A kind of preparation method and application of graphene-coated nano-dysprosium oxide

A nanometer dysprosium oxide and graphene coating technology, applied in chemical instruments and methods, rare earth metal oxides/hydroxides, inorganic chemistry, etc., can solve the problem of reducing the connectivity between grains, uneven distribution, and poor dispersion. and other problems, to achieve the effect of improving superconductivity, improving reactivity, and inhibiting agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

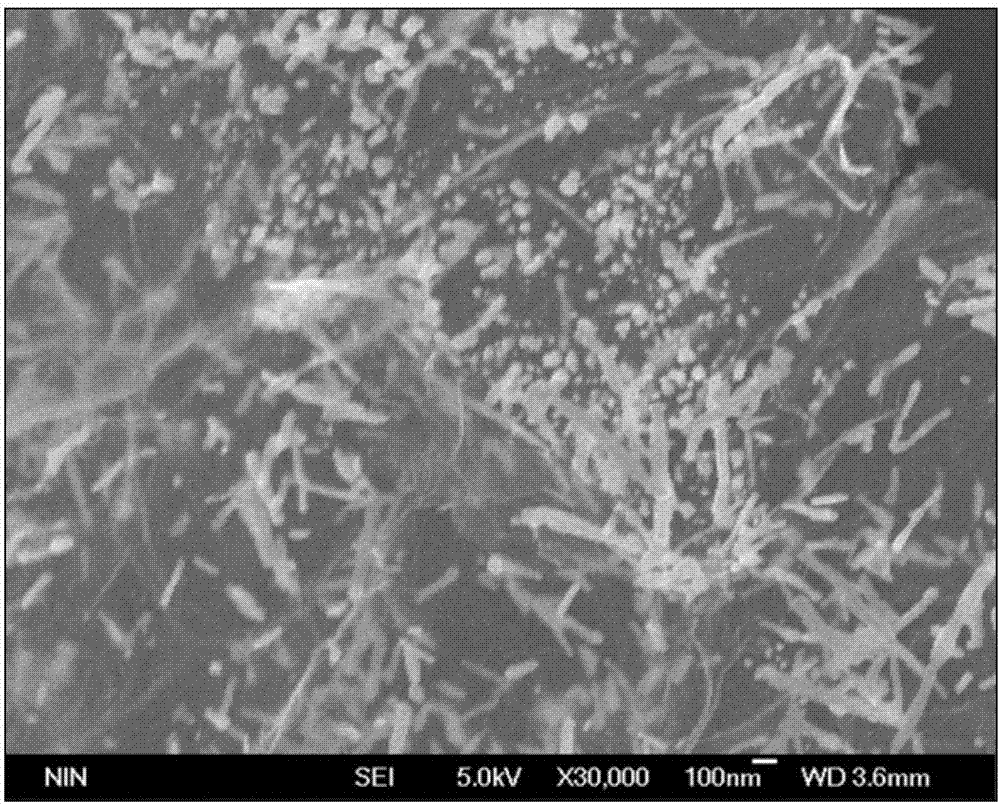

Image

Examples

Embodiment 1

[0026] The method for preparing graphene-coated nano-dysprosium oxide in this embodiment comprises the following steps:

[0027] Step 1. Dissolve dysprosium acetate in a mixed solvent of ethanol and propionic acid to obtain a dysprosium acetate solution, place the dysprosium acetate solution in a pyrolysis reactor, and first dry it at a temperature of 120°C. Then, under a moist oxygen atmosphere, continue to heat up to 500°C with a heating rate of 2°C / min to obtain dysprosium oxide nanoparticles; the volume ratio of ethanol and propionic acid in the mixed solvent is 1:1; the moist oxygen The volume percentage of oxygen in the atmosphere is 96.5%, and the balance is water vapor;

[0028] Step 2, dissolving dysprosium nitrate in an aqueous solution of tert-butylamine, and then placing it in a hydrothermal reaction kettle to obtain dysprosium oxide nanocolumns after hydrothermal reaction; in the aqueous solution of tert-butylamine, tert-butylamine and The volume ratio of water i...

Embodiment 2

[0036] The method for preparing graphene-coated nano-dysprosium oxide in this embodiment comprises the following steps:

[0037] Step 1. Dissolve dysprosium acetate in a mixed solvent of ethanol and propionic acid to obtain a dysprosium acetate solution, place the dysprosium acetate solution in a pyrolysis reactor, and first dry it at a temperature of 120°C. Then, under a moist oxygen atmosphere, continue to heat up to 500°C with a heating rate of 5°C / min to obtain dysprosium oxide nanoparticles; the volume ratio of ethanol and propionic acid in the mixed solvent is 1:1; the moist oxygen The volume percentage of oxygen in the atmosphere is 94%, and the balance is water vapor;

[0038] Step 2, dissolving dysprosium nitrate in the aqueous solution of aminoacetic acid, and then placing it in a hydrothermal reaction kettle to obtain dysprosium oxide nanocolumns after the hydrothermal reaction; the volume ratio of aminoacetic acid to water in the aqueous solution of aminoacetic aci...

Embodiment 3

[0045] The method for preparing graphene-coated nano-dysprosium oxide in this embodiment comprises the following steps:

[0046] Step 1. Dissolve dysprosium acetate in a mixed solvent of ethanol and propionic acid to obtain a dysprosium acetate solution, place the dysprosium acetate solution in a pyrolysis reactor, and first dry it at a temperature of 120°C. Then, under a moist oxygen atmosphere, continue to heat up to 500°C with a heating rate of 1°C / min to obtain dysprosium oxide nanoparticles; the volume ratio of ethanol and propionic acid in the mixed solvent is 1:1; the moist oxygen The volume percentage of oxygen in the atmosphere is 99.4%, and the balance is water vapor;

[0047] Step 2, dissolving dysprosium nitrate in an aqueous solution of tert-butylamine, and then placing it in a hydrothermal reaction kettle to obtain dysprosium oxide nanocolumns after hydrothermal reaction; in the aqueous solution of tert-butylamine, tert-butylamine and The volume ratio of water i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com