Nonmetal-ion-doped lanthanum tungstate type mixed proton-electron conductor hydrogen permeation material, and preparation method and application of same

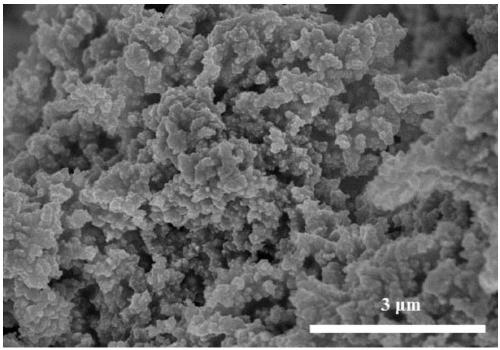

An ion doping, electronic conductor technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of low hydrogen permeability and insufficient stability, and achieve small particle diameter, long-term stable operation, The effect of low powder phase forming temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

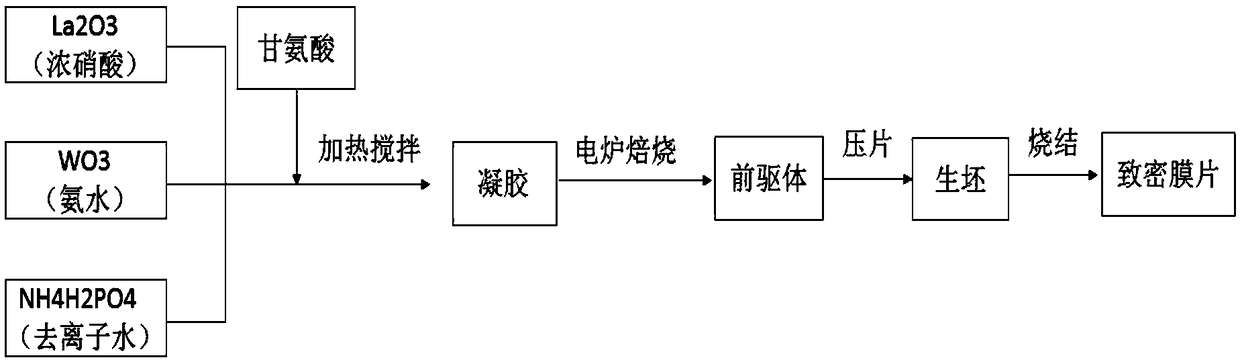

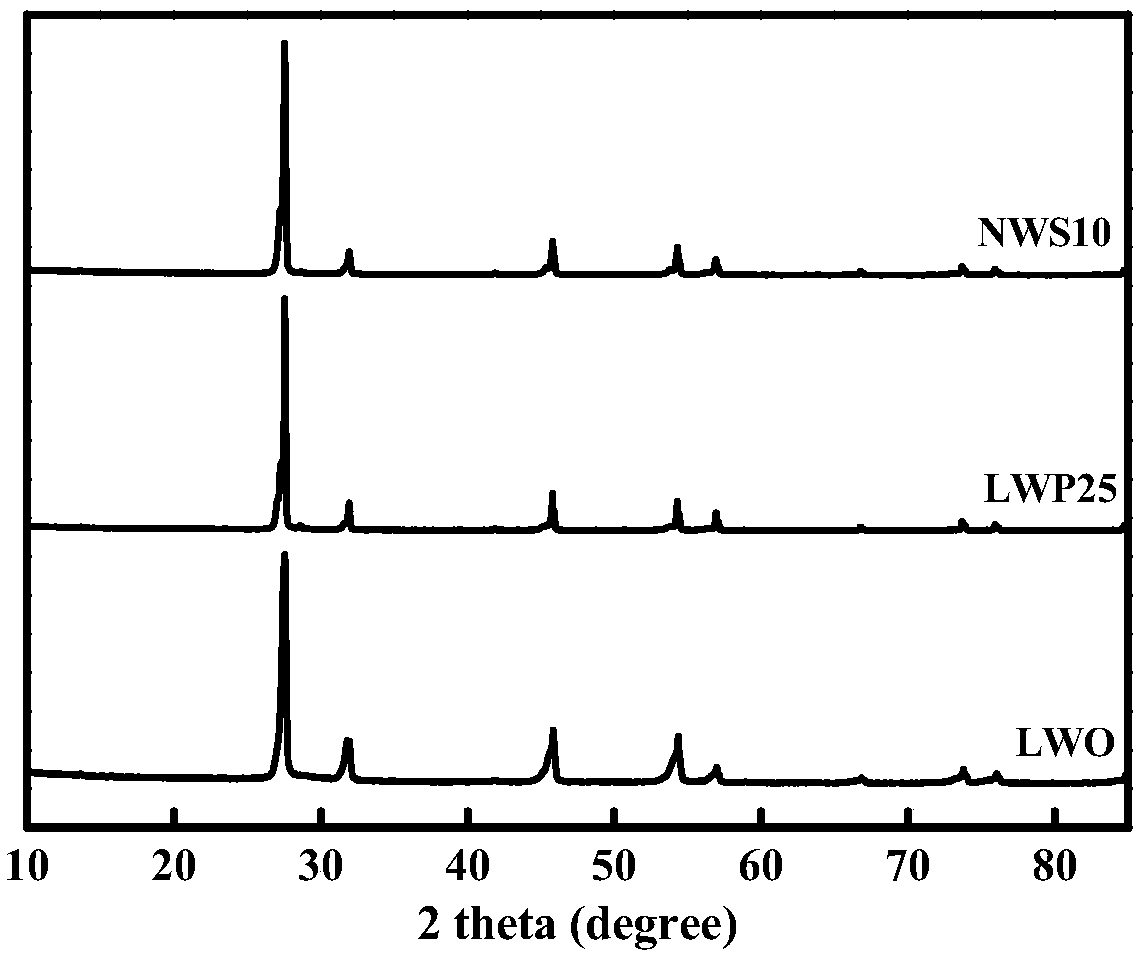

[0035] A phosphorus ion-doped lanthanum tungstate-based mixed proton-electron conductor hydrogen permeable material La 5.5 W 0.75 P 0.25 o 12-δ (δ = 0.5) (LWP25) and undoped lanthanum tungstate based mixed proton-electron conductor material La 5.5 WO 12-δ (δ = 0.4) (LWO), such as figure 1 Shown, preparation method comprises the following steps:

[0036] (1) Weigh LWP25 raw material: 12.334g La 2 o 3 Dissolved in concentrated nitric acid with a mass fraction of 65%, 2.553g WO 3 Soluble in ammonia water with a mass fraction of 18%, 0.317g NH 4 h 2 PO 4 Dissolve in deionized water, mix the three evenly, add 8.56g glycine to the mixture;

[0037] (2) Weigh LWO raw material: 11.916g La 2 o 3 Dissolved in concentrated nitric acid with a mass fraction of 65%, 3.083g WO 3 Dissolved in ammoniacal liquor with a mass fraction of 18%, the two are mixed evenly, and 8.65g of glycine is added in the mixed solution;

[0038] (3) Heat the nitrate mixture obtained in steps (1)...

Embodiment 2

[0046] A sulfide-doped lanthanum tungstate-based mixed proton-electron conductor hydrogen permeable material Nd of the present embodiment 5.3 W 0.9 S 0.1 o 12-δ (δ = 1) (NWS10) The preparation method includes the following steps:

[0047] (1) Weigh NWP10 raw material: 8.01g Nd 2 o 3 Dissolved in concentrated nitric acid with a mass fraction of 65%, 1.87g WO 3 Soluble in ammonia water with a mass fraction of 18%, 0.103g NH 4 h 2 SO 4 Dissolve in deionized water, mix the three evenly, add 5.56g glycine to the mixture;

[0048] (2) Heat the nitrate mixture obtained in step (1) to 300°C and stir for 24 hours until the solution becomes gel-like, then put the gel into an electric furnace, heat to 150°C and bake to obtain the precursor of the powder ; Put the powder in a muffle furnace, heat it at a rate of 3° C. to 1000° C. per minute for 5 hours, and obtain the powder NWS10.

[0049] (3) Weigh 2g of phase-forming powder NWS10 and put it into a cast iron mold, keep it und...

Embodiment 3

[0052] A phosphorus ion-doped lanthanum tungstate-based mixed proton-electron conductor hydrogen permeable material Eu 5.7 W 0.5 P 0.5 o 12-δ (δ = 0) (EuWP50) preparation method includes the following steps:

[0053] (1) Weigh EWP50 raw material: 10.43g Eu 2 o 3 Dissolved in concentrated nitric acid with a mass fraction of 65%, 1.21g WO 3 Soluble in ammonia water with a mass fraction of 18%, 0.59g NH 4 h 2 PO 4 Dissolve in deionized water, mix the three evenly, add 6.45g glycine to the mixture;

[0054] (2) Heat the nitrate mixture obtained in step (1) to 220°C and stir for 28 hours until the solution takes on the form of a gel, then put the gel into an electric furnace, heat to 250°C and bake to obtain the precursor of the powder ; The powder is placed in a muffle furnace, and the temperature is kept at a rate of 1.5°C to 900°C per minute for 7.5h to obtain the powder EuWP50.

[0055] (3) Weigh 1.8g of phase-forming powder EuWP50 and put it into a cast iron mold, k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com