Silver-loaded chitosan/polyvinyl alcohol micro-ribbon and preparation method and application thereof

A technology of polyvinyl alcohol and polyvinyl alcohol solution, which is applied in the directions of filament/thread forming, textile and papermaking, fiber processing, etc., to achieve the effects of simple preparation process, high specific surface area and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Weigh 10 g of polyvinyl alcohol and dissolve it in 90 g of water, heat and dissolve with magnetic stirring, and prepare 100 g of polyvinyl alcohol solution with a mass fraction of 10%. Weigh 0.2g chitosan and dissolve it in lactic acid to prepare 10g mass fraction of 2% chitosan lactic acid solution. After mixing the above polyvinyl alcohol and chitosan solution at a mass ratio of 70:30, add silver nitrate with 2% of the total mass of polyvinyl alcohol and chitosan, stir in the dark for 48 hours, and prepare spinning solution. Spinning was performed using an electrospinning device with a voltage of 20kV, a syringe pump at a speed of 2.26mL / h, and aluminum foil was used for receiving, and the receiving distance was 15cm. That is, the silver-loaded chitosan / polyvinyl alcohol micro-belts were prepared.

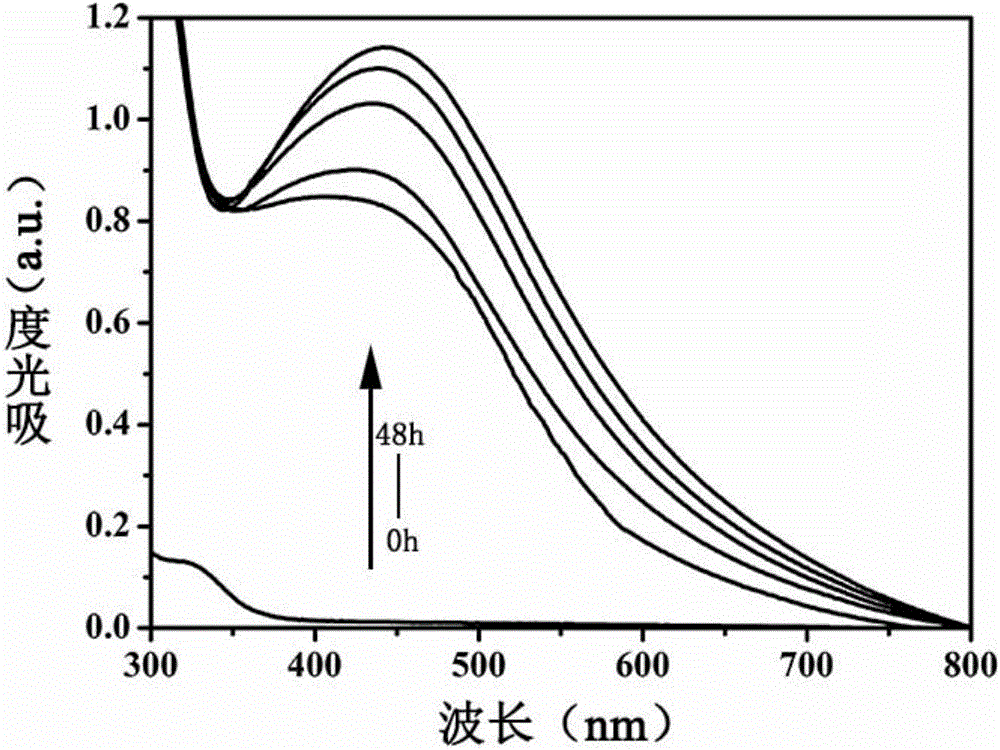

[0035] With the increase of stirring time, the obtained spinning solution has the UV absorption intensity as follows: figure 1 As shown, with the increase of stirring ti...

Embodiment 2

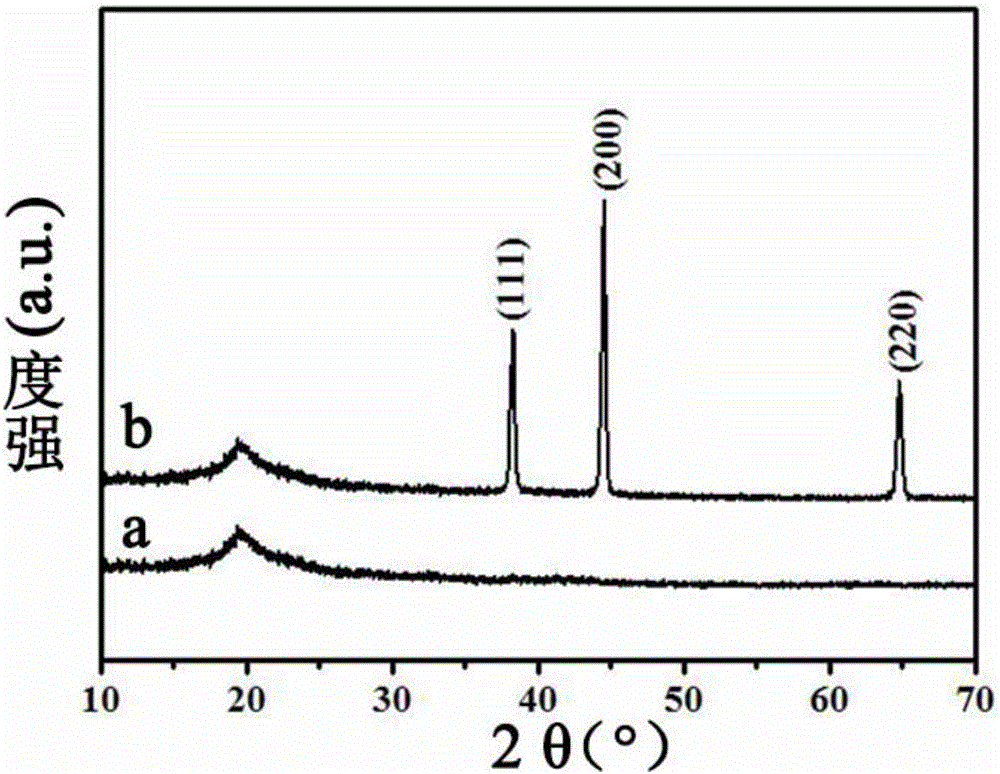

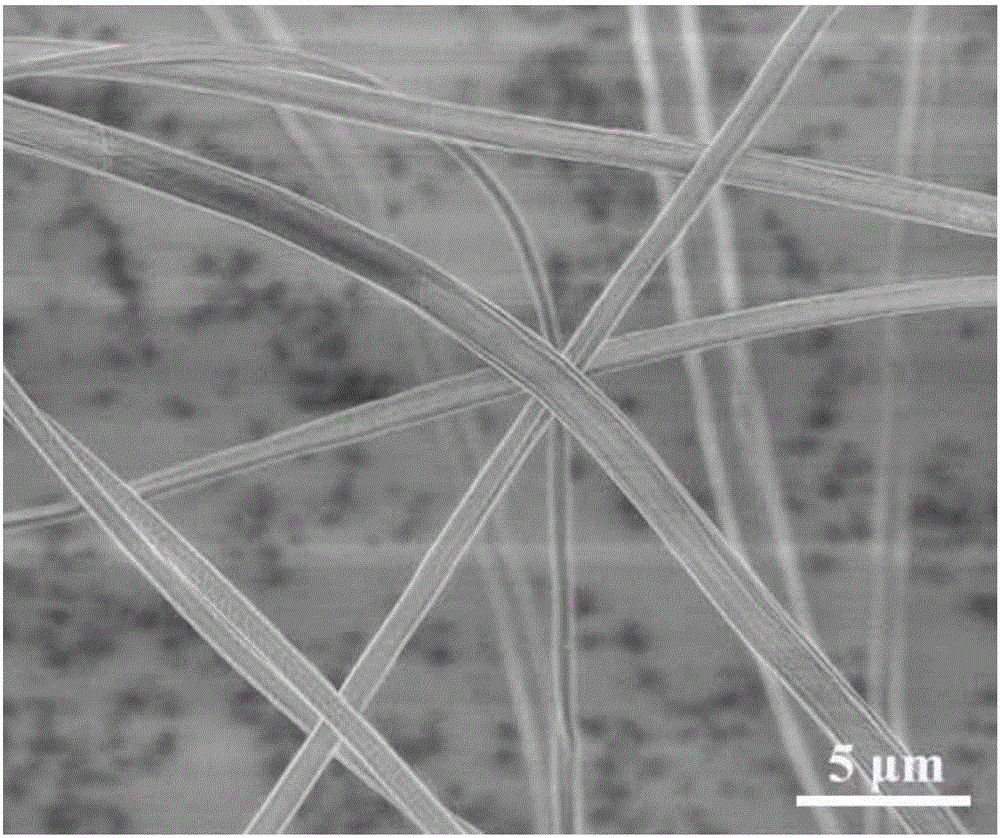

[0037] The mass concentration of the polyvinyl alcohol solution was expanded to 20%, and the other reagents, dosages and process conditions were unchanged, and Example 1 was repeated to obtain the silver-loaded chitosan / polyvinyl alcohol microbelts. The XRD of the prepared micron belt is as follows figure 2As shown, about 20° is the chitosan amorphous peak, and the indexed peak is the peak of elemental silver, which shows that the silver in the micron belt is elemental silver. The scanning and transmission photos of the substrate before and after silver loading are as follows: image 3 , 4 As shown, the prepared composite film is a ribbon-shaped fiber with a diameter of 0.6-1 μm, and the surface of the ribbon-shaped fiber is uniformly covered with silver nanoparticles after silver loading, with a particle diameter of 5-60 nm.

Embodiment 3

[0039] The mass concentration of the chitosan solution was enlarged to 8%, and the other reagents, dosages and process conditions were unchanged, and Example 1 was repeated to obtain the silver-loaded chitosan / polyvinyl alcohol microbelts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com