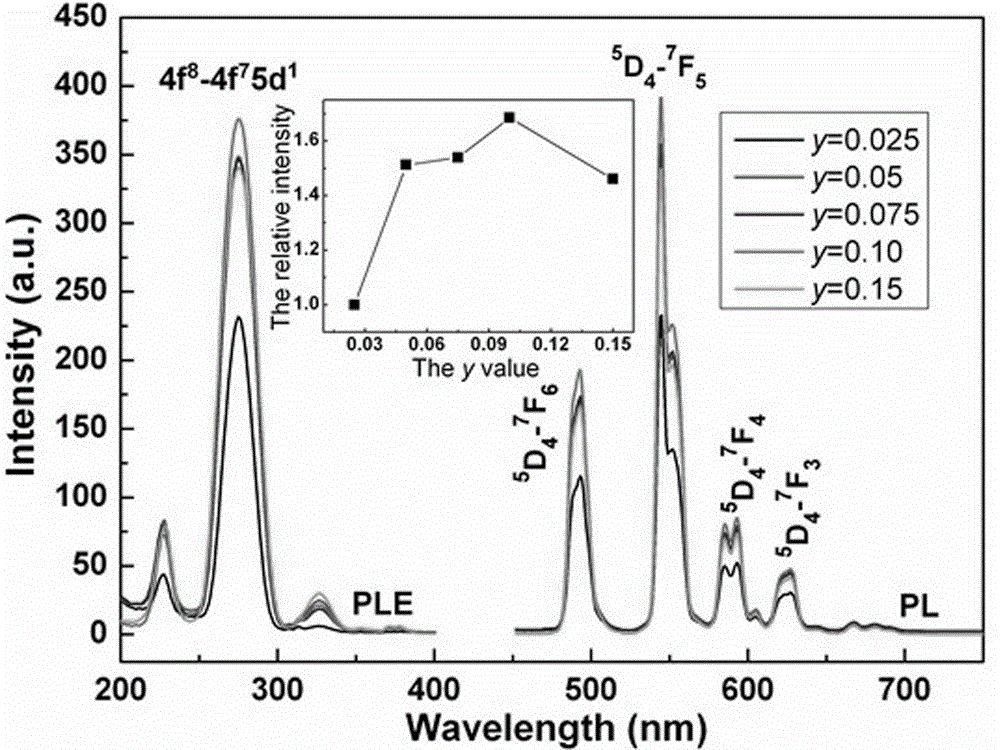

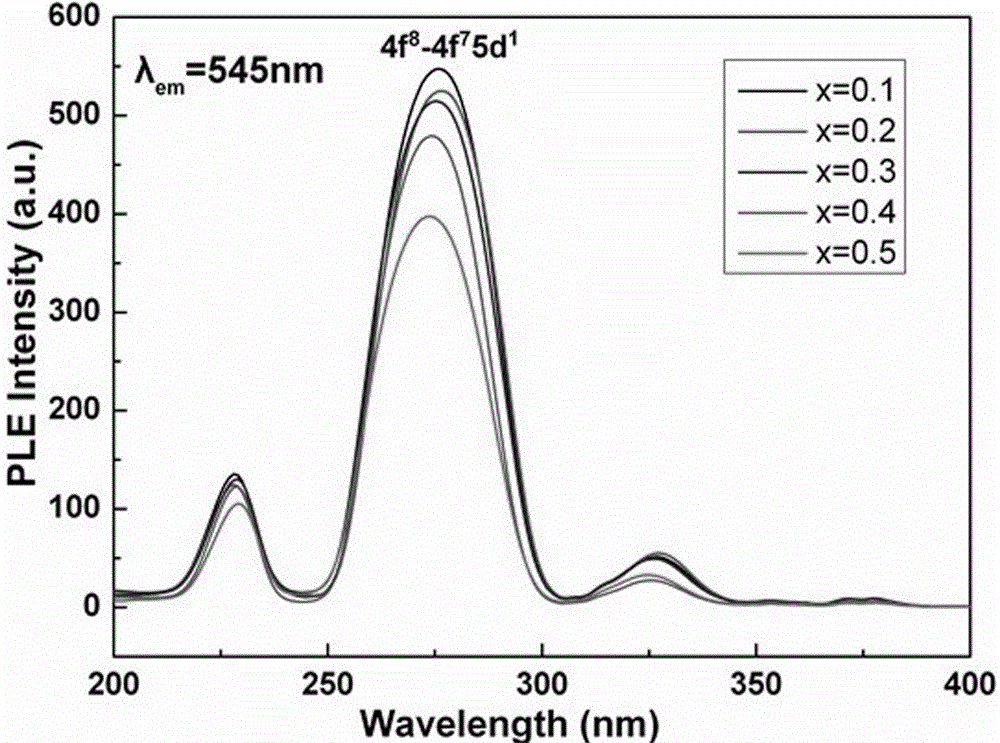

Novel garnet-based high efficiency green phosphor

InactiveCN104910910AGood dispersionStrong green emissionLuminescent compositionsQuantum efficiencyNitrate

The invention provides a novel garnet-based high efficiency green phosphor, a chemical formula is [(Gd1-xLux)1-yTby]Al5O12 (short for (Gd, Lu)AG:Tb<3+>), wherein x is Lu / (Gd+Lu+Tb) and y is Tb / (Gd+Lu+Tb)(x is 0-1.0, y is 0-0.15). The phosphor takes rare earth nitrate and an ammonium aluminium sulfate according to stoichiometric ratio to prepare a mother salting liquid, the mother salting liquid is dropped into a NH4HCO3 precipitating agent solution, the obtained deposition is centrifuged, washed, and dried to obtain the white precursor powder, and phosphor (Gd, Lu)AG:Tb<3+> can be obtained through calcining at different temperature. non radiation energy transmission of Gd<3+> to Tb<3+> is existed, the fluorescence quantum efficiency is high, addition of Lu can obvious improve the stability of a system, and is more suitable for a scintillator material.

Owner:UNIV OF JINAN

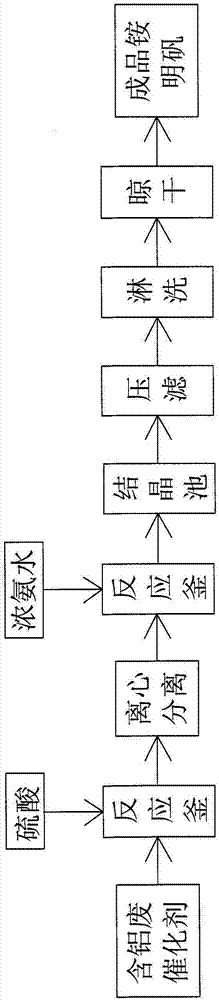

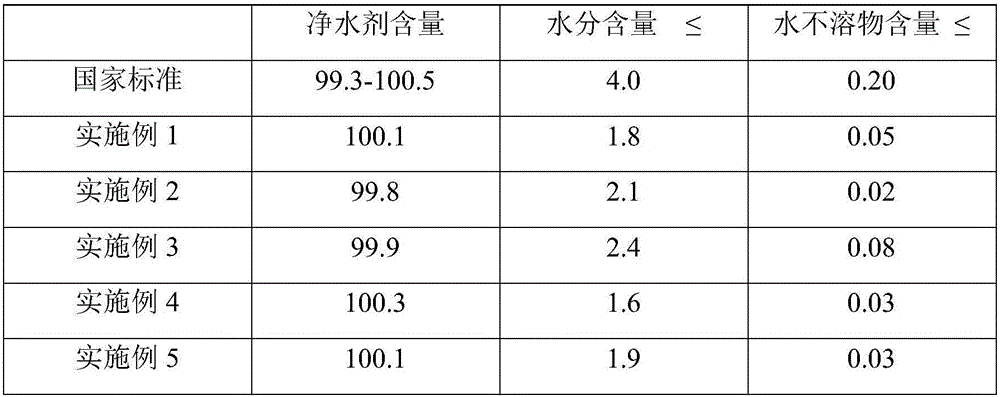

Preparation method of ammonium alum by using waste catalyst as raw material

InactiveCN107055583AReduce the cost of waste treatmentHigh purityAluminium sulfatesPetrochemicalAmmonium aluminium sulfate

The invention discloses a preparation method of ammonium alum by using waste catalyst as a raw material. The method includes steps of adding and immersing sulfuric acid in an aluminum-containing waste catalyst during the production process of a petrochemical industry; after immersing, feeding to a container arranged with a mixer and a heater, and mixing the catalyst under an opening state; after finishing the mixing reaction, centrifugally separating the catalyst by a centrifugal separator to obtain a crude fluid of aluminum sulfate; adding stronger ammonia water in the obtained crude fluid of aluminum sulfate; neutralizing the crude fluid under the state of mixing and heating; controlling the mixing speed of the mixer, the heating temperature of the heater, the neutralization time and the pH value of the reaction system so as to obtain the crude fluid of aluminum sulfate; feeding the obtained crude fluid of crude fluid of aluminum sulfate to a crystalizing pond to crystalize and then perform pressing filter to obtain a crude ammonium alum filter cake; spraying the crude ammonium alum filter cake and controlling the spraying degree; air-drying the filter cake to obtain the finished ammonium alum. The preparation method has the advantages of meeting the requirement of industrial preparation, saving resource, and protecting environment; besides, the purity is ideal.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

Method of manufacturing industrial ammonium aluminium sulfate using waste liquid in production of fosetyl-aluminium bacteriocide

InactiveCN1590300AReduce processing costsTake advantage ofWater/sewage treatmentAluminium sulfatesNitrogenSewage

A process for preparing the industrial aluminium ammonium sulfate from the nitrogen-contained sewage generated in preparing fosetyl-aluminium as bactericide includes regulating the mole concentration of nitrogen is said sewage, reacting on aluminium sulfate, cooling while crystallizing and dewatering.

Owner:镇江市农业科学研究所

Water purifier and preparation method thereof

InactiveCN106145172ASolve the problem of solid waste disposalAvoid pollutionWater/sewage treatment by flocculation/precipitationAluminium sulfatesReaction temperatureSilicon oxide

Owner:QINGDAO HUICHENG PETROCHEM TECH

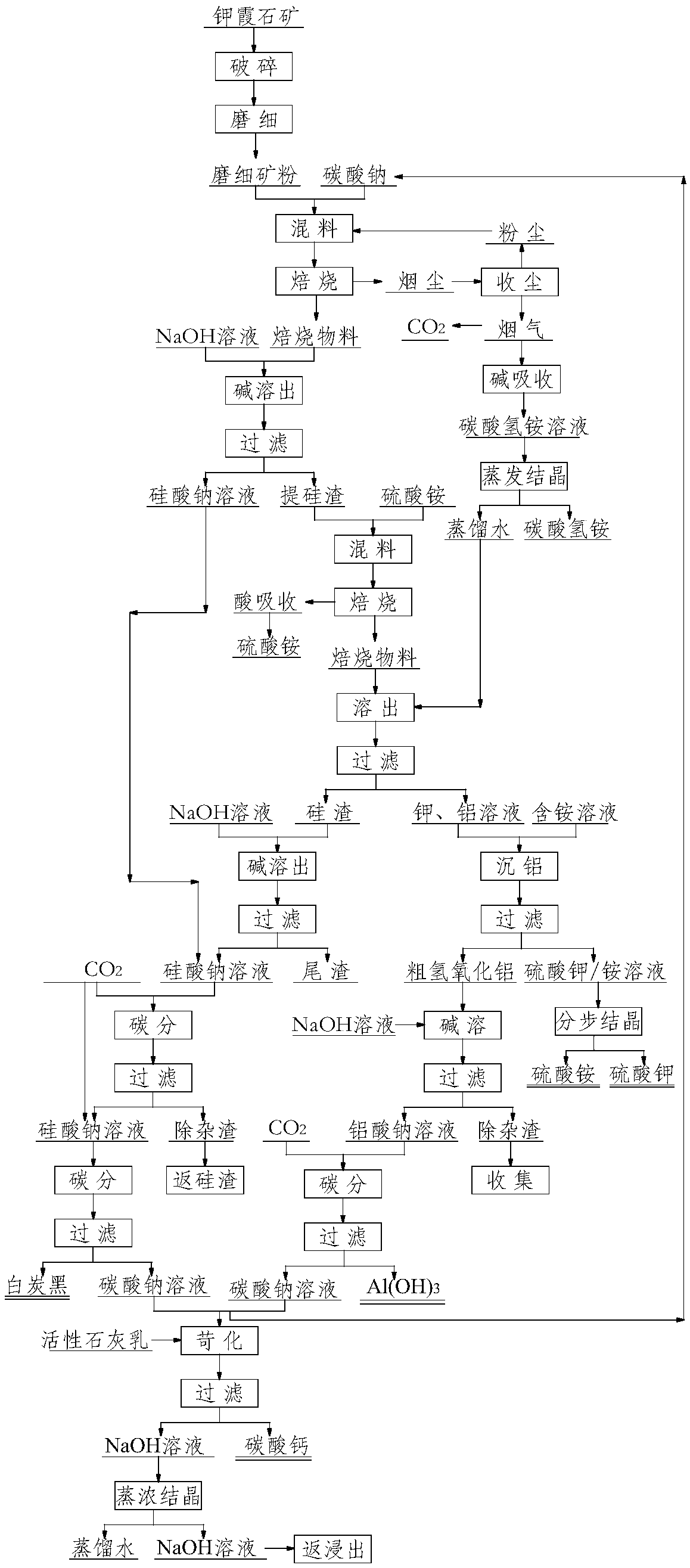

Method for comprehensively utilizing kaliophilite ores

ActiveCN108929947AImplement extractionIncrease profitCalcium/strontium/barium carbonatesAluminium compoundsFiltrationPotassium

The invention relates to a method for comprehensively utilizing kaliophilite ores. The method comprises the following steps: S1, preprocessing the kaliophilite ores; S2, uniformly mixing the preprocessed kaliophilite ores with sodium carbonate, and calcining the obtained mixture to obtain a first calcined material; S3, dissolving the first calcined material with water or a sodium hydroxide solution, and performing separating filtration to obtain pre-desiliconized residues containing potassium and aluminum; S4, uniformly mixing the pre-desiliconized residues with ammonium sulfate, and calciningthe obtained mixture to obtain a second calcined material; and S5, dissolving the second calcined material in water, and performing filtering separation to obtain silicon residues and a potassium-containing ammonium aluminum sulfate solution. The method for comprehensively utilizing the kaliophilite ores has the advantages of great increase of the utilization ratio of elements in the kaliophiliteores, realization of high value-added utilization, small generation amount of waste residues, simple process, and suitableness for large-scale production.

Owner:NORTHEASTERN UNIV

Conjugate anticorrosive waterborne epoxy coating and preparation method thereof

InactiveCN107201151AGood dispersionGood storage stabilityAnti-corrosive paintsEpoxy resin coatingsEpoxyDiacetone alcohol

The invention discloses a conjugate anticorrosive waterborne epoxy coating which is prepared from the following raw materials in parts by weight: 10-14 parts of tetramethyldisiloxane, 15-20 parts of acrylic acid, 0.06-0.08 part of catalyst, 100-130 parts of epoxy resin E44, 3-4 parts of dodecyl trimethyl ammonium chloride, 1-2 parts of diacetone acrylamide, 10-15 parts of pentaerythritol, 0.3-0.6 part of 2-mercapto benzimidazole, 0.4-1 part of octyl isothiazolinone, 0.8-1 part of sodium benzoate, 10-12 parts of kieselguhr, 5-7 parts of diacetone alcohol, 0.1-0.2 part of ethylene thiourea and 0.3-0.4 part of ammonium aluminum sulfate. The coating disclosed by the invention can form a stable film on the surface of a metal substrate and can realize a perfect anticorrosive property and has the advantages of strong adhesion, good film surface toughness, excellent mechanical properties and high peel resistance strength.

Owner:董艺

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com