Gel-state electrode and preparation method thereof

A gel state and electrode technology, which is applied in the field of gel state electrodes and its preparation, can solve the problems that are not conducive to the contact between the electrode and the solid electrolyte interface, the ion transmission speed inside the electrode is not ideal, and the volume change of the electrode cannot be effectively suppressed. Achieve the effect of improving interface contact, avoiding the increase of raw material cost, and improving the rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] At 60°C, 5mol% LiTFSI was dissolved in succinonitrile to prepare a succinonitrile-based plastic crystal electrolyte, then 7wt% FEC was added, and PEO (polyethylene oxide) was added after fully stirring. The mass ratio of PEO and succinonitrile-based plastic crystal electrolyte is 1:20. After fully stirring and dissolving, a transparent gel-state ion-conductive substance is obtained. In LiCoO 2 In the powder and 10wt% of SP, add 35wt% of the gel state substance, after grinding evenly, the composite cathode slurry is evenly coated on the Li 6.4 La 3 Zr 1.4 Ta 0.6 o 12 One side of the ceramic sheet is pasted with aluminum foil as a current collector, and placed in an oven at 60°C for a period of time. By weighing the quality of the ceramic sheet before and after coating, the quality of the composite positive electrode can be obtained.

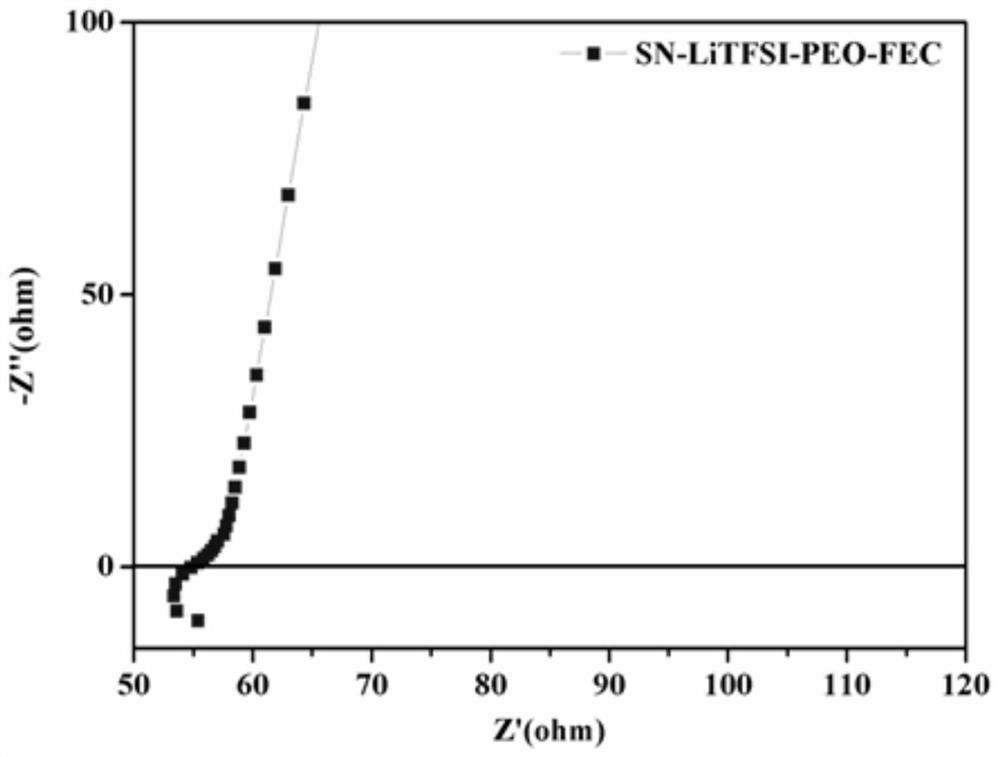

[0041] according to figure 1 And formula σ=L / (R S), wherein L, R and S are respectively the thickness (0.6mm) of the gel state mat...

Embodiment 2

[0044] At 60°C, 5mol% LiTFSI was dissolved in succinonitrile to prepare a succinonitrile-based plastic crystal electrolyte, then 5wt% FEC was added, and PEO was added after fully stirring. The mass ratio of PEO and succinonitrile-based plastic crystal electrolyte is 1:20. After fully stirring and dissolving, a transparent gel-state ion-conductive substance is obtained. In LiCoO 2 In the powder and 10wt% SP, add 45wt% of the gel state substance, after grinding evenly, the composite positive electrode slurry is evenly coated on the Li 6.4 La 3 Zr 1.4 Ta 0.6 o 12 One side of the ceramic sheet is pasted with a stainless steel mesh as a current collector, and placed in an oven at 60°C for a period of time.

Embodiment 3

[0046] At 60 °C, 5 mol% LiTFSI and 1 mol% LiPF 6 Dissolve in succinonitrile to prepare succinonitrile-based plastic crystal electrolyte, and then add 5wt% FEC. After fully stirring evenly, add cyanoethylated polyvinyl alcohol (PVA-CN) at 50°C. The mass fraction of PVA-CN in the succinonitrile-based plastic crystal electrolyte is 5%. After fully stirring and dissolving, add 50wt% LiCoO 2 powder and 10wt% SP, after uniform grinding, the composite cathode slurry was evenly coated on the Li 6.4 La 3 Zr 1.4 Ta 0.6 o 12 One side of the ceramic sheet, and paste aluminum foil as a current collector. Then, it was placed in an oven and heat-treated at 70° C. for 6 hours to generate cross-linking of PVA-CN.

[0047] Owing to the structural similarity, PVA-CN is easily dissolved in the molten succinonitrile-based plastic crystal electrolyte. During heat treatment, LiPF 6 PF produced by decomposition 5 It can initiate cross-linking of PVA-CN.

[0048] In summary, the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com