Patents

Literature

151results about How to "Uniform nucleation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

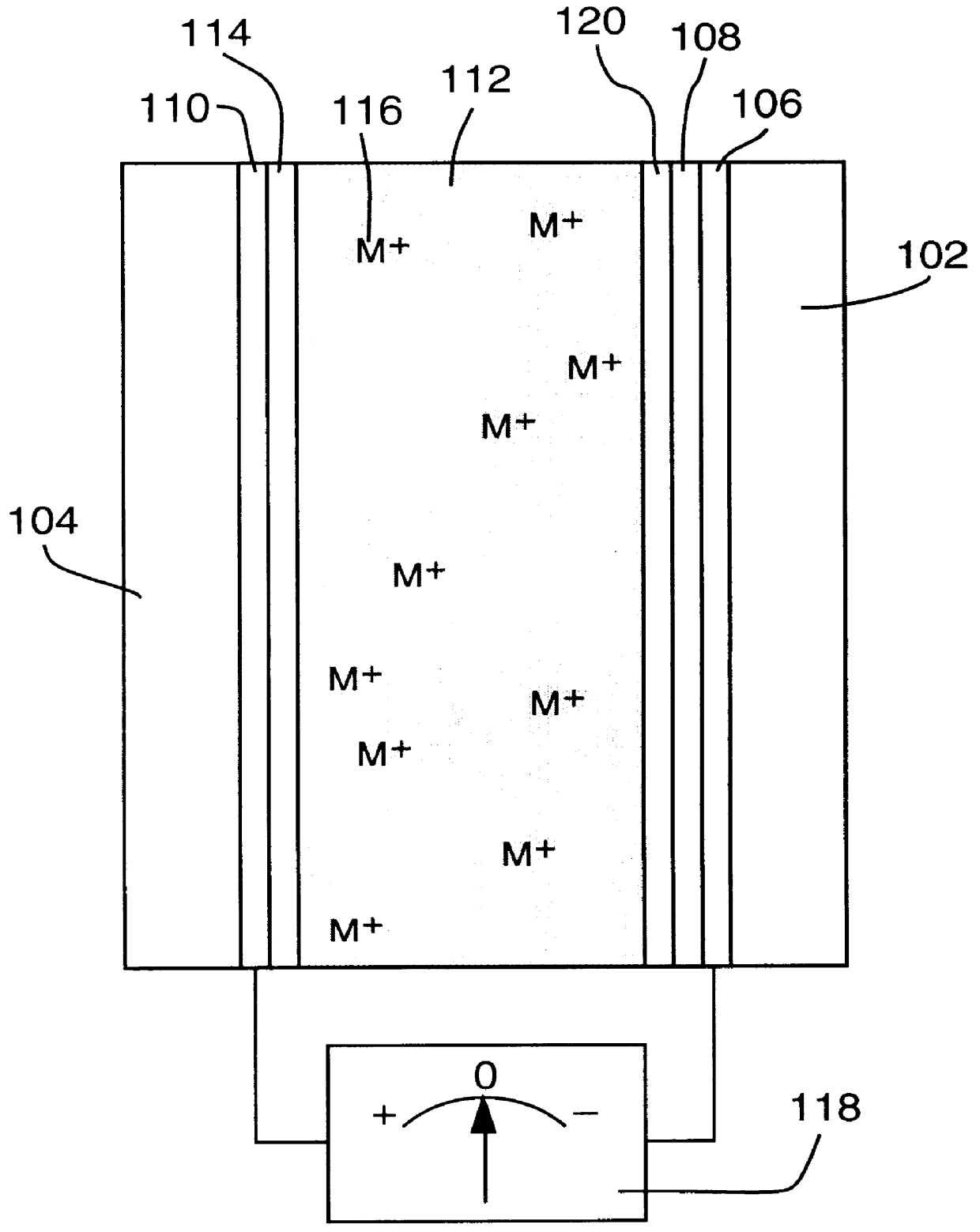

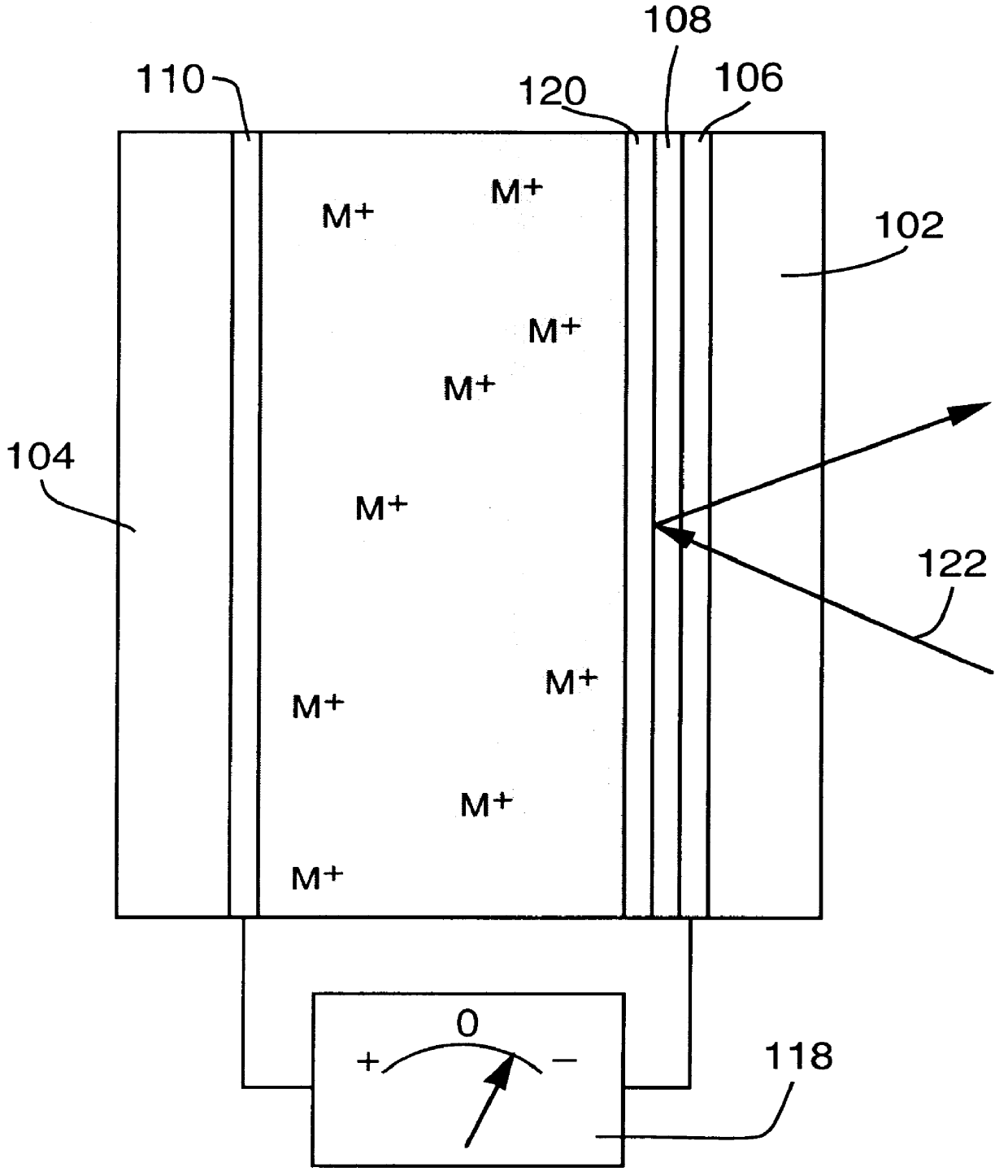

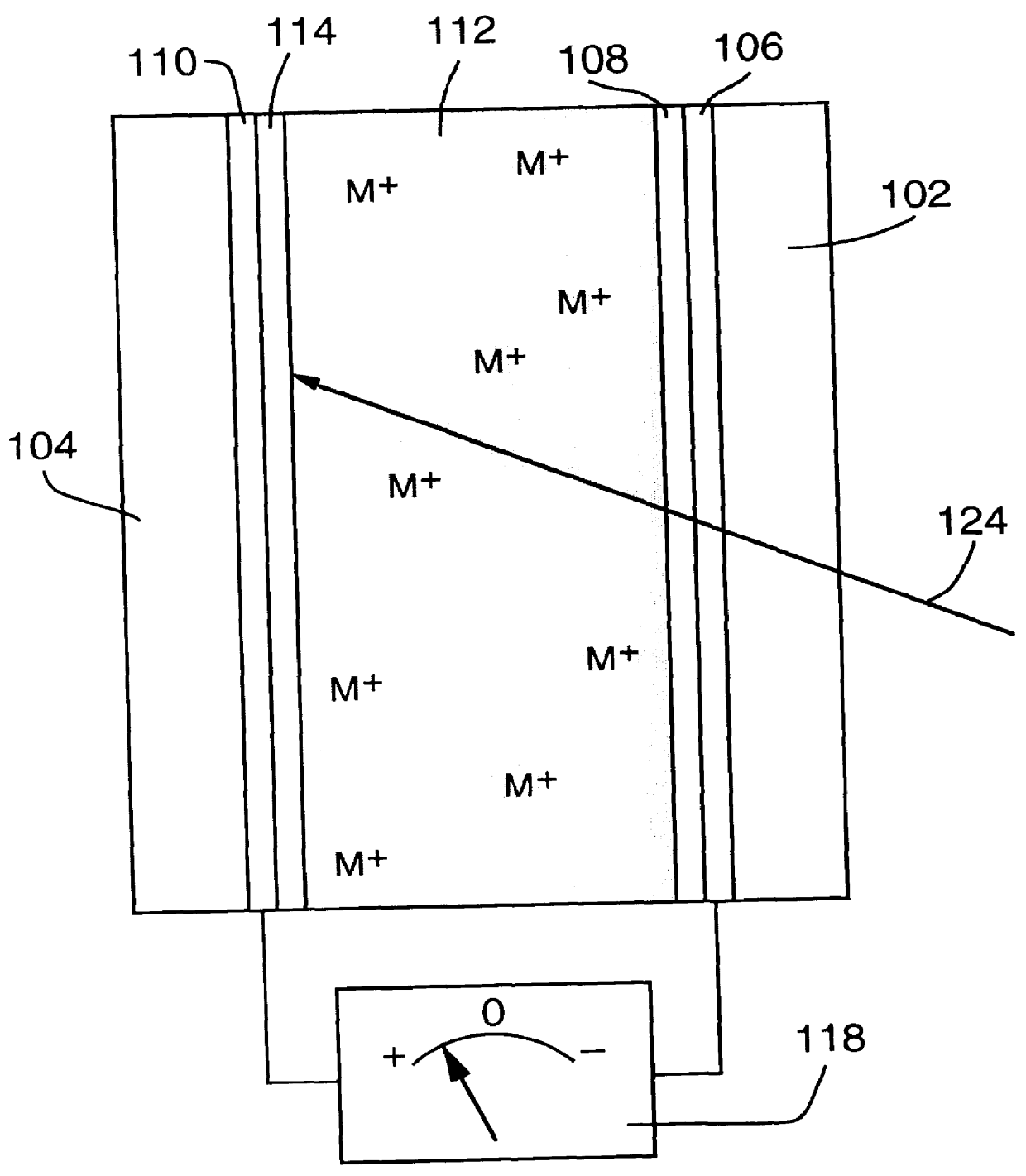

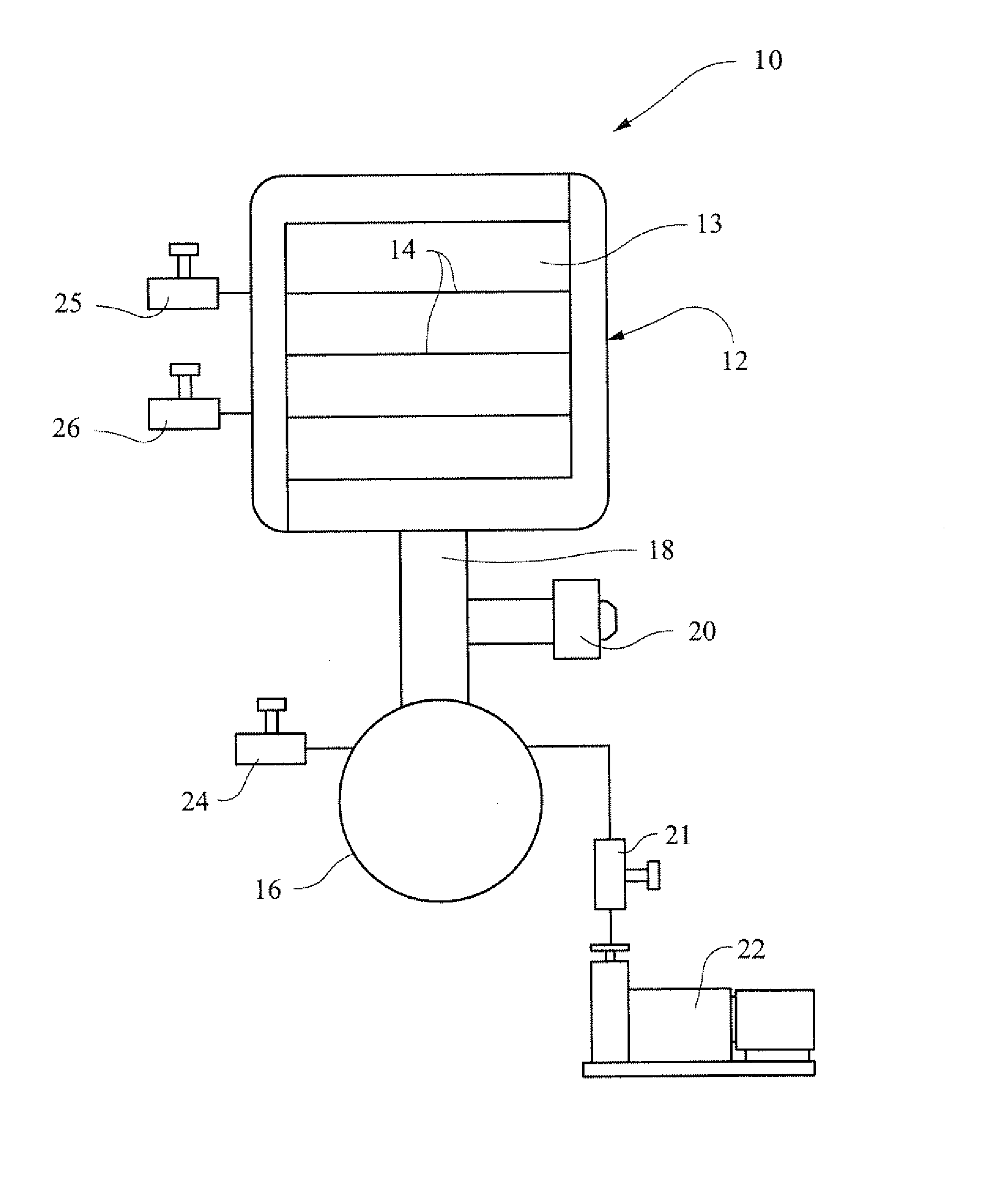

Reversible electrochemical mirror for modulation of reflected radiation

InactiveUS6166847APrecise and Efficient ControlUniform nucleationNon-linear opticsElectricityElectromagnetic radiation

An electrochemical mirror includes a transparent first electrode and a second electrode. An electrolytic solution, disposed between the first and second electrodes, contains ions of a metal which can electrodeposit on the electrodes. A negative electrical potential applied to the first electrode causes deposited metal to be dissolved from the second electrode into the electrolytic solution and to be electrodeposited from the solution onto the first electrode, thereby affecting the reflectivity of the mirror for electromagnetic radiation. A surface modification layer applied to the first electrode ensures that the electrodeposit is substantially uniform, resulting in a mirror layer which increases the reflectivity of the mirror. A positive electrical potential applied to the first electrode causes deposited metal to be dissolved from the first electrode and electrodeposited from the solution onto the second electrode, thereby decreasing the reflectivity of the mirror.

Owner:TELEDYNE SCI & IMAGING

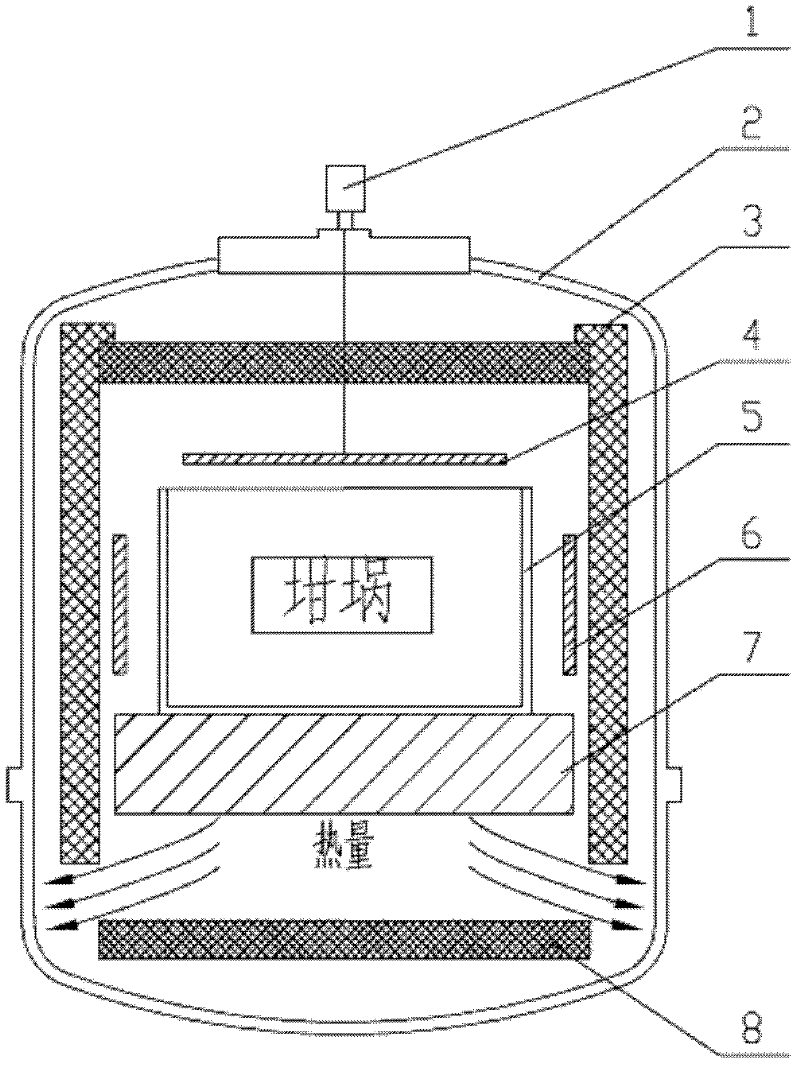

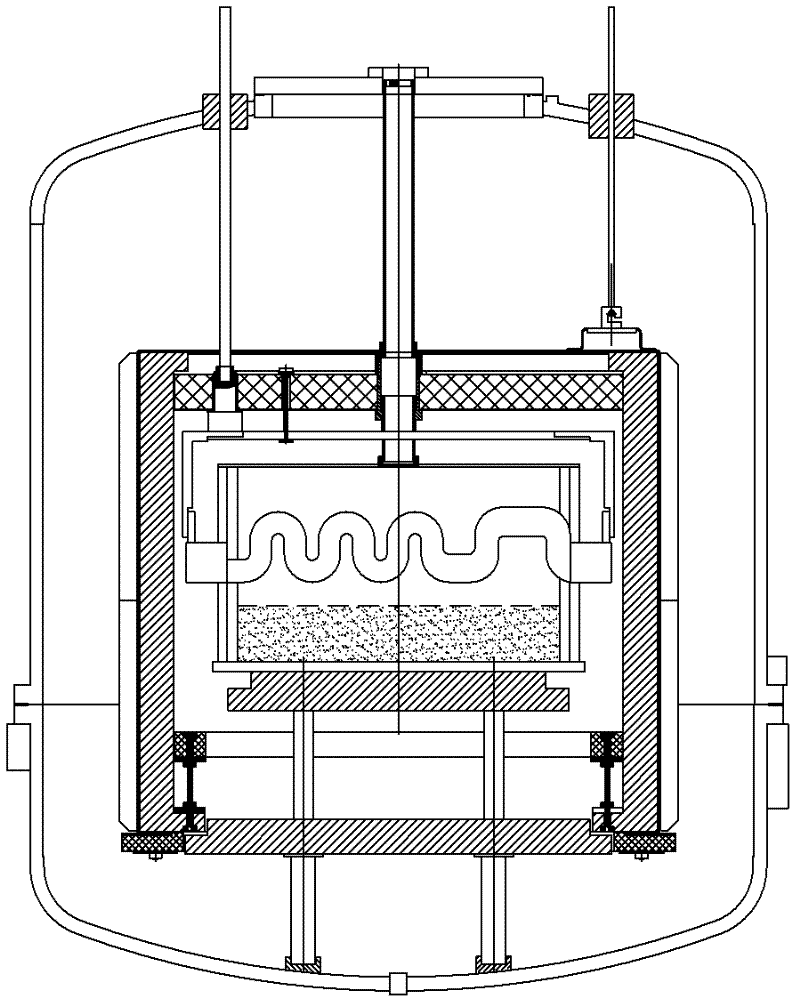

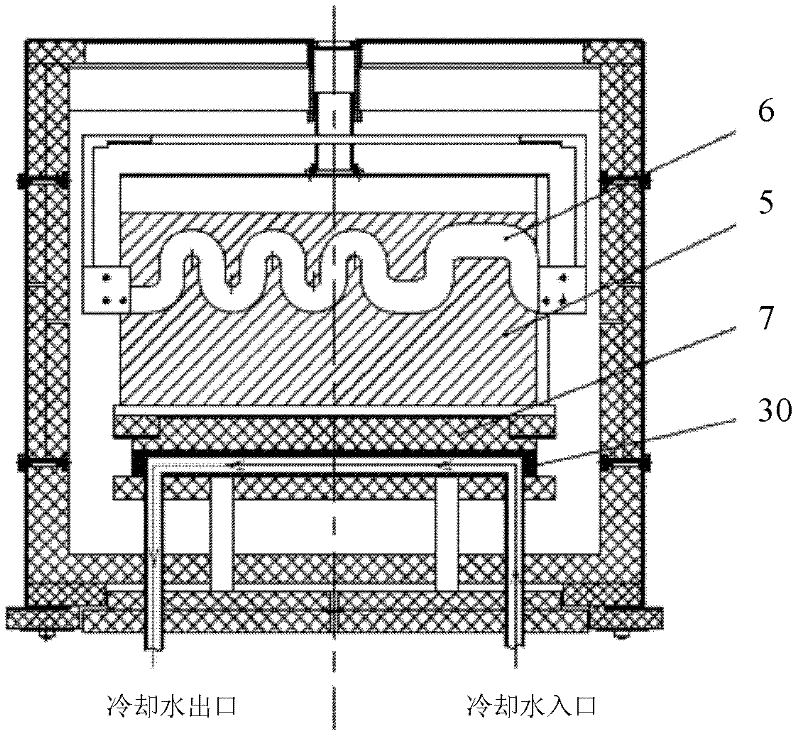

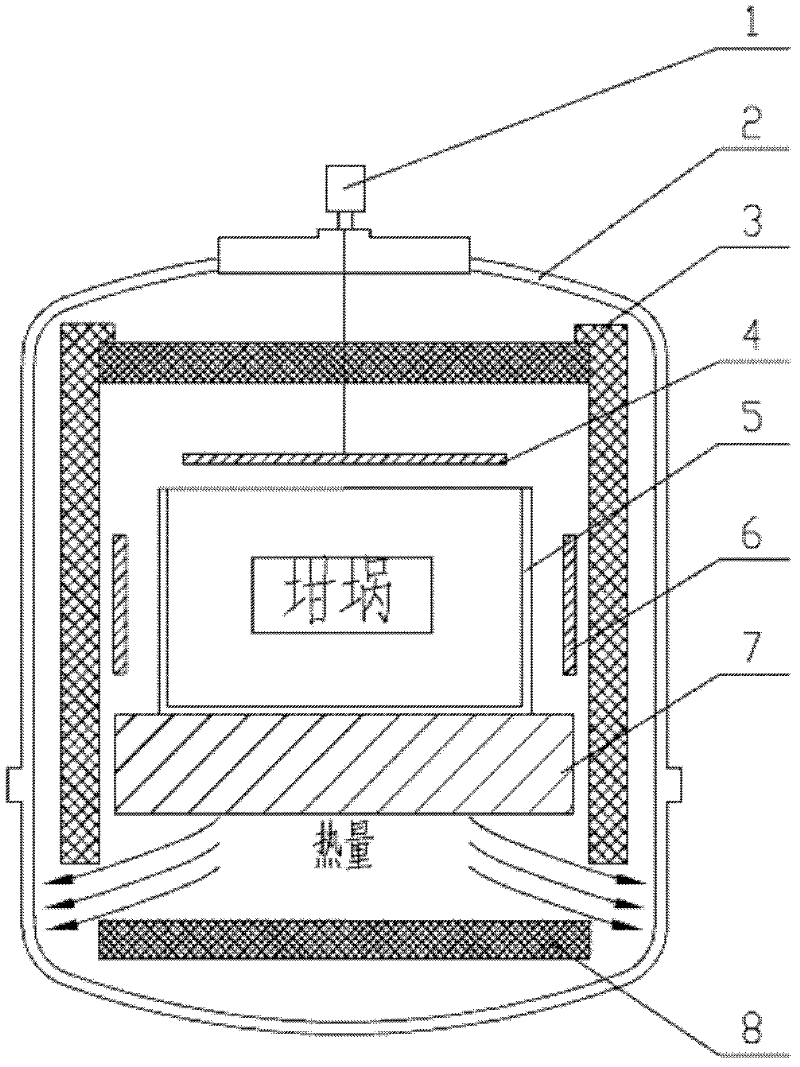

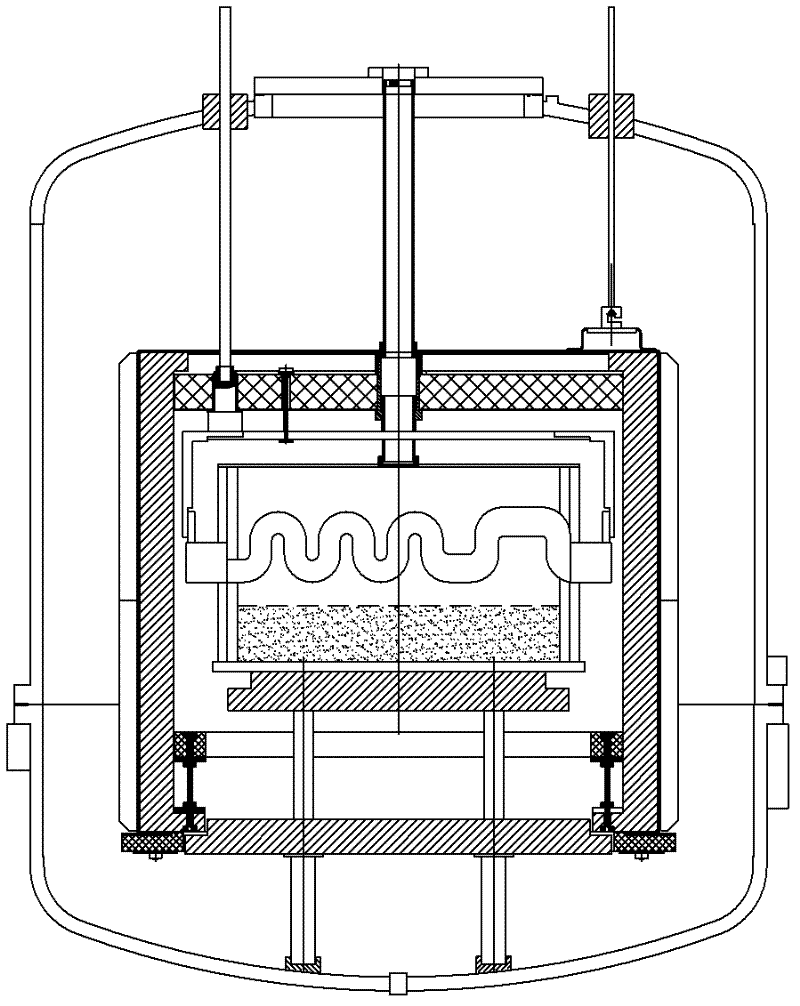

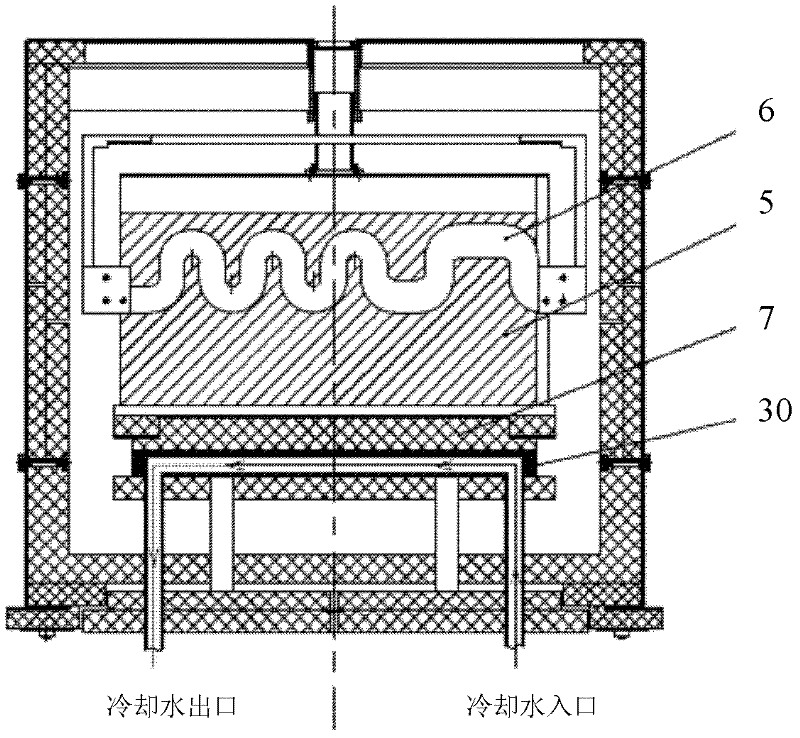

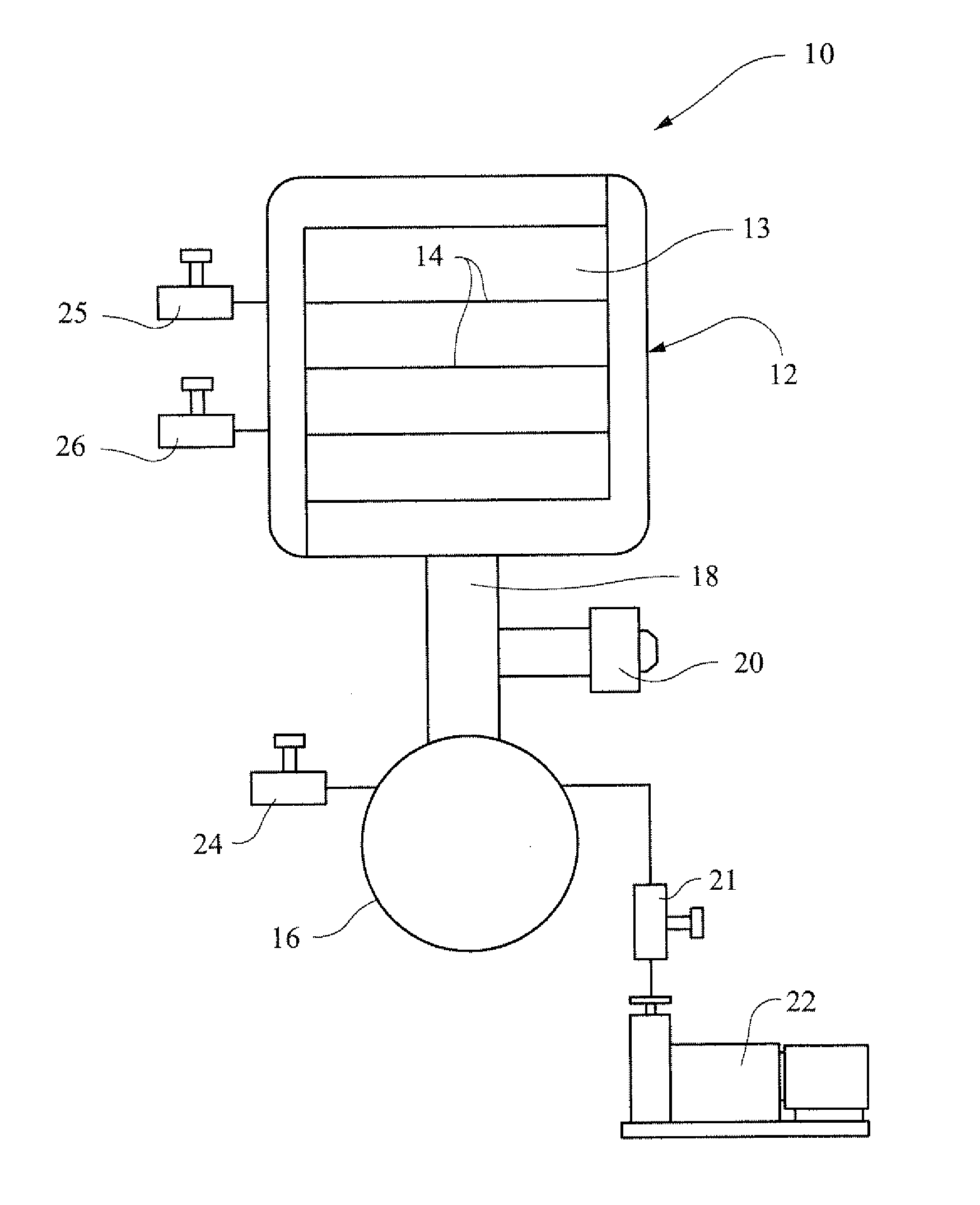

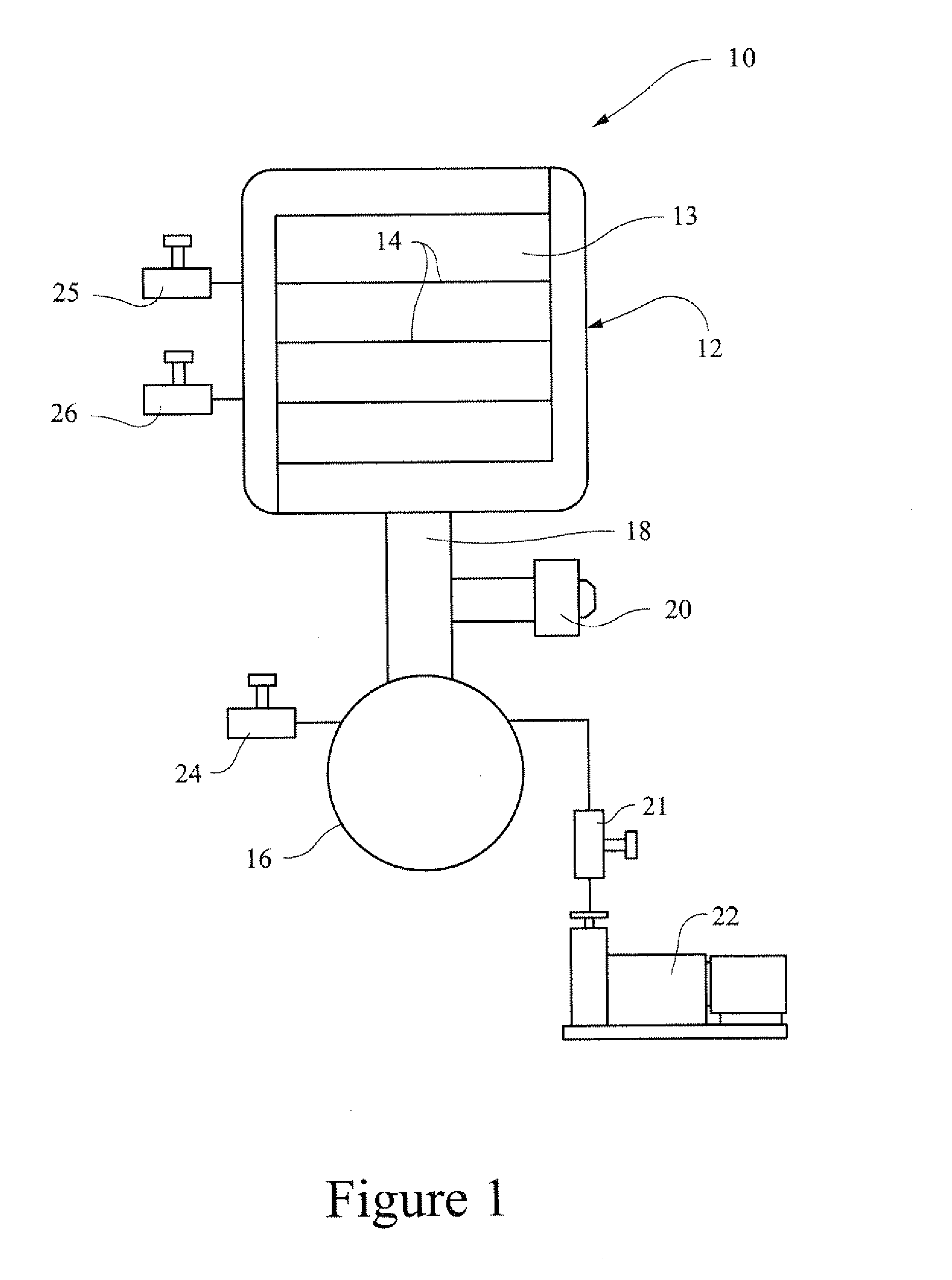

Closed cooling system of gas cooled polysilicon ingot furnace

ActiveCN102234837APrecise temperature controlEasy to controlPolycrystalline material growthSingle crystal growth detailsNuclear engineeringCrucible

The invention relates to the manufacture technical field of polysilicon ingot furnaces, and aims to provide a closed cooling system of a gas cooled polysilicon ingot furnace. The system comprises a heat exchange platform positioned on a supporting column and used for placing a crucible, wherein a cooling gas channel is arranged in the heat exchange platform; a gas inlet and a gas outlet at two ends of the cooling gas channel are respectively connected with a cooling gas inlet pipeline and a cooling gas outlet pipeline; and the heat exchange platform, the cooling gas inlet pipeline, the cooling gas outlet pipeline, a cooling gas power pump group and a cooler form a closed circulation loop of the cooling gas. Compared with the cooling method of radiation cooling and water cooling, the system related by the invention has strong gas cooling control capacity and high industrial controllability; the gas is fed into the heat exchange platform evenly, so that the whole temperature of the heatexchange platform is even, which is in favor of even nucleation of a silicon melt at the bottom of the crucible; and the reducing speed of the temperature at the bottom of the crucible can be precisely controlled during the crystal growth.

Owner:ZHEJIANG JINGSHENG MECHANICAL & ELECTRICAL +1

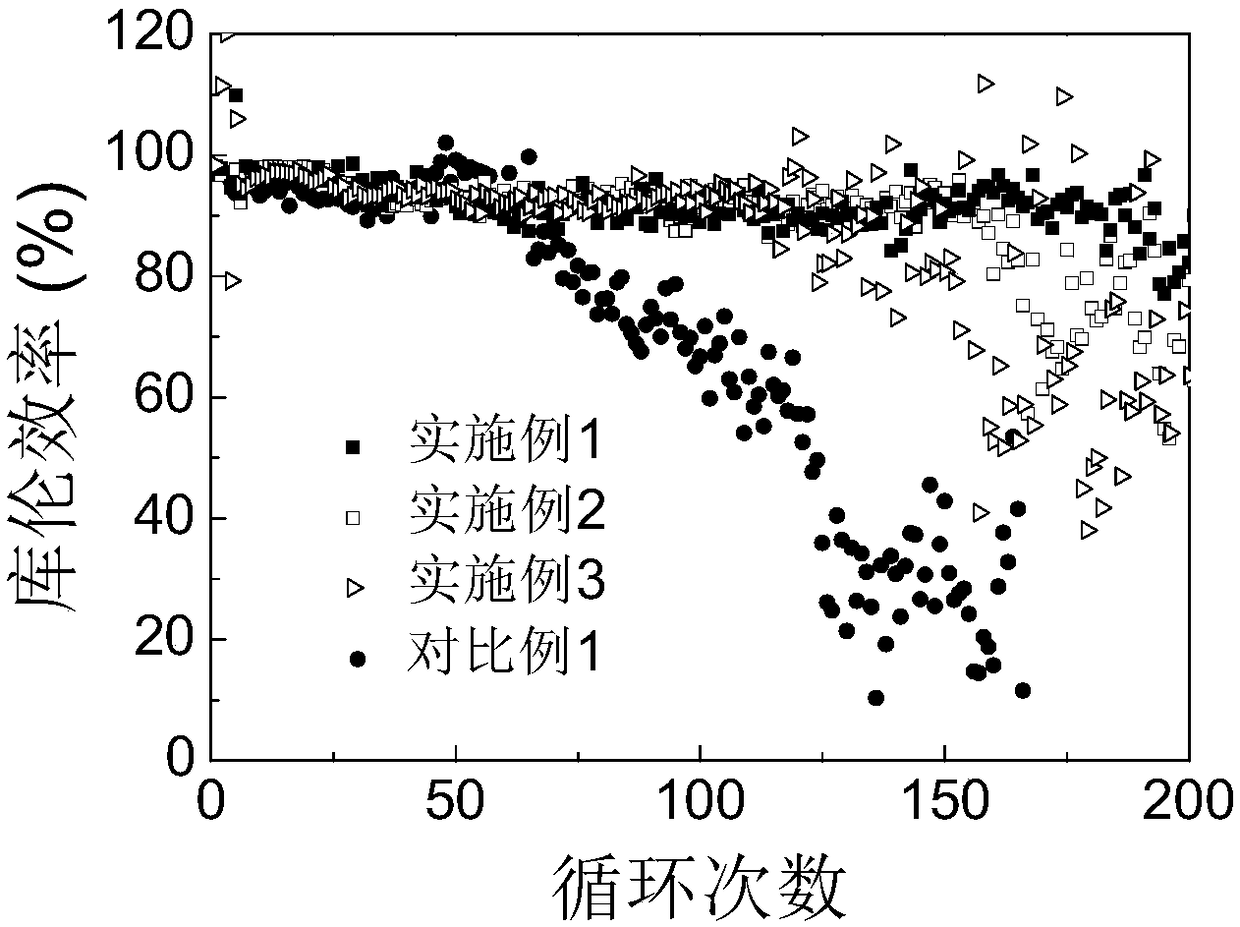

Stable lithium metal negative electrode

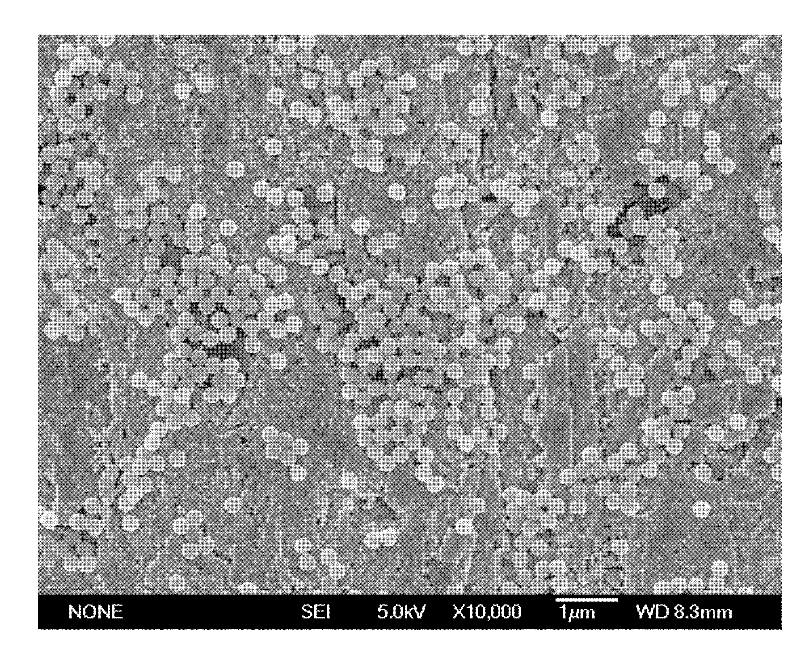

InactiveCN108428858AFacilitates ion transportAchieve even distributionElectrode carriers/collectorsNon-aqueous electrolyte accumulator electrodesLithium dendriteCurrent collector

The invention belongs to the technical field of a battery and particularly relates to a stable lithium metal negative electrode. The stable lithium metal negative electrode comprises a negative electrode current collector and a negative active material layer loaded on the surface of the current collector; the negative active material layer is a lithium metal layer; the negative electrode current collector comprises a current collector body and a lithium-philic nanometer array growing on the current collector body in situ; the thickness of the lithium-philic nanometer array is 0.8 <mu>m to 20 <mu>m. Compared with the prior art, the stable lithium metal negative electrode has the following advantages: the lithium-philic nanosheet array is arranged on the current collector body, so that ion transmission is facilitated, uniform distribution of lithium ions can be realized, the affinity of the stable lithium metal negative electrode and the lithium metal can be improved, a lithium-philic nucleation site is provided, and uniform nucleation and stable deposition of the lithium metal in the deposition process are realized. The array structure growing in situ can guarantee to be in tight contact with a copper current collector and reduce the effective current density of the electrode, so that uniform deposition of the lithium metal is realized; the lithium-philic current collector can inhibit the growth of lithium dendrites.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Three-dimensional self-supported lithium-loving carrier-packaged metal lithium composite negative electrode and preparation method thereof

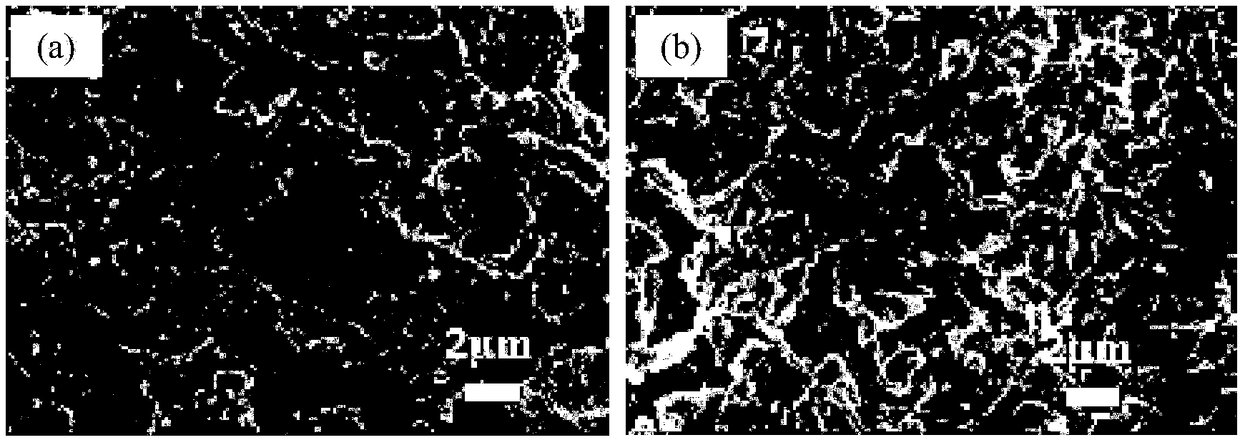

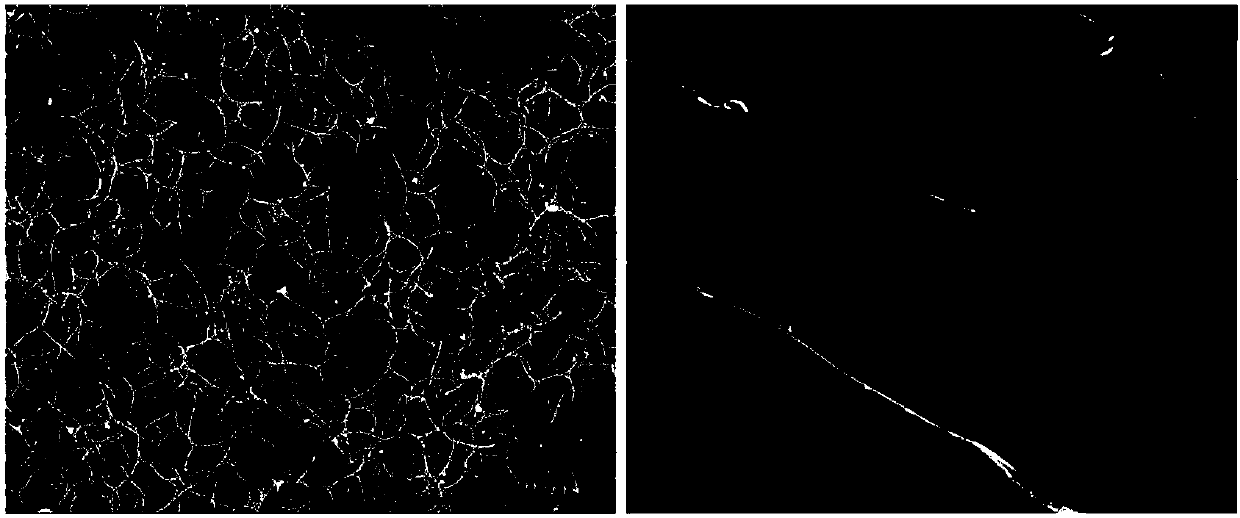

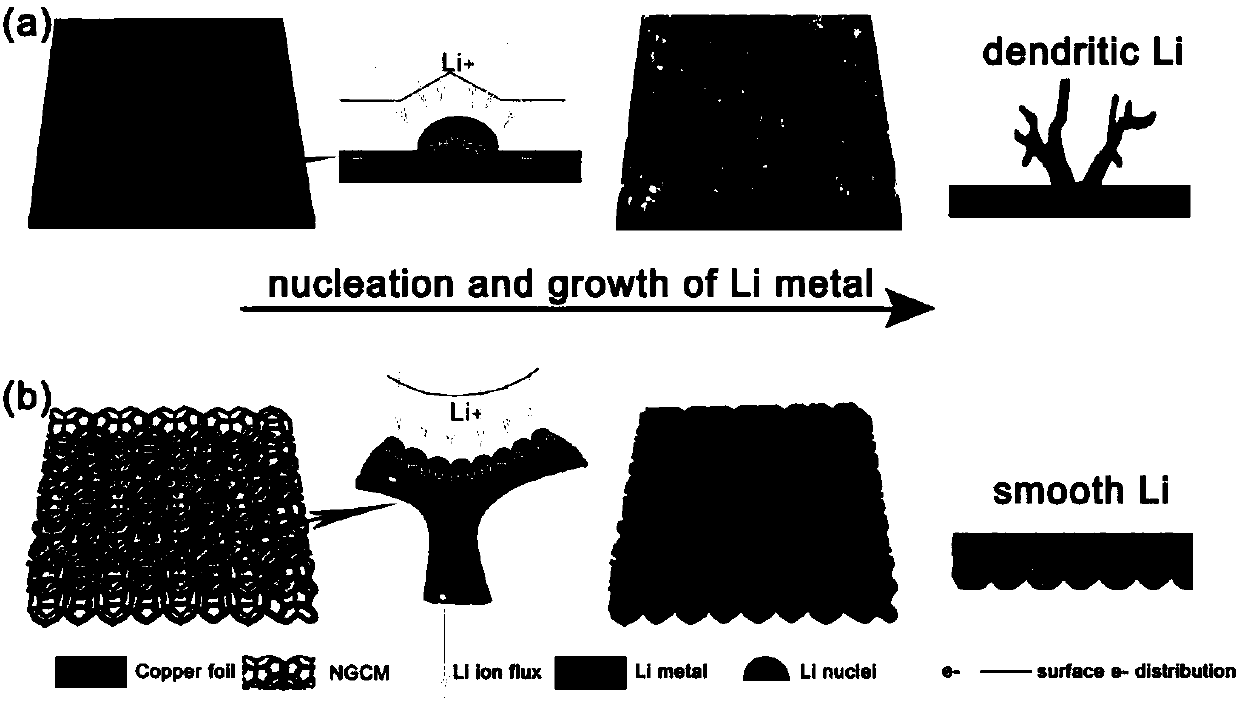

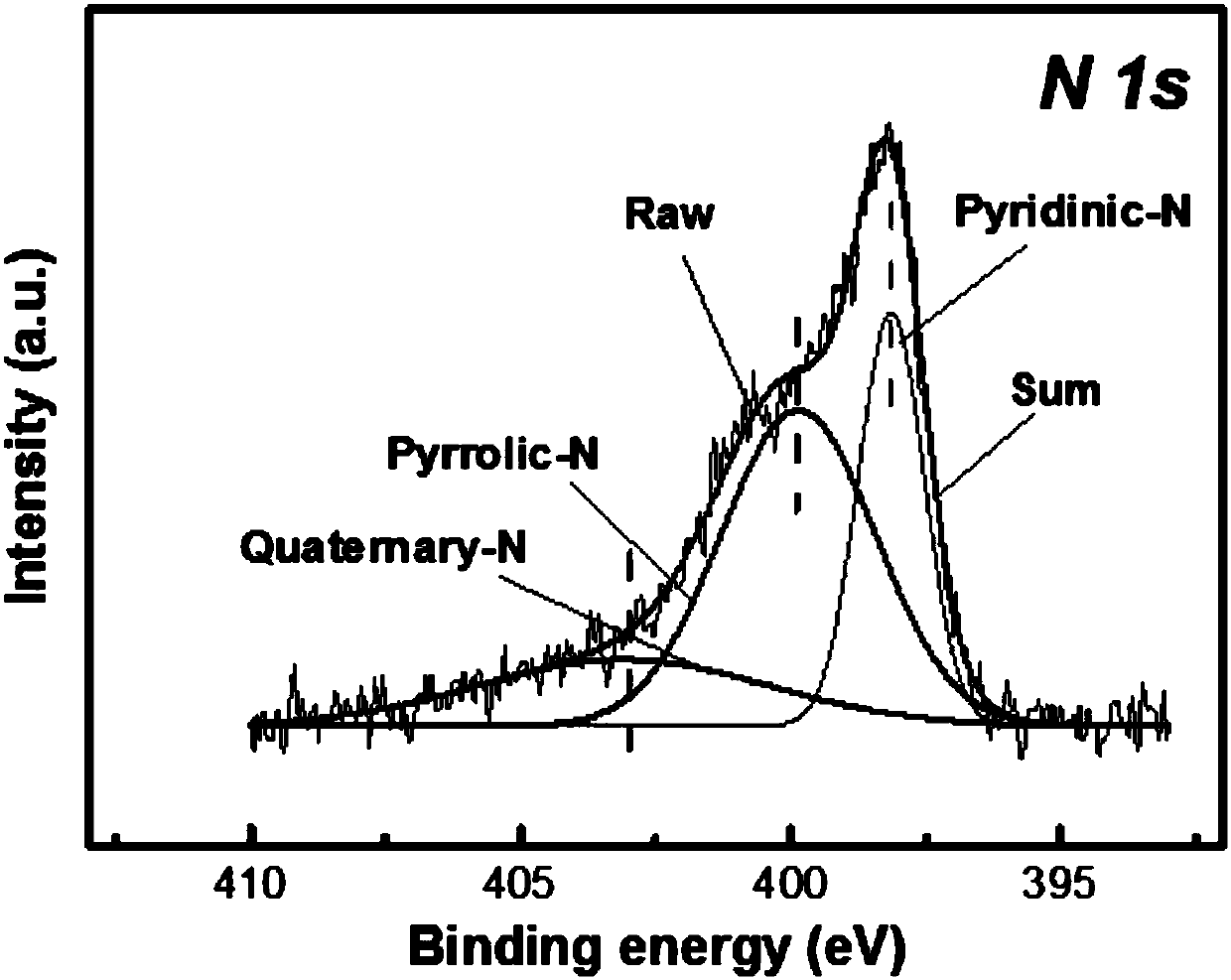

InactiveCN107799736AAvoid uneven electron/ion distributionFacilitates deposition/dissolutionMaterial nanotechnologyCell electrodesLithium electrodeCarbonization

The invention discloses a three-dimensional self-supported lithium-loving carrier-packaged metal lithium composite negative electrode and a preparation method thereof. The three-dimensional self-supported lithium-loving carrier-packaged metal lithium composite negative electrode comprises the following steps of 1) carbonizing melamine foam in an inertia atmosphere to obtain a nitrogen-rich lithium-loving three-dimensional self-supported carrier; and 2) packaging metal lithium in holes of the three-dimensional self-supported carrier to obtain the metal lithium composite negative electrode. Carbon sponge obtained by carbonization of melamine foam is used as a metal lithium carrier, and the metal lithium composite negative electrode has effects of guiding metal lithium to be uniformly deposited and preventing dendrite from being generated. Lithium-loving functional groups are uniformly arranged on the carrier, a lithium-loving coating layer is deposited on a hole surface of the carrier, the lithium-loving performance of the carrier is improved, the volume change of the metal lithium electrode during the circulation process is effectively buffered, moreover, the lithium-loving functional groups uniformly arranged on the three-dimensional carrier are used as active sites for metal lithium deposition, the nucleation over-potential is reduced, uniform nucleation of metal lithium can be effectively controlled, so that the dendrite generation is prevented.

Owner:SHANDONG UNIV

Heat exchange platform with improved structure for polysilicon ingot furnace

ActiveCN102268728APrecise temperature controlEasy to controlPolycrystalline material growthFrom frozen solutionsCrucibleIngot

The invention relates to polycrystalline silicon ingot furnace equipment, and aims to provide a heat exchange platform of an improved structure for a polycrystalline silicon ingot furnace. The heat exchange platform is used for holding a polycrystalline silicon ingot furnace crucible and realizing heat exchange, and is provided with a gas inlet and a gas outlet; and the interior of the heat exchange platform is provided with a cooling gas channel, and is connected with the gas inlet and the gas outlet. Compared with the radiation cooling and the water-cooling type cooling technologies, the heat exchange platform disclosed by the invention is strong in control capacity and high in industrial controllability when being used for gas refrigeration; and furthermore, because the gas enters the heat exchange platform uniformly, the overall temperature of the heat exchange board is uniform, so that the uniform nucleation of a silicon melt at the bottom of the crucible is facilitated, and the temperature reduction speed at the bottom of the crucible in the crystal growth process can be precisely controlled.

Owner:SHANGYU JINGXIN ELECTROMECHANICAL TECH +1

Method for quickly preparing large-size single-crystal graphene

ActiveCN104389016ASpread flatEasy to manufacturePolycrystalline material growthFrom chemically reactive gasesLiquid copperWater vapor

The invention relates to a method for quickly preparing large-size single-crystal graphene on a liquid copper substrate by a chemical vapor deposition process. The method comprises the following steps: in a hydrogen and inert gas atmosphere, introducing vapor and a carbon source, growing large-size single-crystal graphene by using catalytic cracking of the carbon source on the liquid copper substrate surface, and cooling to room temperature in an inert gas atmosphere to obtain the large-size single-crystal graphene. Compared with the traditional solid metal substrate, the liquid copper substrate used in the method has the advantages of high growth speed, uniform nucleation and the like and can be recycled in the aspect of graphene preparation. The carbon source and water content are regulated to implement the controllable graphene size, thereby obtaining the centimeter-sized single-crystal graphene. The prepared graphene is applicable to preparing field-effect transistor devices.

Owner:INST OF CHEM CHINESE ACAD OF SCI

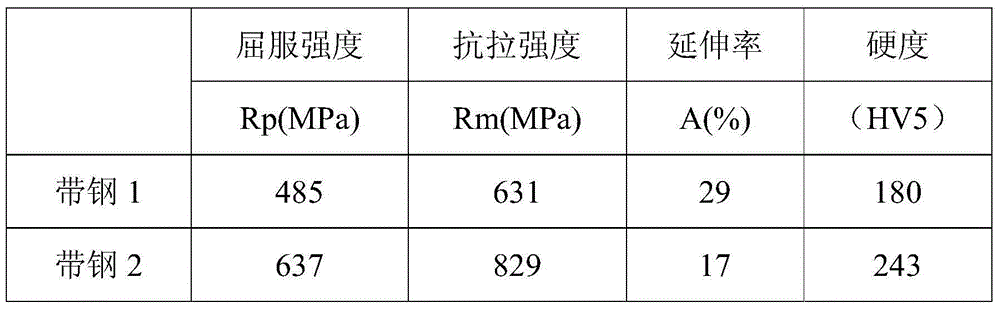

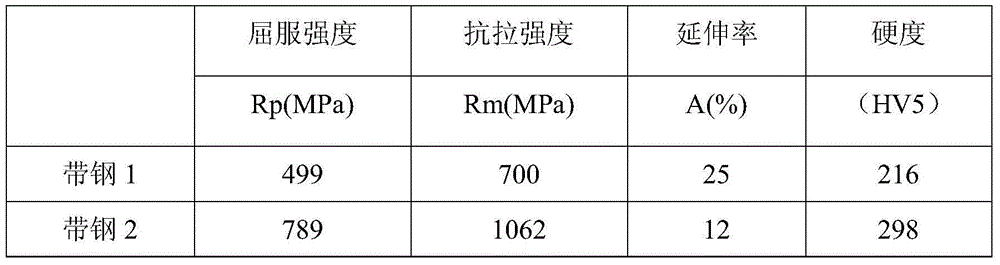

Rolling technology for high-carbon steel in thin slab casting and rolling

ActiveCN104438326AIncrease nucleation sitesUniform nucleationTemperature control deviceTension/compression control deviceThree stageSlow cooling

The invention provides a rolling technology for high-carbon steel in thin slab casting and rolling. The rolling technology includes the processes of continuous casting, heat evening, scale removing, rolling, inter-stand cooling, laminar cooling, reeling and insulation cover slow cooling. The rolling technology is characterized in that the rolling process includes three stages of Austenite perfect recrystallization rolling, non-recrystallization area Austenite rolling and two-phase area rolling. Medium-and-high-carbon steel structures rolled through the rolling technology are even and fine ferrite and particular pearlite, banded structures can be improved, the mechanical property is good, the annealing process does not need to be conducted before forming, cost is reduced, and quite high practicability is achieved.

Owner:武汉钢铁有限公司

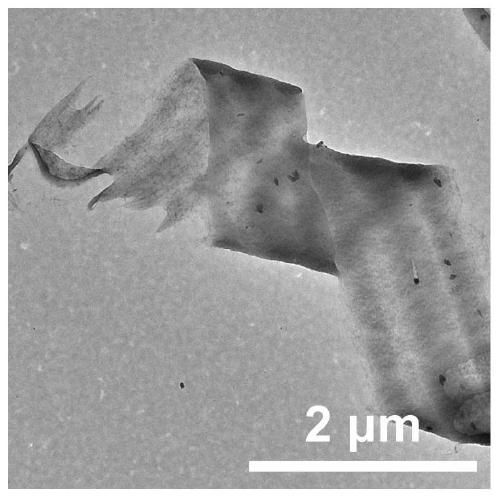

Composite lithium metal negative electrode based on MXene aerogel and synthesis method thereof

InactiveCN110429242AReduce local current densityInhibition of volume expansionElectrochemical processing of electrodesNegative electrodesSynthesis methodsNucleation

The invention discloses a composite lithium metal negative electrode based on an MXene aerogel and a synthesis method thereof, which belong to the field of lithium batteries. The composite lithium metal negative electrode comprises metal lithium and the MXene aerogel, wherein the MXene aerogel is assembled by cross-linking of two-dimensional MXene sheets and has a three-dimensional hierarchical porous structure; the MXene aerogel pores are filled with the metal lithium; and the thickness of the MXene aerogel is 300 mum to 800 mum. According to the composite lithium metal negative electrode prepared in the invention, rich pro-lithium functional groups on the surface of the MXene aerogel can be specifically combined with the lithium ions, uniform nucleation of lithium is thus realized, formation of lithium dendrites is suppressed, and the coulombic efficiency, the safety and the cycle life of the lithium metal negative electrode are effectively improved.

Owner:DALIAN UNIV OF TECH

Biodegradable Polymer Composition

InactiveUS20120077905A1Improve compatibilityFacilitates transesterificationPharmaceutical non-active ingredientsPolymer scienceSide chain

The invention relates to a biodegradable polymer composition comprising the following components (a)-(f) and / or product(s) formed from a reaction between the components: (a) one or more biodegradable polyesters; (b) polysaccharide; (c) polymer having pendant carboxylic acid groups; (d) transesterification catalyst; (e) polyepoxide; and (f) fatty acid sodium salt.

Owner:CHEN CHANGPING +1

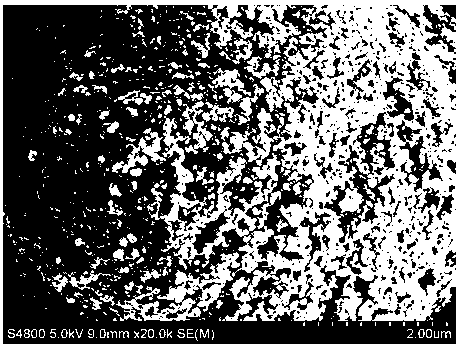

Powder catalyst for synthesizing ultrafine granular diamond

ActiveCN104226355AImprove crystal qualityLower melting temperaturePhysical/chemical process catalystsUltra-high pressure processesSingle crystalMaterials science

The invention discloses a powder catalyst for synthesizing ultrafine granular diamond. The powder catalyst is mainly prepared from the following alloying components by weight percent: 20% to 25% of Fe, 3% to 5% of Co, 0.5% to 2% of Ce, 3% to 5% of Mn, 0.5% to 1% of SiC, 0.5% to 1% of Mo and the balance being Ni. By utilizing the technical scheme of the powder catalyst, the high-purity ultrafine-particle spherical or approximately spherical powder catalyst can be prepared, and the granularity of the obtained powder catalyst is 600 to 1000 meshes. When the powder catalyst is applied to synthesis of ultrafine diamond single crystal, single-crystal diamonds within 400 meshes can be produced.

Owner:HENAN POWER NEW MATERIAL

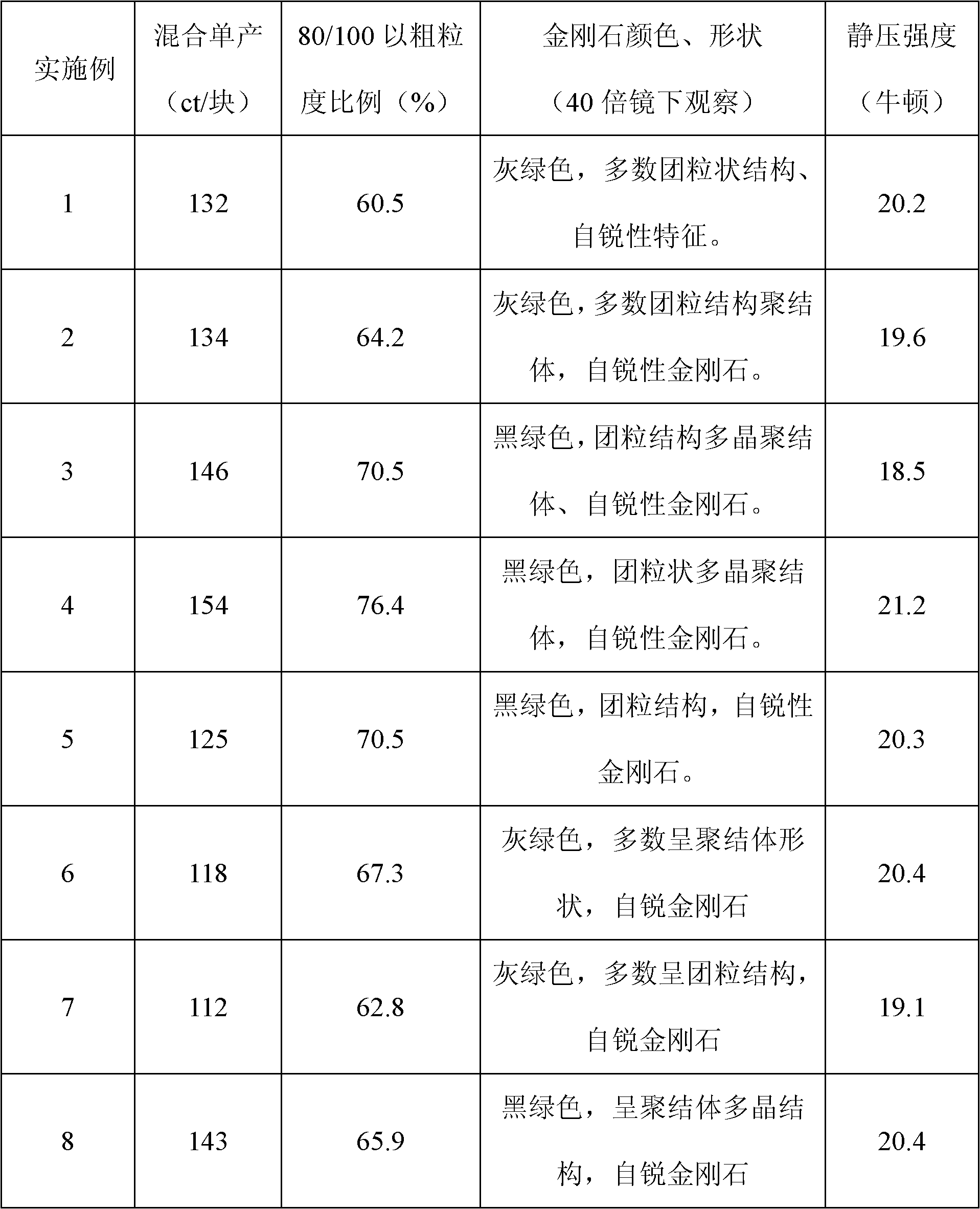

FeMnNi powder accelerant with low cost and preparation method and application

InactiveCN103170347ALow costMany holesDiamondMetal/metal-oxides/metal-hydroxide catalystsNitrogenGraphite

The invention relates to a FeMnNi powder accelerant with low cost, wherein the alloy comprises the components in percentage by weight as follows: 30-50% of Mn, 0-10% of Ni, 1-3% of Cr, 0.1-0.8% of C, 0.05-0.2% of Si and the balance of Fe. The oxygen content of a powder accelerant product optimized is less than or equal to 300ppm, and the nitrogen content is less than or equal to 180ppm. The accelerant is prepared by a gas atomization process of inertial gas, so that the accelerant powder is spherical or approximately spherical with uniform alloy composition. Diamond synthesized by the accelerant and graphite in proportion is greyish-green or dark green in color, and the crystal form of the diamond is a polygonal aggregate in a granular structure. The per mixed unit yield reaches over 154 carat / block by cavity with diameter of 40mm, the static pressure strength is average about 20N, and the coarsness proportion of 80 / 100 reaches over 60%, so that the accelerant is an ideal raw material for manufacturing an efficient diamond grinding apparatus for crisp and hard materials.

Owner:GRIMAT ENG INST CO LTD

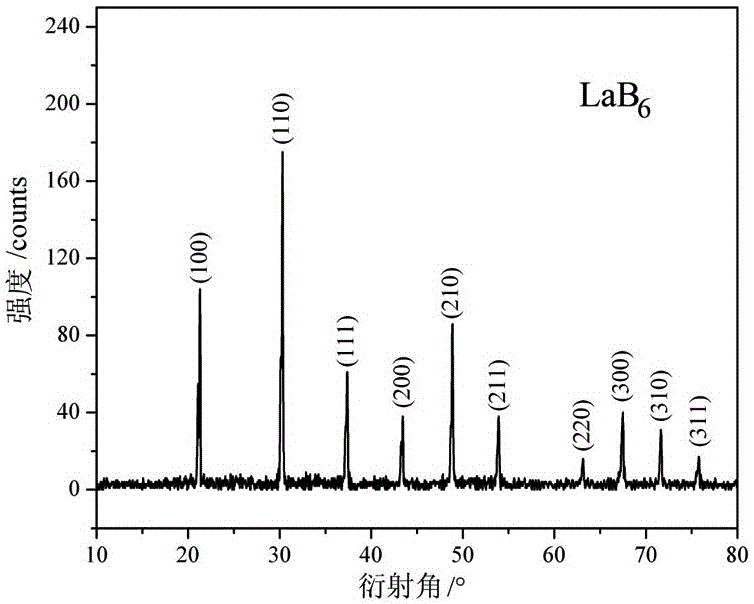

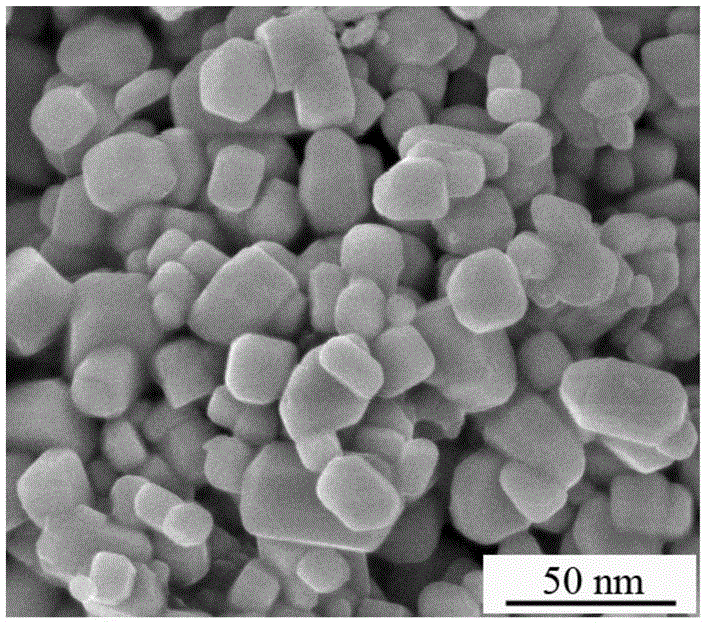

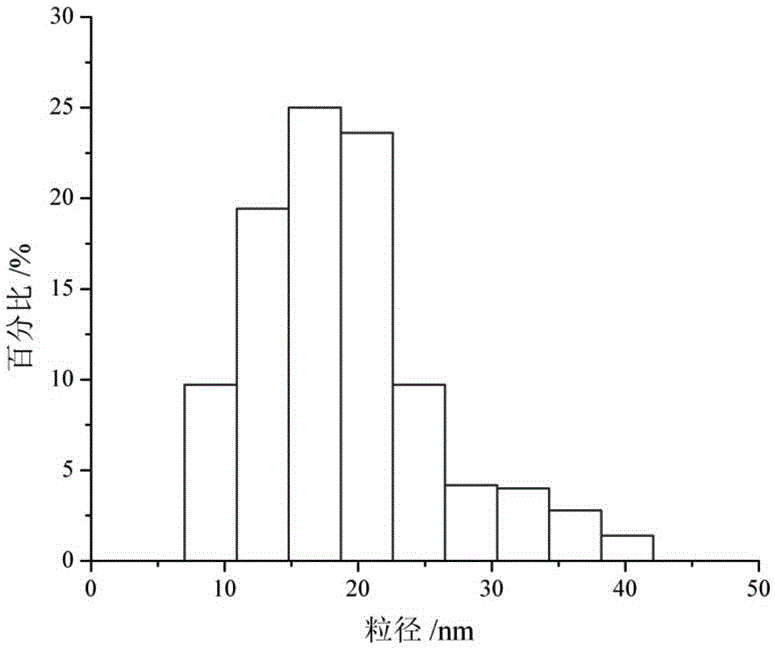

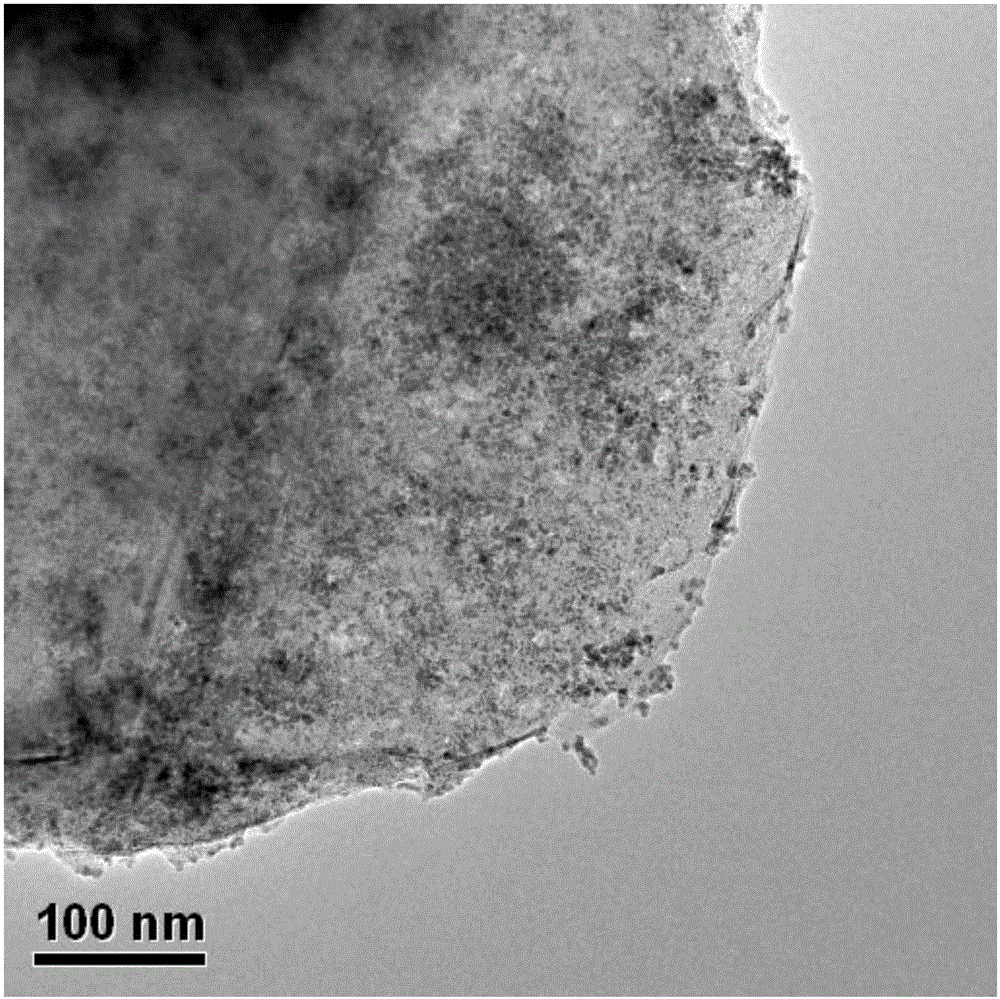

Preparation method of lanthanum hexaboride nanometer powder and application of lanthanum hexaboride nanometer powder

ActiveCN106395843AHigh purityFine and uniform particle sizeMetal boridesNanotechnologyLanthanumLiquid phase

The invention discloses a preparation method of lanthanum hexaboride nanometer powder and an application of the lanthanum hexaboride nanometer powder. The preparation method includes: mixing a lanthanum source and a boron source with fused salt prior to heating to a molten state to enable the lanthanum source and the boron source to perform liquid phase reaction in the fused salt and allow the lanthanum source to be reduced to lanthanum hexaboride by the boron source, and obtaining an initial product after cooling; washing and filtering the initial product to remove the fused salt, and obtaining the lanthanum hexaboride nanometer powder after drying. The preparation method has the advantages that the prepared lanthanum hexaboride nanometer powder is controllable in particle size, uniform in particle size, agglomeration free, high in purity, wide in source of raw materials, low in reaction temperature, simple and controllable in process, free from specific requirements on equipment, low in cost and the like, the lanthanum hexaboride nanometer powder prepared with the method can be used for preparing lanthanum hexaboride blocks or coated cathode electron emitter materials, and high application value is achieved.

Owner:NAT UNIV OF DEFENSE TECH

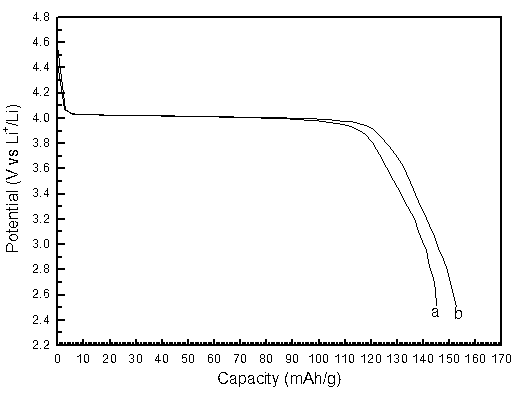

Method for preparing lithium manganese phosphate positive material of lithium battery by spray pyrolysis

The invention relates to a method for preparing a lithium manganese phosphate positive material of a lithium battery by spray pyrolysis and belongs to the technical field of the positive materials of lithium batteries. According to the method, homogeneous nucleation of lithium manganese phosphate is promoted through the high-temperature spray pyrolysis under the condition of an inert atmosphere, so as to reduce the temperature and the time of the follow-up reaction to obtain the lithium manganese phosphate positive material with excellent electrochemical performance. The method disclosed by the invention is simple; and since raw materials are mixed in molecular ion level and the temperature and the time of the follow-up reaction are reduced after the high-temperature spray pyrolysis, the obtained lithium manganese phosphate material has the advantages of high purity, complete crystal structure, fine and uniform particles and the excellent electrochemical performance.

Owner:DONGFANG ELECTRIC CORP LTD

Composite lithium metal negative electrode based on MXene nanoribbon and general synthesis method of composite lithium metal negative electrode

ActiveCN111293276AFix production issuesSolve application problemsElectrochemical processing of electrodesElectrode carriers/collectorsPolymer dissolutionMetallic lithium

The invention discloses a composite lithium metal negative electrode based on an MXene nanoribbon and a general synthesis method of the composite lithium metal negative electrode, and belongs to the field of lithium batteries. The MXene nanoribbon is formed by overlapping two-dimensional MXene nanosheets in a staggered manner along the axial direction. The preparation method comprises the steps ofpreparing MXene / polymer composite fibers with a core-shell structure by utilizing an electrostatic spinning machine, selectively removing the high-molecular polymer of the core by utilizing the difference of the solubility of different polymers and adopting a water solvent, and expanding the shell layer at the same time to obtain an MXene nanoribbon structure with controllable structure and size;and depositing lithium metal into pores or cavities of a three-dimensional current collector formed by the MXene nanoribbon through an electro-deposition method to obtain the composite lithium metalnegative electrode. The MXene nanoribbon structure prepared by the invention can effectively reduce the local current density of the electrode and inhibit the volume expansion of metal lithium. Meanwhile, rich lithium-philic functional groups on the surface of MXene can be specifically combined with lithium ions, uniform nucleation of lithium is achieved, generation of lithium dendrites is inhibited, the safety of the lithium metal battery is improved, and the basic problem puzzling large-scale production of the lithium metal battery is solved.

Owner:DALIAN UNIV OF TECH

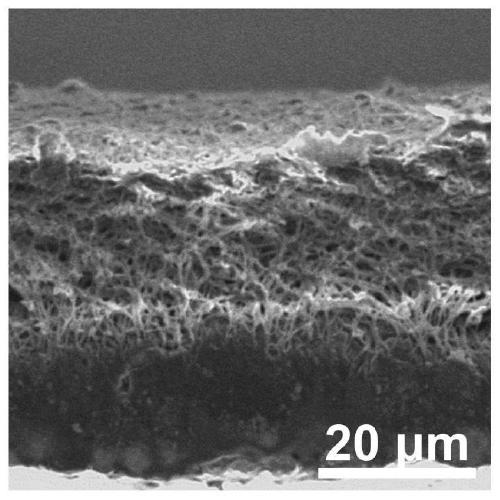

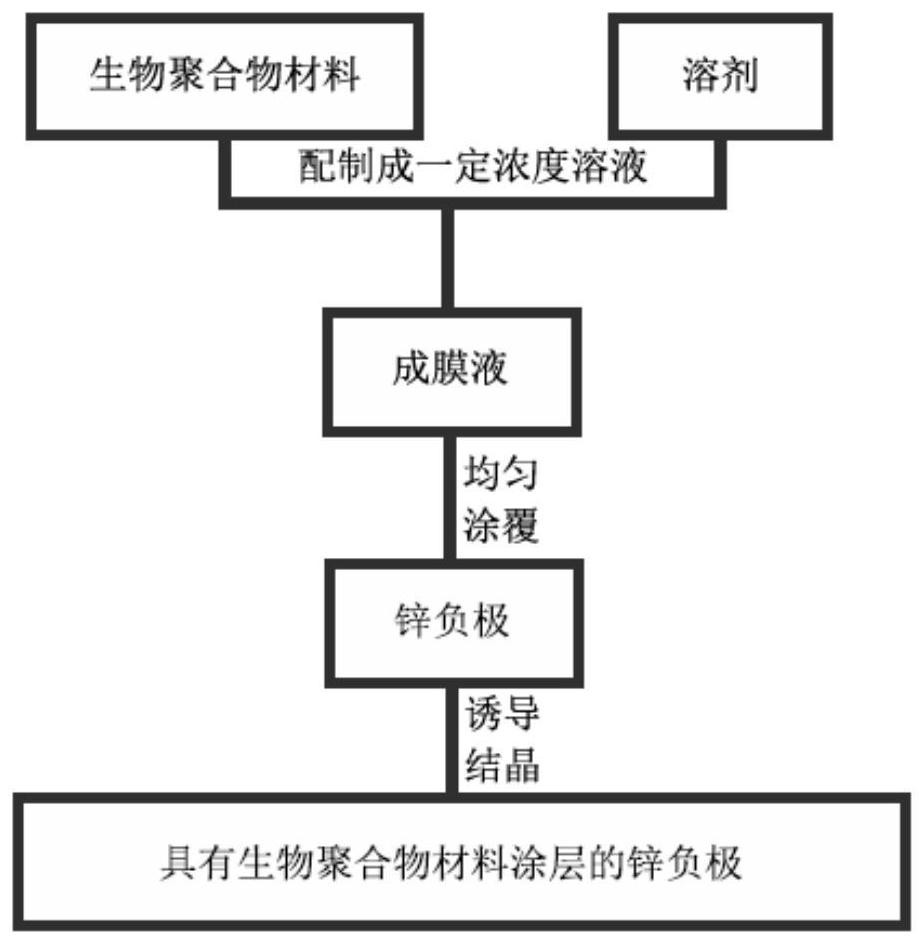

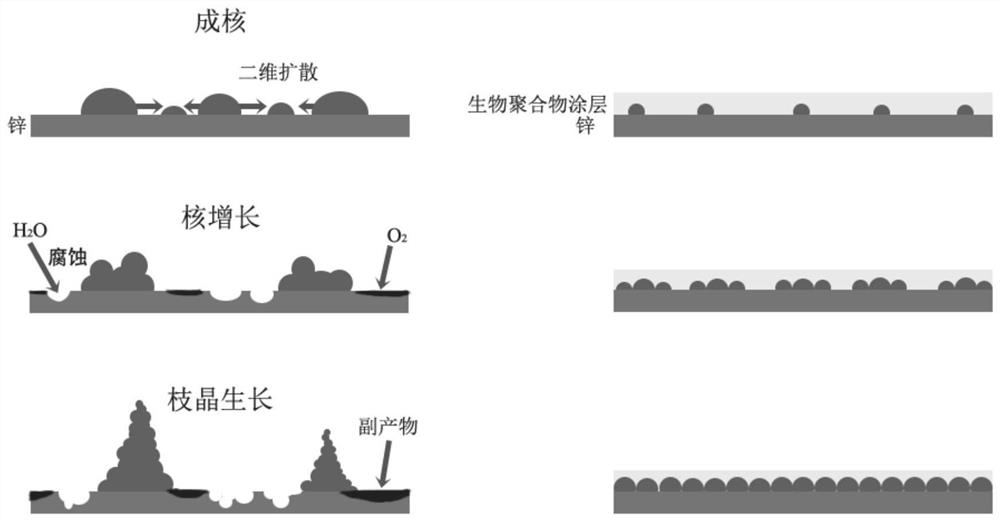

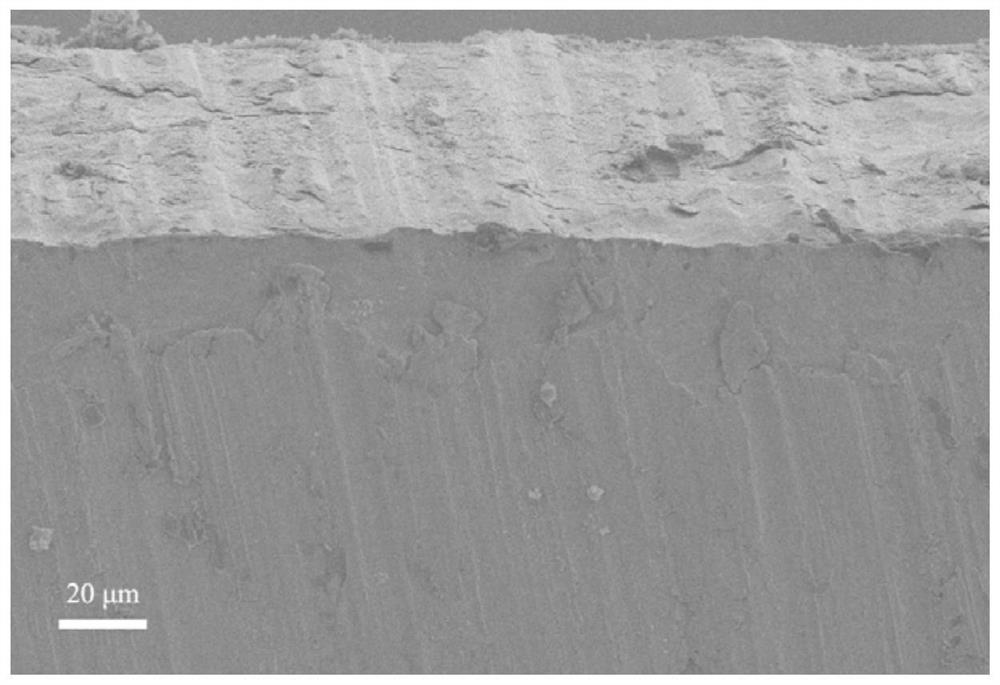

Electrode with biopolymer coating and preparation method thereof

PendingCN112563446AReduces corrosion and passivationPromotes uniform nucleationSecondary cellsElectrode collector coatingElectrical batteryElectrolyte

The invention discloses an electrode with a biopolymer coating and a preparation method of the electrode. According to the method, a film forming solution prepared by dissolving biopolymer, gel and zinc salt in a solvent is used for uniformly coating an electrode, and then a crystallization method is used for inducing a coating material to crystallize, so that the electrode with a uniform biopolymer coating is obtained. The contact between water and oxygen in the aqueous battery and the electrode is reduced through the hydrophobic group of the biopolymer, and the corrosion and passivation of the electrolyte to the electrode are effectively reduced. And the biopolymer coating can increase the nucleation barrier, effectively inhibit the growth of zinc dendrites, improve the cycle performanceof the aqueous zinc battery and prolong the service life of the aqueous zinc battery.

Owner:YANGZHOU UNIV

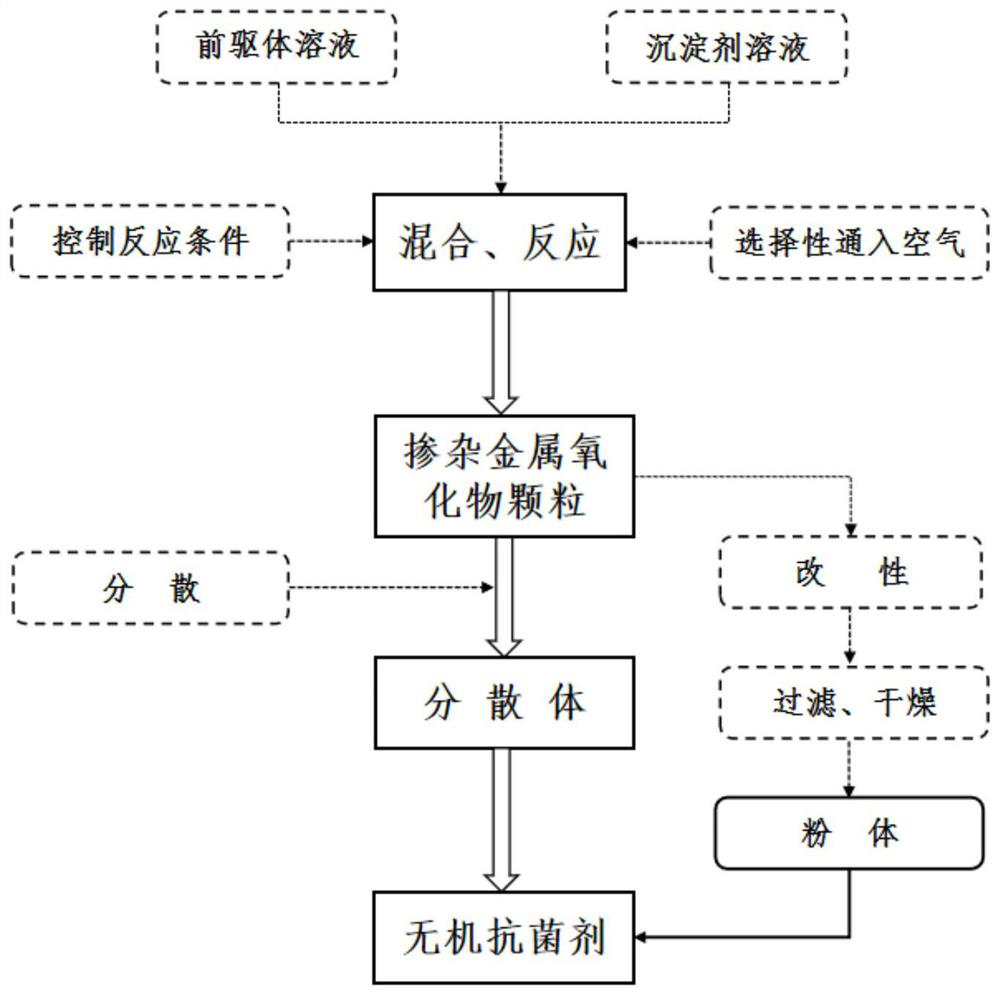

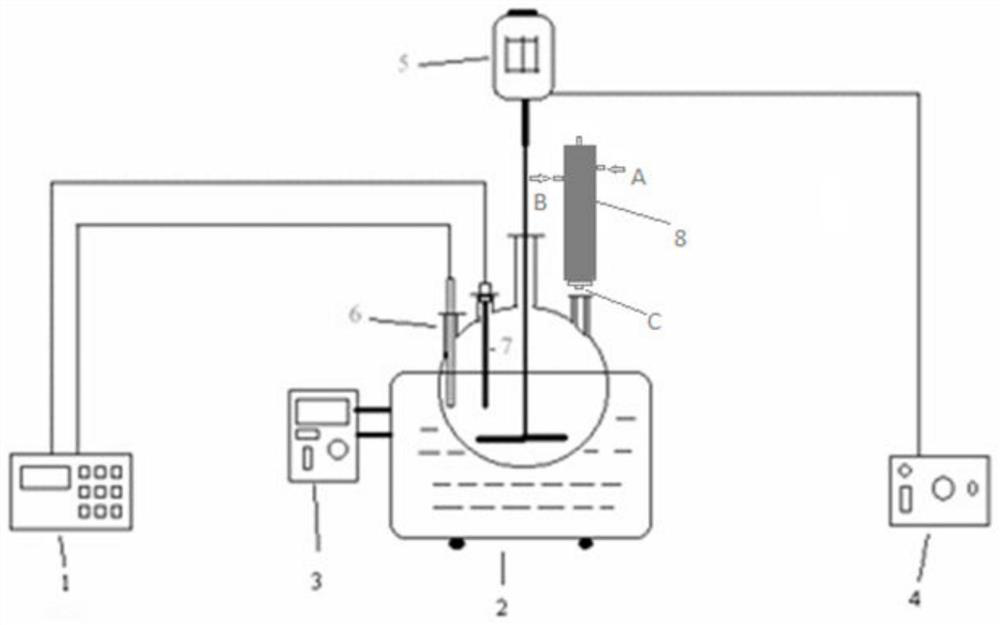

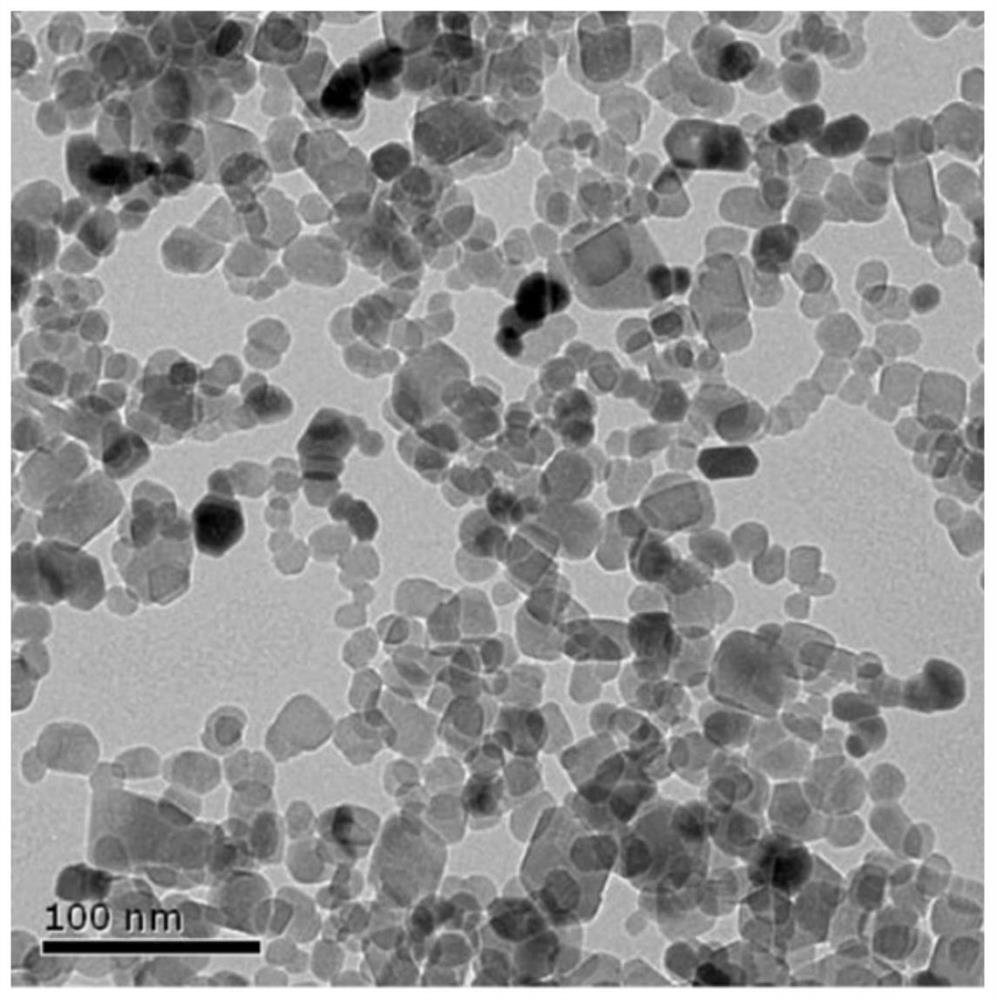

Preparation method of metal oxide doped nanoparticle, dispersoid or powder for resisting bacteria and preventing mildew

ActiveCN113287635AUniform responseMicroscopically mixed evenlyBiocideAntifouling/underwater paintsMildewAnti bacterial

The invention discloses a metal oxide doped nanoparticle, dispersoid or powder for resisting bacteria and preventing mildew and a preparation method thereof The metal oxide doped nanoparticle, dispersoid or powder for resisting bacteria and preventing mildew is prepared by the following preparation method: 1) providing a metal oxide-doped precursor solution and a precipitant solution; 2) reacting the doped metal oxide precursor solution and the precipitant solution in a high-shear strong mixing state to obtain doped metal oxide particles; (3) carrying out post-treatment and dispersion on the doped metal oxide particles to form a dispersion or drying to obtain powder; in the doped metal oxide, the main phase metal is a transition metal element, and the doped element is one or more than two of a main group element or a subgroup element. The obtained doped metal compound particles are effective components of an inorganic antibacterial agent, and are good in antibacterial effect and mildew-proof effect.

Owner:XIANGTAN UNIV +1

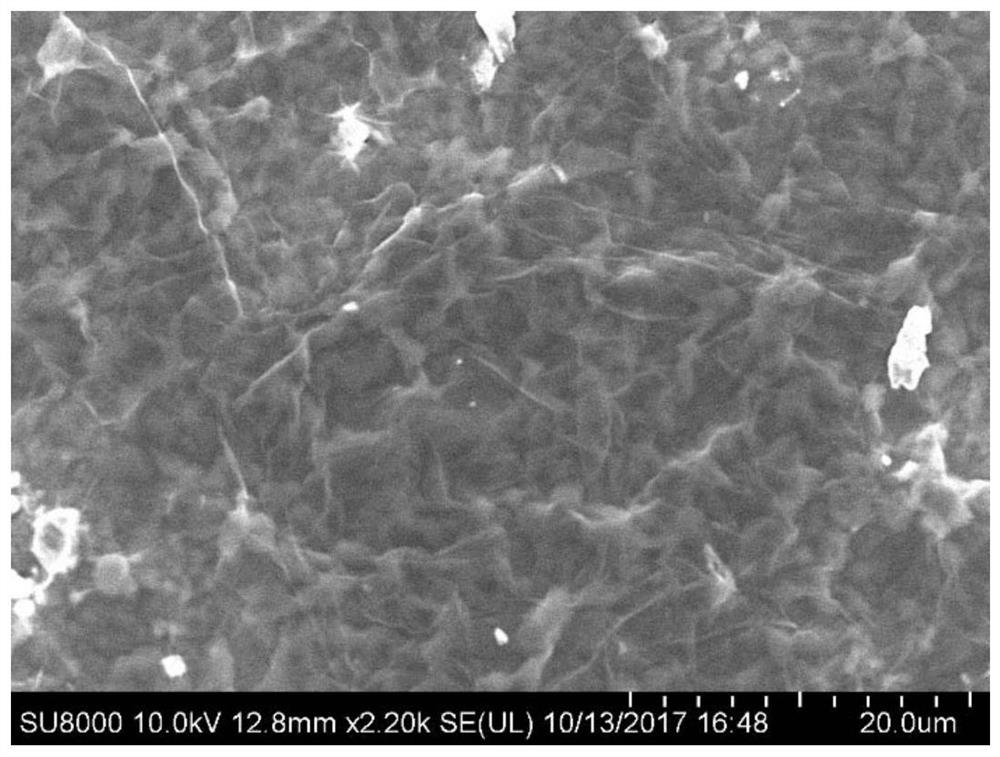

Preparation method of low-temperature high-magnetic induction grain-oriented silicon steel

ActiveCN109136503AHeating fastRapid heating technology is to increase the temperature rise of decarburization annealingAverage sizeSteel belt

The invention relates to the technical field of metallurgy, in particular to a preparation method of low-temperature high-magnetic induction grain-oriented silicon steel. The method includes the steps: smelting; casting blank heating; hot rolling; normalizing; cold rolling; decarburizing annealing; nitriding annealing; coating of high-temperature annealing separating agents; high-temperature annealing; stretching, leveling, insulating layer coating and annealing. The decarburizing annealing process comprises a heating stage and a soaking stage, the heating speed nu of a steel belt is 150DEGC / s-1500 DEG C / s, the temperature rises to 700 DEG C to the temperature of the soaking stage at the heating stage, and the temperature of the soaking stage is 825-845 DEG C. According to the method, by the aid of a rapid heating technique in the decarburizing annealing process, decarburizing annealing time is calculated, the average size and a size fluctuation coefficient of a primary crystal particle after nitriding treatment are defined according to the heating speed, the size of a primary crystal of the low-temperature high-magnetic induction grain-oriented silicon steel is controlled, and uniformity is improved, so that the magnetic performance of the silicon steel is improved.

Owner:武汉钢铁有限公司

Controlled nucleation during freezing step of freeze drying cycle using pressure differential ice fog distribution

ActiveUS20120272544A1Prolong nucleation timeReduce uniformityDrying solid materials without heatFreeze-dryingProcess engineering

A method of controlling and enhancing the nucleation of product in a freeze dryer, wherein the product is maintained at a predetermined temperature and pressure in a chamber of the freeze dryer, and a predetermined volume of ice fog is created in a condenser chamber separate from the product chamber and connected thereto by a vapor port. The ice fog has a predetermined pressure that is greater than that of the product chamber, and is rapidly conveyed through the vapor port into the product chamber for even distribution therein to create uniform and rapid nucleation of the product in different areas of the product chamber.

Owner:MILLROCK TECH

Fluorescent latex particles and preparation method thereof

ActiveCN102174144AUniform nucleationTightly boundLuminescent compositionsFluorescenceUltrapure water

The invention provides a method for preparing fluorescent latex particles, which comprises the following steps of: a) mixing an acrylic ester monomer, a fluorescent dye and ultrapure water in a weight ratio of (1-15):(0.004-0.4):100, stirring, heating, and performing soap-free emulsion polymerization under the action of an initiator to obtain a first reaction product; and b) filtering and centrifuging the reaction product obtained in the step a), removing supernatant, and washing residues left after the supernatant is removed to obtain the fluorescent latex particles. Process conditions in the preparation method are mild, and the prepared fluorescent latex particles have a uniform and controllable particle size and high monodispersity.

Owner:SINOCARE

Preparation method for novel negative electrode material of lithium ion battery

InactiveCN105742597AReduce the rate of hydrolysisUniform nucleationMaterial nanotechnologyCell electrodesChemistryUrea

The invention relates to a preparation method for a novel negative electrode material of a lithium ion battery, belongs to the technical field of a lithium ion battery material, and aims to provide a preparation method for a novel nanometer SnO<2> / C composite negative electrode material of the lithium ion battery. The preparation method for the novel negative electrode material of the lithium ion battery comprises the steps of dissolving a tin source into a mixed acetone water system, stirring until the tin source is fully dissolved, then adding urea and polyvinylpyrrolidone, stirring for 2-5h, then adding expanded graphite, next, moving the solution to a hydrothermal reaction kettle, and performing hydrothermal synthesis at a temperature of 90-130 DEG C for 2-10h, naturally cooling the reaction kettle to the room temperature, and performing suction filtration, washing and drying on the obtained product, and baking under an inert atmosphere at a temperature of 600 DEG C for 3h to obtain the nanometer SnO<2> / C composite negative electrode material of the lithium ion battery.

Owner:SHANXI UNIV

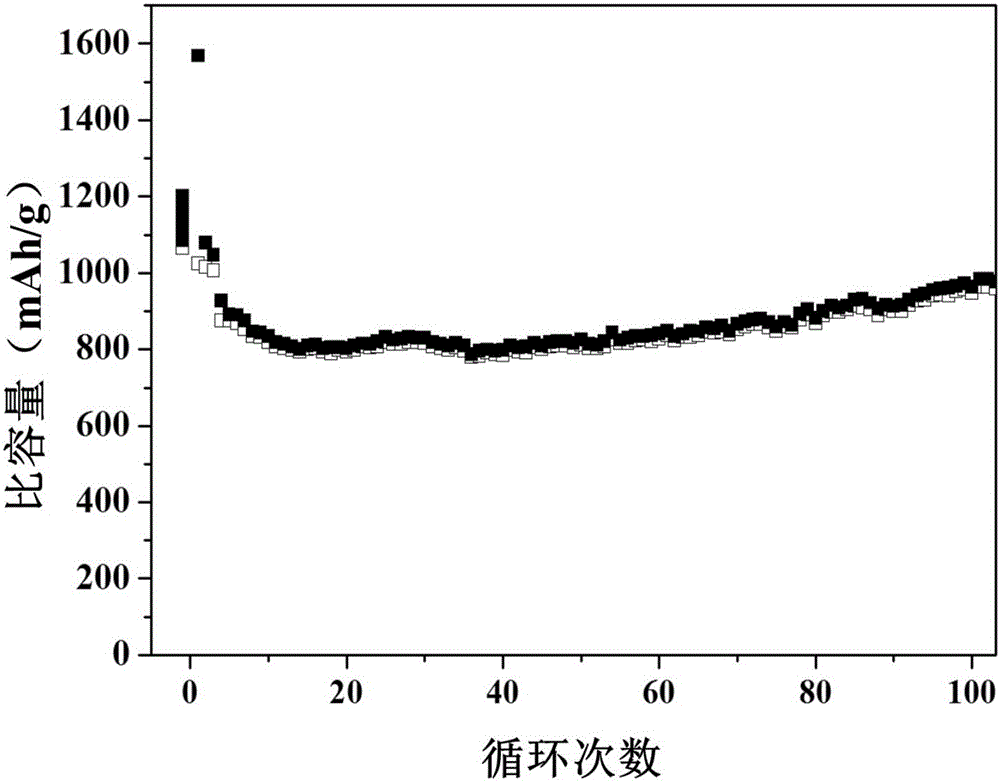

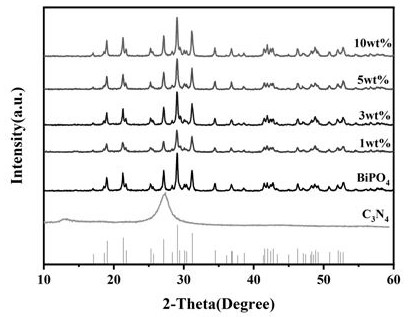

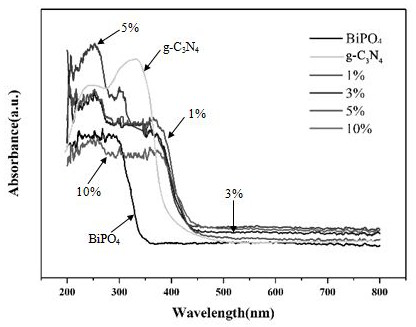

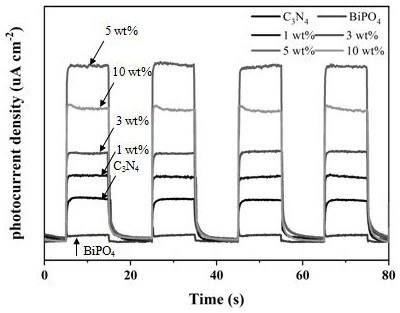

Bismuth phosphate-based heterojunction photocatalyst and preparation method thereof

InactiveCN112138700AEfficient separationUniform nucleationPhysical/chemical process catalystsHeterojunctionMicrowave method

The invention discloses a bismuth phosphate-based heterojunction photocatalyst and a preparation method thereof. The photocatalyst is a heterojunction photocatalyst constructed by bismuth phosphate and graphite-phase carbon nitride. The preparation method comprises the following steps: preparing nanorod-like BiPO4 by a microwave method, preparing light and thin g-C3N4 by a calcining method grinding and compounding g-C3N4 and BiPO4 through a ball milling method to obtain a heterojunction photocatalytic material g-C3N4 / BiPO4; the prepared heterojunction photocatalyst is high in activity, high inlight utilization rate, good in stability and reusability, simple in preparation process, economical, efficient and good in application prospect.

Owner:NANJING INST OF ENVIRONMENTAL SCI MINIST OF ECOLOGY & ENVIRONMENT OF THE PEOPLES REPUBLIC OF CHINA +1

Production method for medium-high carbon high-strength steel homogenized casting blank

The invention relates to a production method for a medium-high carbon high-strength steel homogenized casting blank. The invention adopts the technical scheme that the production method comprises the step that a compound filler cored wire is fed into medium-high carbon high-strength molten steel in a continuous casting crystallizer or an ingot mold, wherein the fed compound filler cored wire accounts for 0.3 to 1.2 percent by weight of the medium-high carbon high-strength molten steel, the feeding speed Vband of the compound-filled cored wire is equal to A*Vcasting*(Ttundish -Tliqudus) / Tliqudus, and the vibrating frequency of a band feeding machine is 50-35,000 Hz; the compound filler cored wire is a mixture of passivated iron sand and a high-melting-point carbonitride, the carbonitride accounts for 1-10 percent by weight of the compound filler cored wire, and the high-melting-point carbonitride is a carbonitride formed by Zr and / or Nb. The production method provided by the invention is simple in process, low in cost and convenient to operate; the macrostructure of the produced medium-high carbon high-strength steel homogenized casting blank is obviously improved, and axial / central segregation and internal cracks caused by chemical elements are remarkably reduced or eliminated, so that the plasticity and toughness of a rolled steel plate are improved.

Owner:WUHAN UNIV OF SCI & TECH

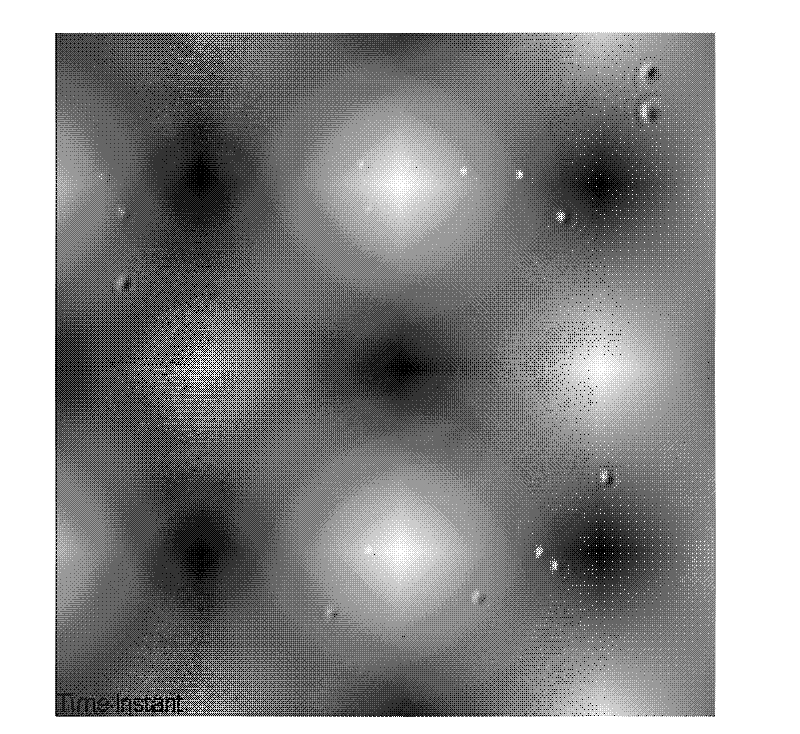

Controlled nucleation during freezing step of freeze drying cycle using pressure differential ice fog distribution

ActiveUS8839528B2Reduce uniformityProlong nucleation timeDrying solid materials without heatDrying gas arrangementsFreeze-dryingProcess engineering

A method of controlling and enhancing the nucleation of product in a freeze dryer, wherein the product is maintained at a predetermined temperature and pressure in a chamber of the freeze dryer, and a predetermined volume of ice fog is created in a condenser chamber separate from the product chamber and connected thereto by a vapor port. The ice fog has a predetermined pressure that is greater than that of the product chamber, and is rapidly conveyed through the vapor port into the product chamber for even distribution therein to create uniform and rapid nucleation of the product in different areas of the product chamber.

Owner:MILLROCK TECH

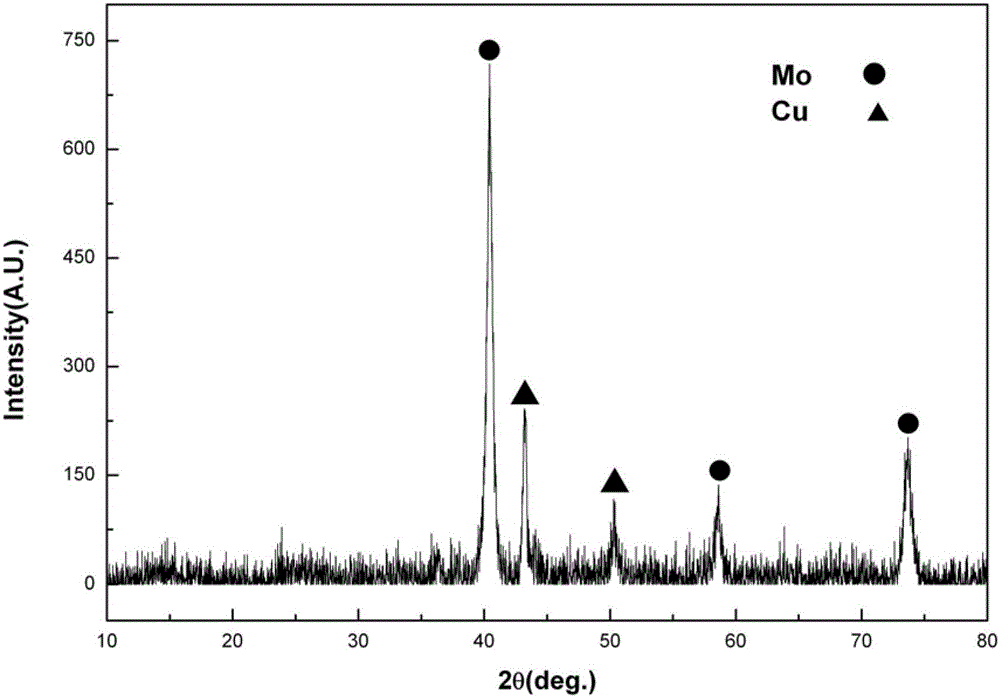

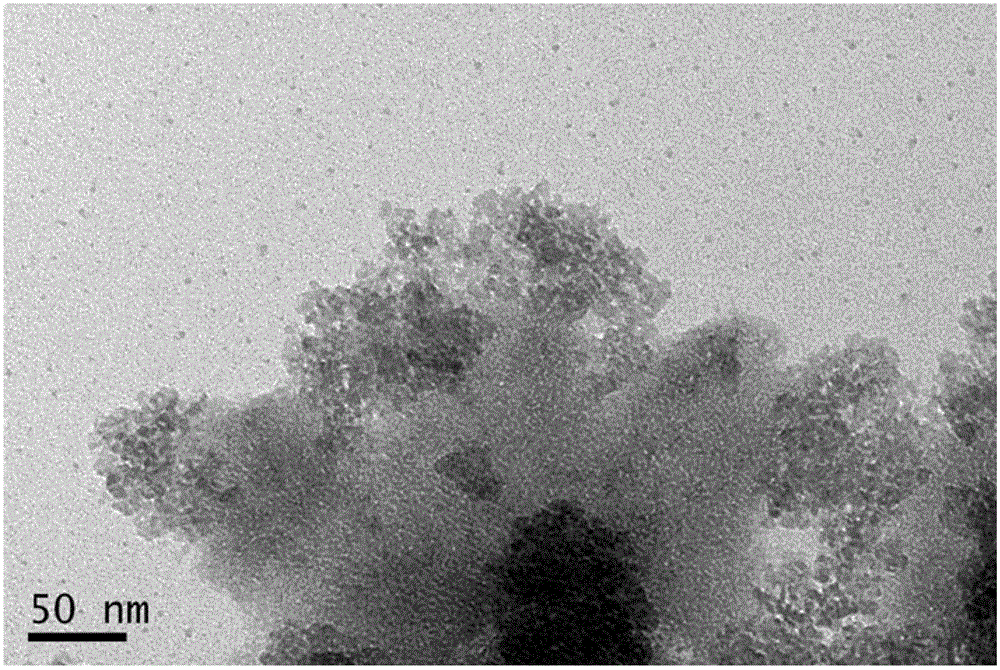

Method for reducing and preparing nano molybdenum-copper composite powder with low temperature

A method for reducing and preparing nano molybdenum-copper composite powder with low temperature comprises two steps: step 1, preparing molybdenum-copper oxide precursor, and step 2, preparing nano molybdenum-copper composite powder. In step 1, a water solution of molybdenum salt and an ammonia water solution of copper salt are mixed, the mixed solution is heated through micro-wave heating for fast concentration, and resolvents are removed to obtain molybdenum-copper oxide precursor powder; and in step 2, molybdenum-copper oxide precursor powder is heated to be 325 to 400 DEG C, calcined, taken out of a stove, cooled by air, and then heated to 525 to 625 DEG C for reducing after being placed in an H2 atmosphere, so as to obtain nano molybdenum-copper composite powder. The nano molybdenum-copper composite powder prepared according to the method has the advantages that the specific surface area is large; the crystal grains are fine and the purity is high. As molybdenum-copper oxide precursor powder is prepared by combining a simple and effective liquid phase chemical method with micro-wave heating, and nano molybdenum-copper composite powder is prepared through calcining and reducing, the method provided by the invention is simple and fast; the process is easy to control; the powder yield is large; the efficiency is high; the reducing temperature of powder is greatly reduced; and suitability for industrialized mass production is realized.

Owner:CENT SOUTH UNIV

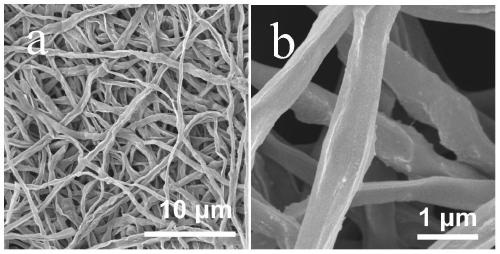

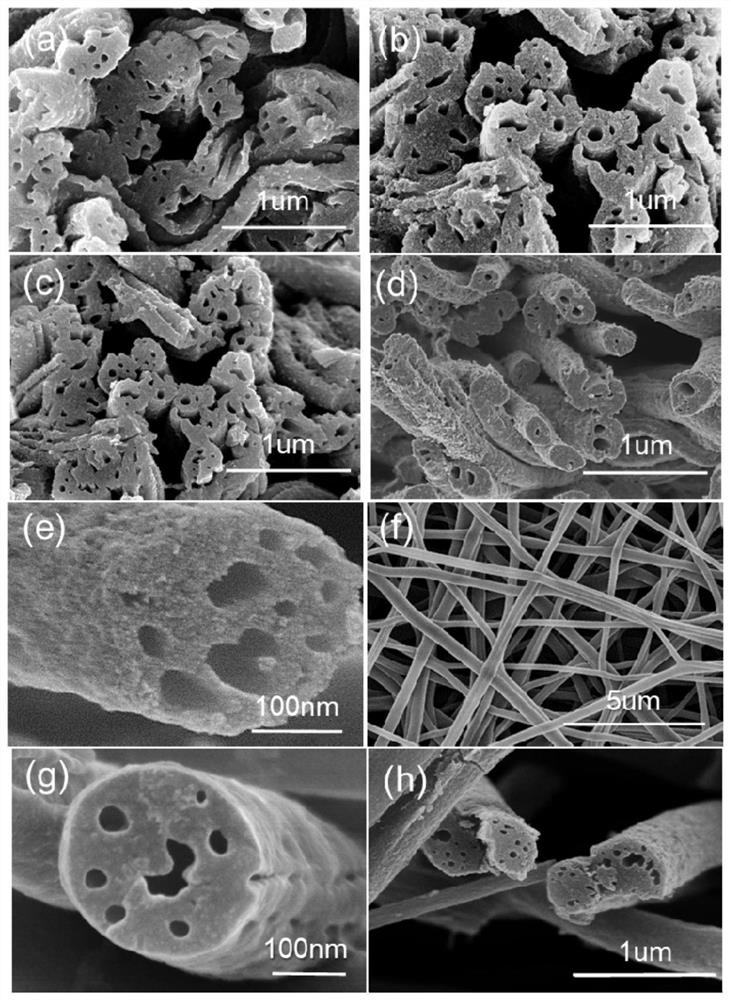

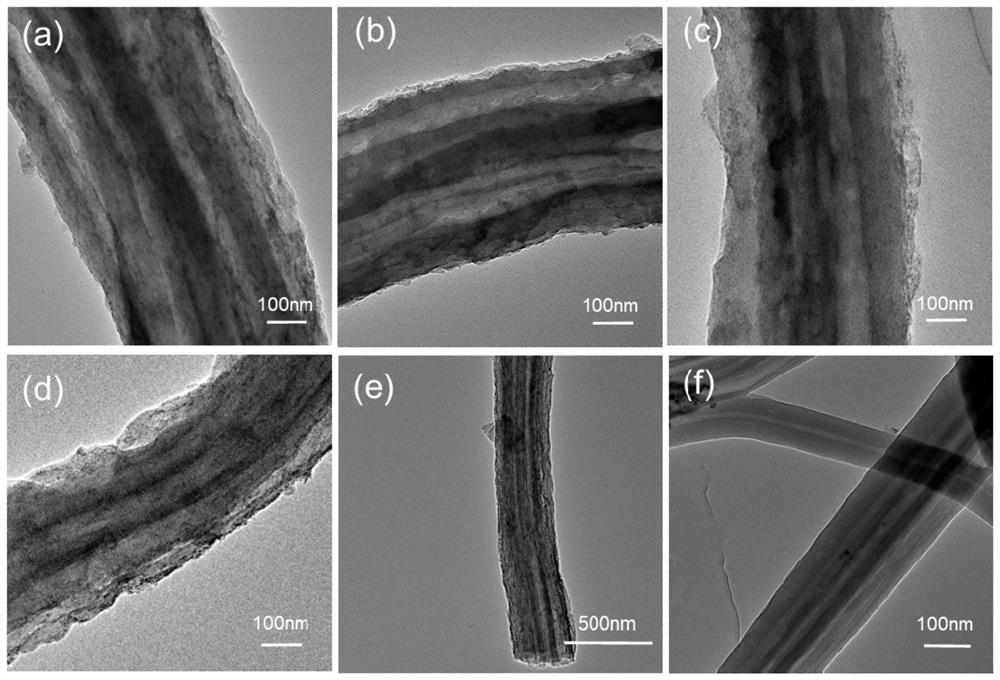

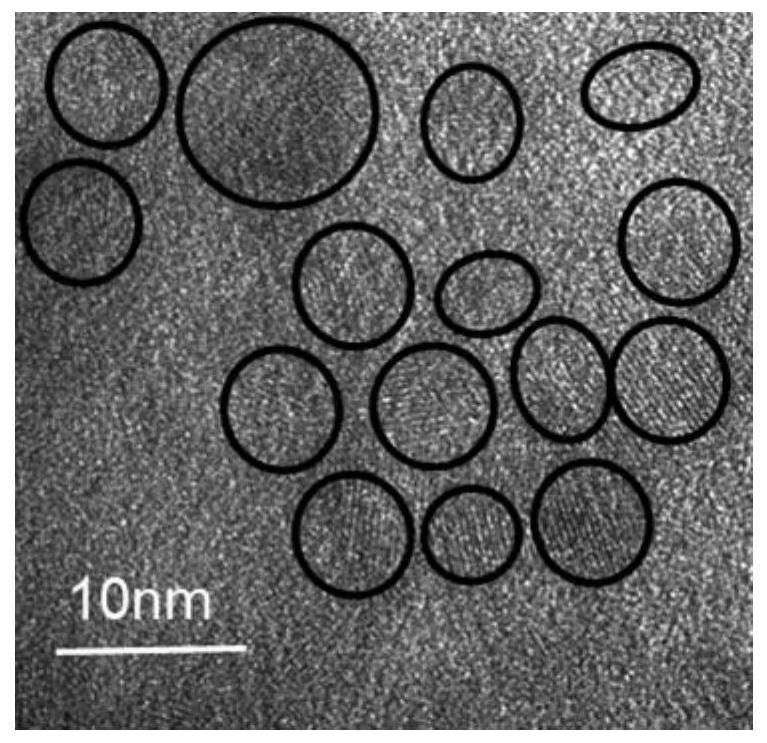

Porous multi-hollow flexible composite nanofiber membrane material and preparation method thereof

ActiveCN113073426AImprove flexibilityHigh mechanical strengthHollow filament manufactureNon-woven fabricsHollow fibreFiber

The invention relates to a porous multi-hollow flexible composite nanofiber membrane material and a preparation method thereof. According to the method, a porous multi-hollow flexible composite nanofiber membrane is prepared through coaxial electrostatic spinning, wherein an outer layer solution for coaxial electrostatic spinning consists of a sacrificial high-molecular polymer, a retained high-molecular polymer and a solvent A, and an inner layer solution for coaxial electrostatic spinning is composed of a sacrificial high-molecular polymer, a material capable of generating a substance with semiconductor characteristics and low surface energy in the spinning process, and a solvent B; and then the sacrificial high-molecular polymer in the porous multi-hollow flexible composite nanofiber membrane is removed to obtain the membrane material formed by stacking porous multi-hollow nanofibers, wherein the porous multi-hollow nanofibers are provided with a plurality of hollow pipelines and three-dimensional penetrating through hole micro-nano structures with the hollow surfaces. The membrane material disclosed by the invention has relatively high flexibility and mechanical strength, and the problems of fragility, low mechanical strength and the like of a porous composite fiber material and a single hollow fiber material are solved.

Owner:DONGHUA UNIV

Production method of medium-low carbon high-strength steel homogenized casting blank

The invention relates to a production method of a medium-low carbon high-strength steel homogenized casting blank. The invention adopts the technical scheme as follows: the production method comprises the following step: feeding a cold steel belt into medium-low carbon high-strength molten steel inside a continuous casting machine crystallizer or an ingot mold, wherein the cold steel belt accounts for 0.3-1.0% of the medium-low carbon high-strength molten steel by weight; the cold steel belt feeding speed Vband is equal to A*Vcasting*(Ttundish-Tliqudus) / Tliquidus; the vibration frequency of a belt feeder is 50-35000 Hz; the cold steel belt comprises 0.2-0.65% of C or 1-3% of silicon by weight; the melting point of the cold steel belt is 3-30 DEG C lower than that of the cast casting blank; the surface of the cold steel belt is coated with anti-rusting oil; the thickness of the cold steel belt is 1-6 mm. The production method disclosed by the invention is simple in process, low in cost and convenient to operate; the macrostructure of the produced medium-low carbon high-strength steel homogenized casting blank is obviously improved, the axial / center segregation and internal cracks caused by chemical elements are obviously weakened or eliminated, the ductility and the toughness of the rolled steel plate are improved, the HIC detection qualification rate of the engineering structure steel and the corrosion-resisting steel is increased.

Owner:WUHAN UNIV OF SCI & TECH

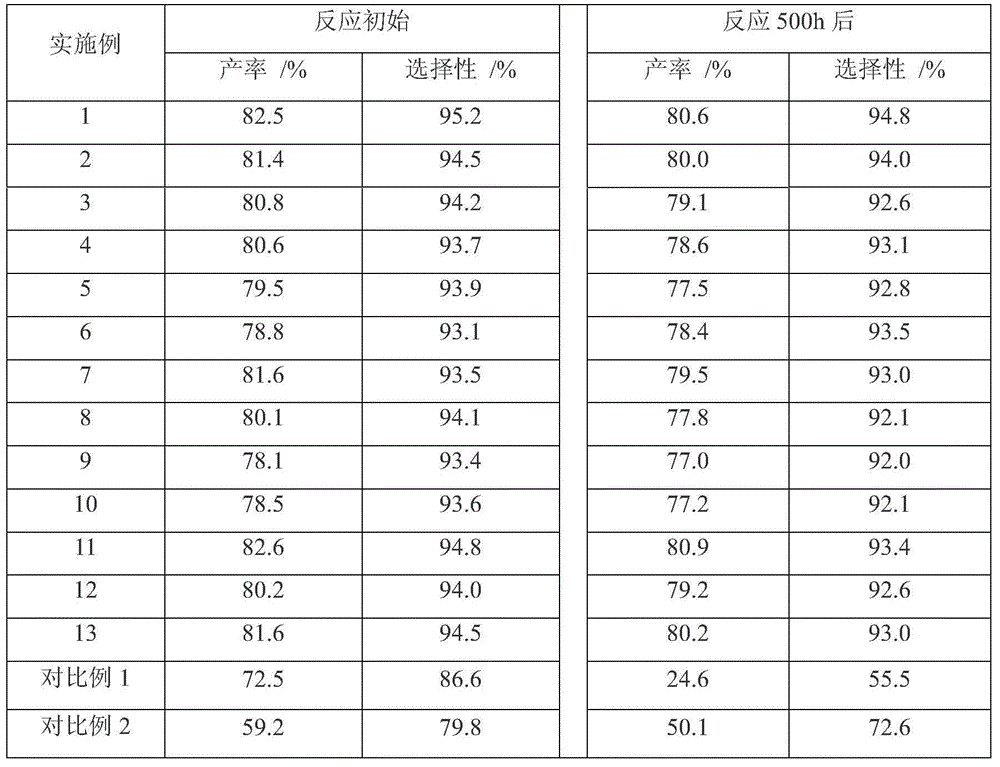

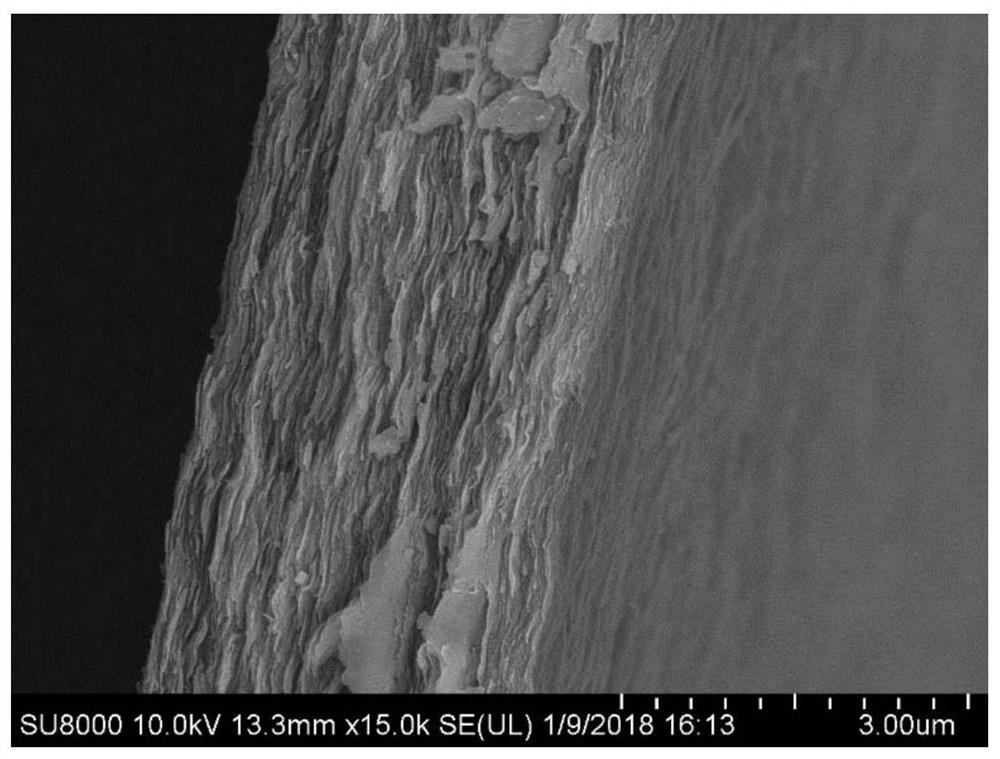

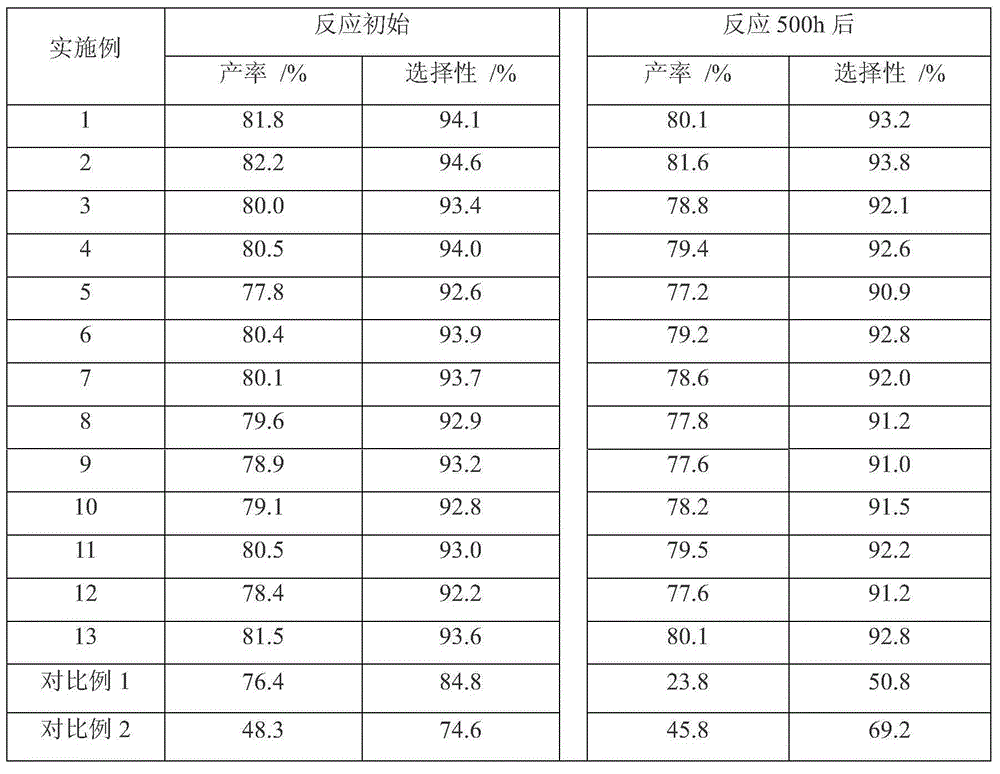

Butylene oxidative dehydrogenation used for fixed beds, and preparation method thereof

ActiveCN105749931AHigh activityImprove stabilityHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsNitrateFixed bed

The main composition of a butylene oxidative dehydrogenation used for fixed beds is AaBbCcDd.FexOe, wherein a is 2-10, b is 0.01-0.1, c is 0.01-0.5, d is 0.01-0.5, x is 6-20, e is a value meeting valence requirements, A is Cr, Co or Cu, B is W, C is Ca, Mg, Sr or Ba, and D is K, V or Zn. The invention also provides a preparation method of the catalyst. The method comprises the following steps: processing metal precursors, sequentially adding the processed precursors to a certain concentration of an iron nitrate solution, reacting, and adding a certain amount of a binder to obtain a precursor precipitate slurry; gradually adding ammonia water to the slurry to adjust the pH value of the slurry; carrying out thermal modification on the slurry at a certain temperature; filtering and washing the slurry, filtering the slurry, and carrying out strip extrusion molding; and carrying out roasting modification at 100-500DEG C for 12-28h to obtain the finished catalyst.

Owner:PETROCHINA CO LTD

Transition metal carbon/nitride-based current collector for negative electrode of metal secondary battery as well as preparation method and application of transition metal carbon/nitride-based current collector

InactiveCN111952596AUniform growthLight weightElectrode carriers/collectorsLi-accumulatorsChemical physicsElectrical battery

The invention provides a transition metal carbon / nitride-based current collector for a negative electrode of a metal secondary battery as well as a preparation method and application of the transitionmetal carbon / nitride-based current collector, and the method can be used for better controlling the content of polar functional groups on the surface and between layers of the current collector and preparing a flexible and bendable current collector. When the atomic percentage content of polar functional groups on the surface and between layers of the current collector is in the range of 43-55%,metal ions can be induced to be uniformly deposited in the charge-discharge cycle process, so that the problem that dendrites are easily generated on a metal negative electrode is solved, the safety of the metal secondary battery is improved, and the cycle life of the metal secondary battery is prolonged. Moreover, the current collector does not contain metal, so that the current collector has thecharacteristic of light weight, the overall energy density of the metal negative electrode can be further improved, and compared with the prior art, the secondary metal negative electrode prepared byadopting the current collector has the advantages of long cycle life, high safety, high energy density, capability of being applied to flexible wearable equipment and the like.

Owner:HUAZHONG AGRI UNIV

Preparation method of lithium iron phosphate/graphene flaky composite material

ActiveCN107611385AEasy to prepareUniform nucleationCell electrodesSecondary cellsLithium iron phosphateNanofiber

The invention relates to a preparation method of a lithium iron phosphate / graphene flaky composite material, which comprises the following steps of: preparing high molecule spinning precursor solution; preparing a high-molecular polymer nanofiber membrane; preparing lithium iron phosphate precursor slurry; and preparing a graphene oxide-lithium iron phosphate precursor high-molecular polymer composite thin film, and calcining to obtain the lithium iron phosphate / graphene flaky composite material. The preparation method is simple; the prepared composite material is of a flaky structure and uniform in thickness; a template is easy to remove; and the lithium iron phosphate / graphene flaky composite material has excellent electrochemical performance.

Owner:山东丽芳洁环保材料有限公司

Supported catalyst used for butylene oxidative dehydrogenation to prepare butadiene, and preparation method thereof

ActiveCN105749928AHigh activityImprove stabilityHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsFixed bedDehydrogenation

The invention relates to a supported catalyst used for butylene oxidative dehydrogenation to prepare butadiene, and a preparation method thereof. The method is characterized in that the butylene oxidative dehydrogenation catalyst is prepared through co-precipitation, dipping, roasting modification and grinding molding steps, and the general formula of the prepared catalyst is AaBbCcDd.FexOe, wherein A is one of Cu, Zn, Cr and Ni, B is one of Co, Mn, Mo and Sn, C is one of Ca, Sr, Ba and Mg, and D is W. The catalyst is used in fixed bed butylene oxidative dehydrogenation for preparing butadiene, the butadiene yield is 77-82%, and the butadiene selectivity is 92-95%.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com