Stable lithium metal negative electrode

A technology of lithium metal negative electrode and lithium metal, which is applied in the field of lithium metal negative electrode, can solve the problems of battery capacity loss, reduction of electrode volume energy density, and damage of solid electrolyte interfacial film, so as to reduce effective current density, facilitate industrialization, and benefit The effect of ion transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

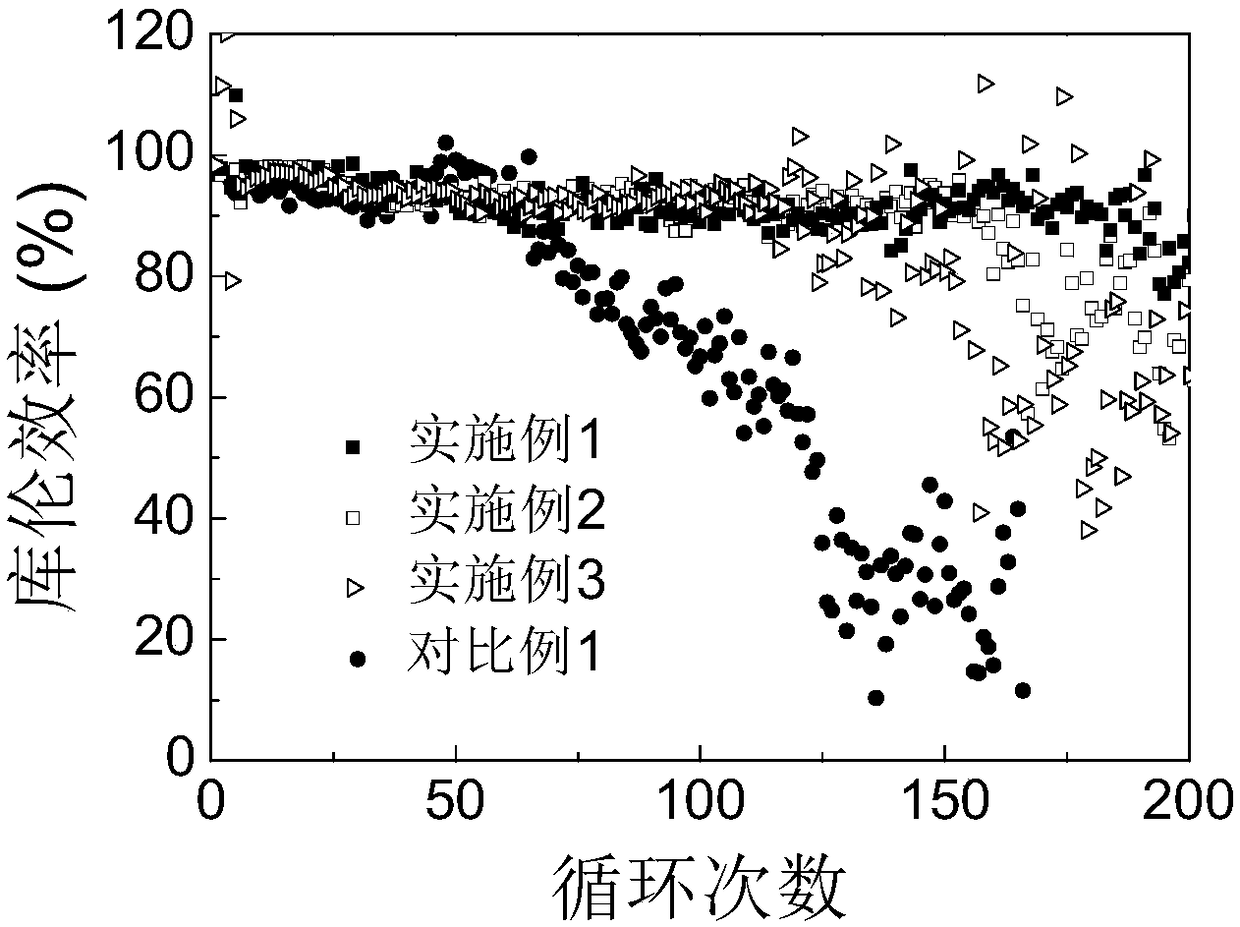

Embodiment 1

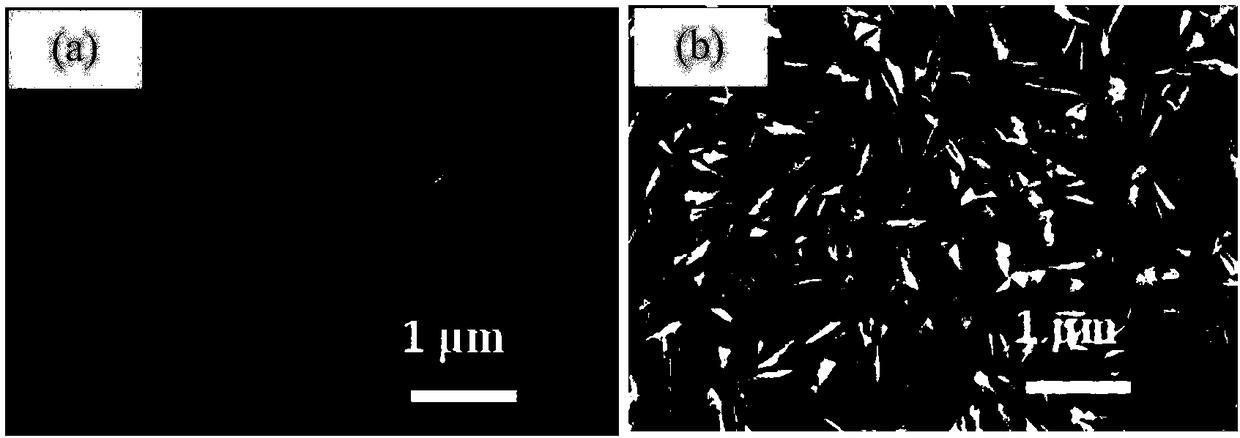

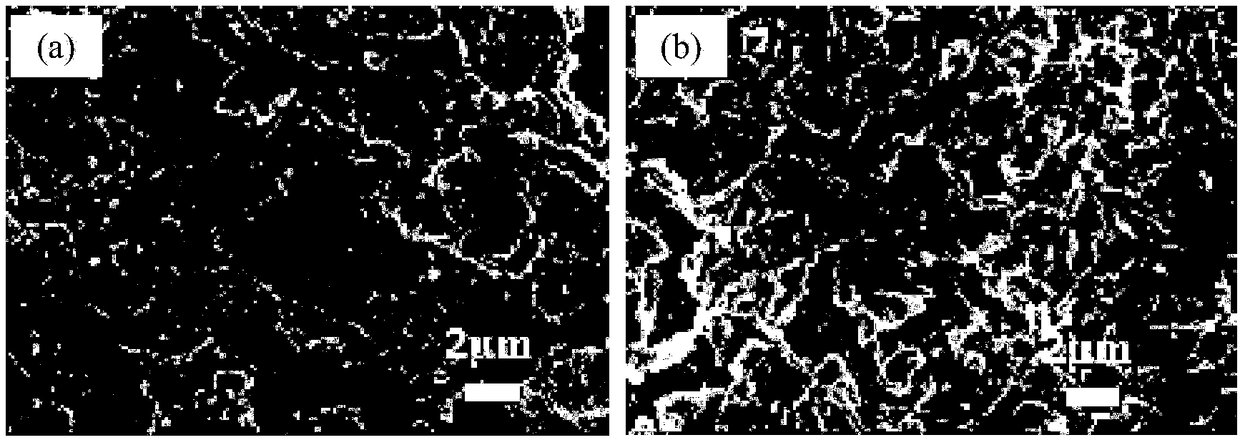

[0037] This embodiment provides a stable lithium metal negative electrode, including a negative electrode current collector and a negative electrode active material layer attached to the surface of the current collector. The negative electrode active material layer is a lithium metal layer. Lithophilic nano-array on the current collector body, and the current collector body is copper foil, the lithium-friendly nano-array is a copper oxide nanosheet array, the thickness of the lithium-friendly nano-array is 0.8 μm-20 μm, and the nano-sheet spacing in the lithium-friendly nanoarray is 100nm-1μm.

[0038] Its preparation method comprises the following steps:

[0039] Step 1, soak the copper foil with 2mol / L dilute hydrochloric acid for 10 minutes at room temperature, then wash it with deoxygenated ethanol three times, and finally wash it once with deoxygenated deionized water;

[0040] Step 2, soak the copper foil cleaned in step 1 in dilute ammonia solution with a concentration...

Embodiment 2

[0046] The difference from Example 1 is: the reaction time in step 2 is 4 hours, and all the other are the same as Example 1, and will not be repeated here.

Embodiment 3

[0048] The difference from Example 1 is: the reaction time in step 2 is 12 hours, and all the other are the same as Example 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com