Patents

Literature

31results about How to "Reduce phase temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

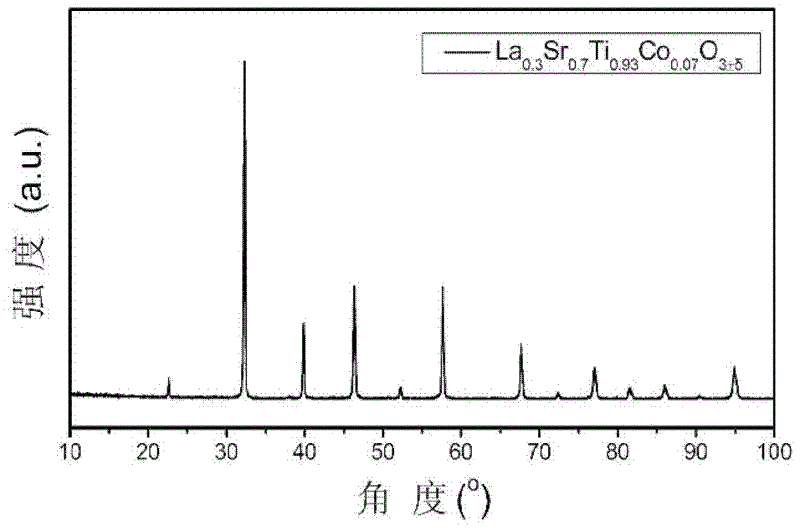

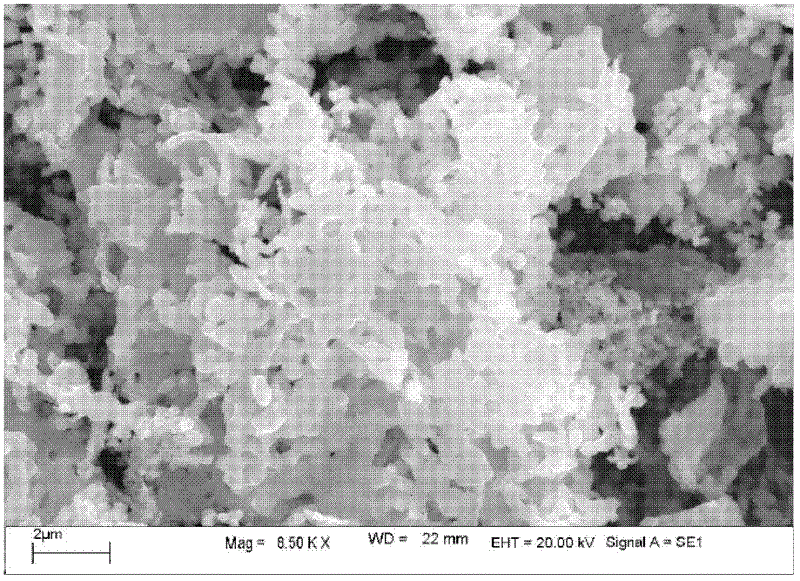

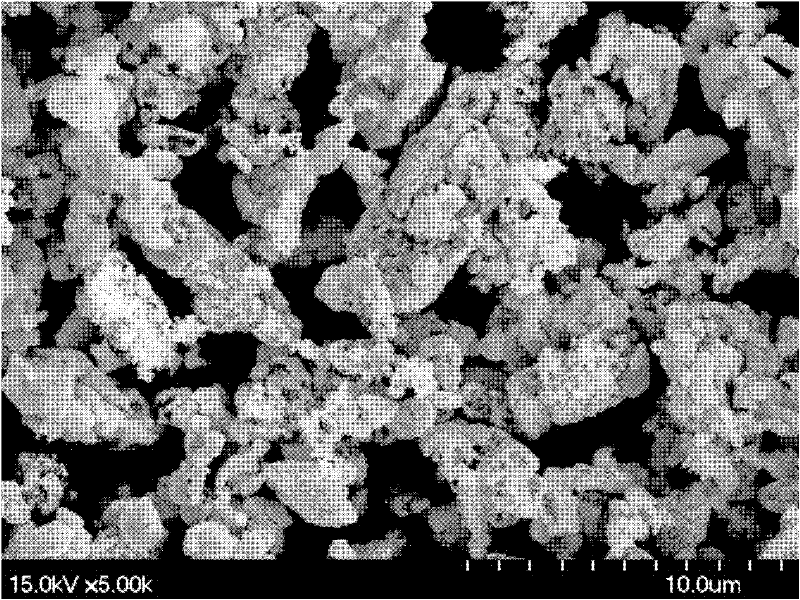

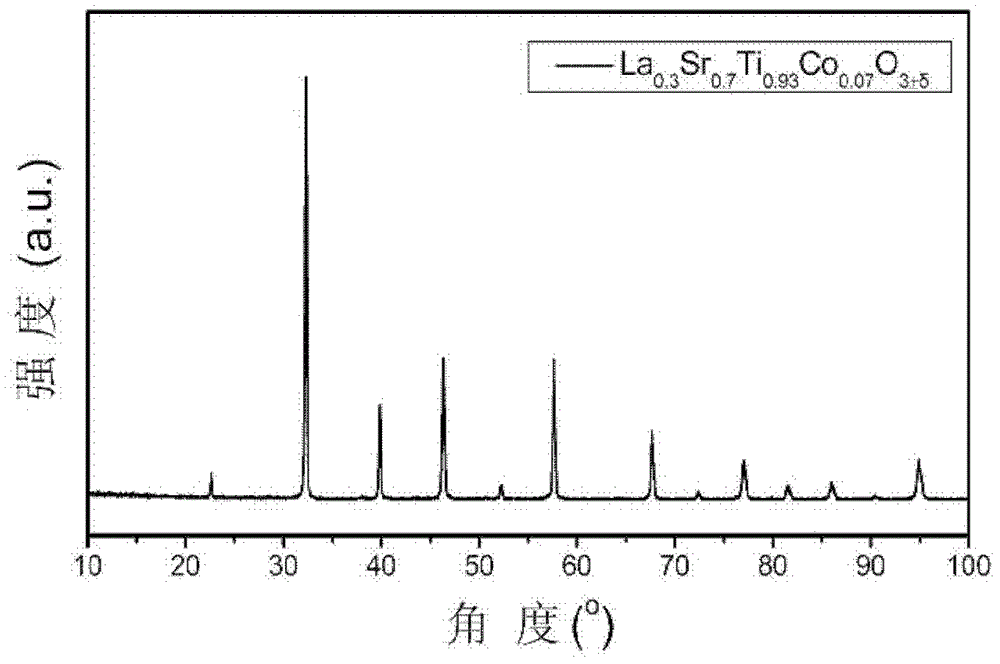

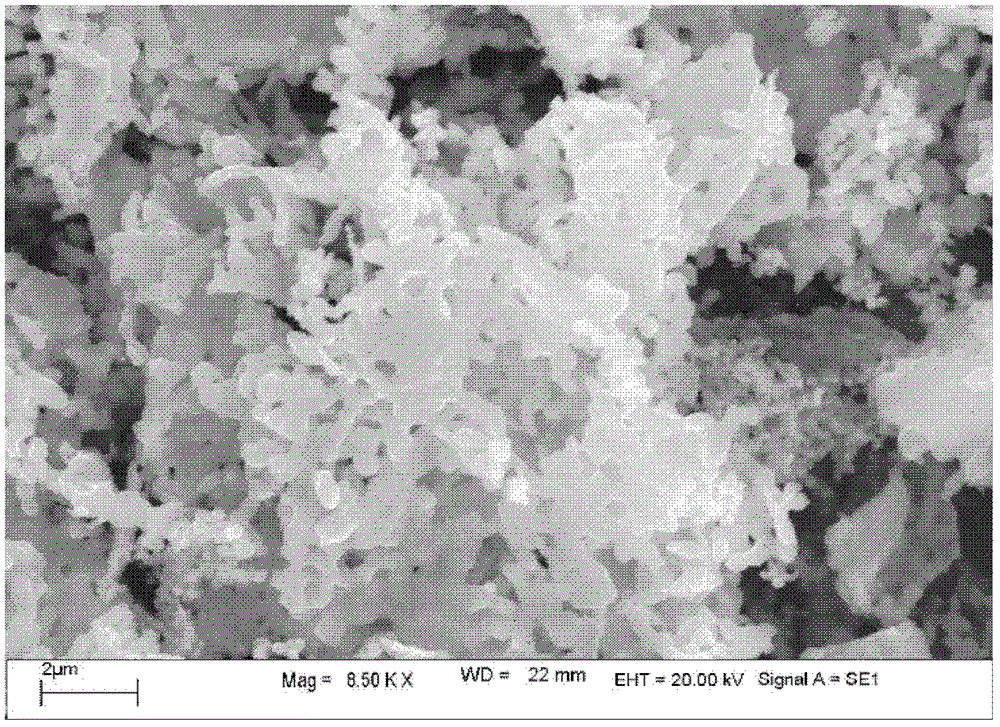

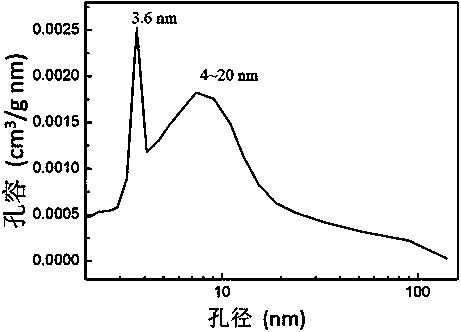

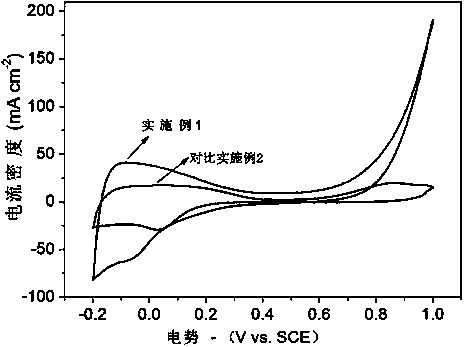

Preparation method for strontium titanate lanthanum based powder material

InactiveCN102617139ASmall particle sizeHigh activityCell electrodesWater bathsSpontaneous combustion

A preparation method for a strontium titanate lanthanum based powder material belongs to the field of fuel cells. The method adopts a citric acid-nitrate spontaneous combustion method, using citric acid as a complexing agent and a reducing agent, using nitric acid as an oxidizing agent, introducing a sintering acid ammonium nitrate in-situ, dissolving with metal nitrate in deionized water, adding a tetrabutyl titanate citric acid solution to form an even transparent solution, heating in water bath, removing surplus water, forming even sol, and heating the sol in a muffle furnace till spontaneous combustion happens to form fluffy precursor powder. Then Grinding and calcining in an electric furnace to obtain single strontium lanthanum based anode powder. The preparation method has the advantages of being simple in synthesis process, low in cost, fine and even in powder particles and low in material phase forming temperature. The method is also applicable to synthesis preparation of strontium titanate based nanometer powder and can be used for laboratory synthesis and industrial production of a solid oxide fuel cell anode powder material.

Owner:UNIV OF SCI & TECH BEIJING

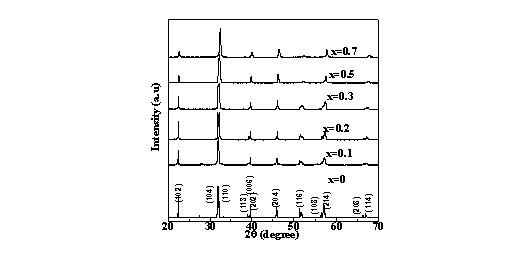

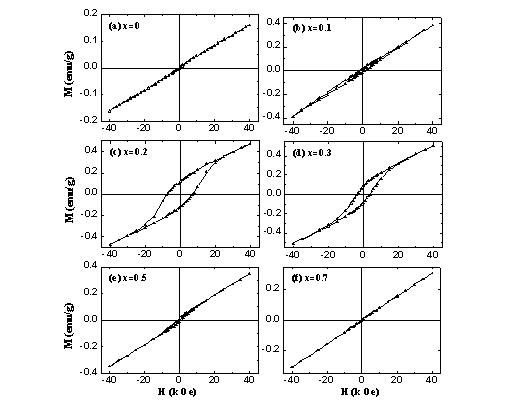

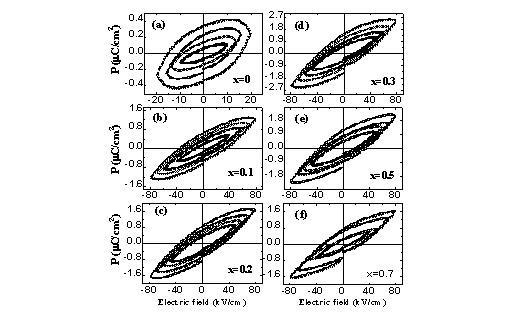

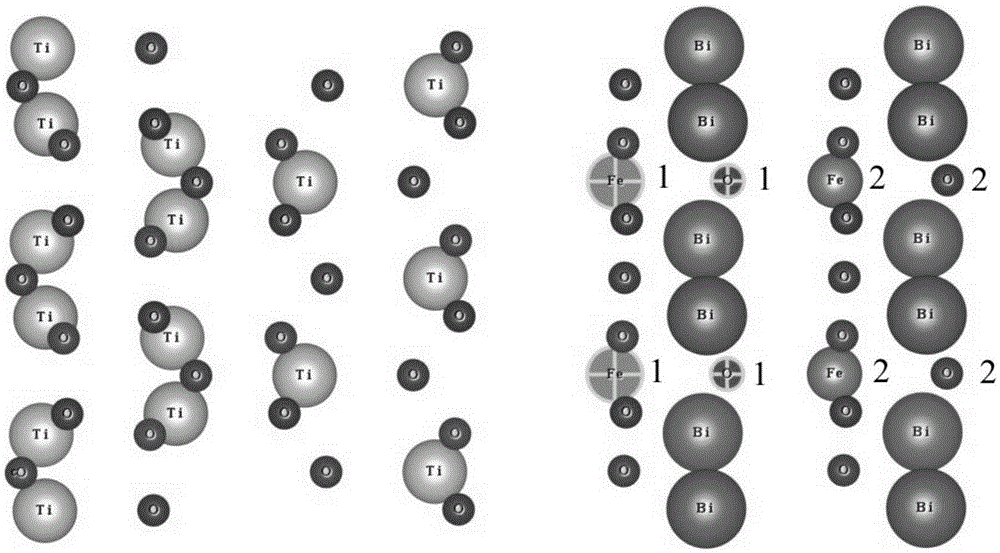

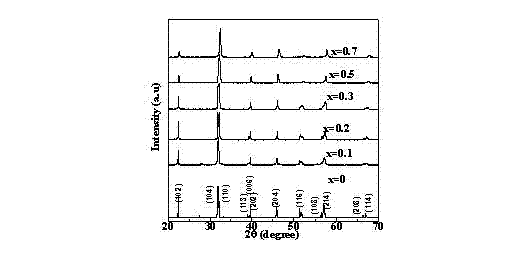

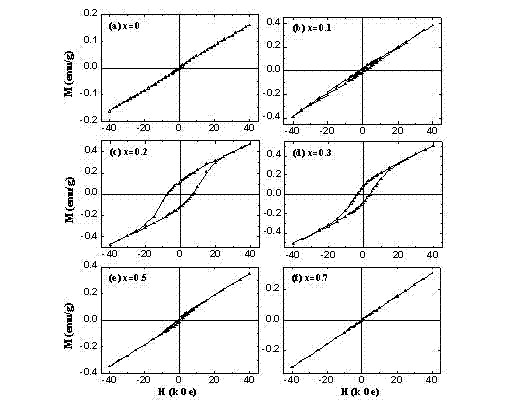

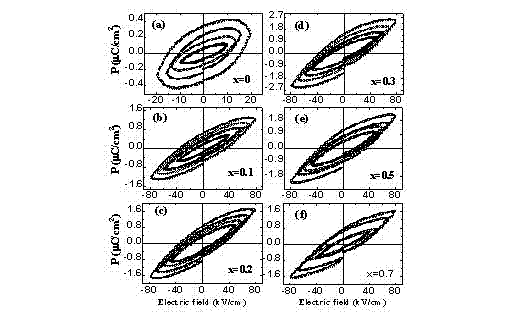

BiFeO3-Bi0.5Na0.5TiO3 base multiferroic solid solution ceramic and preparation method thereof

InactiveCN101941838AReduce leakage currentFerroelectric/ferromagnetic coexistence at room temperatureMicrowave resonanceTableting

The invention belongs to the technical field of information functional materials and in particular relates to BiFeO3-Bi0.5Na0.5TiO3 base multiferroic solid solution ceramic and a preparation method thereof. The preparation method comprises the following steps of: dissolving bismuth nitrate and ferric nitrate in a citric acid solution to form a transparent BiFeO3 solution; dissolving butyl titanate, bismuth nitrate and sodium nitrate into the citric acid solution to form a transparent Bi0.5Na0.5TiO3 solution; mixing the BiFeO3 solution and the Bi0.5Na0.5TiO3 solution by a certain molar ratio and then regulating the pH value to 7-7.5 with ammonia water; aging, dewatering and drying the mixed solution to form black xerogel; grinding the xerogel and carrying out heat treatment to remove organic matters to obtain precursor powder; and grinding, tabletting and sintering the precursor powder to obtain the BiFeO3-Bi0.5Na0.5TiO3 base multiferric solid solution ceramic. The BiFeO3-Bi0.5Na0.5TiO3 base multiferric solid solution ceramic has the characteristics of single phase structure, low leakage current, ferroelectric / ferromagnetic coexistence at room temperature, and the like and has wideapplication prospect in the aspects of manufacturing emerging spin valve devices, magnetoelectric storages, magnetoelectric sensors and microwave resonance devices.

Owner:HUAZHONG UNIV OF SCI & TECH

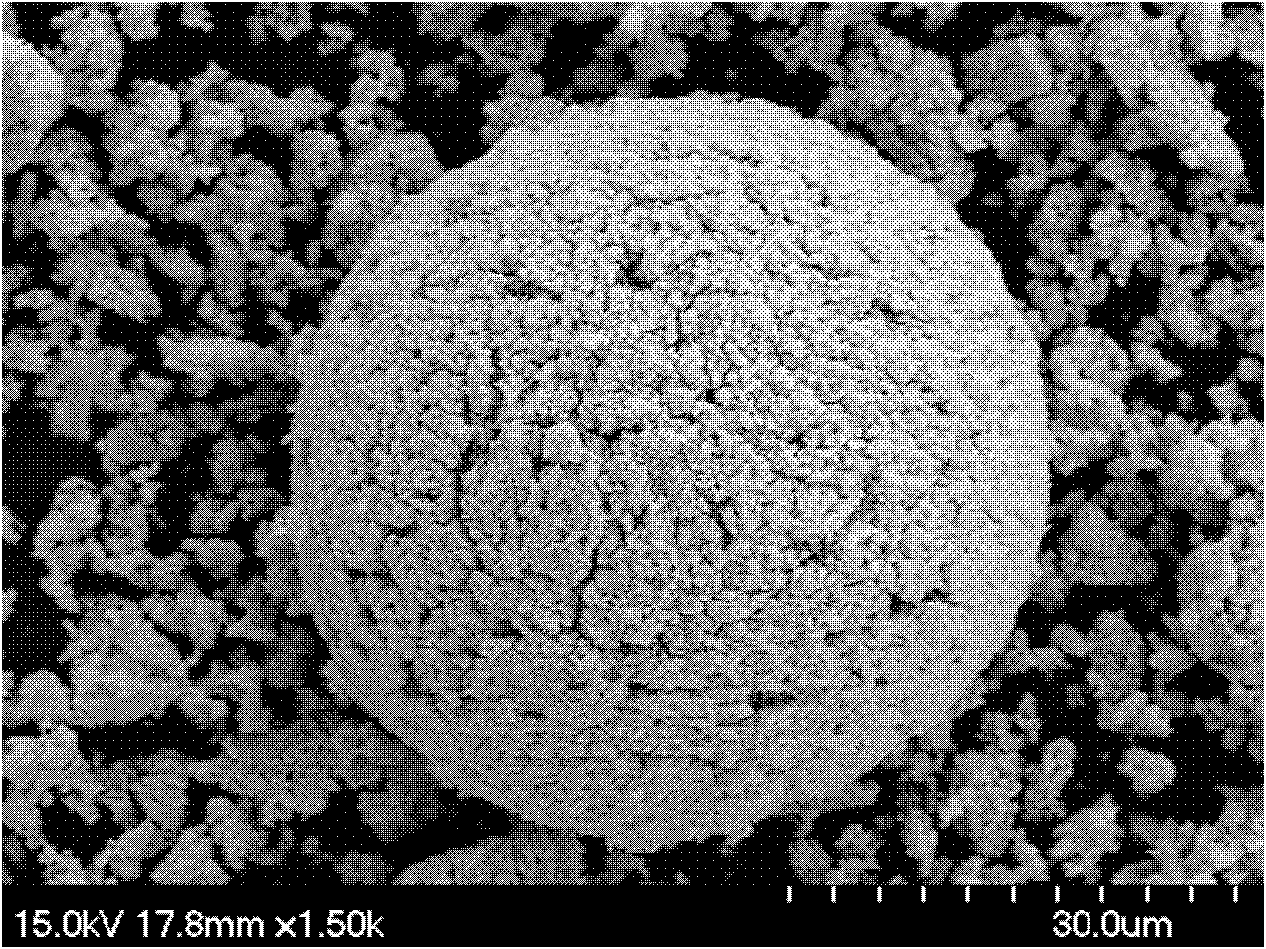

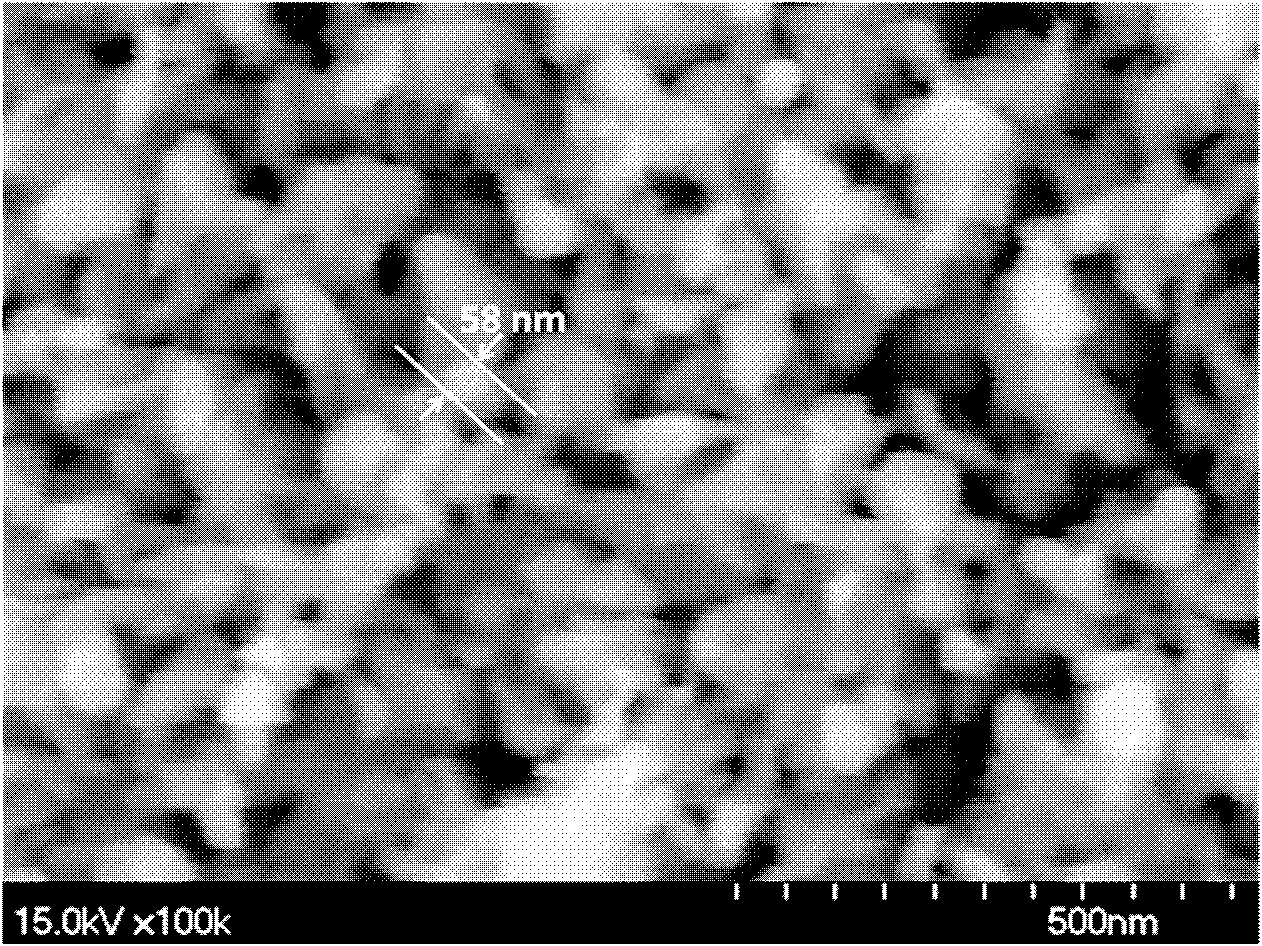

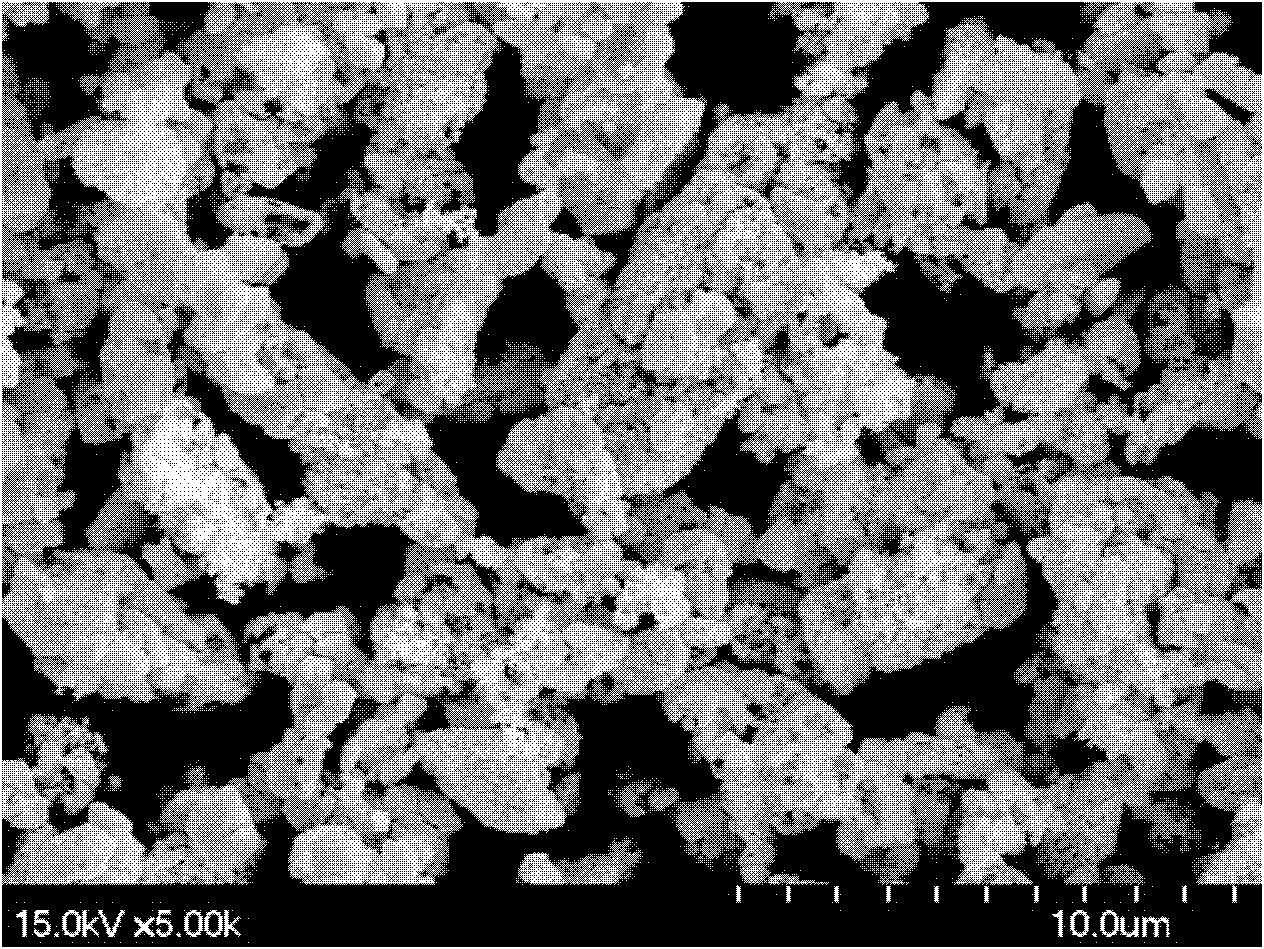

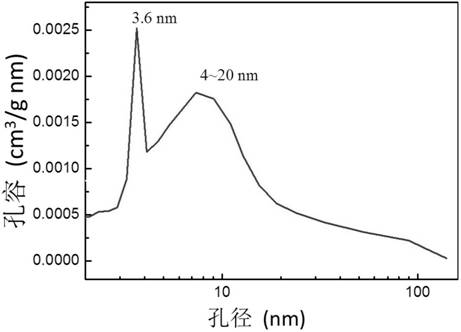

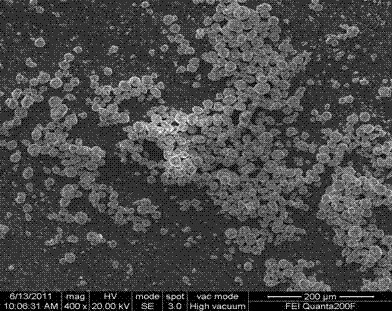

Preparation method of mesoporous hollow sphere-shaped tungsten carbide

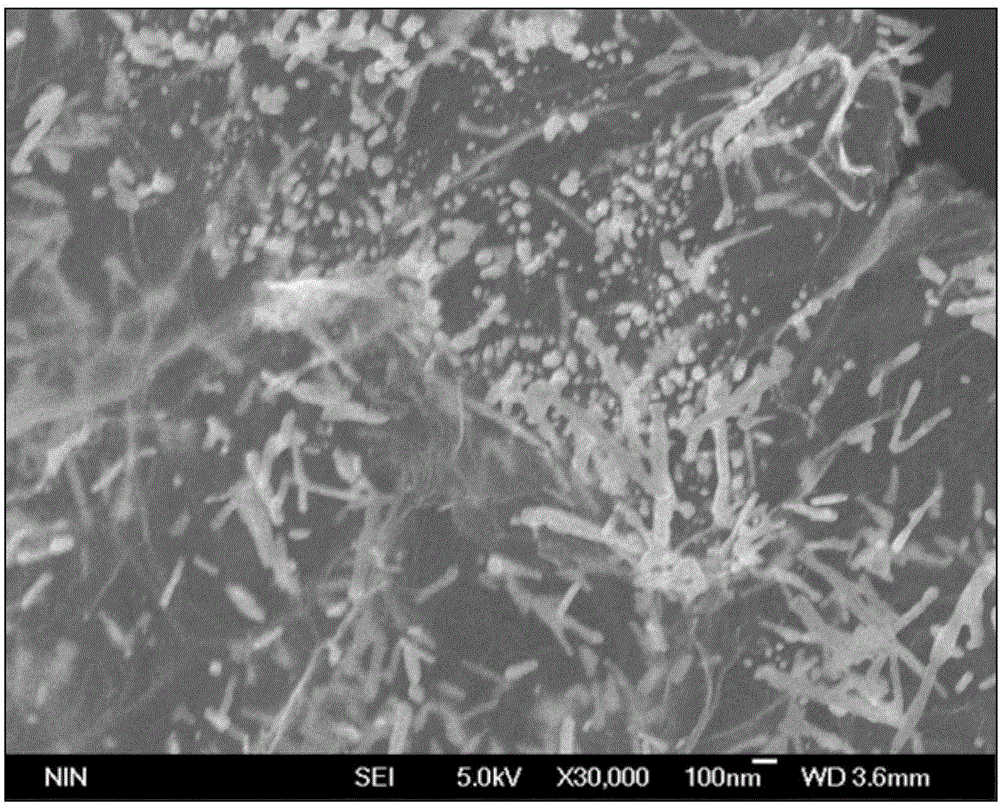

ActiveCN102070143AFine particleChange compositionTungsten/molybdenum carbideUltrasound - actionFiltration

The invention discloses a preparation method of mesoporous hollow sphere-shaped tungsten carbide. The preparation method comprises the following steps: (1) preparing 30%-70% ammonium metatungstate solution at room temperature; (2) fixing a glass container with absolute ethanol in an ultrasonic apparatus, adding the ammonium metatungstate solution obtained in the step (1) at the speed of 1-5 mu l / drop at an interval of 2-8 seconds per drop in the absolute ethanol in the presence of ultrasonic, immediately pelleting and then generating precipitate, dispersing the precipitate by continuous ultrasonic action, and then obtaining ammonium metatungstate particles by filtration and vacuum drying; and (3) carbonizing the obtained metatungstate particles at the atmosphere of CO / H2, and then obtaining the mesoporous hollow sphere-shaped tungsten carbide. The preparation method is simple to operate, the used solvent is clean and environment-friendly, and the prepared metatungstate particles consist of nano tungsten carbide particles.

Owner:ZHEJIANG UNIV OF TECH

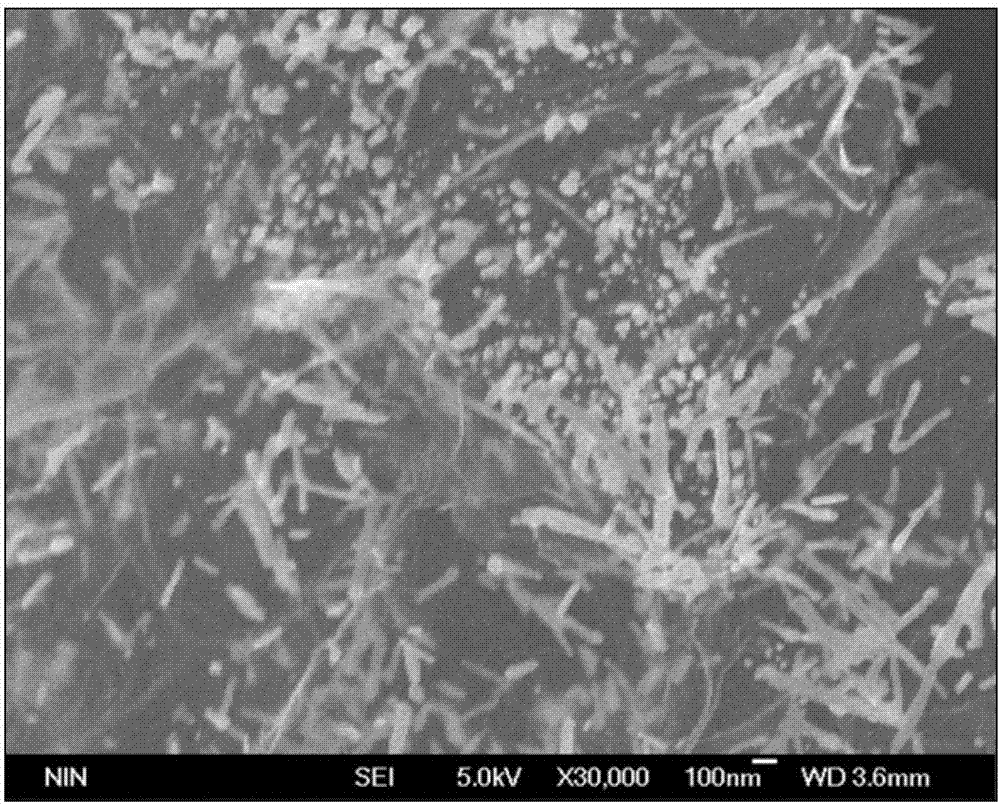

Preparation method and application of graphene-coated nano dysprosium oxide

ActiveCN106315656AInhibition of agglomerationInhibit the generation of agglomerationRare earth metal oxides/hydroxidesNanopillarNanoparticle

The invention provides a preparation method of graphene-coated nano dysprosium oxide. The method comprises the following steps that dysprosium oxide nanoparticles are prepared through a pyrolysis method; 2, dysprosium oxide nanometer columns are prepared through a hydrothermal method; 3, a graphene oxide solution is prepared; 4, the dysprosium oxide nanoparticles and the dysprosium oxide nanometer columns are added into the graphene oxide solution, stirring and filtering are conducted in sequence, filter residues are obtained, and the filter residues are subjected to heat treatment to obtain graphene-coated nano dysprosium oxide. In addition, the invention provides application of graphene-coated nano dysprosium oxide prepared through the method in the process of preparing two-element-doped magnesium diboride superconducting bulk materials. According to the preparation method, the technological method is simple, graphene with high surface area is adopted as a coating, the dysprosium oxide nanoparticles and the dysprosium oxide nanometer columns can be uniformly dispersed on the graphene without generating agglomeration, and the critical current density Jc performance of the two-element-doped magnesium diboride superconducting bulk materials in a low field and a high field can be improved conveniently.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Preparation method of high-current-carrying multi-core Bi-2223 superconducting tape under magnetic field

ActiveCN110085367AHigh densityIncreased flux pinning forceSuperconductors/hyperconductorsApparatus for heat treatmentCarrying capacityGrain boundary

The invention discloses a preparation method of a high-current-carrying multi-core Bi-2223 superconducting tape under a magnetic field. The method comprises the following steps: 1, adding Bi-2223 precursor powder and CaCuO2 power into a silver sleeve so as to obtain a first tube loading composite; 2, drawing and assembling the first tube loading composite so as to obtain a second tube loading composite; 3, drawing the second tube loading composite into a multi-core Bi-2223 tape; 4, preserving the heat of the multi-core Bi-2223 tape so as to obtain the pretreated multi-core Bi-2223 tape; and 5,thermally treating the pretreated multi-core Bi-2223 tape so as to obtain a multi-core Bi-2223 superconducting tape. The powder tube loading process improves the Bi-2223 grain orientation and grain boundary quality and improves the grain orientation and bonding properties so that the current carrying capacity of the Bi-2223 superconducting tape under the magnetic field can be enhanced and the application in magnets and other fields can be facilitated.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

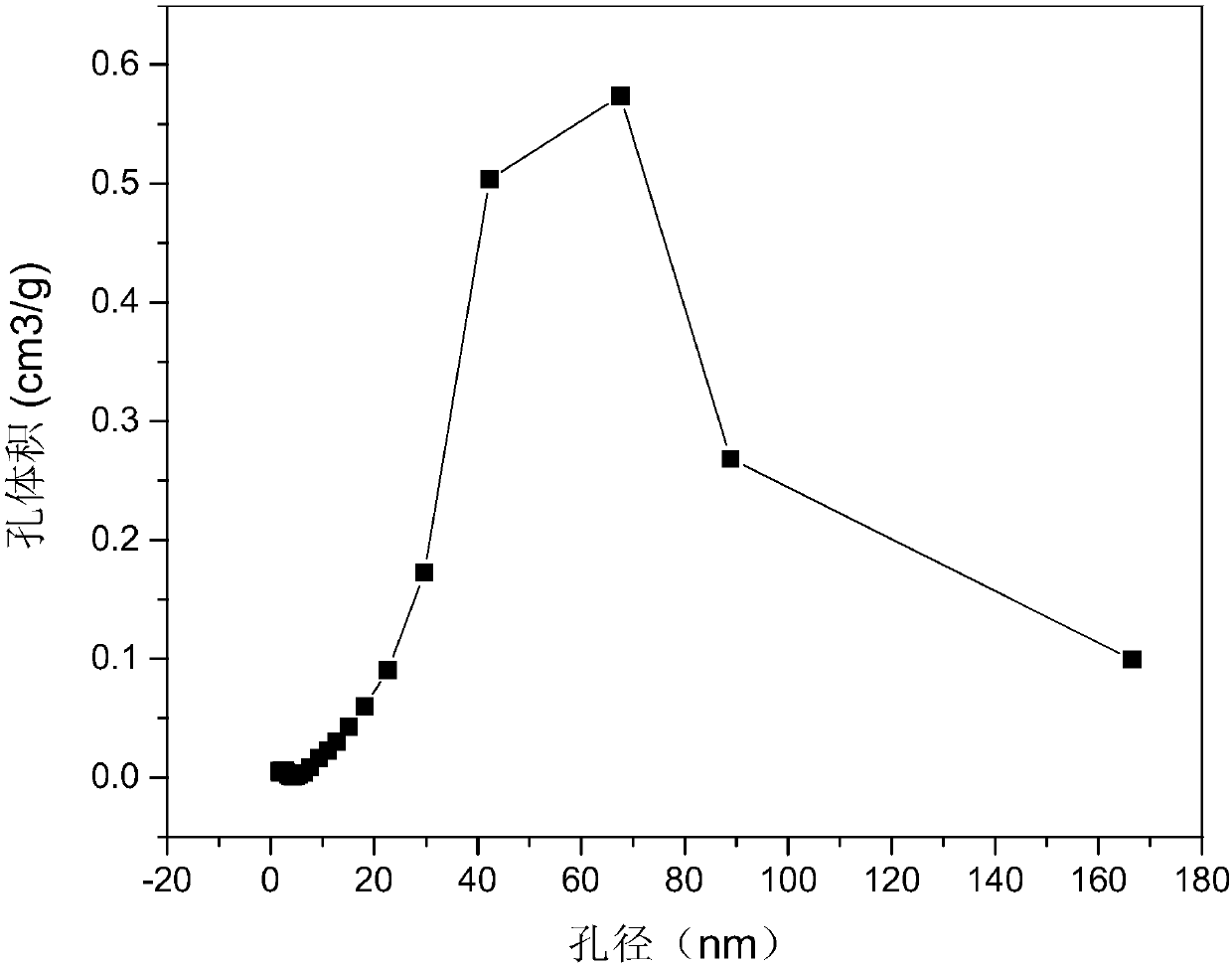

Preparation method of hexaaluminate catalysts with high specific surface areas

InactiveCN108097242ARaw materials are easy to getLow priceMetal/metal-oxides/metal-hydroxide catalystsAir atmosphereIon

The invention discloses a preparation method of hexaaluminate catalysts AAl12-xBxO19-delta with high specific surface areas. The preparation method comprises the following steps: (1) weighing nitratescorresponding to elements A, B and Al according to a stoichiometric ratio, dissolving the weighed nitrates into deionized water to prepare corresponding nitrate mixed solutions; (2) adding a certainamount of saccharides into the nitrate mixed solutions prepared in the step (1), heating, and stirring to form sols; then, drying the sols to obtain precursors; (3) heating the precursors, obtained inthe step (2), up to 800-1500 DEG C in an inert atmosphere, and roasting; then, calcining in an oxidizing atmosphere, cooling and then crushing to obtain the hexaaluminate catalysts with high specificsurface areas. According to the preparation method, a carbon coating layer, formed by roasting in the inert atmosphere, is used for preventing excessive growth and aggregation of the crystal grains,a carbon layer is removed by calcining in an air atmosphere, and the hexaaluminate catalysts with pure phase structures are further formed; the prepared catalysts have the advantages of being high inspecific surface areas, small in grain sizes and high in methane combustion catalysis activity.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

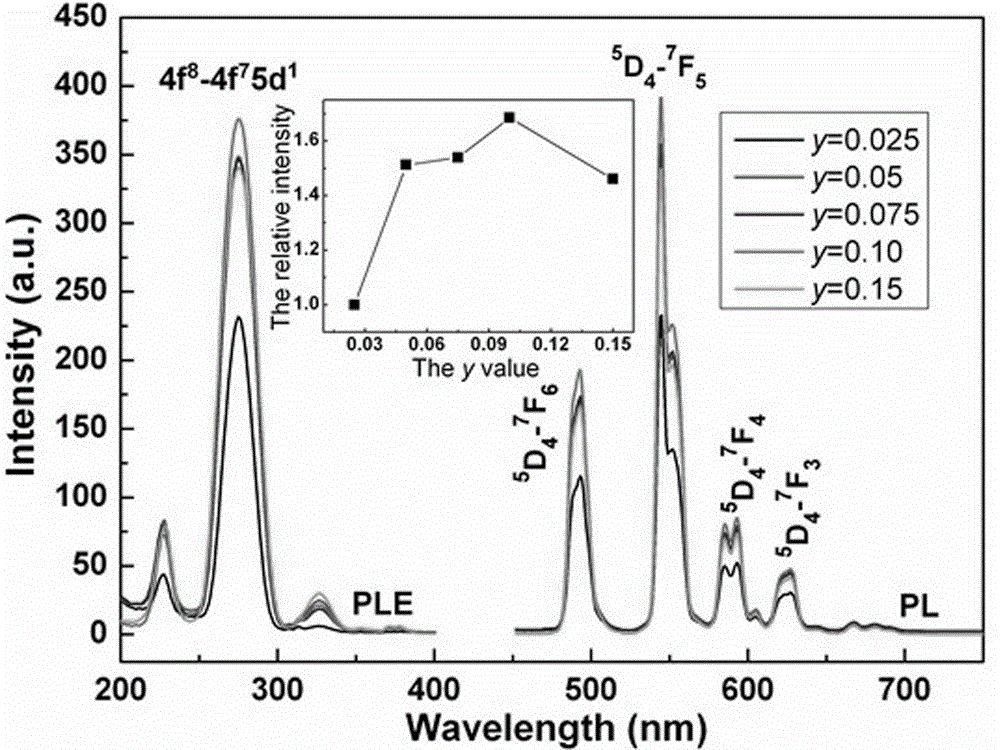

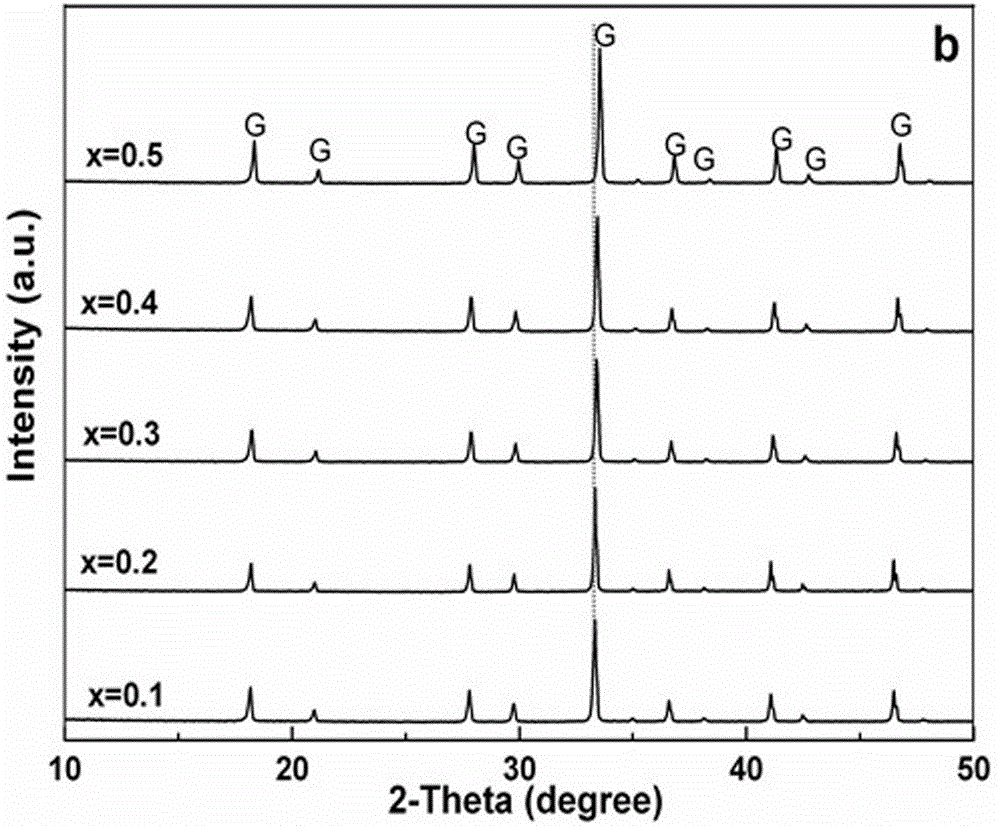

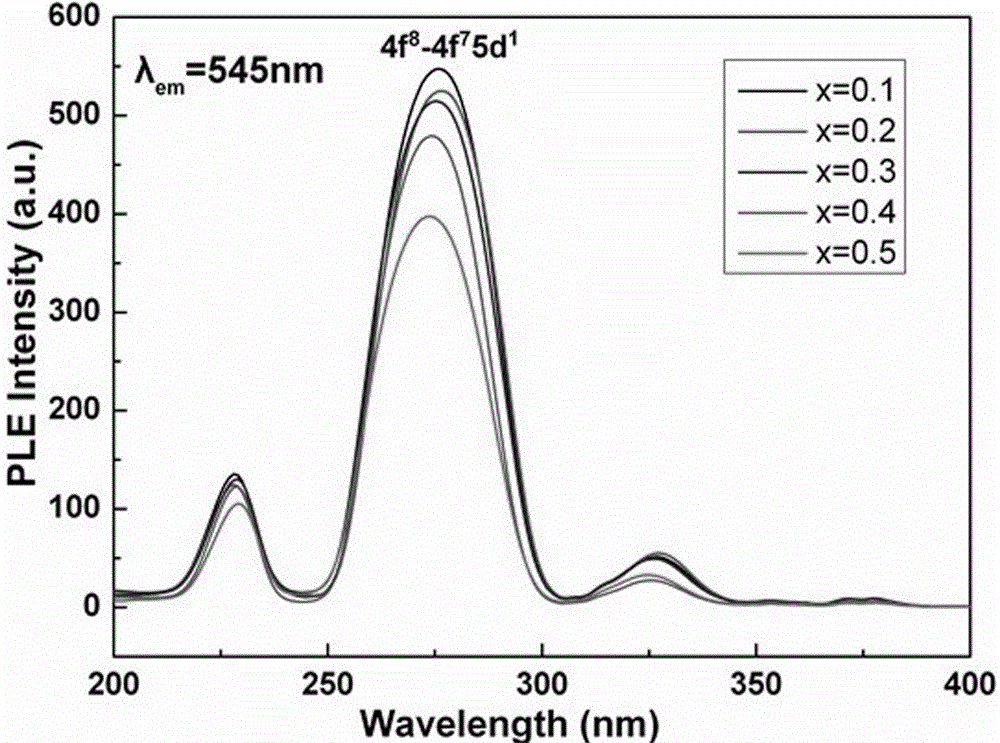

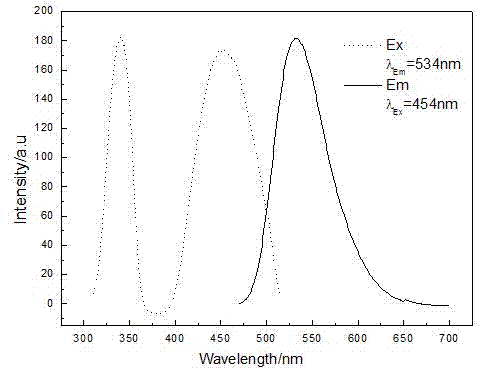

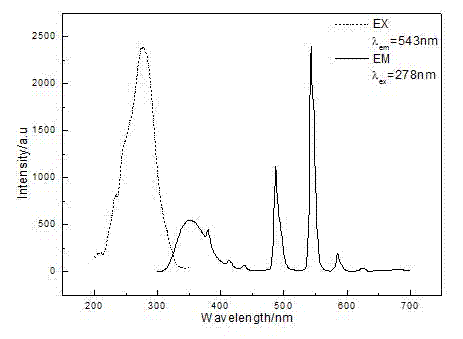

Novel garnet-based high efficiency green phosphor

InactiveCN104910910AGood dispersionStrong green emissionLuminescent compositionsQuantum efficiencyNitrate

The invention provides a novel garnet-based high efficiency green phosphor, a chemical formula is [(Gd1-xLux)1-yTby]Al5O12 (short for (Gd, Lu)AG:Tb<3+>), wherein x is Lu / (Gd+Lu+Tb) and y is Tb / (Gd+Lu+Tb)(x is 0-1.0, y is 0-0.15). The phosphor takes rare earth nitrate and an ammonium aluminium sulfate according to stoichiometric ratio to prepare a mother salting liquid, the mother salting liquid is dropped into a NH4HCO3 precipitating agent solution, the obtained deposition is centrifuged, washed, and dried to obtain the white precursor powder, and phosphor (Gd, Lu)AG:Tb<3+> can be obtained through calcining at different temperature. non radiation energy transmission of Gd<3+> to Tb<3+> is existed, the fluorescence quantum efficiency is high, addition of Lu can obvious improve the stability of a system, and is more suitable for a scintillator material.

Owner:UNIV OF JINAN

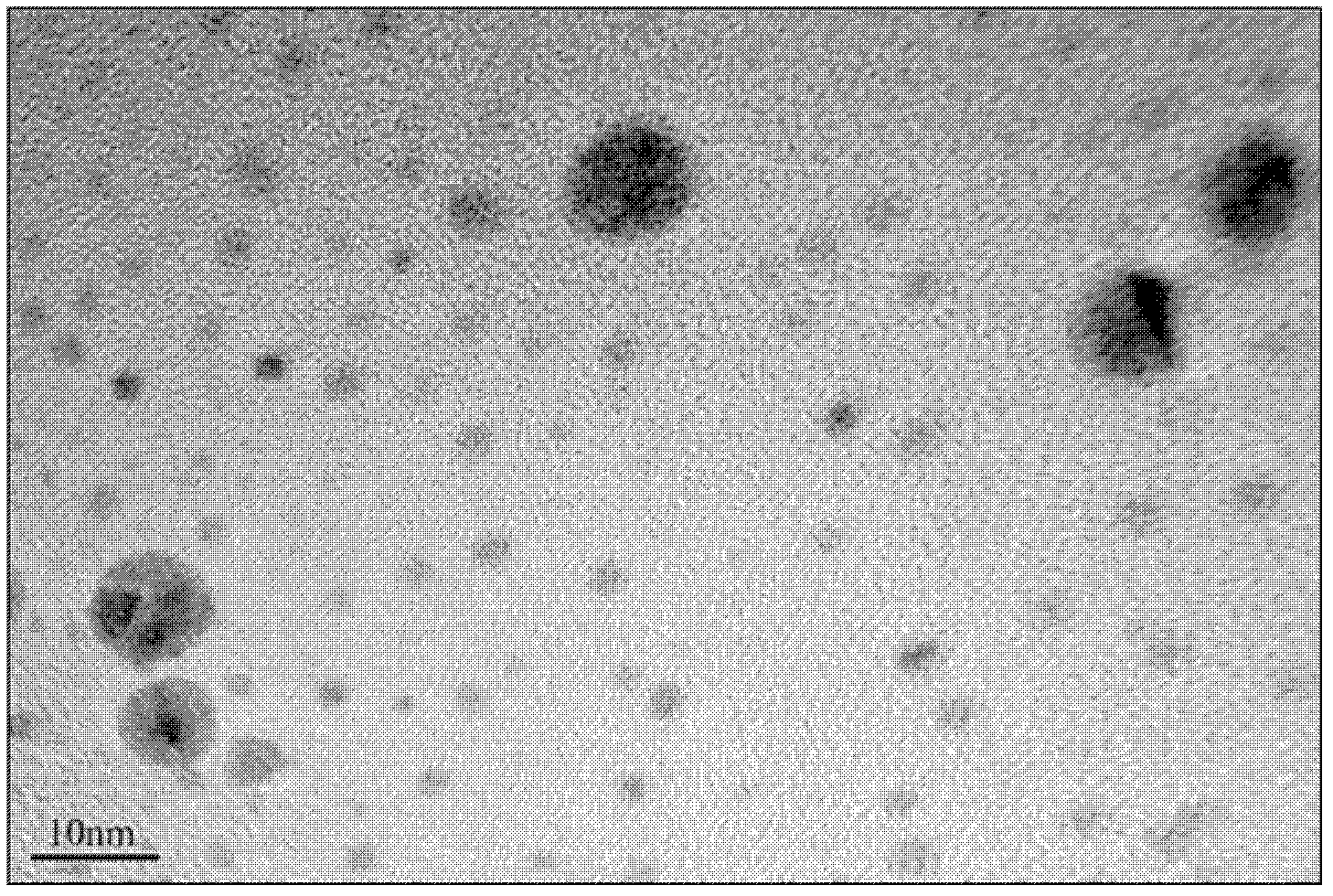

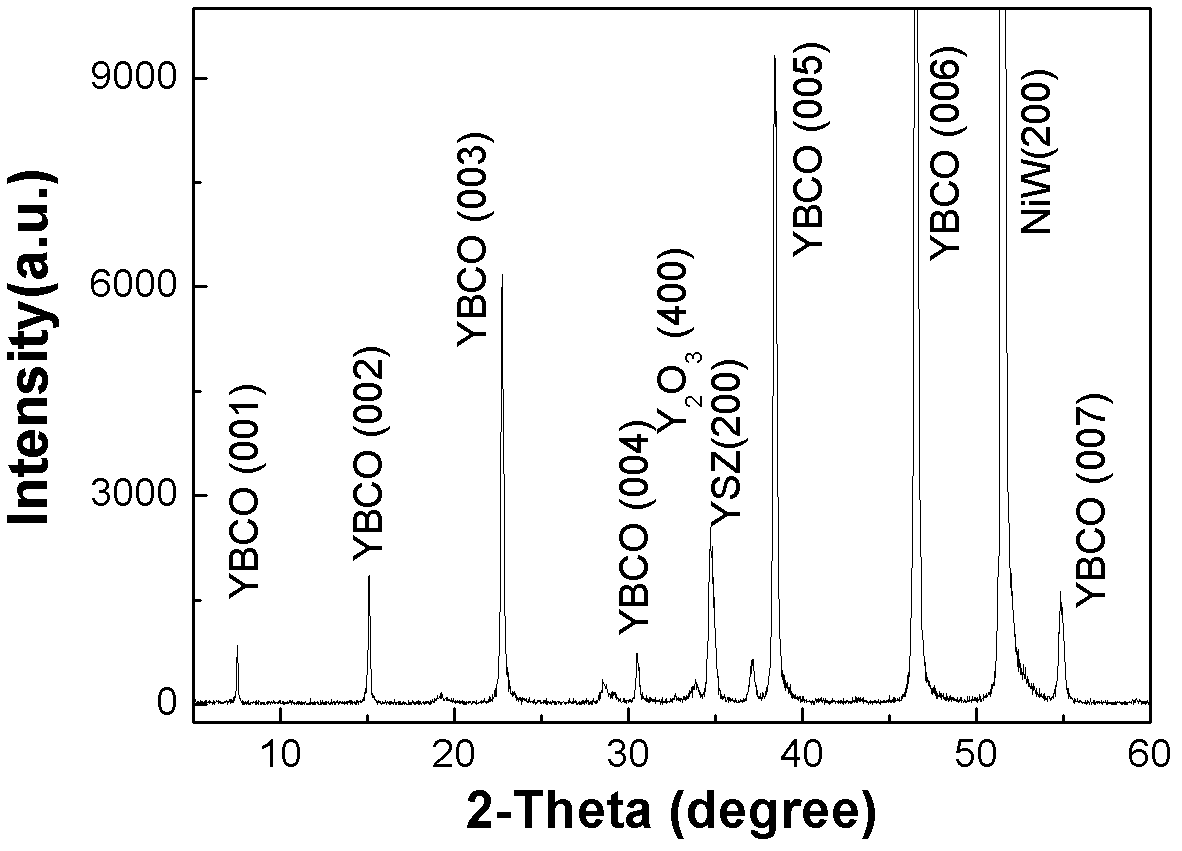

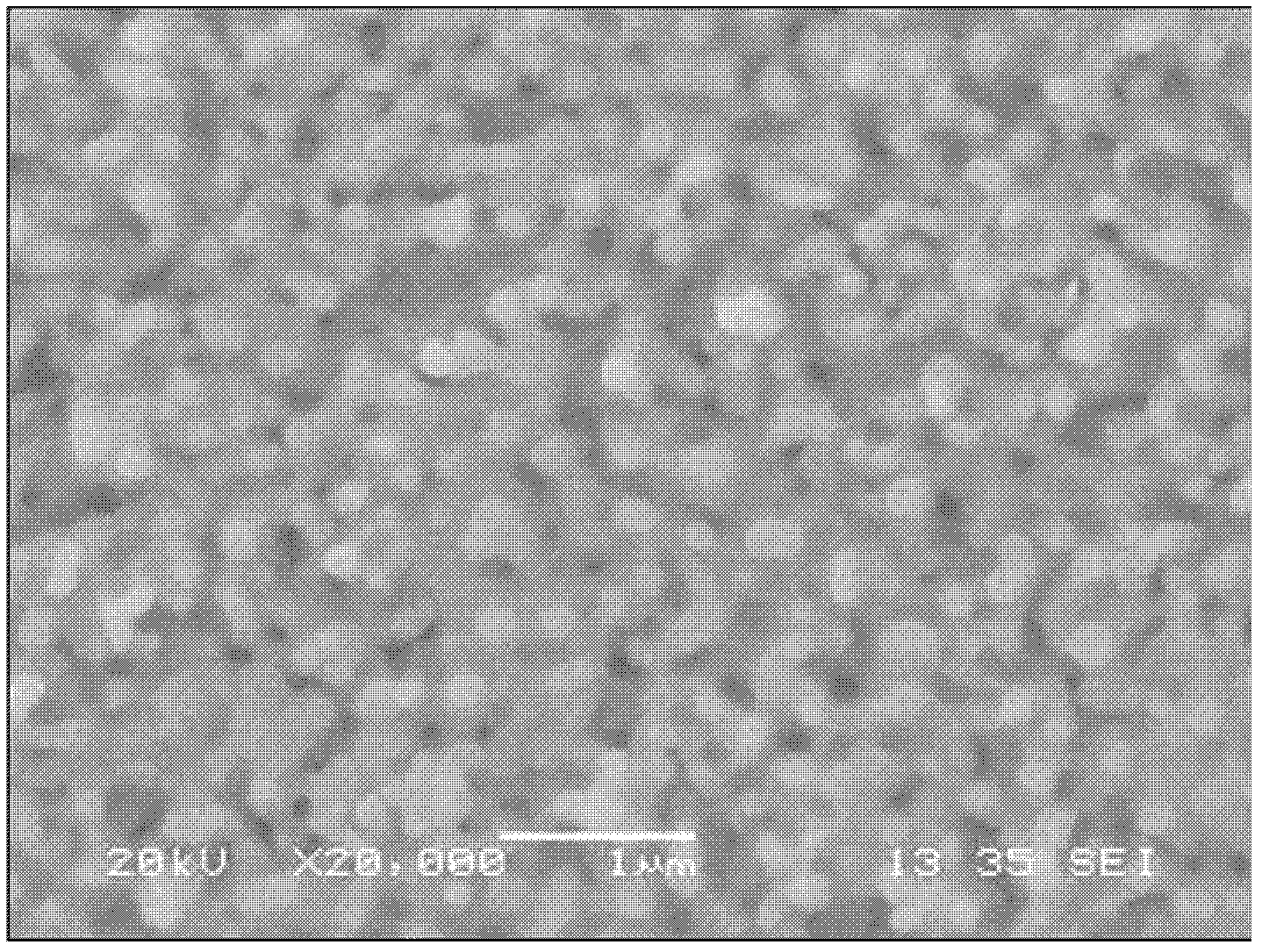

Preparation method of nanosilver-doped yttrium barium copper oxide film

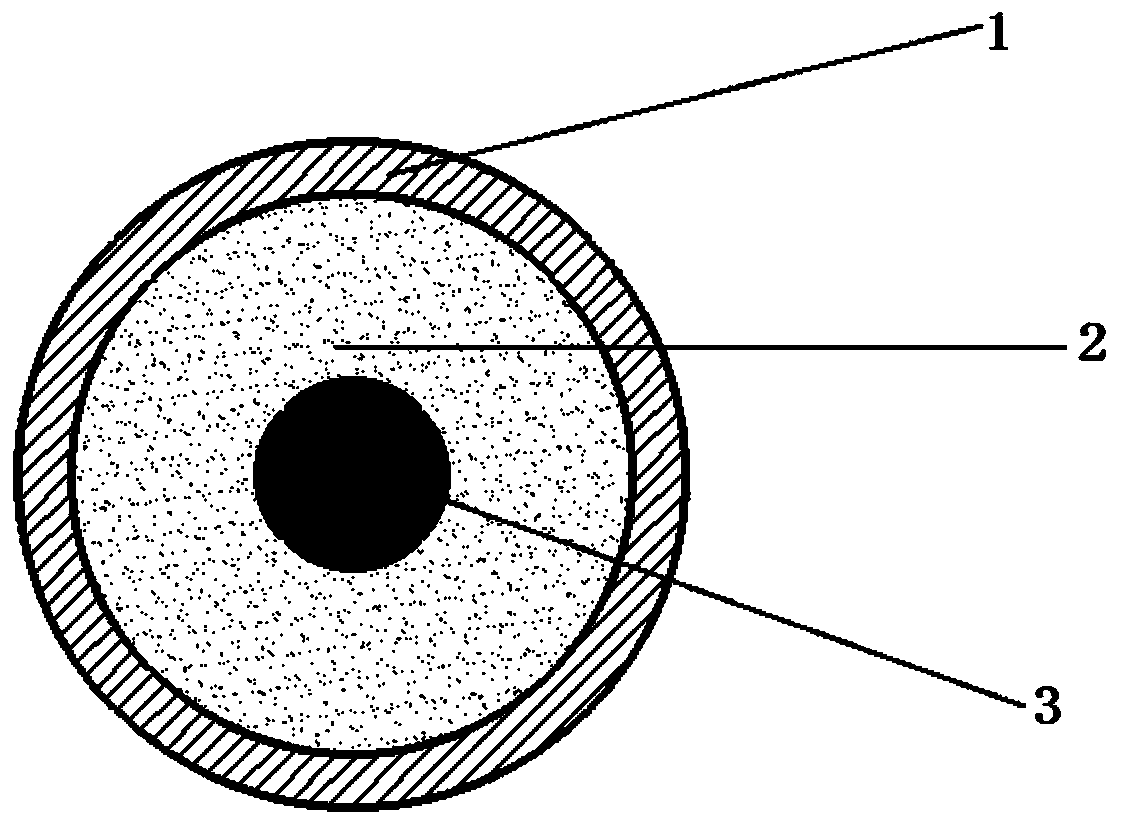

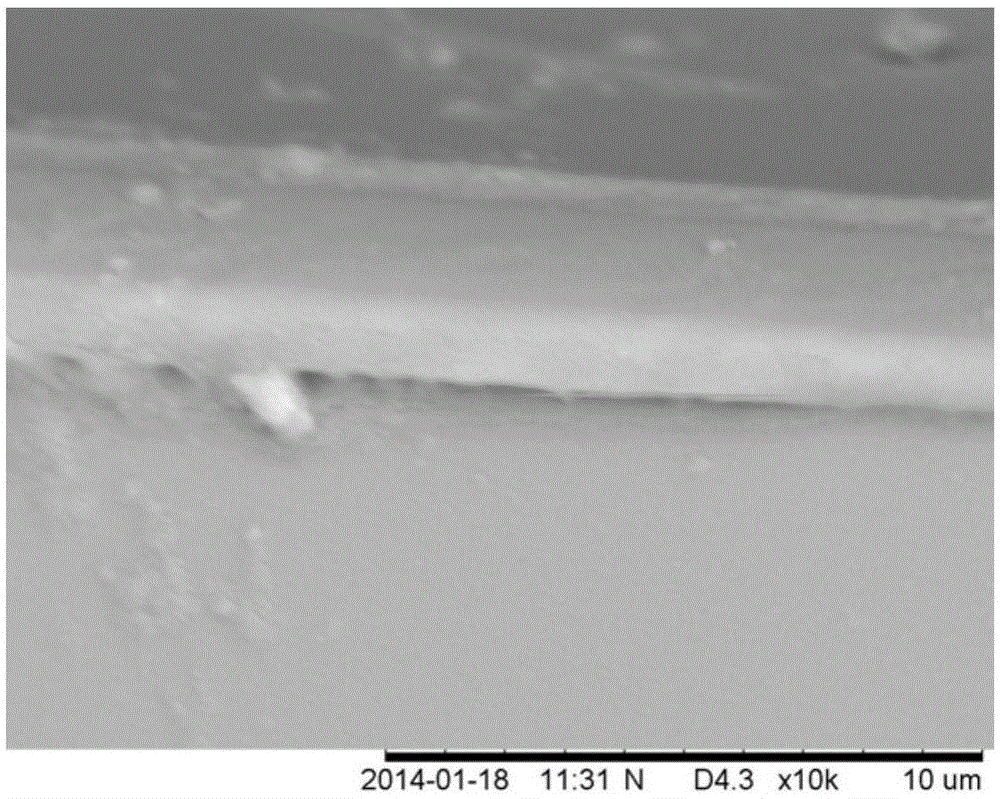

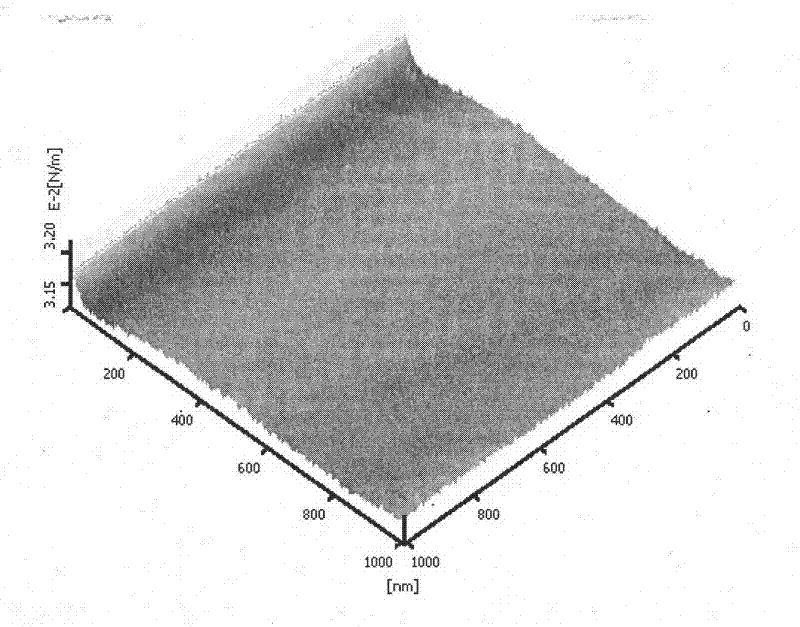

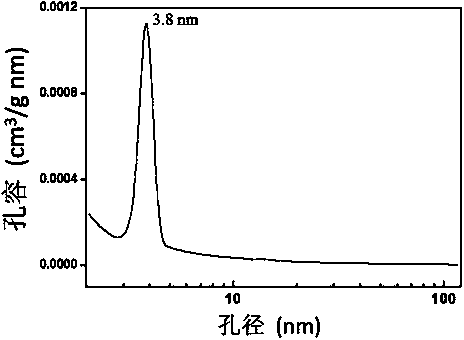

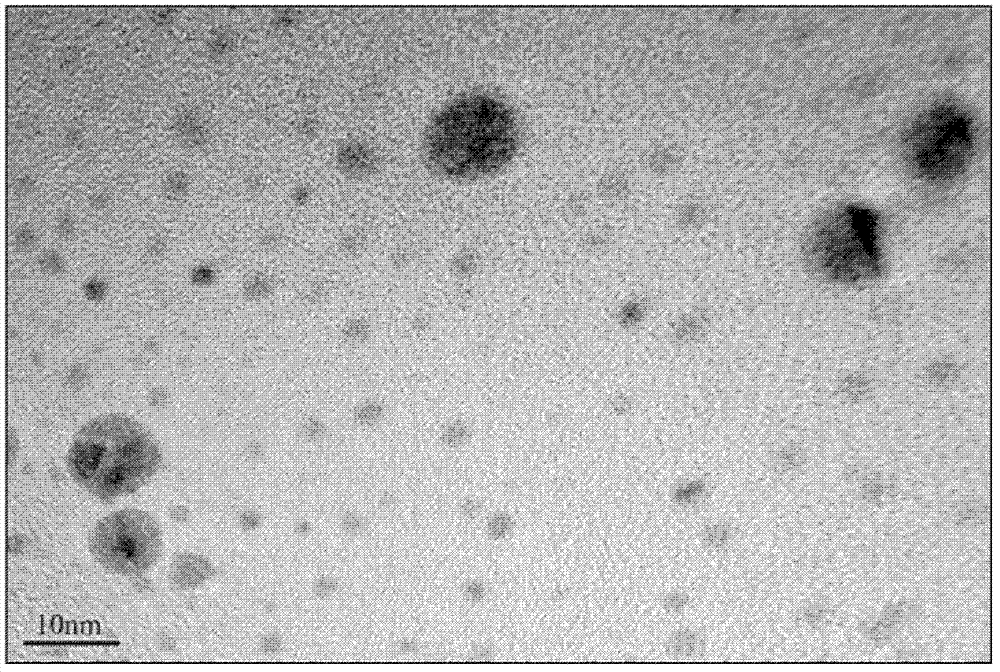

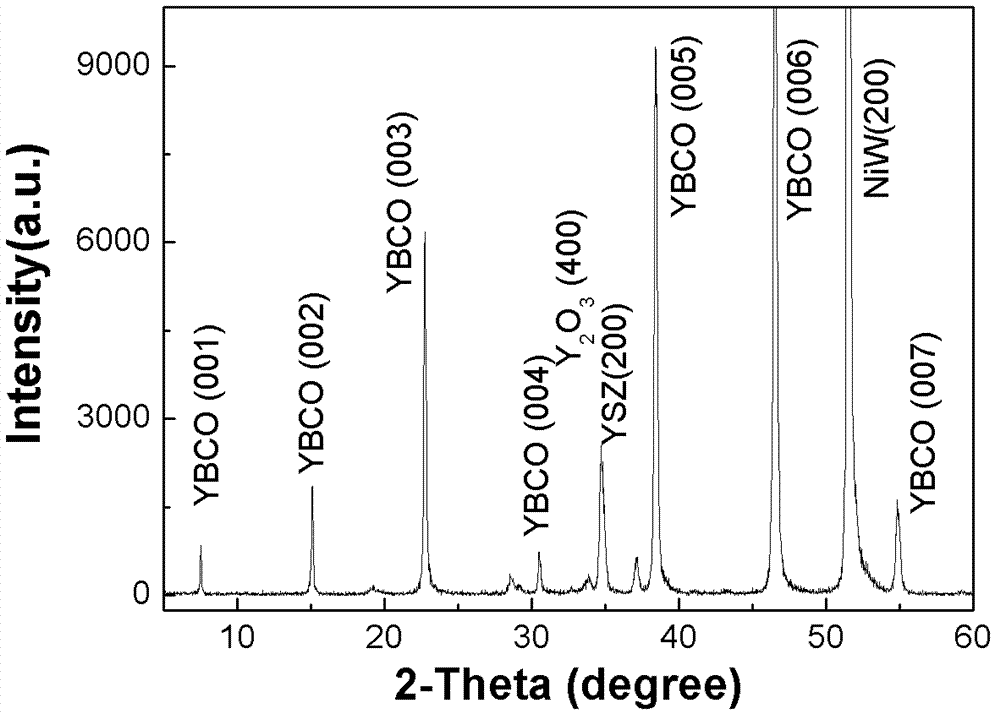

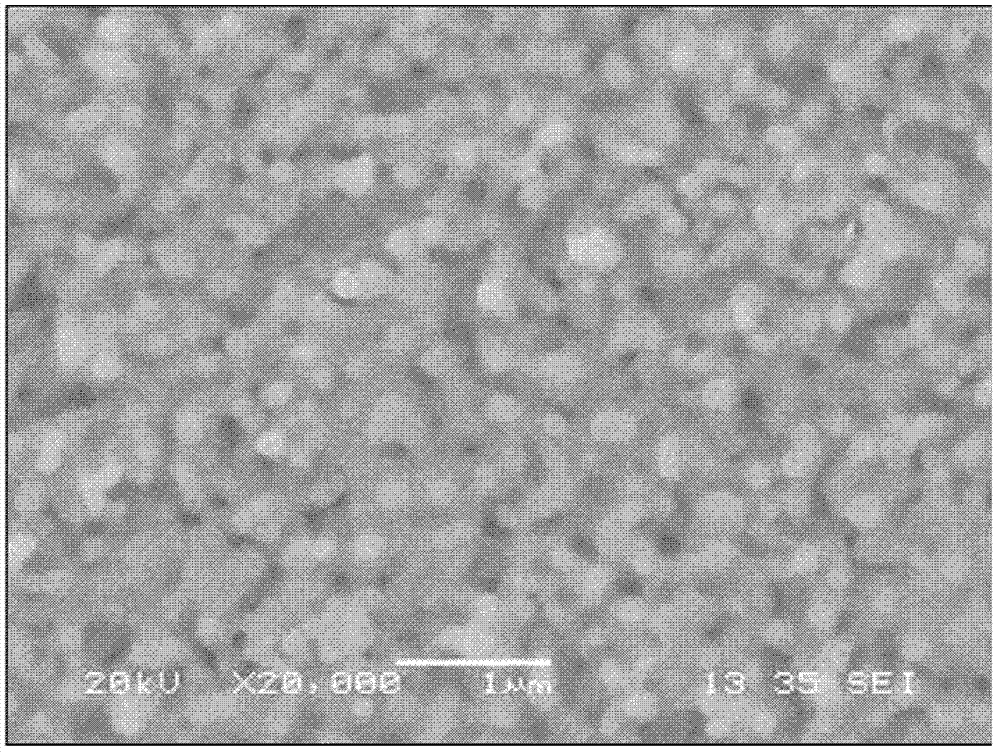

ActiveCN102351571AHigh purity without impuritiesRealize contactlessElectrochemical responseYttrium barium copper oxide

The invention discloses a preparation method of a nanosilver-doped yttrium barium copper oxide film, which comprises the following steps: 1. preparing a nanosilver sol by electrochemical reaction, adding the nanosilver sol into a yttrium barium copper oxide precursor liquid to prepare a precursor sol; 2. evenly applying the precursor sol on a CeO2 / YSZ / Y2O3 / NiW substrate to obtain a wet film; 3. carrying out low-temperature pyrolysis to obtain a precursor film; 4. crystallizing to obtain the nanosilver-doped yttrium barium copper oxide film. The electrochemical reaction for preparing nanosilver particles does not need dispersant, reducer or other complex compounds, and can easily obtain the high-purity impurity-free nanosilver sol; the nanosilver particles in the prepared precursor sol aredistributed uniformly, do not aggregate, and have high stability, and the dimension of the nanosilver particles is smaller than 20 nm; the nanosilver-doped yttrium barium copper oxide film obtained by applying the precursor sol has the advantages of low phase formation temperature and uniform nucleation, and has a superconductive layer which is 400-600nm thick and has excellent superconductivity.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

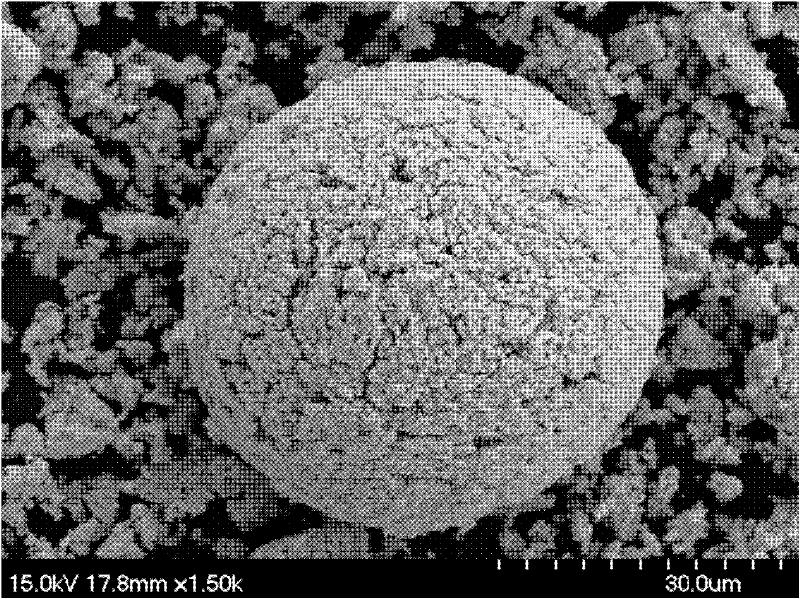

Method for preparing double mesoporous high (100) crystal plane tungsten carbide material

ActiveCN102689902APromote growthImprove adsorption and desorption capacityTungsten/molybdenum carbideTungstateDesorption

The invention discloses a method for preparing a double mesoporous high (100) crystal plane tungsten carbide material. The method comprises the following steps of: (1) preparing a mixed aqueous solution of ammonium meta-tungstate and copper sulfate, adding a 5 to 50 mass percent ammonium carbonate aqueous solution dropwise at the speed of 50 to 200mu L / min during ultrasonic oscillation to deposit solid particles, and filtering after a dropwise adding process to obtain precursor particles; (2) drying the precursor particles in vacuum at the temperature of between 60 and 100 DEG C, putting the precursor particles into a tube furnace and carbonizing to obtain a mesoporous tungsten carbide composite material; and (3) performing acid treatment on the mesoporous tungsten carbide composite material, and thus obtaining the double mesoporous tungsten carbide material. Double mesoporous tungsten carbide (WC) which is prepared by the method is formed by piling up nano WC particles, and the growth of a WC (100) crystal plane is promoted, so that the sorption / desorption capacity of the WC to hydrogen (H2) and the electro-catalysis property of the WC are improved.

Owner:ZHEJIANG UNIV OF TECH

Preparation method of yttrium aluminum garnet yellow fluorescent powder for white light LED

ActiveCN102367383BSmall particle sizeIncrease brightnessGas discharge lamp usageLuminescent compositionsDissolutionOrganic fuel

The invention relates to a preparation method of yttrium aluminum garnet yellow fluorescent powder for white light LED (light-emitting diode). The method comprises the steps of: according to a stoichiometric ratio of each metallic element in Y3-x-yGdxAl5O12: yCe<3+>, preparing a mixed nitrate solution of metals contained in a target product; adding a soluble salt, an organic fuel and ammonium nitrate, heating the solution for dissolution till approximately a sticky state, conducting microwave irradiation so as to initiate self-propagating combustion; carrying out washing, drying, grinding andsieving, thus obtaining the yttrium aluminum garnet yellow fluorescent powder of a necessary particle size. The yttrium aluminum garnet yellow fluorescent powder prepared in the invention has controllable particle size, uniform size, regular appearance, and excellent light-emitting performance, and has the advantages of convenient implementation, simple equipment, short synthesis time, no need for long-time material mixing, high-temperature calcination, and ball-milling crushing. Therefore, the preparation method of the invention is a rapid and energy-saving new method for controlling the synthesis of yttrium aluminum garnet yellow fluorescent powder of different particle sizes.

Owner:NANCHANG UNIV

Preparation method of mesoporous hollow sphere-shaped tungsten carbide

ActiveCN102070143BFine particleChange compositionTungsten/molybdenum carbideUltrasound - actionFiltration

The invention discloses a preparation method of mesoporous hollow sphere-shaped tungsten carbide. The preparation method comprises the following steps: (1) preparing 30%-70% ammonium metatungstate solution at room temperature; (2) fixing a glass container with absolute ethanol in an ultrasonic apparatus, adding the ammonium metatungstate solution obtained in the step (1) at the speed of 1-5 mu l / drop at an interval of 2-8 seconds per drop in the absolute ethanol in the presence of ultrasonic, immediately pelleting and then generating precipitate, dispersing the precipitate by continuous ultrasonic action, and then obtaining ammonium metatungstate particles by filtration and vacuum drying; and (3) carbonizing the obtained metatungstate particles at the atmosphere of CO / H2, and then obtaining the mesoporous hollow sphere-shaped tungsten carbide. The preparation method is simple to operate, the used solvent is clean and environment-friendly, and the prepared metatungstate particles consist of nano tungsten carbide particles.

Owner:ZHEJIANG UNIV OF TECH

Light emitting diode capable of emitting white light

InactiveCN102931327AImprove luminositySimple structureGas discharge lamp usageLuminescent compositionsFluorescenceLight-emitting diode

The invention provides a light emitting diode (LED) capable of emitting white light, relates to the technical field of fluorescence conversion, and solves the problems of low luminous efficiency, poor performance and high cost of an existing LED capable of emitting white light. The LED comprises a blue InGaN chip, yellow light fluorescence powder and packaging materials, wherein the yellow light fluorescence powder and packaging materials are uniformly mixed at the proportion of 0-50 percent by weight, and are coated on the blue InGaN chip to manufacture the LED capable of emitting white light after encapsulating and curing; and the chemical formula of the yellow light fluorescence powder is Ca1-a-x-y MaO : Ce<3+>xR<+>y, wherein a, x and y are molar fraction of elements, and the value range is that the a is smaller than or equal to 0.1 and larger than 0, the x is equal to the y, the x or the y is smaller than or equal to 0.05 and larger than 0, M represents Be<2+>, Mg<2+>, Sr<2+>, Ba<2+>, and Zn<2+> or Cd<2+>, and R represents Li, Na, K, Rb, Cs, and Ag or Cu. The LED provided by the invention has excellent luminescent performance.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

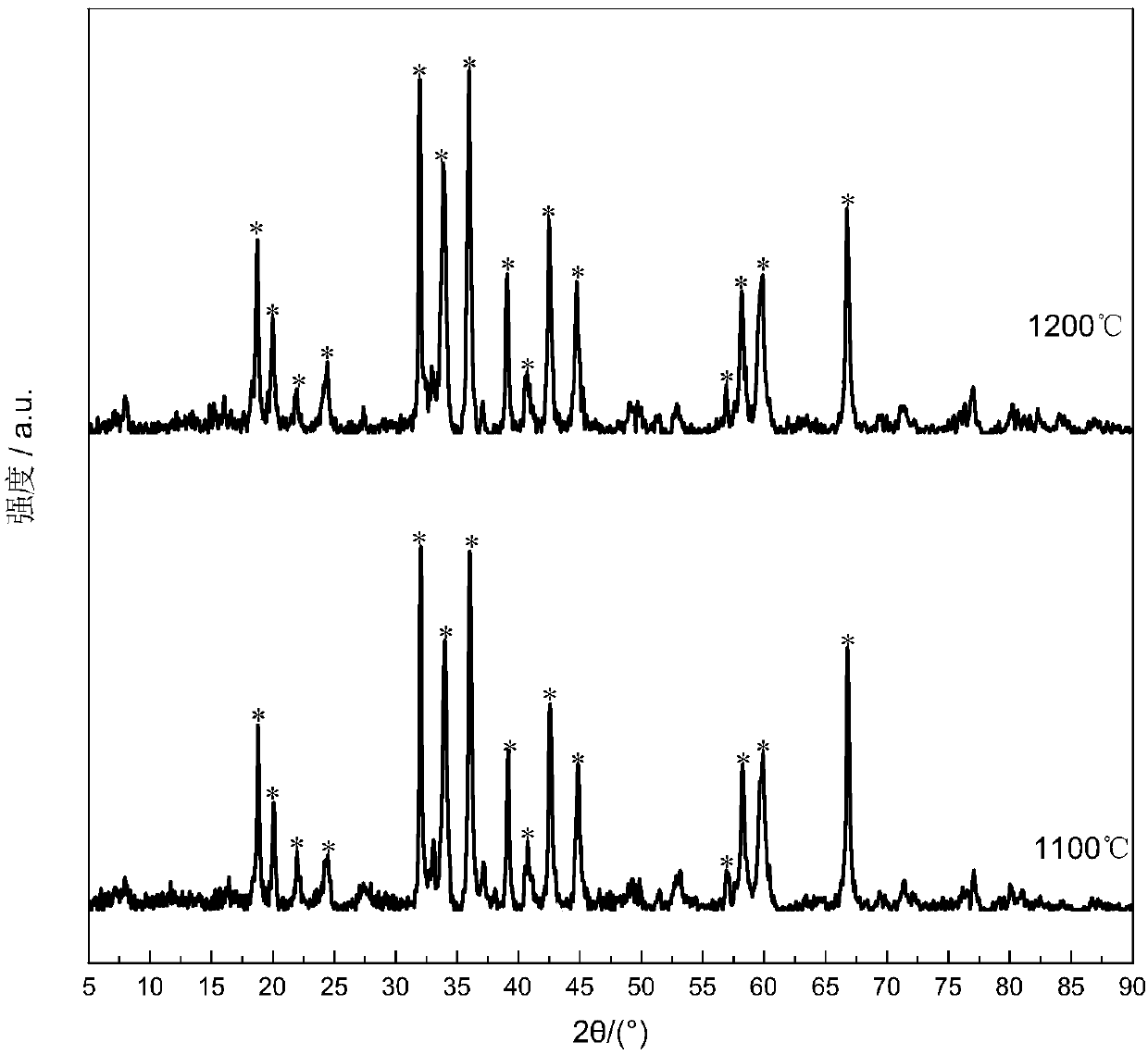

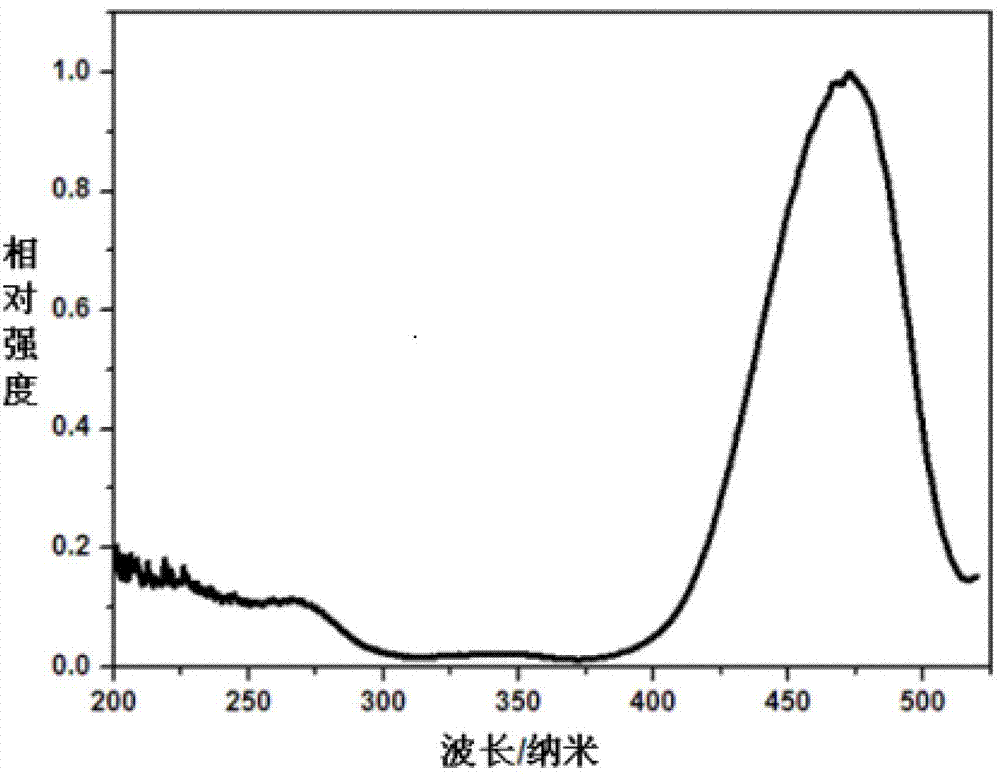

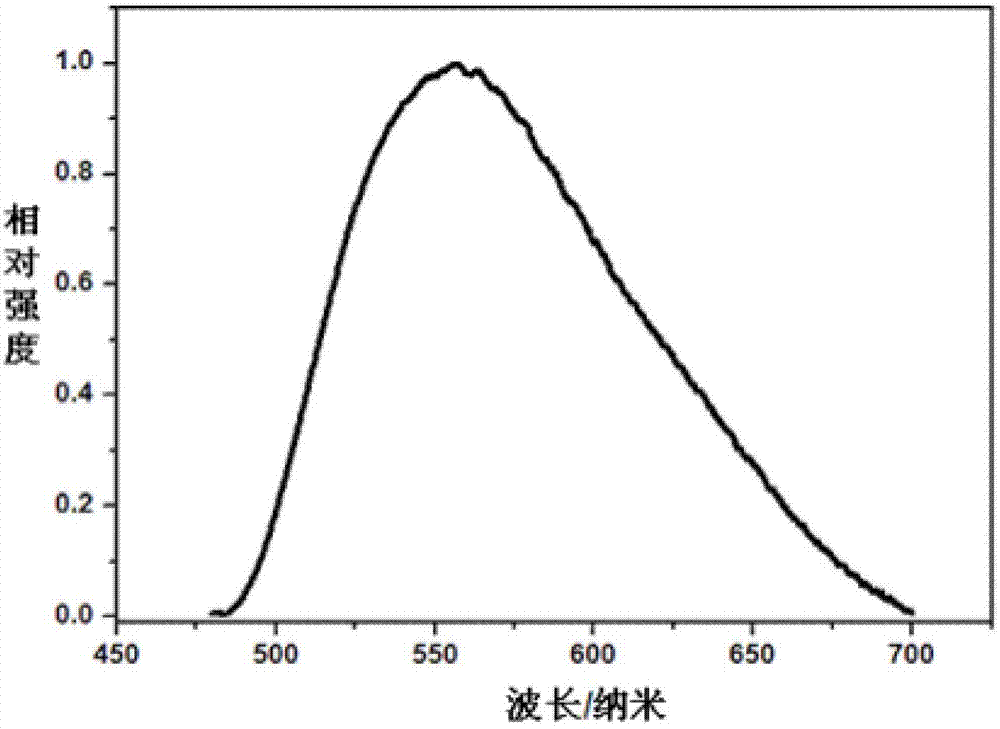

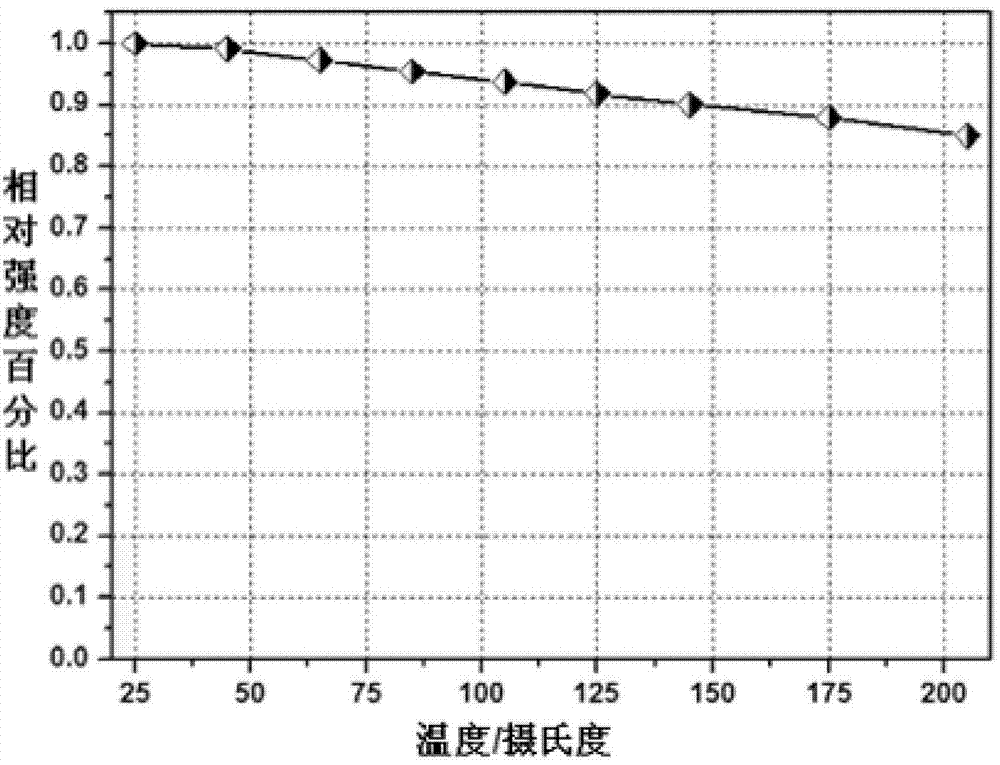

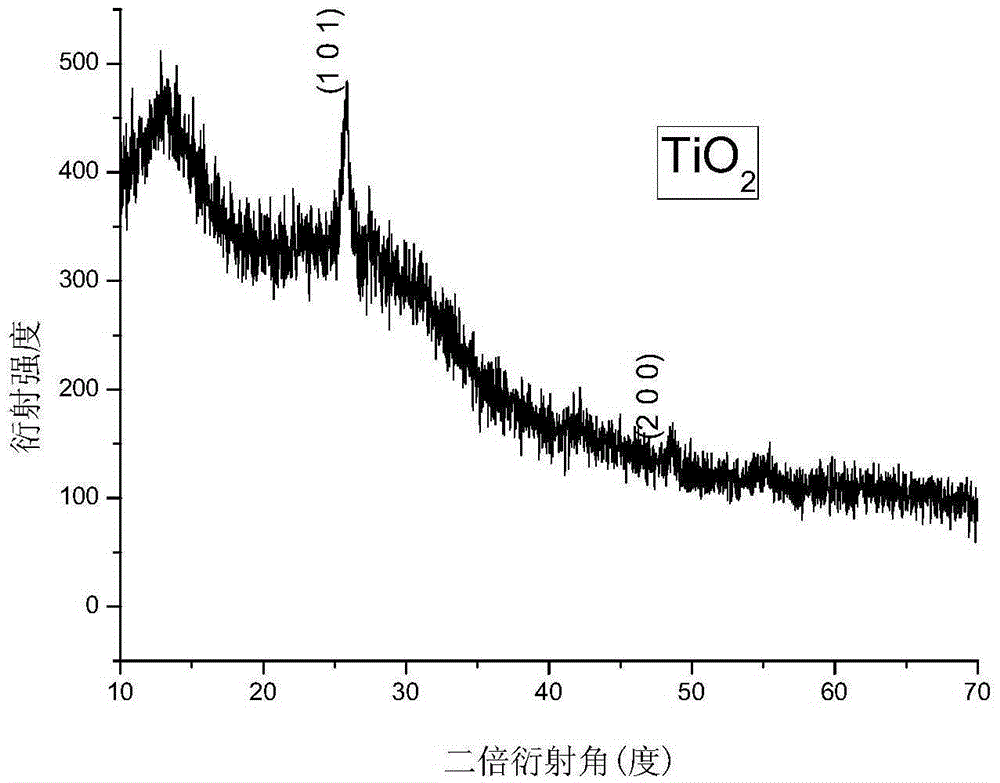

Preparation method of bifeo3 material, bifeo3/tio2 composite film and application of the composite film

InactiveCN103771532BReduce phase temperatureEasy to preparePhotovoltaic energy generationSemiconductor devicesAbsorptanceComposite film

The invention relates to a preparation method of BiFeO3 material, BiFeO3 / TiO2 composite film and application of the composite film. The preparation method of the involved BiFeO3 material comprises: first dissolving bismuth nitrate and ferric nitrate in ethylene glycol methyl ether to obtain solution 1, then dissolving citric acid in solution 1 to obtain solution 2; then adjusting the pH of solution 2 with acetic acid to 3-5; get BiFeO3 sol. The BiFeO3 / TiO2 composite thin film involved includes a substrate, and the substrate is coated with a double-layer thin film, and the double-layer thin film is a BiFeO3 thin film layer and a TiO2 thin film layer. Through the absorption spectrum test and theoretical analysis of the double-layer thin film of the present invention, its absorption rate in the visible light band has been greatly improved. The application involved is about the application of the above-mentioned BiFeO3 / TiO2 composite film to prepare photovoltaic materials, solar cells, photoelectric functional device materials with orientation control, and visible light catalytic bactericidal materials.

Owner:NORTHWEST UNIV

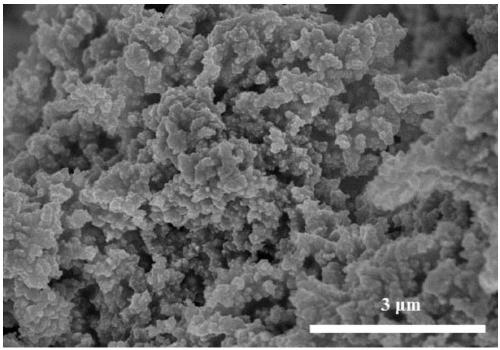

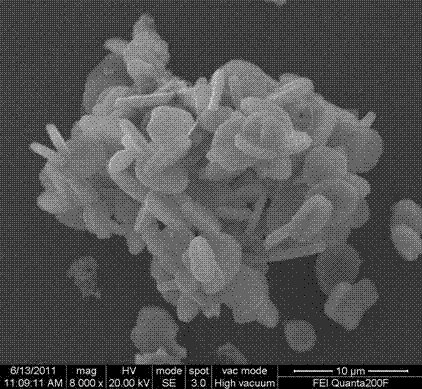

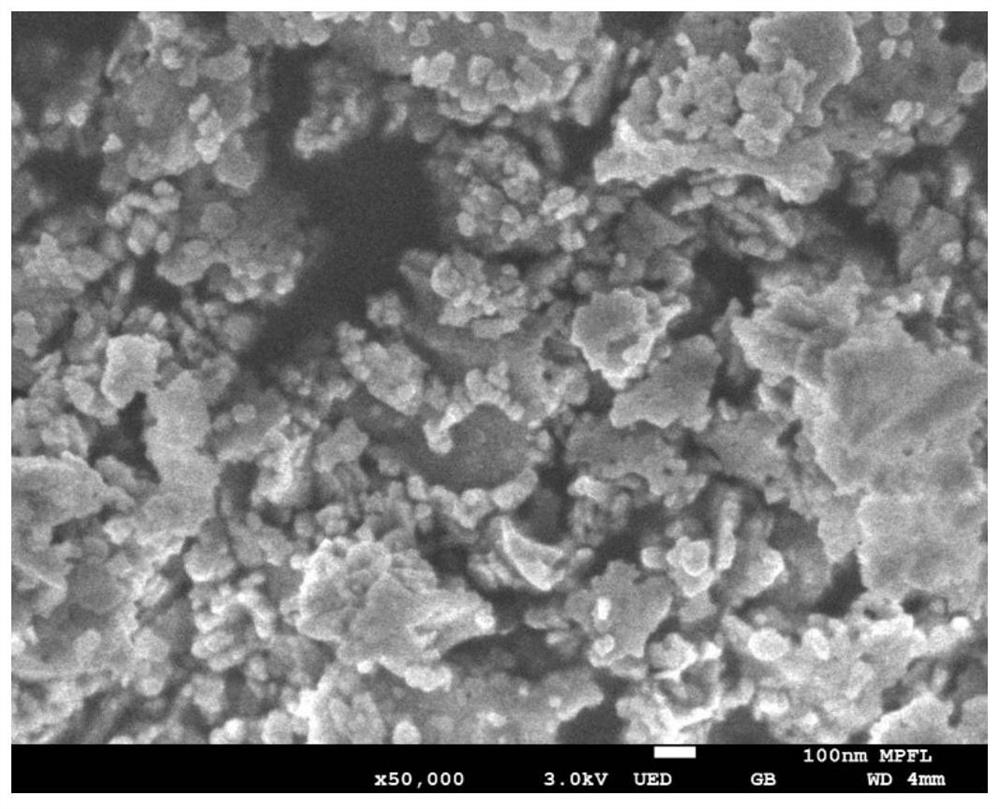

Preparation method of conductive metal doped metallic oxide nano particles

InactiveCN103940879AControlled hydrolysisReduce phase temperatureMaterial analysis by electric/magnetic meansAmmonium hydroxideHydrolysis

The invention discloses a preparation method of conductive metal doped metallic oxide nano particles, belonging to the technical field of nano particle preparation. The method comprises the following steps: (1) preparing a complexing agent solution; (2) acidifying; (3) adding with a metallic oxide raw material; (4) regulating pH value; (5) adding conductive metal soluble salt; (6) baking; and (7) decarbonizing. According to the method, appropriate amounts of concentrated nitric acid and ammonium hydroxide are added to well control hydrolysis of the metallic oxide raw material in solution, and the complexing property of the complexing agent to metal ions is utilized to perform complexation on conductive metal in conductive metal soluble salt, and the reaction is carried out slowly at high temperature, and therefore, the conductive metal doped metallic oxide nano particles are prepared; the method has the advantage of simplicity and convenience in operation, and the prepared nano particles have the characteristics of small particle size, good uniformity and good doping effect.

Owner:GUANGDONG TESTING INST OF PROD QUALITY SUPERVISION +1

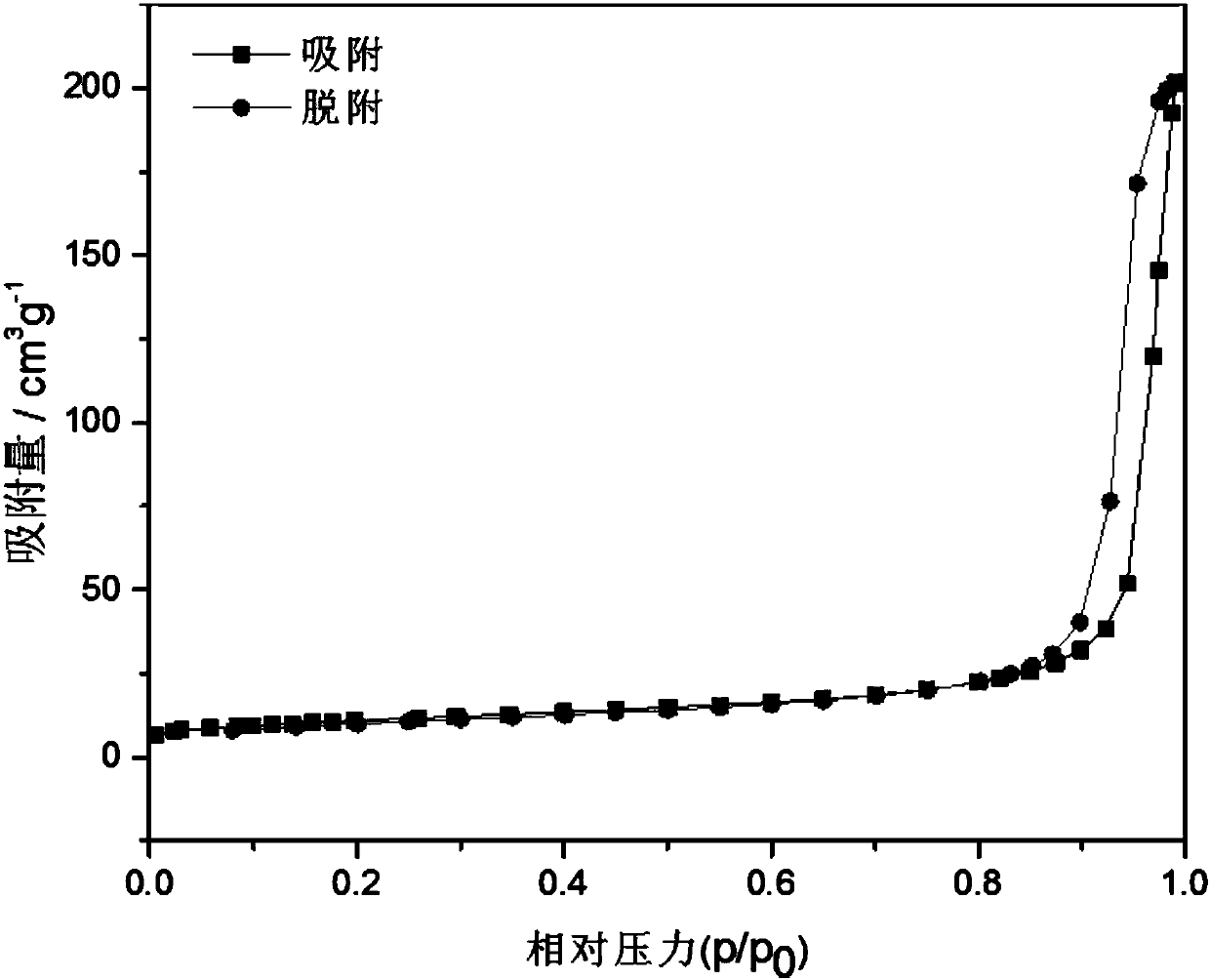

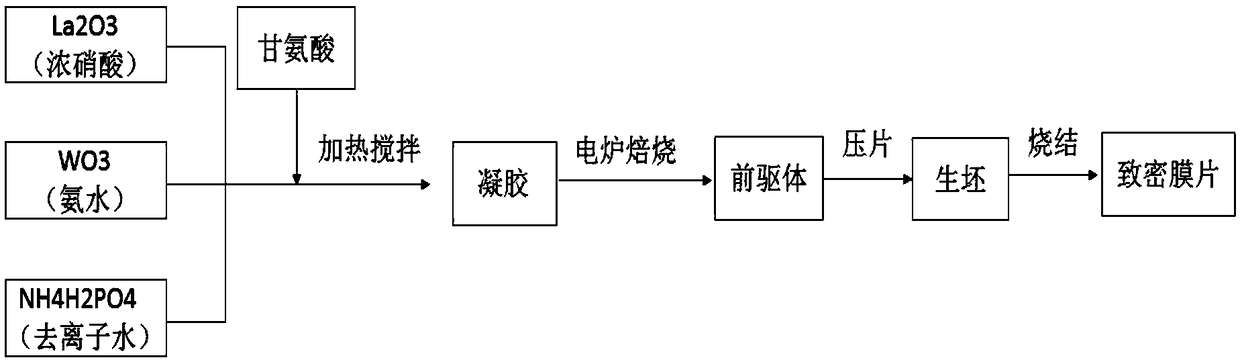

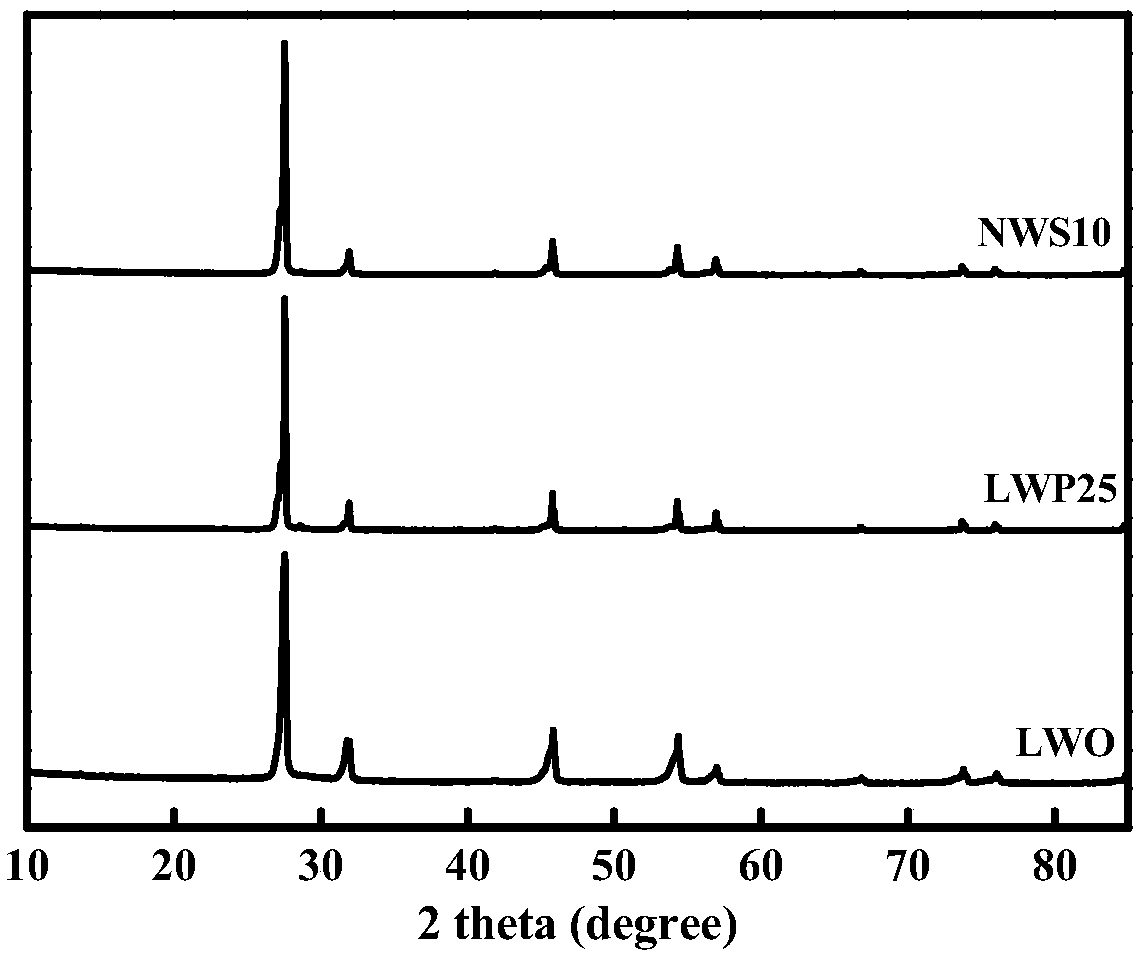

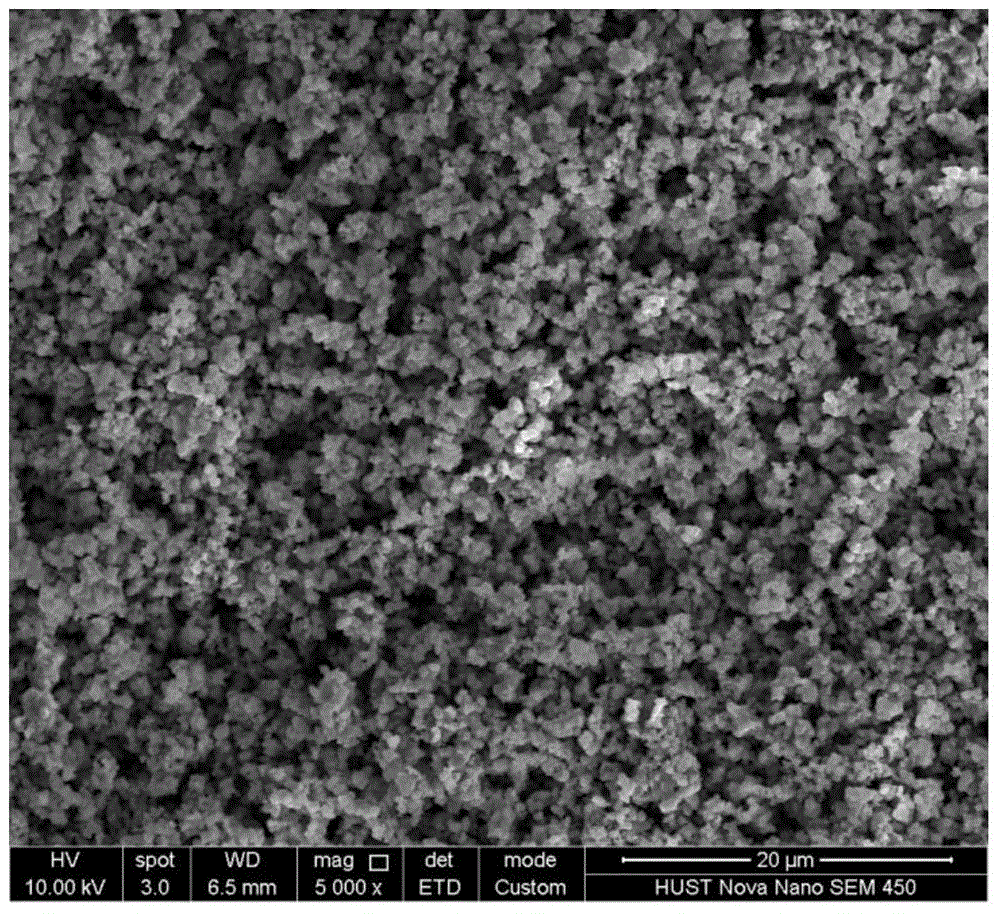

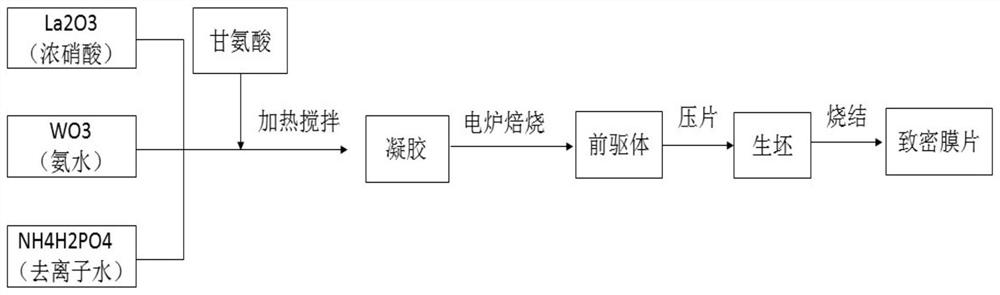

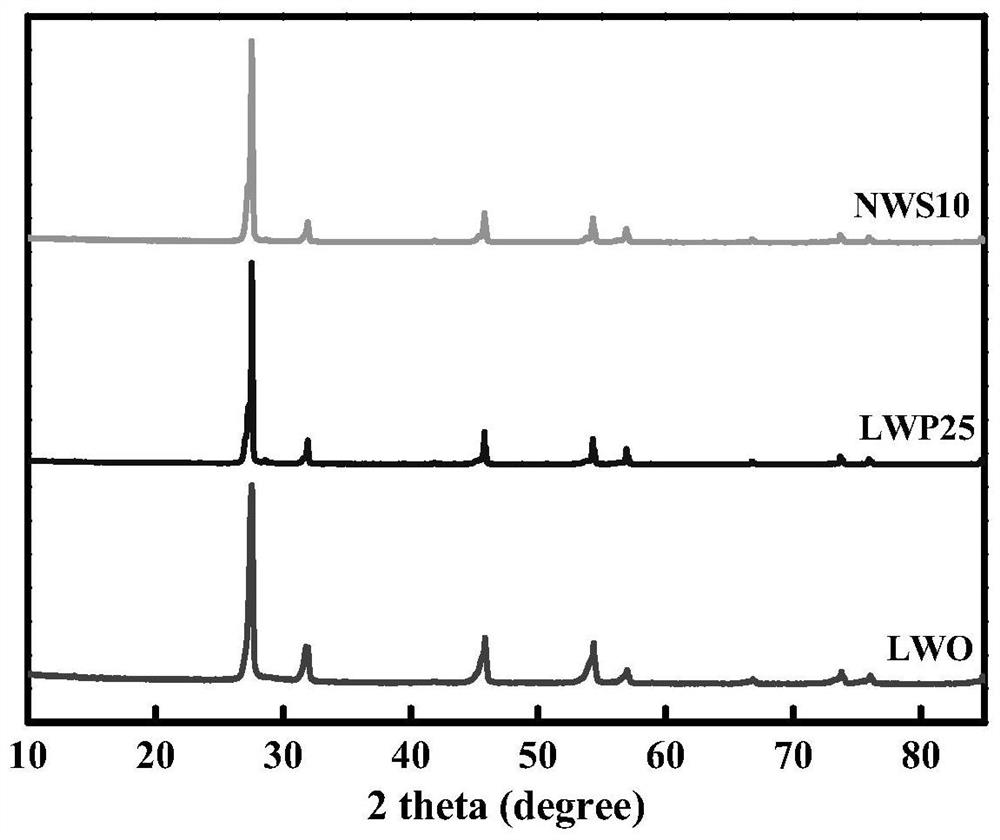

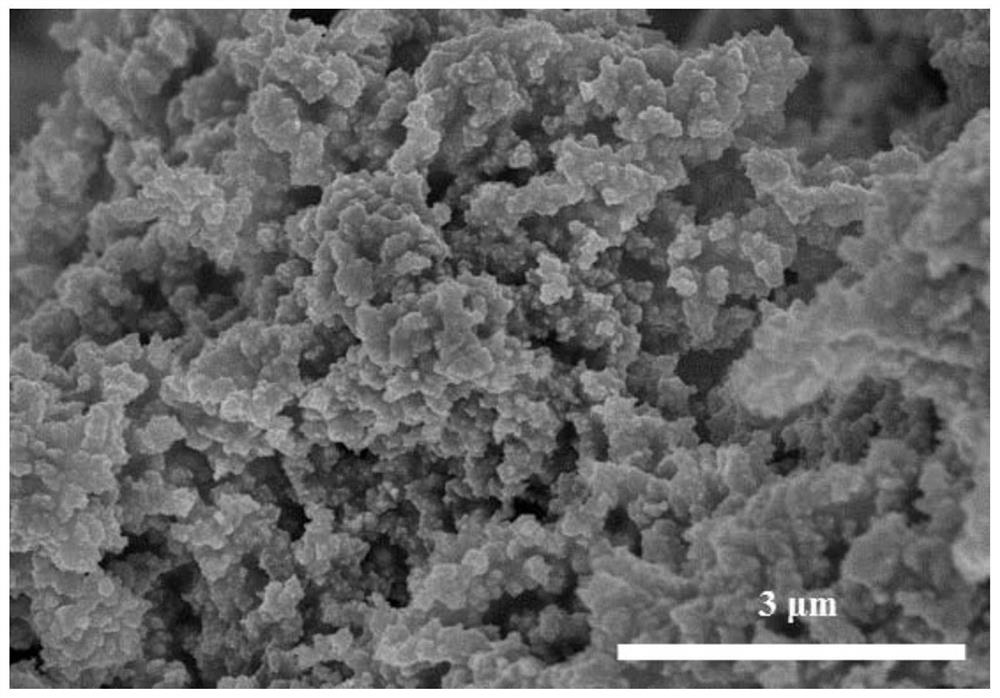

Nonmetal-ion-doped lanthanum tungstate type mixed proton-electron conductor hydrogen permeation material, and preparation method and application of same

ActiveCN108947529ASmall particle diameterReduce phase temperatureGas treatmentDispersed particle separationElectrical conductorLanthanide

The invention discloses a nonmetal-ion-doped lanthanum tungstate type mixed proton-electron conductor hydrogen permeation material, and a preparation method and an application of same. The chemical general formula of the material is LnW<1-x>M<x>O<12-delta>, wherein Ln is one of the following lanthanides including La, Nd, Eu and Er, M is one of nonmetal elements P and S and the delta refers to non-stoichiometry, 0 <= delta <= 1, 5.3 <= a <= 5.7 and 0 <= x <= 0.5. The material can be prepared through a glycine-nitrate combustion process. The electronic conductivity of the material is enhancedby doping the nonmetal ions, and further the hydrogen permeation capacity is increased. The material, in a hydrogen-containing atmosphere, has excellent operation stability and can be used for separating hydrogen from a hydrogen-containing gas mixture.

Owner:SOUTH CHINA UNIV OF TECH

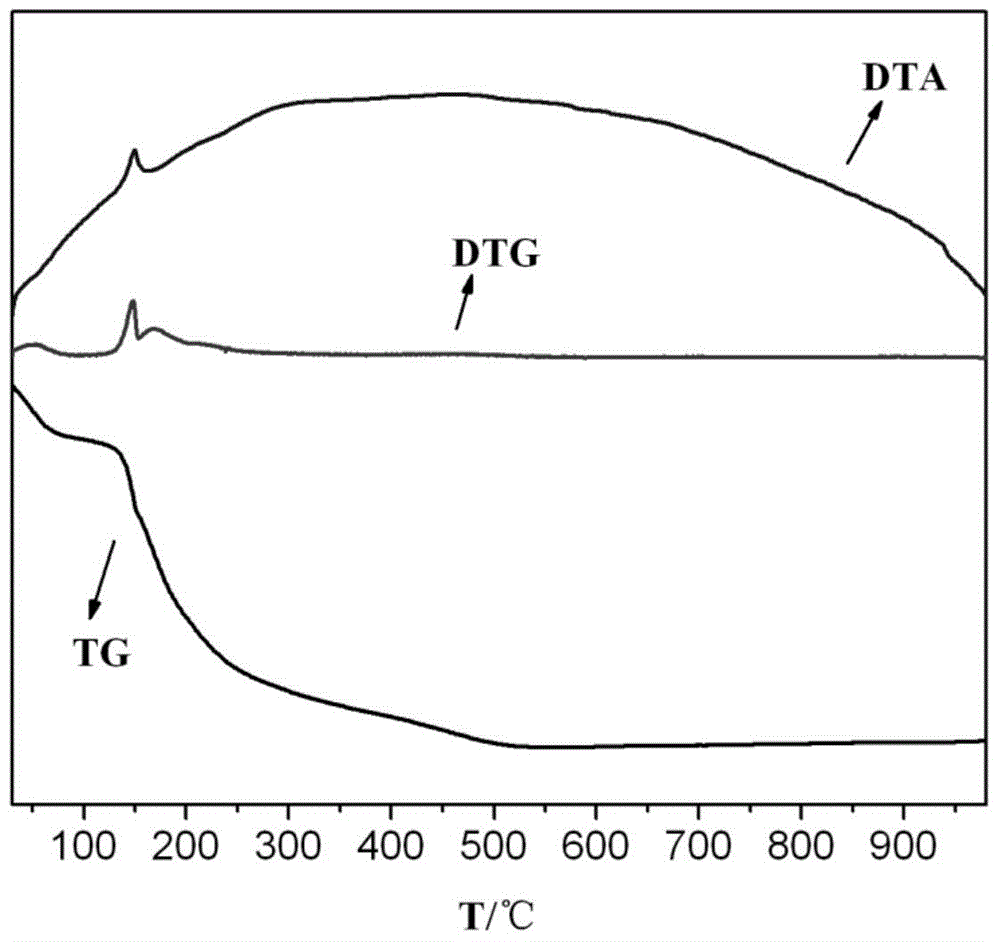

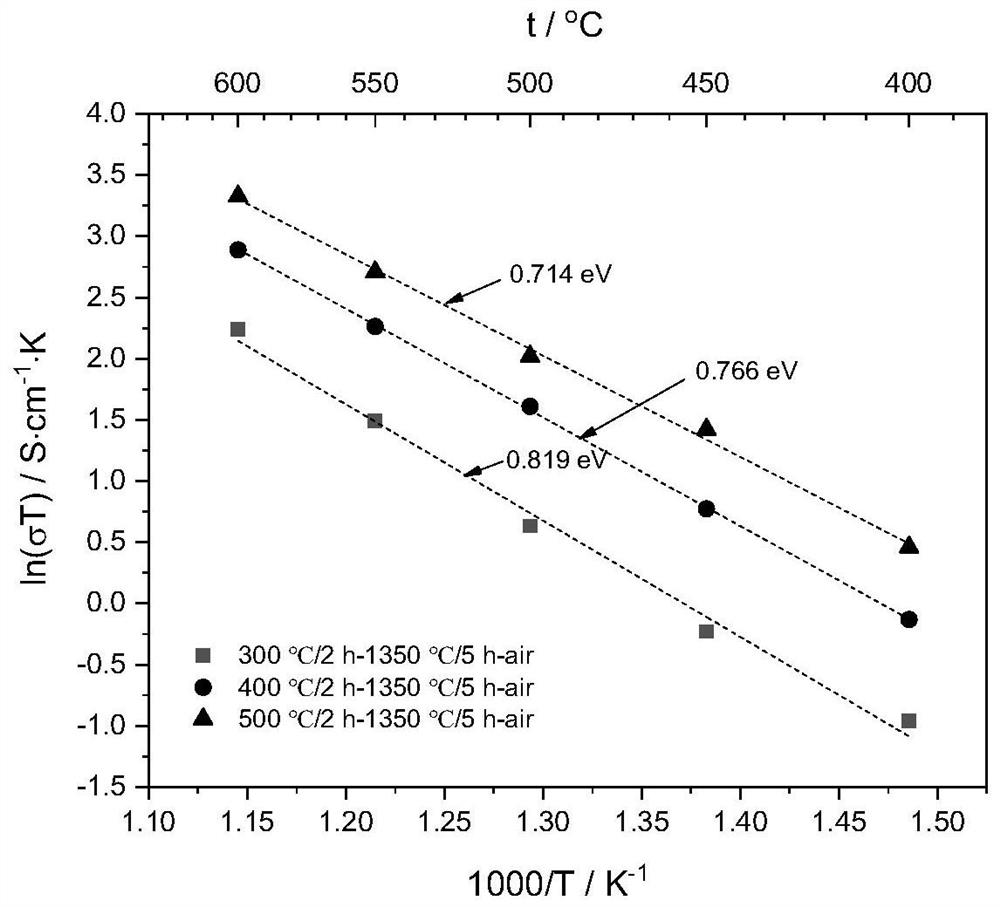

A kind of preparation method of nasicon type lithium ion solid electrolyte

ActiveCN103825052BGood for modification and dopingReduce phase temperatureFinal product manufactureElectrolyte accumulators manufactureSaturated aqueous solutionElectrolyte

The invention discloses a preparation method of an NASICON-type lithium ion solid electrolyte. The method comprises the following steps: dissolving lithium nitrate and aluminum nitrate in a citric acid solution, and stirring to form a transparent and uniform nitrate mixed solution; dissolving tetrabutyl titanate in anhydrous ethanol, and stirring to form an alcoholic solution of tetrabutyl titanate; slowly adding the alcoholic solution of tetrabutyl titanate to the nitrate mixed solution, and stirring to a transparent mixed solution; dissolving ammonium biphosphate in water to obtain a saturated aqueous solution of ammonium biphosphate, adding the saturated aqueous solution of ammonium biphosphate to the transparent mixed solution in a dropwise manner, and stirring to obtain an emulsion; adjusting the pH value of the emulsion, and drying the emulsion to obtain an xerogel; carrying out heat treatment of the xerogel, and grinding the obtained xerogel to form fine powder which is precursor powder; and compacting the precursor powder to form a green body, and sintering to obtain NASICON-type lithium ion solid electrolyte slices. The method has the advantages of low energy consumption, simplicity, easy implementation, and convenience for large-scale industrialized production, and the obtained solid electrolyte has a high conductivity.

Owner:HUAZHONG UNIV OF SCI & TECH

A preparation method of high current-carrying multi-core bi-2223 superconducting tape under magnetic field

ActiveCN110085367BHigh densityIncreased flux pinning forceSuperconductors/hyperconductorsApparatus for heat treatmentCondensed matter physicsGrain boundary

The invention discloses a preparation method of a high-current-carrying multi-core Bi-2223 superconducting tape under a magnetic field. The method comprises the following steps: 1, adding Bi-2223 precursor powder and CaCuO2 power into a silver sleeve so as to obtain a first tube loading composite; 2, drawing and assembling the first tube loading composite so as to obtain a second tube loading composite; 3, drawing the second tube loading composite into a multi-core Bi-2223 tape; 4, preserving the heat of the multi-core Bi-2223 tape so as to obtain the pretreated multi-core Bi-2223 tape; and 5,thermally treating the pretreated multi-core Bi-2223 tape so as to obtain a multi-core Bi-2223 superconducting tape. The powder tube loading process improves the Bi-2223 grain orientation and grain boundary quality and improves the grain orientation and bonding properties so that the current carrying capacity of the Bi-2223 superconducting tape under the magnetic field can be enhanced and the application in magnets and other fields can be facilitated.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

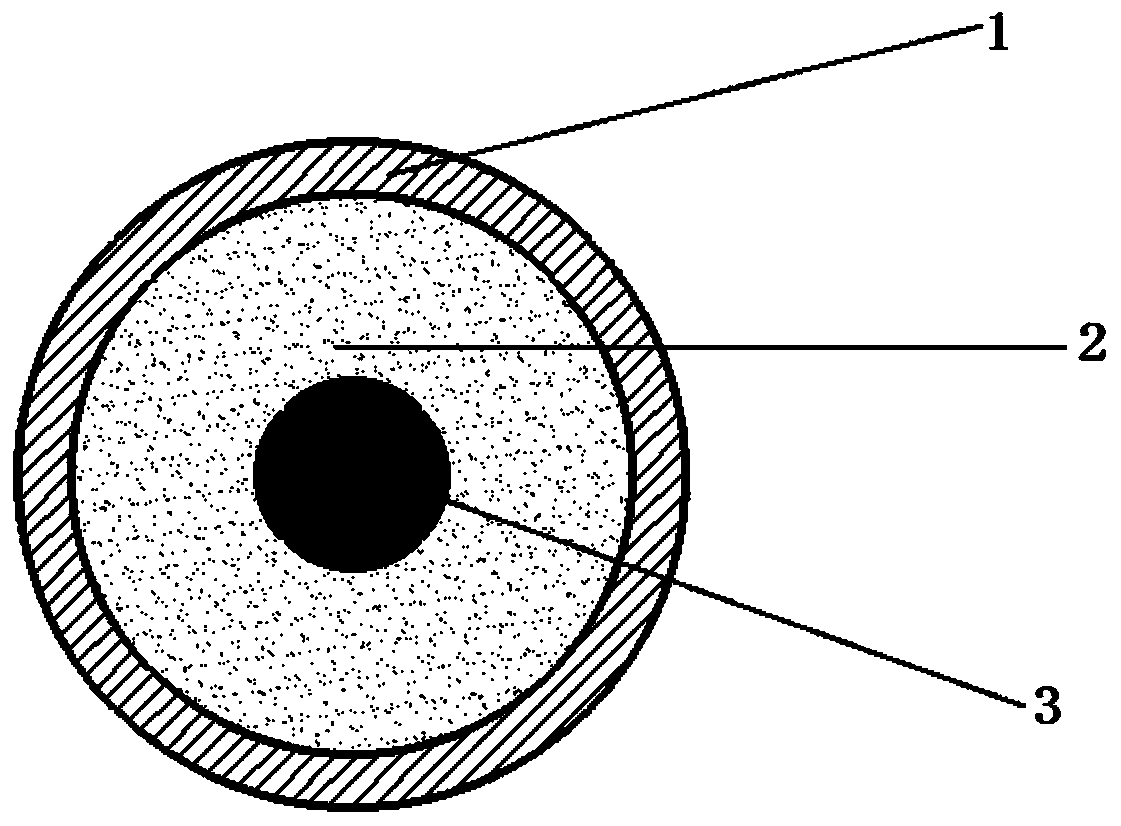

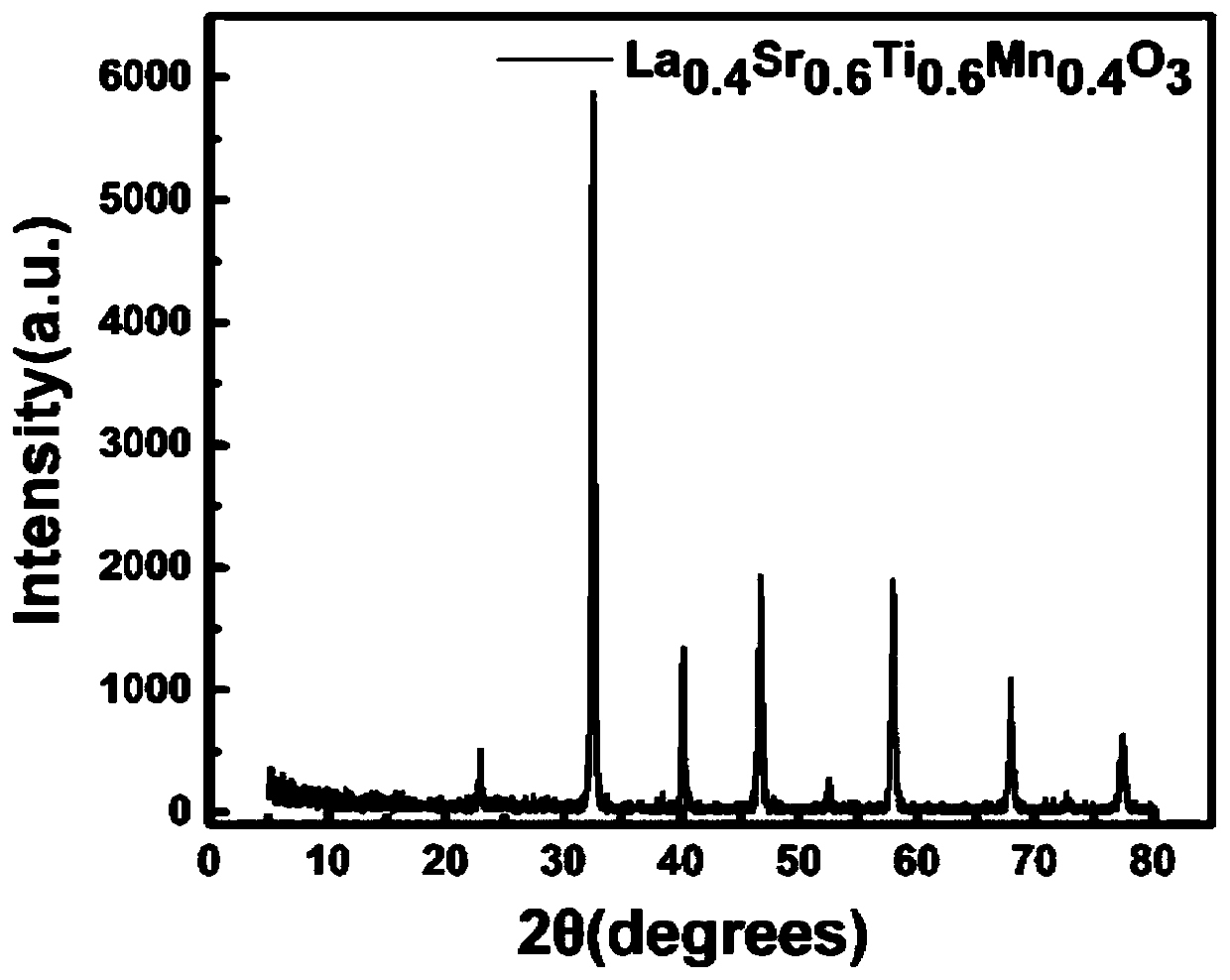

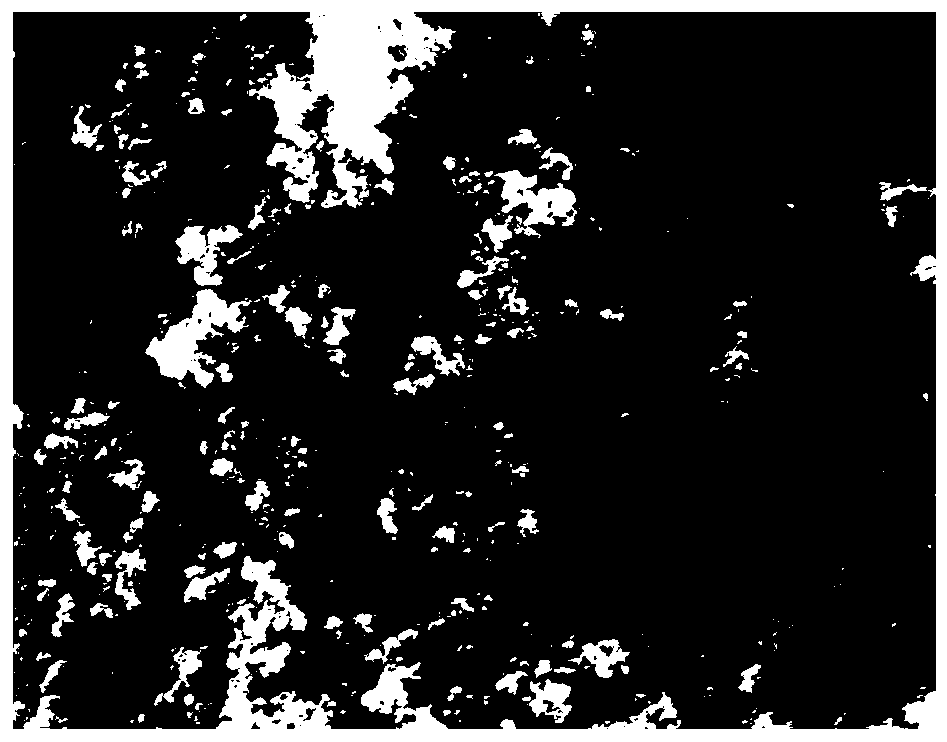

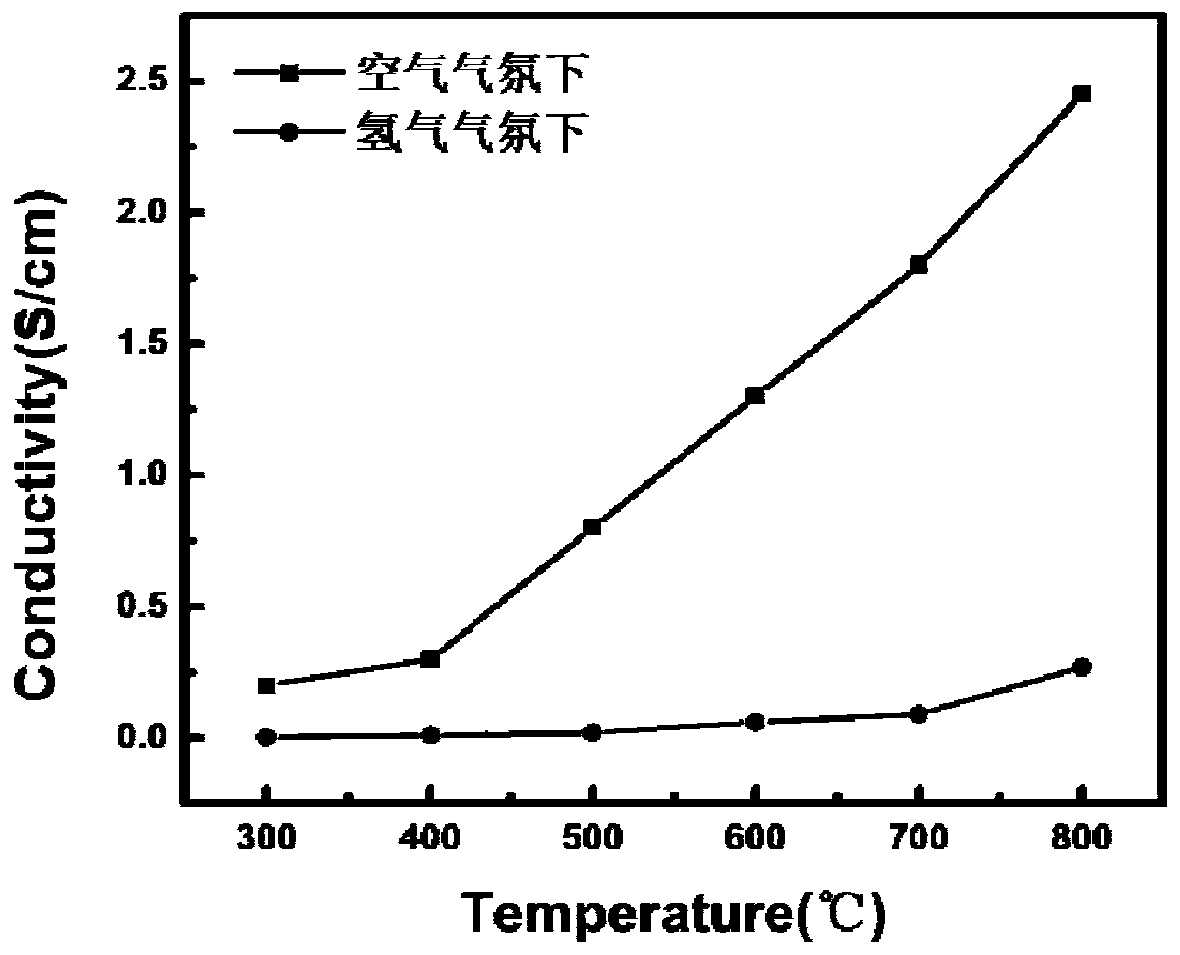

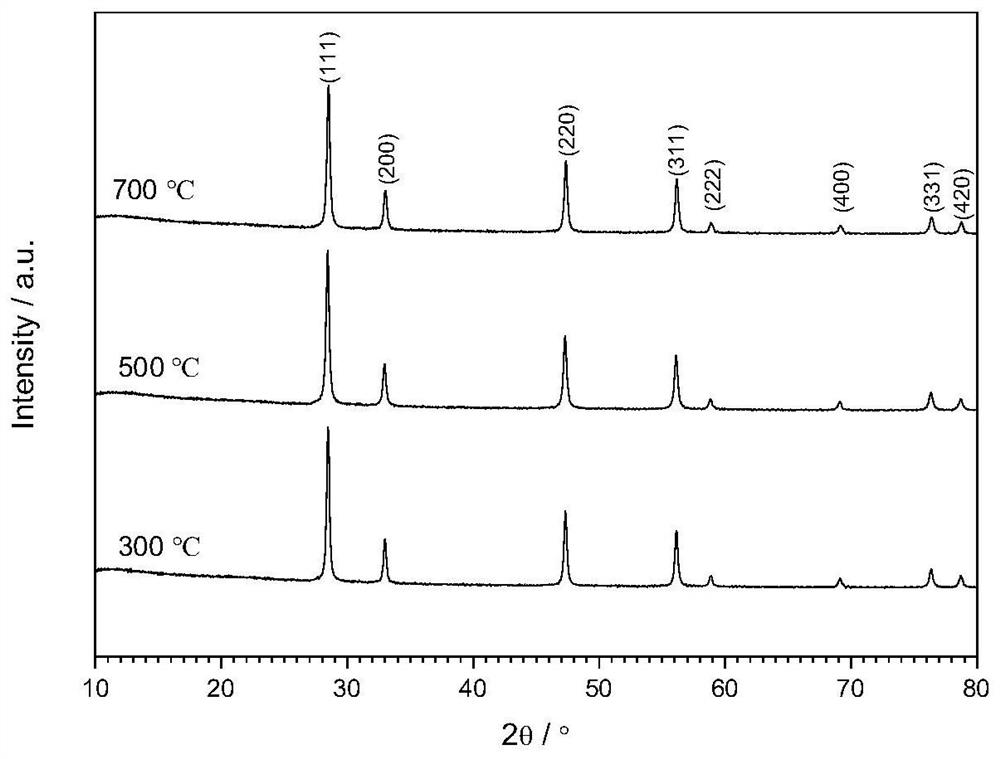

Synthesis method of strontium titanate-based materials for solid oxide fuel cells

ActiveCN108054394BReduce phase temperatureUniform particle size distributionCell electrodesMANGANESE ACETATEStrontium titanium oxide

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

A non-metal ion-doped lanthanum tungstate-type mixed proton-electron conductor hydrogen permeable material and its preparation method and application

ActiveCN108947529BSmall particle diameterReduce phase temperatureGas treatmentDispersed particle separationElectrical conductorHydrogen atmosphere

The invention discloses a non-metal ion-doped lanthanum tungstate-type mixed proton-electron conductor hydrogen permeable material, a preparation method and application thereof. The general chemical formula of the material is Ln a W 1‑x m x o 12‑δ , where Ln is one of the lanthanides La, Nd, Eu, Er; M is one of the non-metallic elements P and S; δ is a non-stoichiometric ratio; 0≤δ≤1, 5.3≤a≤5.7,0 ≤x≤0.5. The material of the present invention can be prepared by glycine-nitrate combustion method. In the material of the present invention, the electrical conductivity of the membrane material is improved by the doping of non-metal ions, so that the hydrogen permeability of the membrane material is improved. Moreover, the material has good operational stability in a hydrogen-containing atmosphere, and can be used to separate hydrogen from a hydrogen-containing mixed gas.

Owner:SOUTH CHINA UNIV OF TECH

A preparation method of graphene-supported multi-component doped magnesium diboride superconducting bulk material

ActiveCN106205861BImprove performanceEvenly distributedSuperconductors/hyperconductorsSuperconductor devicesVacuum dryingGraphite oxide

The invention discloses a preparation method for a graphene-loaded multielement-doped magnesium diboride superconducting bulk material. The preparation method comprises the steps of 1, dropwise adding ethyl silicate and titanium ethoxide into a graphene oxide solution, and stirring uniformly to obtain a mixture material; 2, performing a hydrothermal reaction, filtering and washing and then carrying out vacuum drying to obtain graphene-loaded multielement mixture powder; 3, performing heat treatment to obtain graphene-loaded multielement-doped powder; 4, mixing boron powder and magnesium powder and grinding, then adding the mixture powder to the graphene-loaded multielement-doped powder, uniformly grinding and pressing and shaping to obtain a bulk material; and 5, performing sintering on the bulk material under protection of an inert atmosphere, and performing furnace cooling to the room temperature to obtain the graphene-loaded multielement-doped magnesium diboride superconducting bulk material. The preparation method is simple; the prepared multielement dopant is uniform in dispersion, free of agglomeration, high in activity and can rapidly enter magnesium diboride lattices, thereby reducing the phase-forming temperature of the doped magnesium diboride; and in addition, the prepared magnesium diboride bulk material has excellent performance.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

BiFeO3-Bi0.5Na0.5TiO3 base multiferroic solid solution ceramic and preparation method thereof

InactiveCN101941838BReduce leakage currentFerroelectric/ferromagnetic coexistence at room temperatureMicrowave resonanceLow leakage

Owner:HUAZHONG UNIV OF SCI & TECH

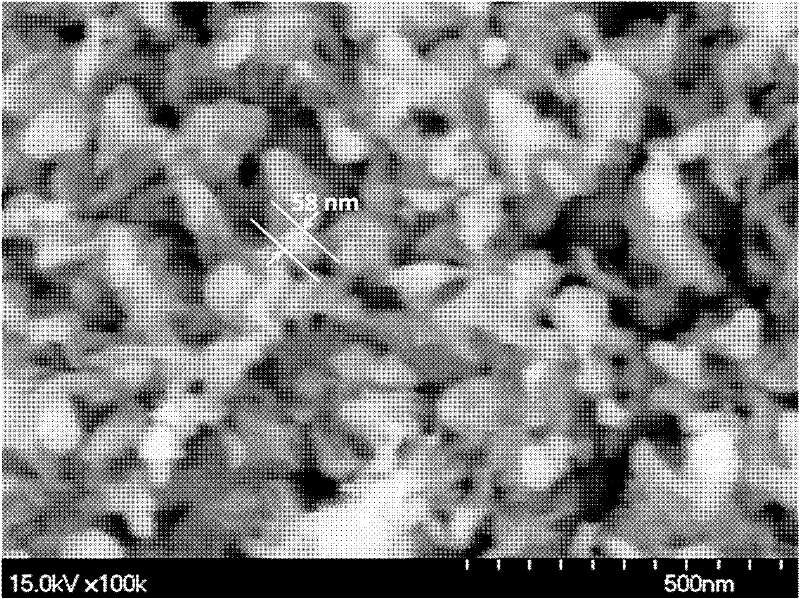

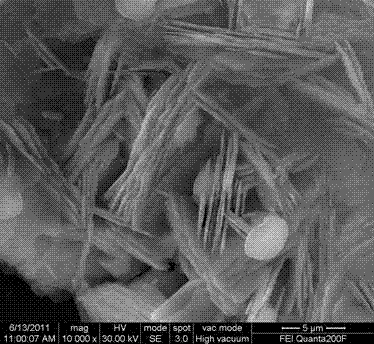

Method for preparing mesoporous needle-shaped tungsten carbide

InactiveCN101671019BControl granularityIncrease pore densityTungsten/molybdenum carbideHydrogenTungstate

The invention discloses a method for preparing mesoporous needle-shaped tungsten carbide. The preparation method comprises the following steps of: controlling the ambient temperature to be 10-30 DEG C; adding deionized water into ammonium meta-tungstate and ammonium carbonate which has a mass ratio of 1:0.75-2, for preparing a precursor culture solution in which the total mass fraction of the ammonium meta-tungstate and the ammonium carbonate is 2.5-50 wt%; stirring the precursor culture solution for 1-15 minutes, then placing the precursor culture solution in an open system for 2-24 hours, and obtaining self-growing ammonium meta-tungstate needle-shaped crystal after centrifuging and drying; and carrying out one-step reduction and carbonization of the self-growing ammonium meta-tungstateneedle-shaped crystal in a hydrogen-rich atmosphere, and thus obtaining the mesoporous needle-shaped tungsten carbide. The mesoporous needle-shaped tungsten carbide prepared by the preparation methodis formed by the piling of nano-tungsten carbide grains, has controllable crystal length, well-developed aperatures, is simply prepared and operated and can be well used in the crystallization field.

Owner:ZHEJIANG UNIV OF TECH

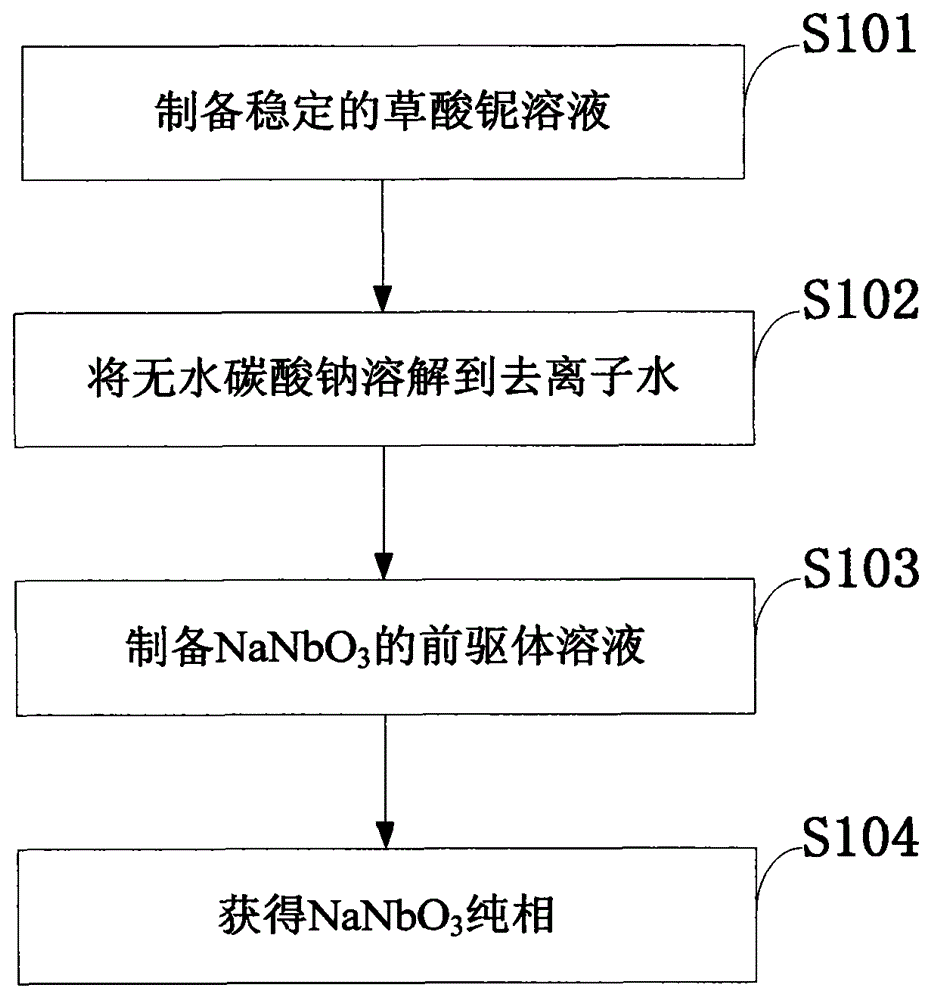

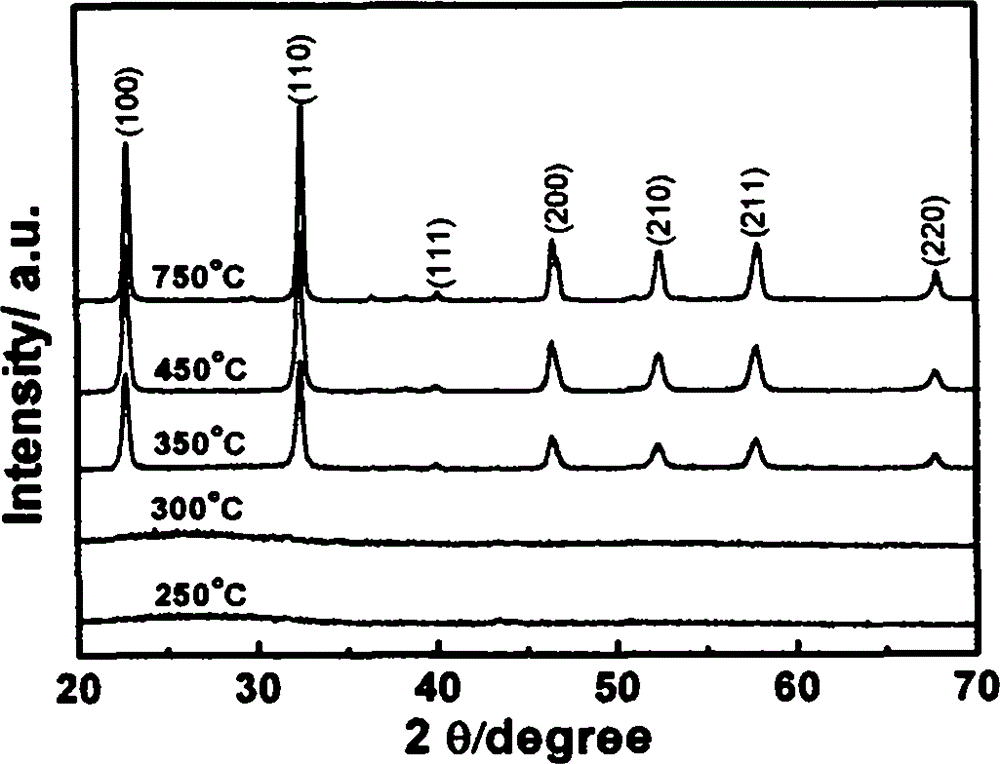

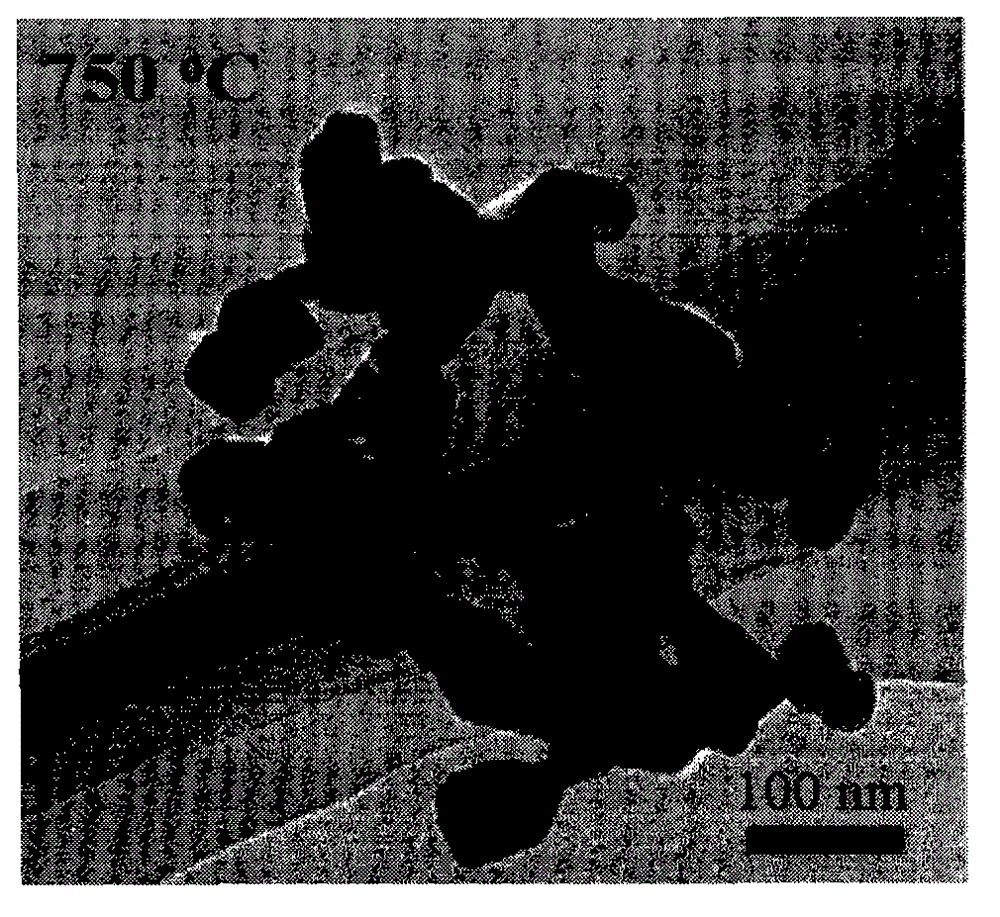

Method for preparing submicron NaNbO3 ceramic powder at low temperature

The invention discloses a method for preparing submicron NaNbO3 ceramic powder at low temperature. The method comprises the following steps of: preparing a stable niobium oxalate solution; dissolving anhydrous sodium carbonate in deionized water; preparing a NaNbO3 precursor solution; and obtaining the NaNbO3 pure phase. The method disclosed by the invention is simple in process, low in requirements for equipment, low in synthesis temperature, short in thermal insulation time, low in energy consumption, and cheap in required material, the prepared powder has the characteristics of good crystalline grain development degree, fine granularity, and very light aggregation, and phase formation temperature is especially low.

Owner:陕西光电子先导院科技有限公司

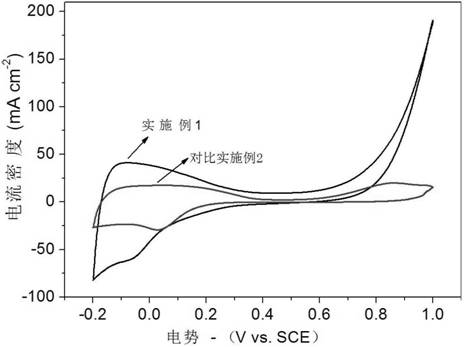

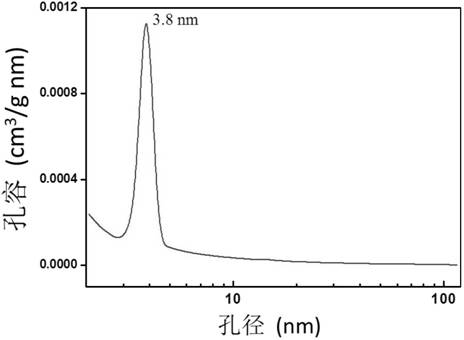

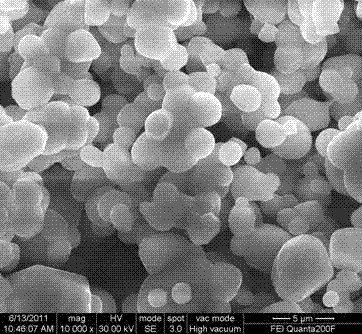

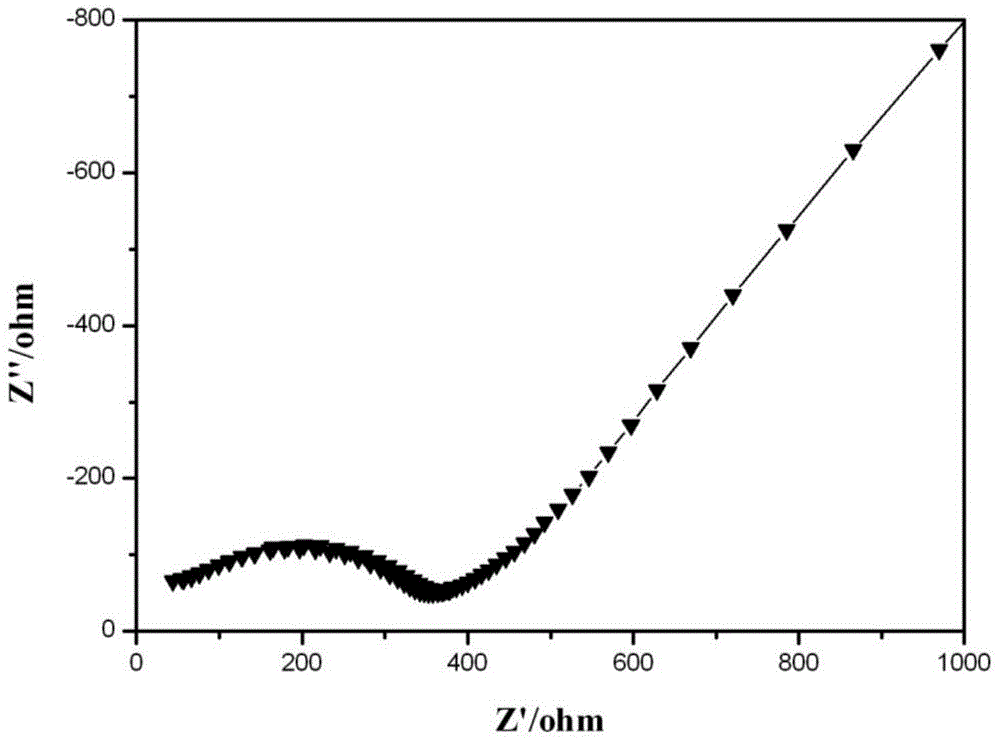

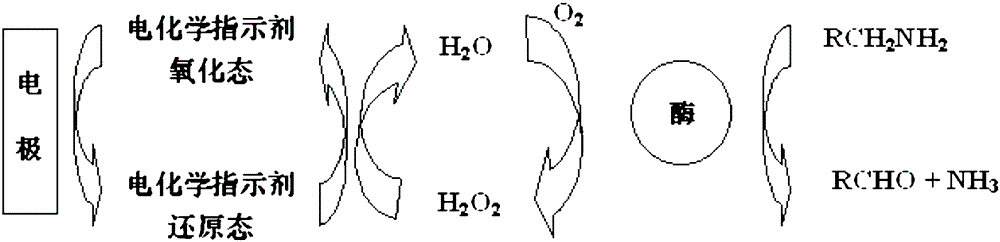

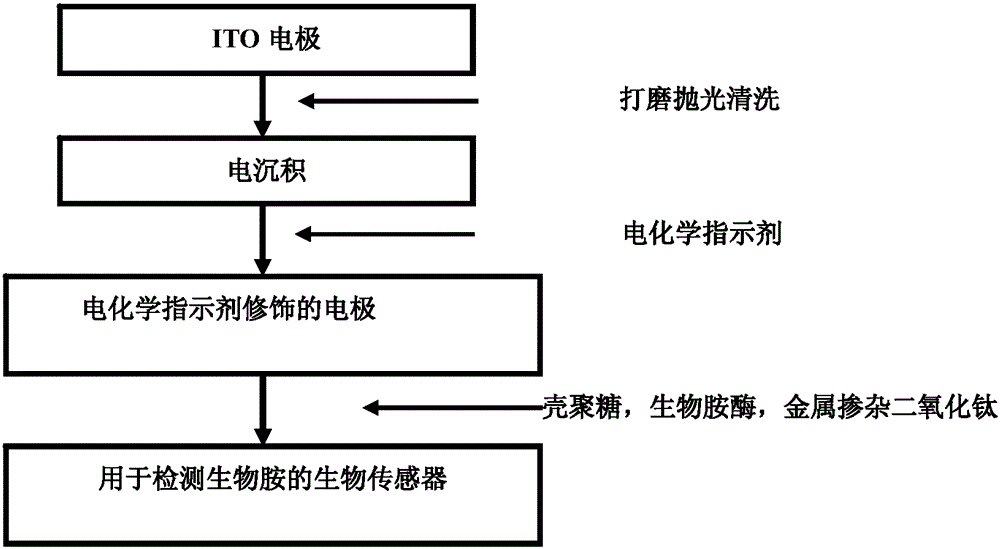

Biosensor for detecting biogenic amines and its production method

InactiveCN103926296BHigh sensitivityLow detection limitMaterial analysis by electric/magnetic meansComposite filmElectrochemistry

The invention discloses a biosensor for detecting biogenic amine and a preparation method thereof, belonging to the technical field of sensor detection. The biosensor comprises an electrode with the surface provided with a composite film, the composite film consists of an electrochemical indicator, biogenic amine enzyme, and metallic oxide nanoparticles doped with conductive metals; the metallic oxide has semiconductor property; the mole percent of the conductive metals and the metallic oxide is 0.5-10mol%. According to the biosensor, the surface of the electrode is coated with the metallic oxide nanoparticles doped with conductive metals, the electrochemical indicator and biogenic amine enzyme; the nanoparticles are introduced to the construction of the biological sensitive interface by utilizing the surface effect, quantum size effect and dielectric confinement effect and the like of the nanoparticles; the conductive metals are doped in the metallic oxide nanoparticles; the electron transfer efficiency of the composite film is improved, redox electrochemical signals are enhanced, the sensitivity of the sensor is improved and the detection limit is lowered.

Owner:GUANGDONG TESTING INST OF PROD QUALITY SUPERVISION +1

Preparation method of flaky aluminate green phosphor

ActiveCN102367384BParticle size controllableEasy to implementLuminescent compositionsPhosphorOrganic fuel

The invention relates to a preparation method of a flaky aluminate green phosphor. The preparation method comprises the following steps: 1, respectively weighing corresponding raw materials according to the amount of an object product to be prepared and the stoichiometric ratio of all metal elements in Ce1-xTbxMgAl11O19, and preparing a mixed nitrate solution of metals contained in the object product; 2, adding an organic fuel to the mixed nitrate solution obtained in step 1, and heating to dissolve; 3, adding ammonium fluoride to the mixed solution obtained in step 2, heating to dissolve, and continuously concentrating the mixed solution until that the mixed solution is in an approximately sticky state; 4, initiating the sticky solution obtained in step 3 to be subjected to self-propagating combustion; 5, post-treating self-propagating combusted products obtained in step 4; and 6, washing, drying, grinding, and sieving the product obtained in step 5 to obtain the object product. The preparation method of the invention, which has the advantages of phase forming temperature reduction, calcining time shortening, excellent luminescent performance, controllable particle size, uniform size, regular morphology, simple enforcement, low cost, rapidness, and energy saving, has a good industrialization application prospect.

Owner:江苏优氟防腐科技有限公司

A kind of preparation method of strontium titanate lanthanum base powder material

InactiveCN102617139BSmall particle sizeHigh activityCell electrodesSpontaneous combustionWater baths

Owner:UNIV OF SCI & TECH BEIJING

Method for preparing double mesoporous high (100) crystal plane tungsten carbide material

ActiveCN102689902BPromote growthImprove adsorption and desorption capacityTungsten/molybdenum carbideDesorptionTungstate

Owner:ZHEJIANG UNIV OF TECH

Preparation method of nanosilver-doped yttrium barium copper oxide film

ActiveCN102351571BHigh purity without impuritiesRealize contactlessCable/conductor manufactureElectrochemical responseYttrium barium copper oxide

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

A kind of preparation method and application of graphene-coated nano-dysprosium oxide

ActiveCN106315656BInhibition of agglomerationInhibit the generation of agglomerationRare earth metal oxides/hydroxidesNanopillarNanoparticle

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Method for synthesizing electrolyte powder of solid oxide fuel cell based on complexing freeze-drying method

InactiveCN112490475AHigh sintering activityIncrease concentrationSolid electrolyte fuel cellsElectrolyte immobilisation/gelificationFuel cellsFreeze-drying

The invention discloses a method for synthesizing electrolyte powder of a solid oxide fuel cell based on a complexing freeze-drying method and the obtained electrolyte powder, and belongs to the fieldof electrolyte synthesis. According to the synthesis method, when the fluorite structure cerium oxide-based electrolyte powder conducted by oxygen ions is synthesized, citric acid and glycine are used as complexing agents, and the complexing capacity, the ignition point and the combustion heat of the two complexing agents are different; the total metal ion concentration and the heat release process during heat treatment can be controlled by adjusting the proportion and the total amount of the double complexing agents, stirring is performed at the temperature of 60-90 DEG C to obtain a metal ion complex solution, then freezing and freeze drying are performed to obtain a dry framework of a metal ion complex, heat treatment is performed to obtain pure-phase cerium oxide-based electrolyte powder, and due to the fact that glycine is added and can serve as a combustion agent, combustion can occur after the heating temperature exceeds the ignition point, and the phase forming temperature isreduced; and according to the synthesis method, the pH value of the solution does not need to be adjusted in the synthesis process, the phase forming temperature of the powder is greatly reduced, andthe improvement of the sintering activity of the powder is facilitated.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com