Preparation method of high-activity nickel positive electrode-based nickel-zinc battery

A nickel-zinc battery, a high-activity technology, applied in the field of energy storage, can solve the problems of insufficient utilization of active materials, etc., and achieve the effects of ion transmission, penetration, and large surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

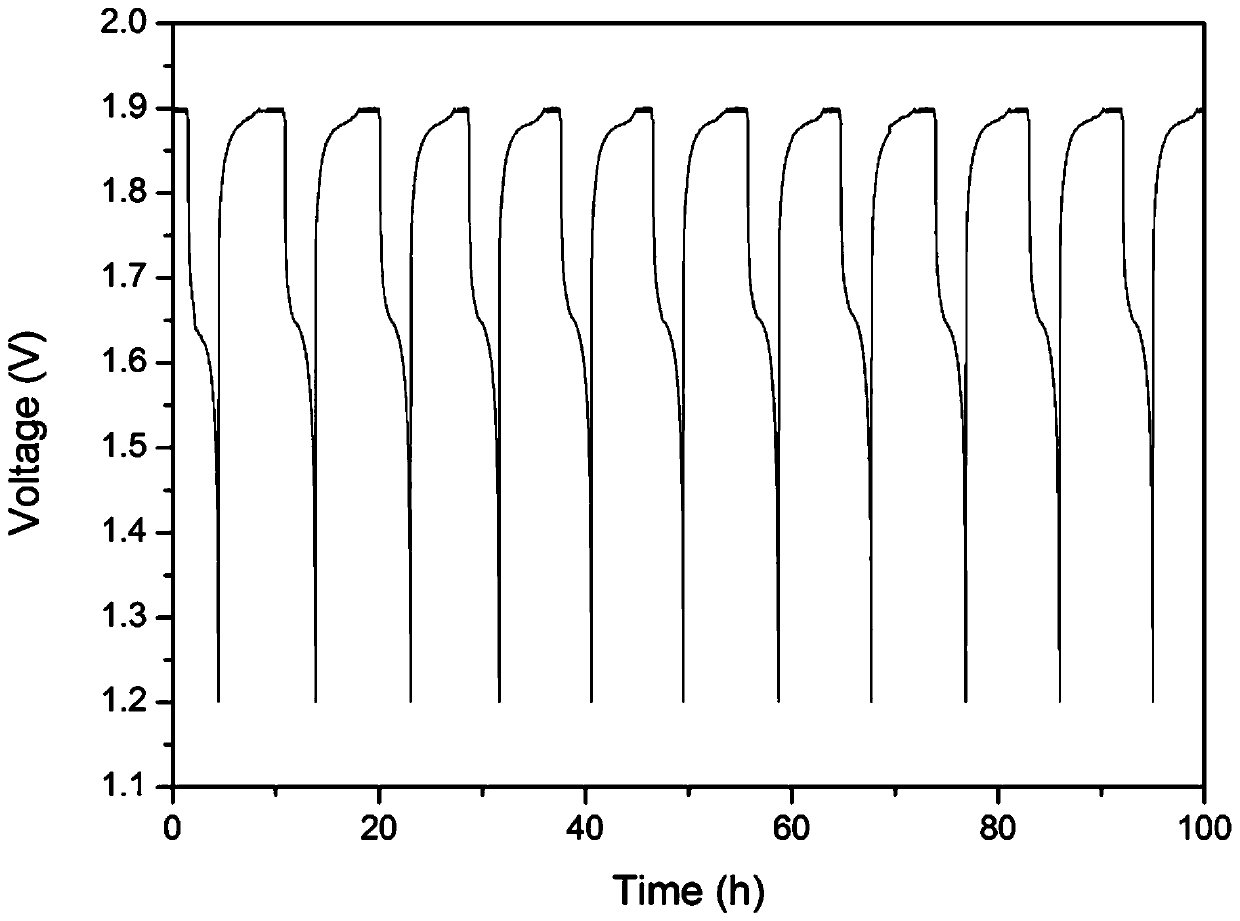

Embodiment 1

[0052] This embodiment relates to a method for preparing a nickel-zinc battery based on a single-atom nickel positive electrode; comprising the following steps:

[0053] 1. Nickel electrode preparation process:

[0054] The first step is to cut the nickel foam into 0.2×1×3cm 3 , followed by ultrasonic cleaning with ethanol and deionized water (18.2 MΩcm), in order to clean the organic matter and other impurities on the nickel foam substrate, the cleaning time of each step is 15 minutes.

[0055] The second step is to activate the nickel foam. The cleaned nickel foam was placed in 2mol / L hydrochloric acid and ultrasonically treated at 30°C for 5min.

[0056] The third step is to clean the activated nickel foam. Wash the hydrochloric acid on the nickel foam with deionized water for 20 minutes. Then the cleaned nickel foam was dried in an oven at 60°C for further use.

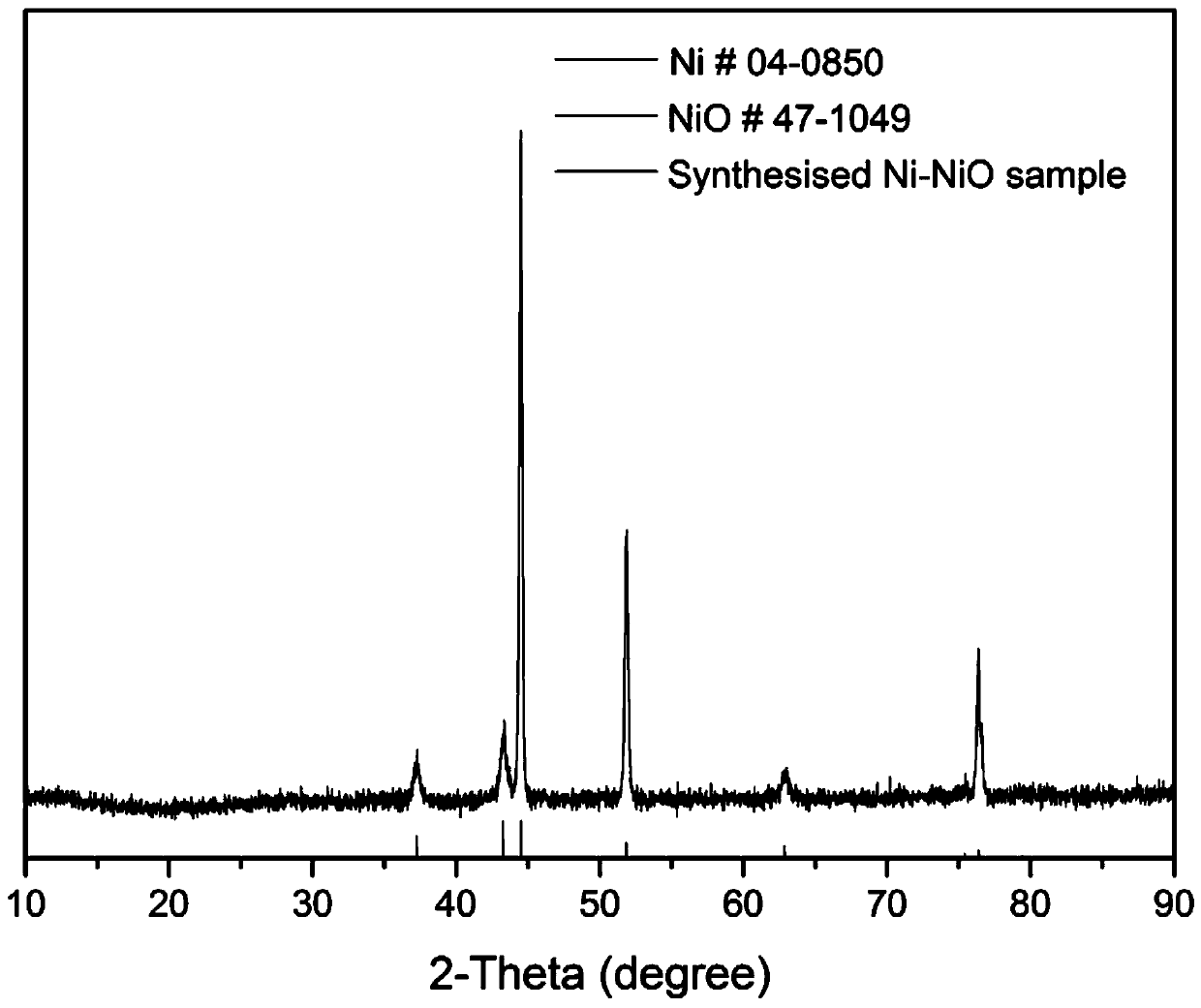

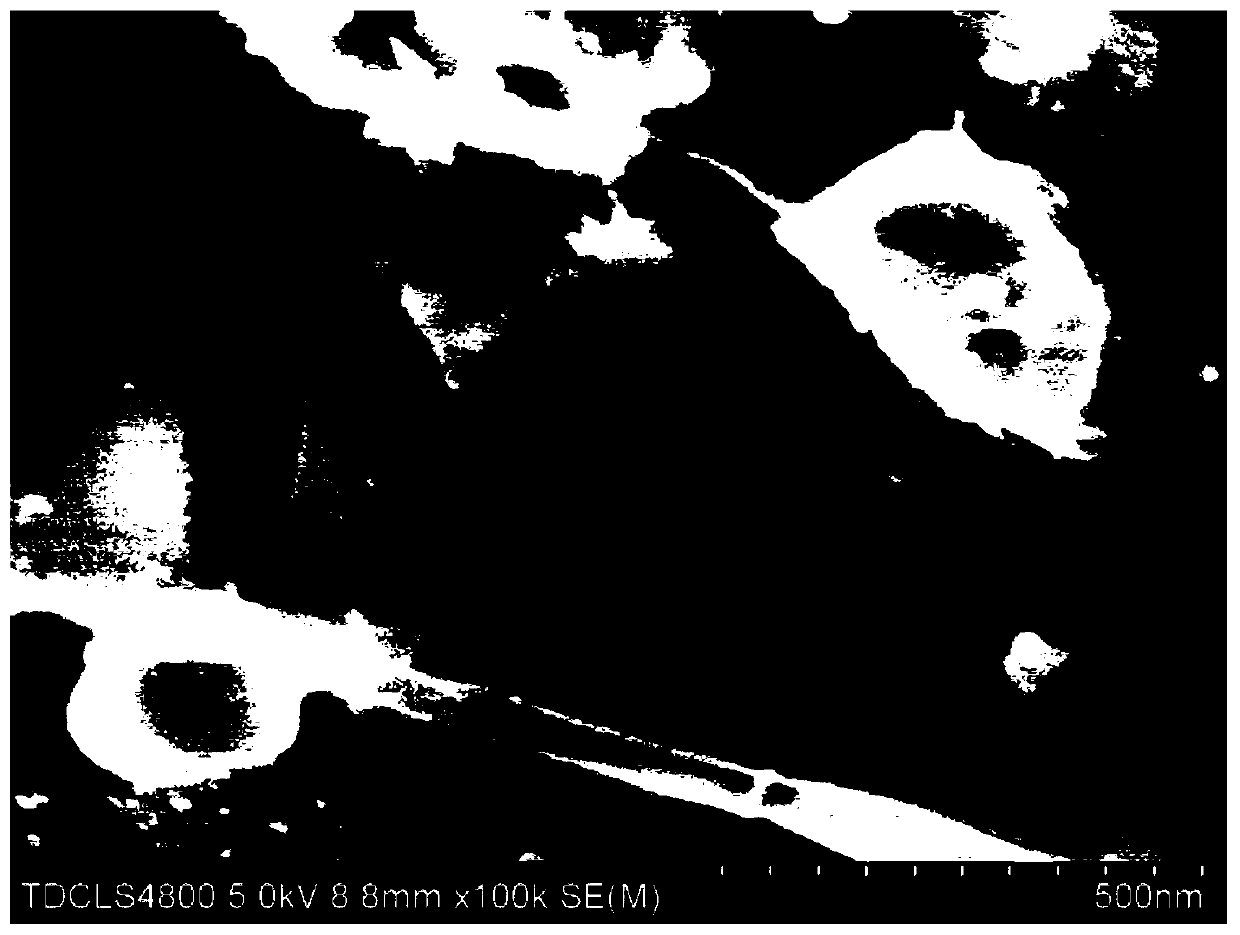

[0057] The fourth step is to prepare Ni-NiO to prepare the precursor solution. A certain amount of H 2 C...

Embodiment 2

[0082] This embodiment relates to a method for preparing a nickel-zinc battery based on a single-atom nickel positive electrode; comprising the following steps:

[0083] 1. Nickel electrode preparation process:

[0084] The first step is to cut the nickel foam into 0.2×1×3cm 3 , followed by ultrasonic cleaning with ethanol and deionized water (18.2MΩcm). In order to clean the organic matter and other impurities on the nickel foam substrate, the cleaning time of each step is 17min.

[0085] The second step is to activate the nickel foam. The cleaned nickel foam was placed in 2.5mol / L hydrochloric acid, and ultrasonically treated at 35°C for 10min.

[0086] The third step is to clean the activated nickel foam. Wash the hydrochloric acid on the nickel foam with deionized water for 30 minutes. Then the cleaned nickel foam was dried in an oven at 60°C for further use.

[0087] The fourth step is to prepare Ni-NiO to prepare the precursor solution. A certain amount of H 2 C ...

Embodiment 3

[0111] This embodiment relates to a method for preparing a nickel-zinc battery based on a single-atom nickel positive electrode; comprising the following steps:

[0112] 1. Nickel electrode preparation process:

[0113] The first step is to cut the nickel foam into 0.2×1×3cm 3 , followed by ultrasonic cleaning with ethanol and deionized water (18.2 MΩcm). In order to clean organic matter and other impurities on the nickel foam substrate, the cleaning time for each step is 20 minutes.

[0114] The second step is to activate the nickel foam. The cleaned nickel foam was placed in 3mol / L hydrochloric acid and ultrasonically treated at 40°C for 15min.

[0115] The third step is to clean the activated nickel foam. Wash the hydrochloric acid on the nickel foam with deionized water for 40 minutes. Then the cleaned nickel foam was dried in an oven at 65°C for later use.

[0116] The fourth step is to prepare Ni-NiO to prepare the precursor solution. A certain amount of H 2 C 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com