Novel garnet-based high efficiency green phosphor

A green fluorescent powder, garnet-based technology, applied in the field of new garnet-based high-efficiency green fluorescent powder and its preparation, can solve the problems of poor stability of fluorescent powder and achieve good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

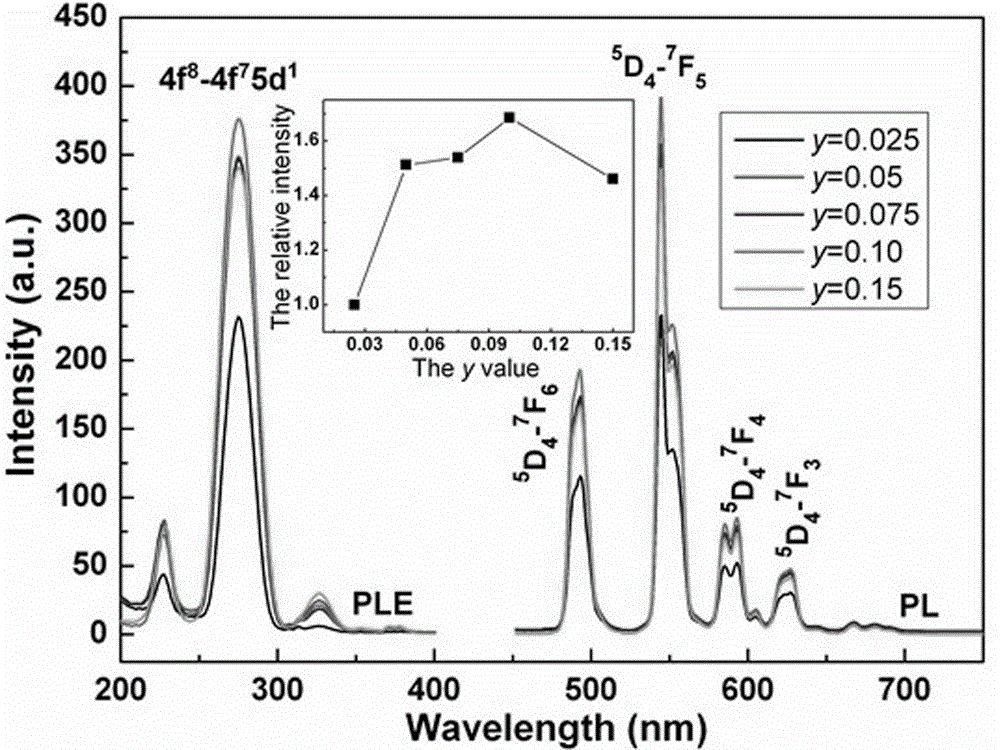

[0028] According to the chemical formula of the phosphor [(Gd 1-x Lu x ) 1-y Tb y ]Al 5 o 12 , take x=0.2; y=0.025, 0.05, 0.075, 0.10, 0.15. Weigh the reagents according to the stoichiometric ratio, and the reagents include Gd 2 o 3 (purity 99.99%), Lu 2 o 3 (purity 99.99%), Tb 2 o 3 (purity 99.99%), aluminum ammonium sulfate (NH 4 Al(SO 4 ) 2 12H 2 O, purity >99%), ammonium bicarbonate (NH 4 HCO 3 , analytically pure) and concentrated nitric acid (HNO 3 , analytically pure). Powdered RE 2 o 3 (RE=Gd, Lu and Tb) dissolved in hot nitric acid to prepare rare earth nitrate solution. And the obtained rare earth nitrate solution and aluminum ammonium sulfate solution (0.15mol / L) were prepared into 200mL mother salt solution according to the molar ratio of RE / Al=3:5. The total concentration of rare earth cations in the mother salt solution was maintained at 0.09 mol / L to ensure a (Gd+Lu+Tb):Al atomic ratio of 3:5. Then, the prepared mother salt solution was d...

Embodiment 2

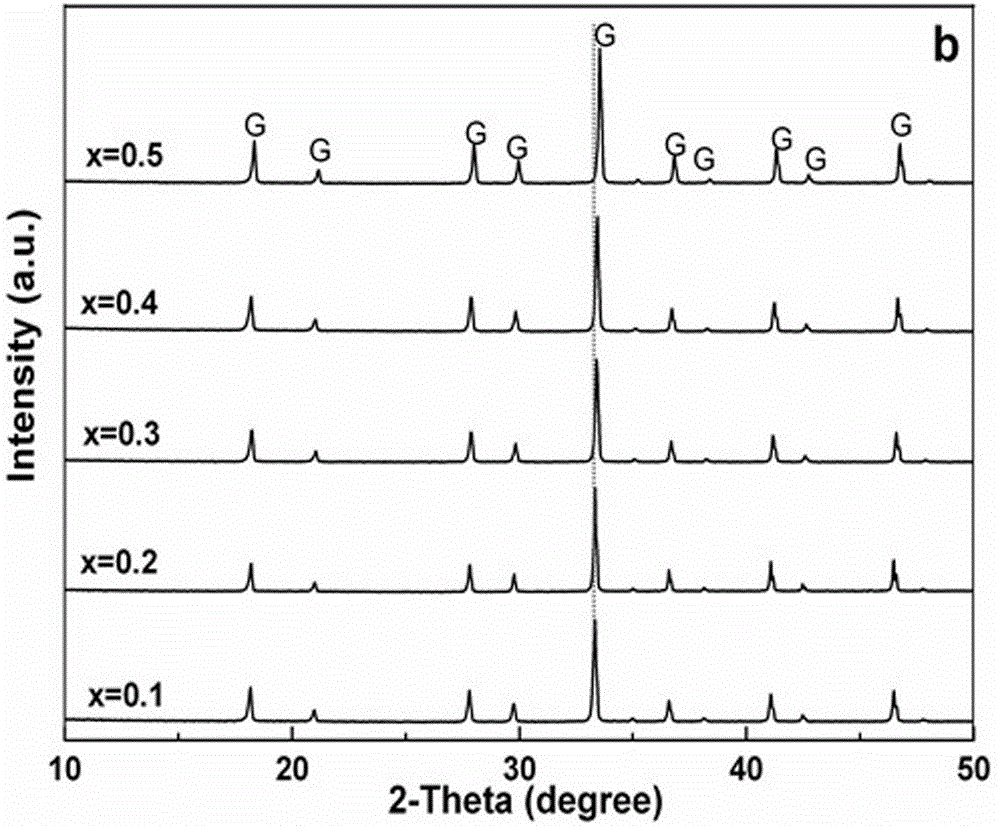

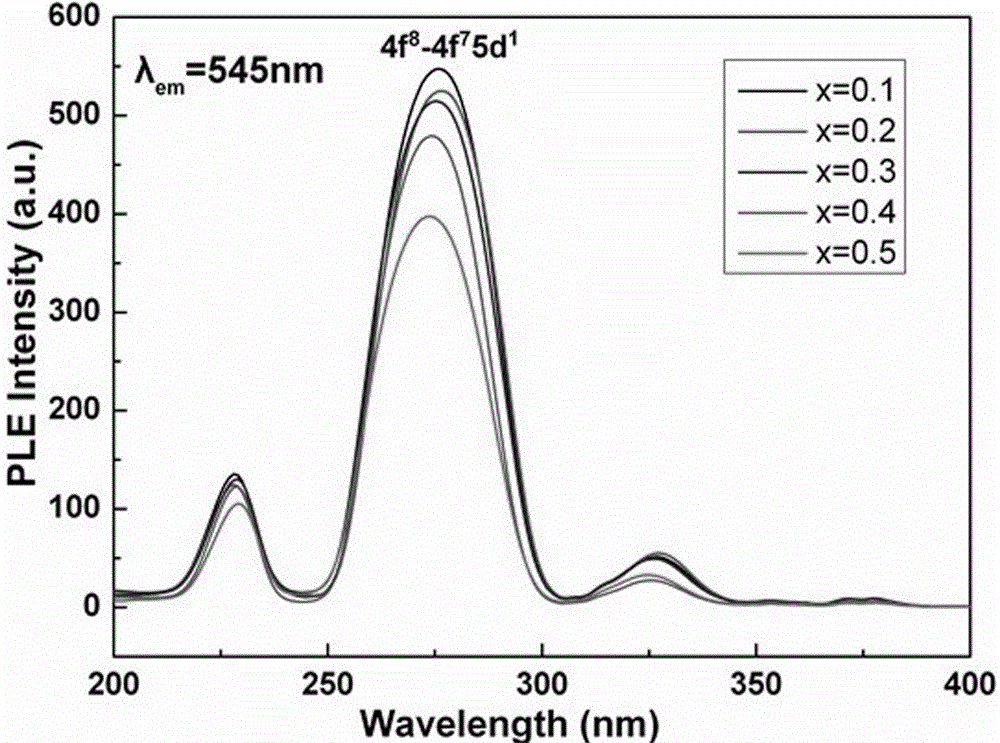

[0031] According to the chemical formula of the phosphor [(Gd 1-x Lu x ) 1-y Tb y ]Al 5 o 12 , take x=0.1, 0.2, 0.3, 0.4, 0.5; y=0.1. Weigh the reagents according to the stoichiometric ratio, and the reagents include Gd2 o 3 (purity 99.99%), Lu 2 o 3 (purity 99.99%), Tb 2 o 3 (purity 99.99%), aluminum ammonium sulfate (NH 4 Al(SO 4 ) 2 12H 2 O, purity >99%), ammonium bicarbonate (NH 4 HCO 3 , analytically pure) and concentrated nitric acid (HNO 3 , analytically pure). Powdered RE 2 o 3 (RE=Gd, Lu and Tb) dissolved in hot nitric acid to prepare rare earth nitrate solution. And the obtained rare earth nitrate solution and aluminum ammonium sulfate solution (0.15mol / L) were prepared into 200mL mother salt solution according to the molar ratio of RE / Al=3:5. The total concentration of rare earth cations in the mother salt solution was maintained at 0.09 mol / L to ensure a (Gd+Lu+Tb):Al atomic ratio of 3:5. Then, the prepared mother salt solution was dropped in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com