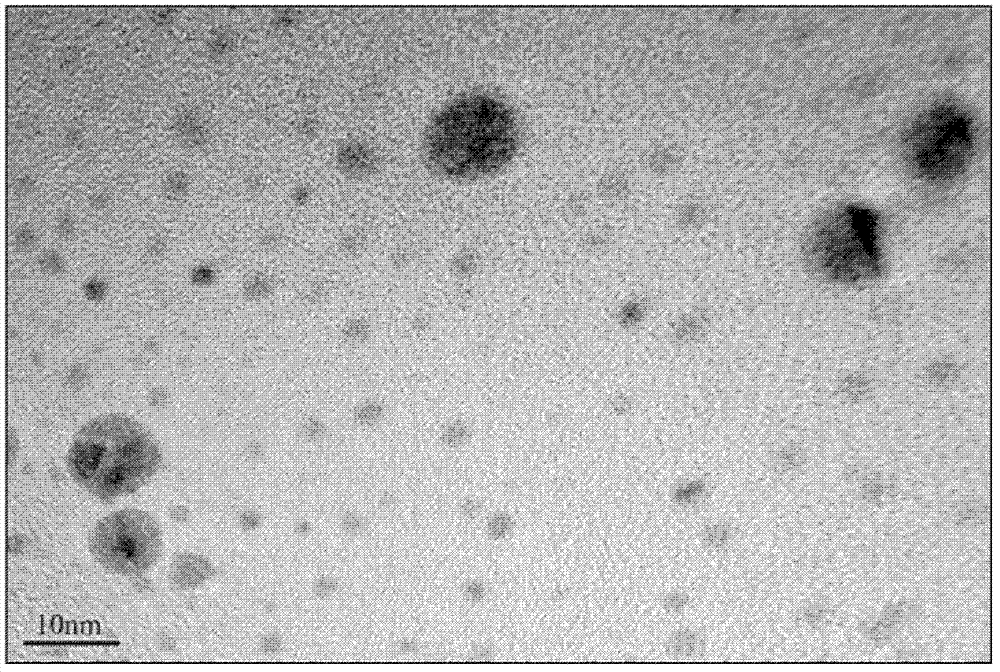

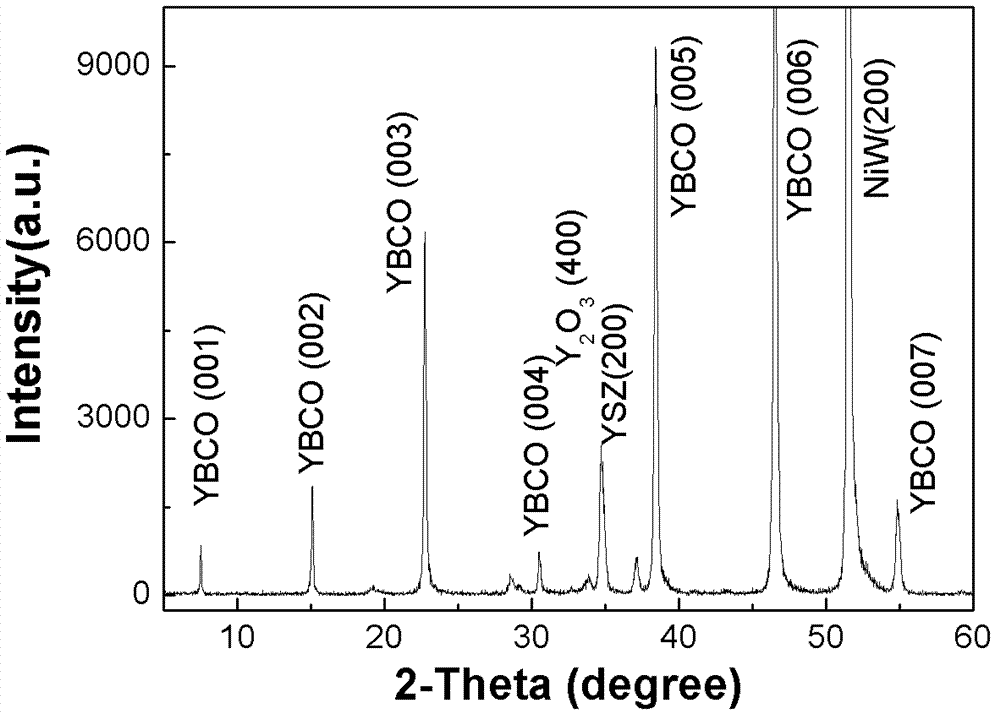

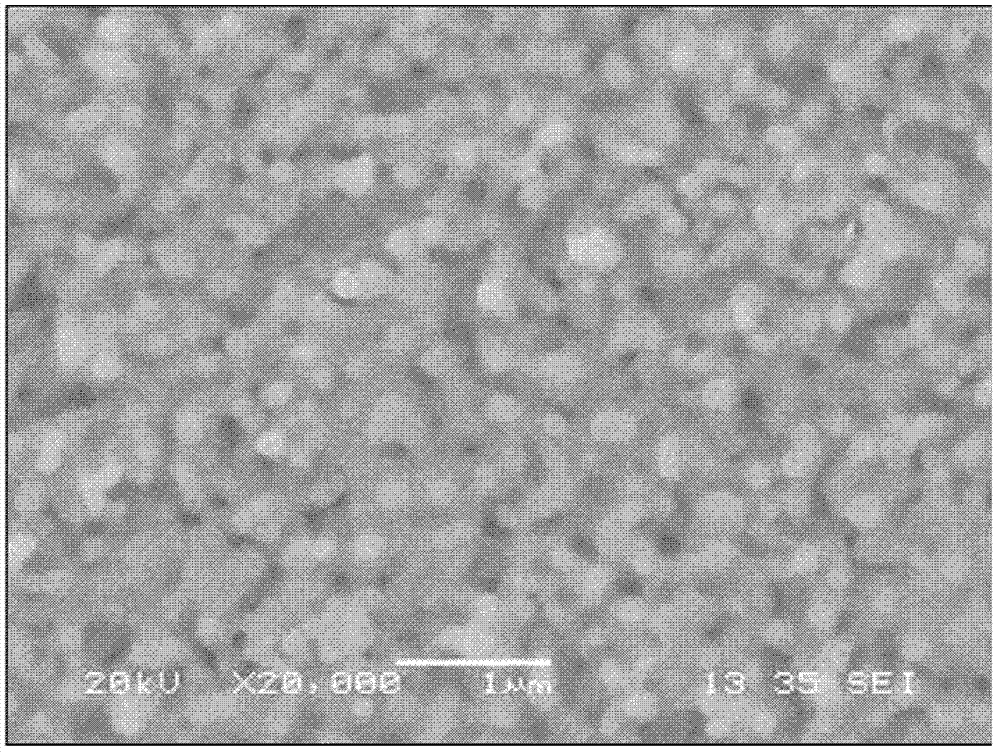

Preparation method of nanosilver-doped yttrium barium copper oxide film

A technology of yttrium-barium-copper-oxide and nano-silver, which is applied in cable/conductor manufacturing, electrical components, circuits, etc., can solve problems such as irregular shape of silver particles, performance degradation of superconducting layer, instability of precursor sol, etc., and achieve nucleation Uniformity, low phase formation temperature, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Step (1) preparation of precursor sol:

[0032] Step 101, dissolving silver nitrate in a mixed solvent of ethanol and water to prepare a solution with a silver nitrate concentration of 0.15 mol / L, using the prepared solution as a reaction solution, and introducing an argon flow into the reaction solution with a stainless steel needle tube as For the cathode, place a stainless steel needle tube 3mm above the surface of the reaction solution, control the gas flow rate to 500mL / min, use silver foil as the anode, and turn on the power for electrochemical reaction. Control the electrochemical reaction voltage to 1KV, current to 10mA, and reaction time to 60min, obtain nano-silver sol; The volume ratio of ethanol and water in the mixed solvent is 1: 2;

[0033] Step 102, dissolving yttrium trifluoroacetate, barium trifluoroacetate and copper benzoate in ethanol according to the atomic ratio of yttrium: barium: copper = 1: 2: 3, to obtain the yttrium barium copper oxygen precu...

Embodiment 2

[0041] Step (1) preparation of precursor sol:

[0042] Step 101, dissolving silver nitrate in a mixed solvent of ethanol and water to prepare a solution with a silver nitrate concentration of 0.2 mol / L, using the prepared solution as a reaction solution, and introducing an argon flow into the reaction solution with a stainless steel needle tube as For the cathode, place a stainless steel needle tube 5mm above the surface of the reaction solution, control the gas flow rate to 1000mL / min, use silver foil as the anode, and turn on the power to carry out the electrochemical reaction. Control the electrochemical reaction voltage to 2KV, current to 20mA, and reaction time to 10min, obtain nano-silver sol; The volume ratio of ethanol and water in the mixed solvent is 1: 10;

[0043] Step 102, dissolving yttrium trifluoroacetate, barium trifluoroacetate and copper benzoate in ethanol according to the atomic ratio of yttrium: barium: copper = 1: 2: 3, to obtain the yttrium barium coppe...

Embodiment 3

[0050] Step (1) preparation of precursor sol:

[0051] Step 101, dissolving silver nitrate in a mixed solvent of ethanol and water to prepare a solution with a concentration of silver nitrate of 0.5 mol / L, using the prepared solution as a reaction solution, and passing an argon flow into the reaction solution with a stainless steel needle tube as For the cathode, place a stainless steel needle tube 2mm above the surface of the reaction solution, control the gas flow rate to 200mL / min, use silver foil as the anode, connect the power supply for electrochemical reaction, control the electrochemical reaction voltage to 0.5KV, the current to 1mA, and the reaction time Be 30min, obtain nano-silver sol; The volume ratio of ethanol and water in the described mixed solvent is 1: 1;

[0052] Step 102, dissolving yttrium trifluoroacetate, barium trifluoroacetate and copper benzoate in ethanol according to the atomic ratio of yttrium: barium: copper = 1: 2: 3, to obtain the yttrium barium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com