Synthesis method of strontium titanate-based materials for solid oxide fuel cells

A technology of solid oxide and synthesis method, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of complex synthesis process, precipitation of titanium-containing precipitation, etc., and achieve the effects of uniform particle size distribution, improved catalytic activity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

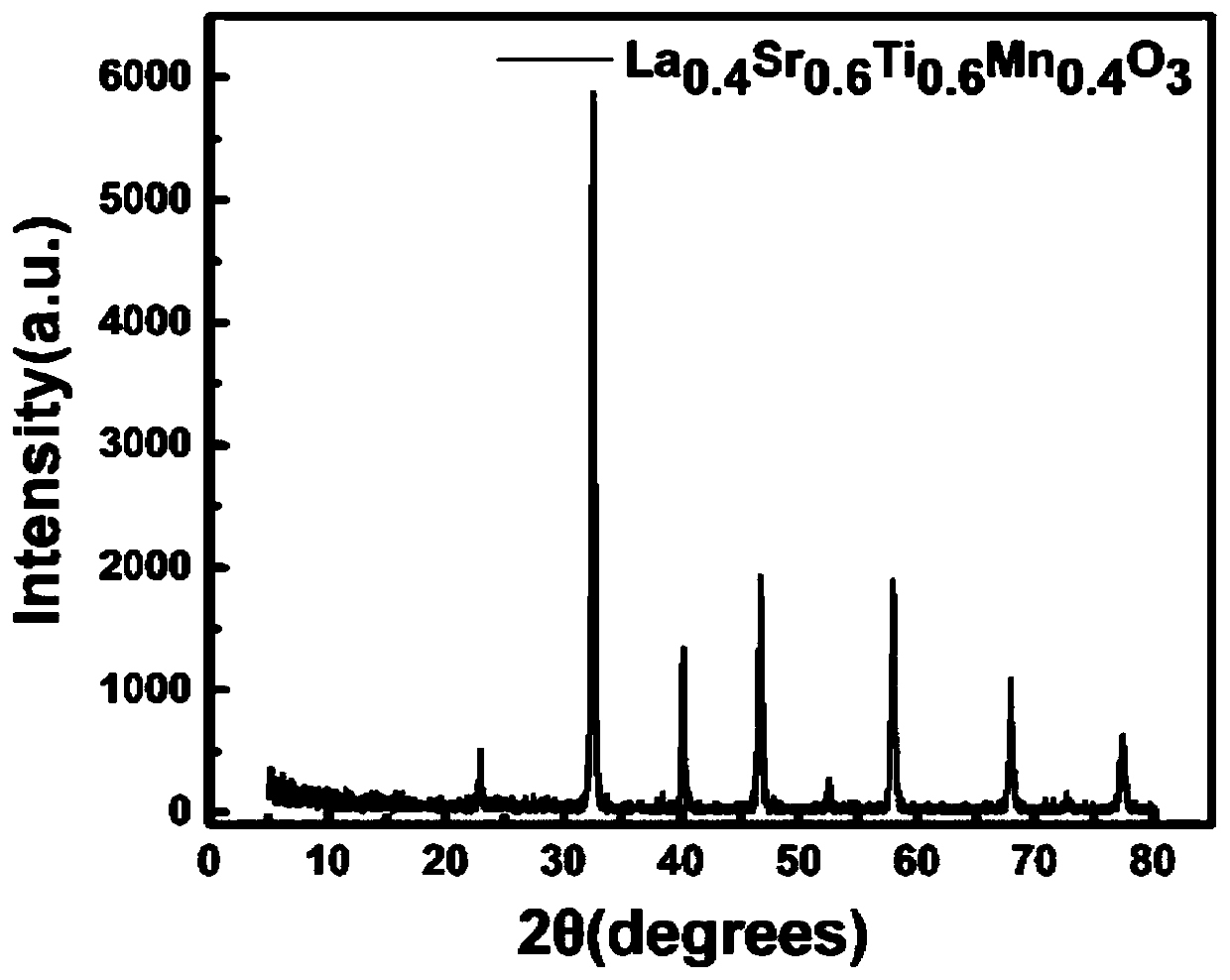

[0027] Press La 0.4 Sr 0.6 Ti 0.6 Mn 0.4 O 3 The stoichiometric ratio is to weigh tetrabutyl titanate, citric acid and metal salt. The required amount of Ti(OCH(CH 3 ) 2 ) 4 Dissolve in DMF, add citric acid to the above solution under stirring conditions. After all citric acid is dissolved, add the metal salt Sr(NO 3 ) 2 , La(NO 3 ) 3 ·6H 2 O and manganese acetate are added and dissolved in the solution. Among them, citric acid is used as a chelating agent, metal ions and citric acid are chelated or complexed to form a chelate, and DMF is used as a solvent and esterification agent. Synthesize 0.1molLa 0.4 Sr 0.6 Ti 0.6 Mn 0.4 O 3 The amount of raw materials required is as follows:

[0028]

[0029] The resulting yellow solution was mechanically stirred at room temperature until the metal salt was completely dissolved and the solution changed from yellow to orange-red. Then heat and stir at 80°C to gradually volatilize DMF to form a viscous gel. During this process, it can be ob...

Embodiment 2

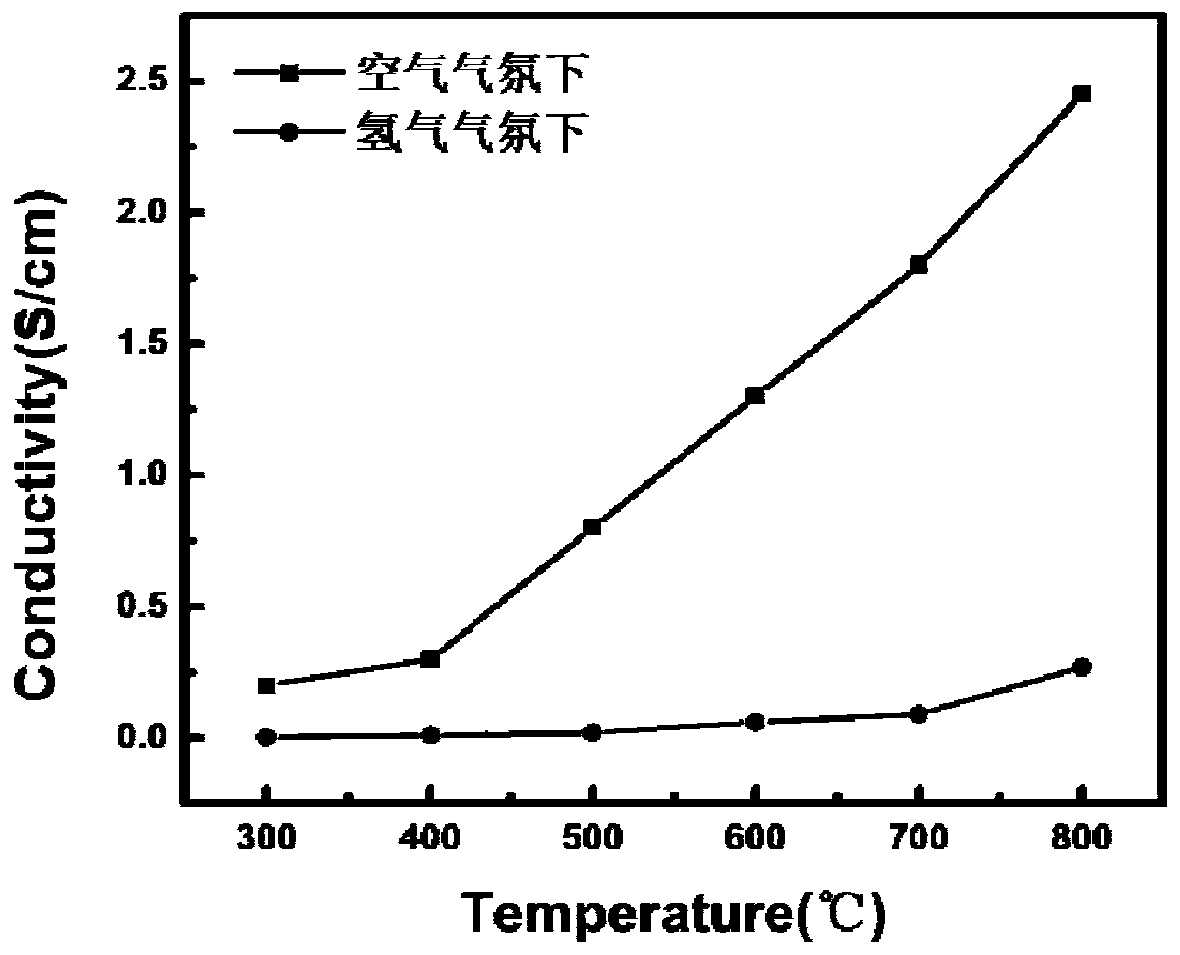

[0032] The four-probe method is used to test the conductivity of the sample in the range of 350°C to 800°C in air and hydrogen atmosphere, with an interval of 50°C. Place the sample in a tube furnace, pass in air or hydrogen atmosphere, and use the four-wire resistance mode of the digital multimeter to test the resistance of the sample. The sample preparation method used in the test is as follows:

[0033] The powder prepared in Example 1 was pressed into a 5mm×5mm×25mm rod shape with a powder tableting machine under a pressure of 300 MPa, and sintered at 1200°C for 6 hours using a temperature-programmed sintering method to obtain a relatively dense sample to be tested. Four silver wires are glued in parallel on the prepared long bar with silver paste, which are used as voltage and current leads respectively.

[0034] Direct current is applied to both ends of the sample, and the voltage between the two voltage lines is measured by a digital multimeter, and the resistance value bet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com