Patents

Literature

77results about How to "Improve interface contact performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

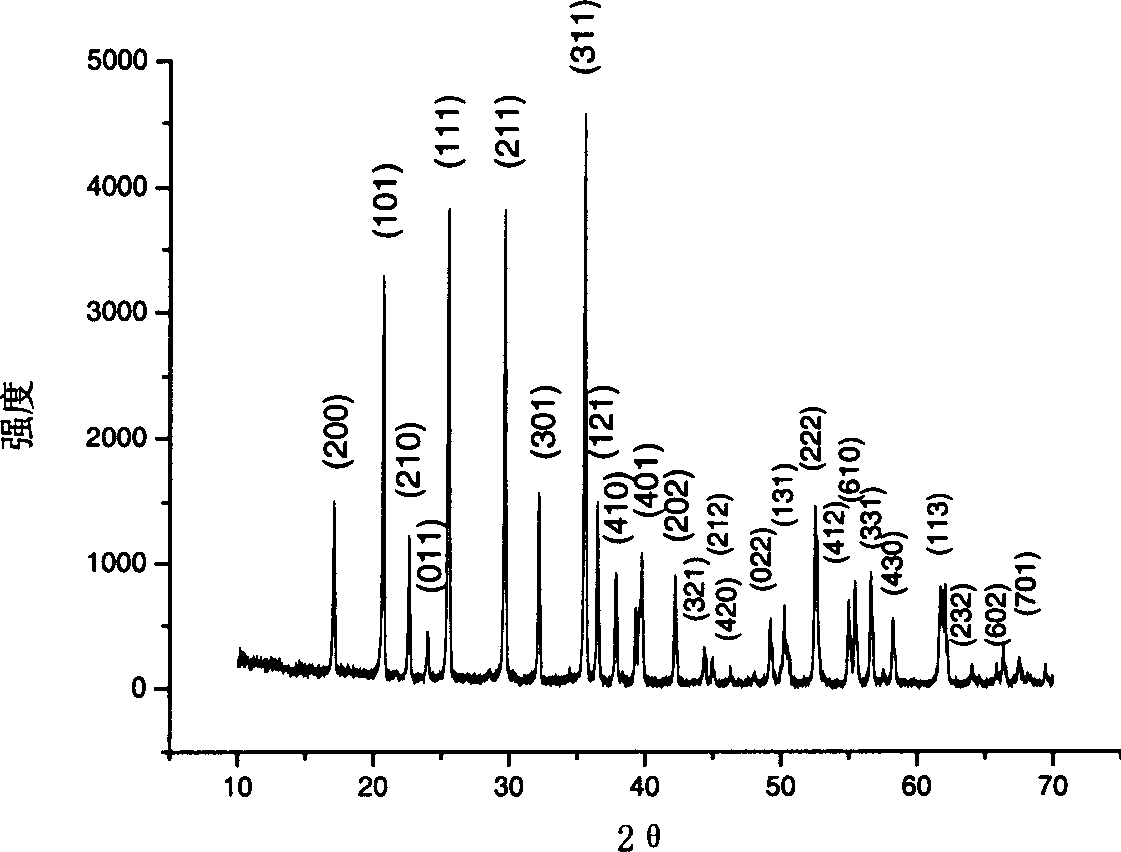

Method for preparing metal Ni, Cu, coated LiFePo4 powder

InactiveCN1649188AShort preparation timeEasy to makeElectrode manufacturing processesLithium compoundsAqueous solutionSolid matter

A preparing method for LiFePO4 powder covered by Ni and Cu includes preparing LiFePO4 powder with uniform diameters, preparing a chemical coating liquid C with Cu, putting powder A in SnCl2 water solution, mixing, filtering and washing, after that, the filtered cake is put into PdCl solution, mixing, filtering and washing to put the solid one into the coating solution B and C to be coated, filtered and washed, the power is processed in inert or recovered atmosphere to get the black LiFePO4 powder covered by the metal.

Owner:TSINGHUA UNIV

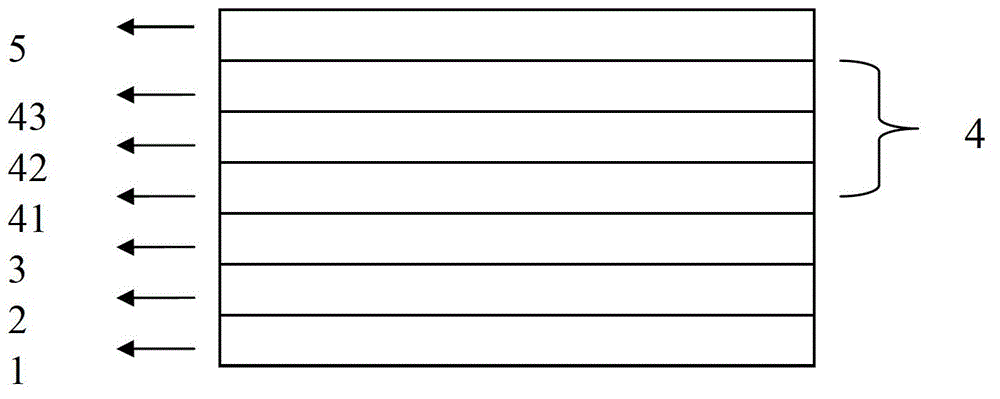

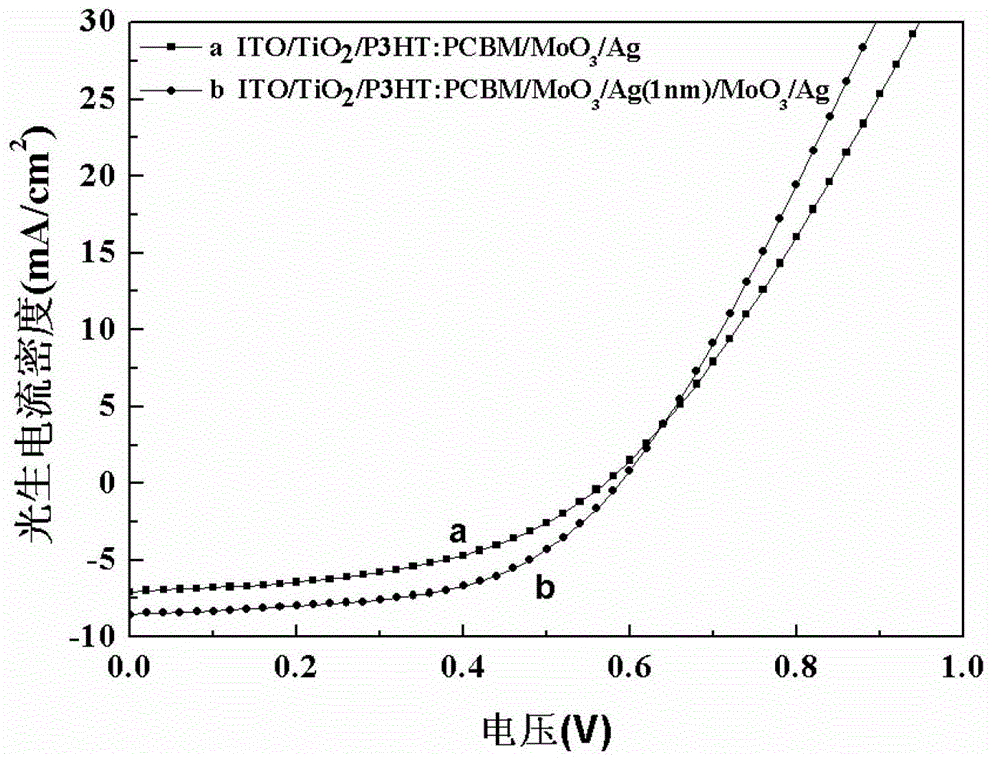

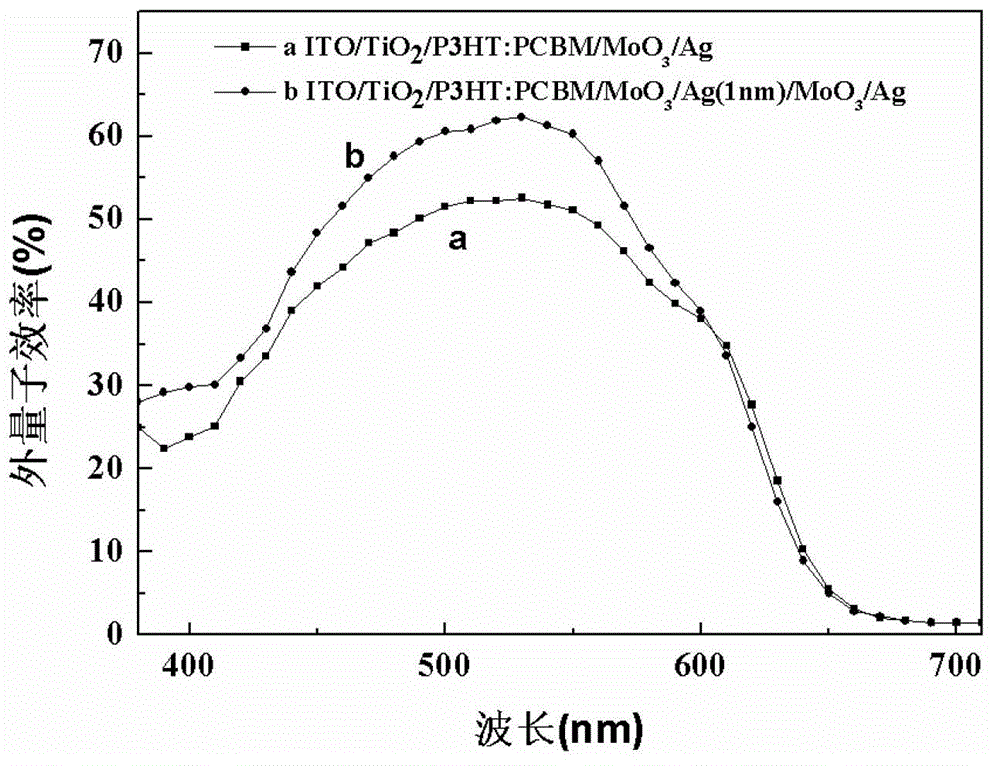

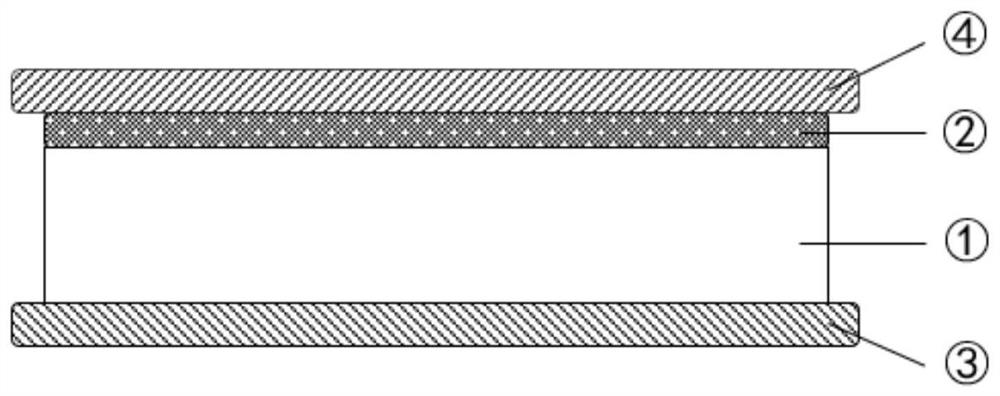

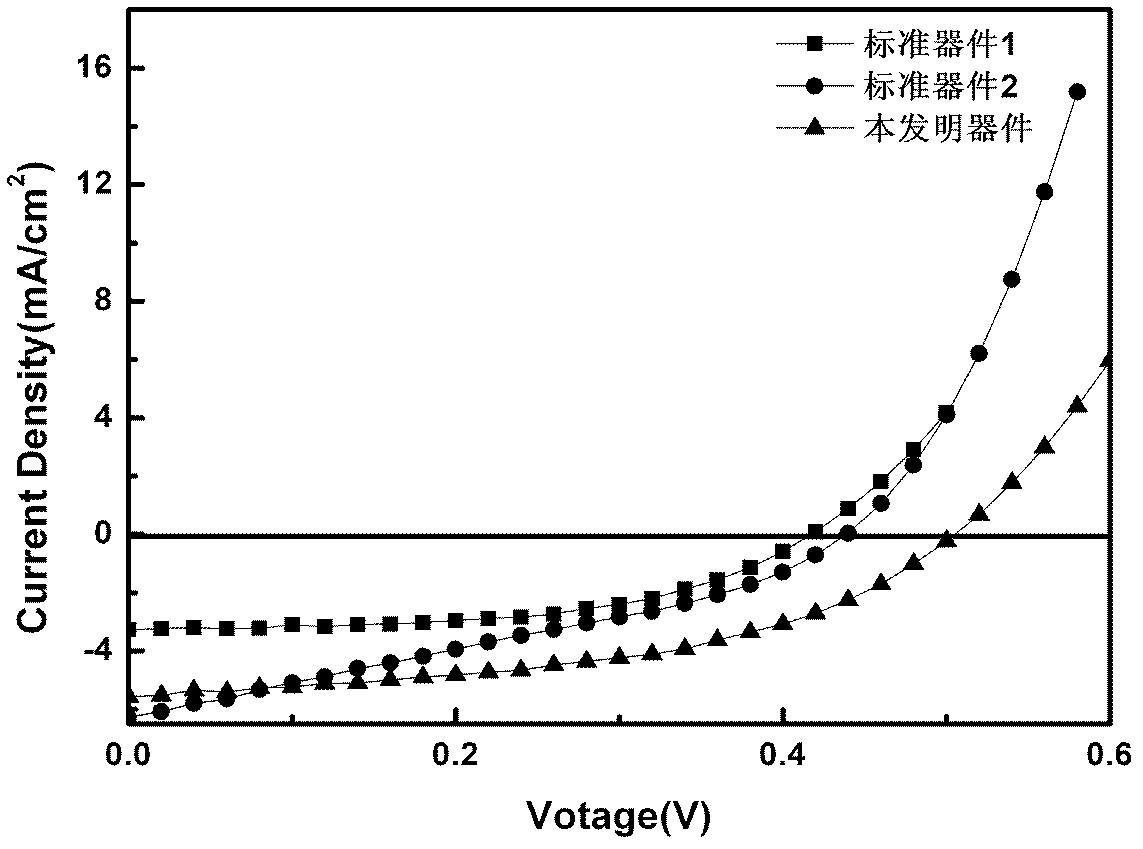

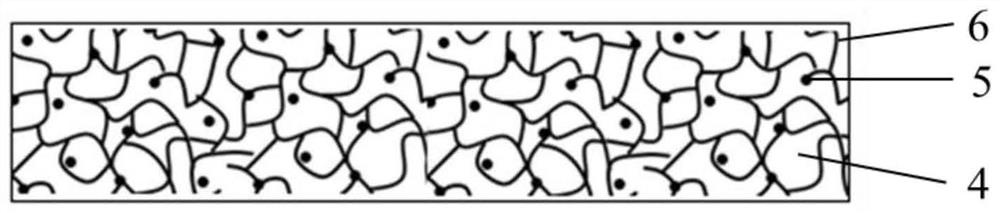

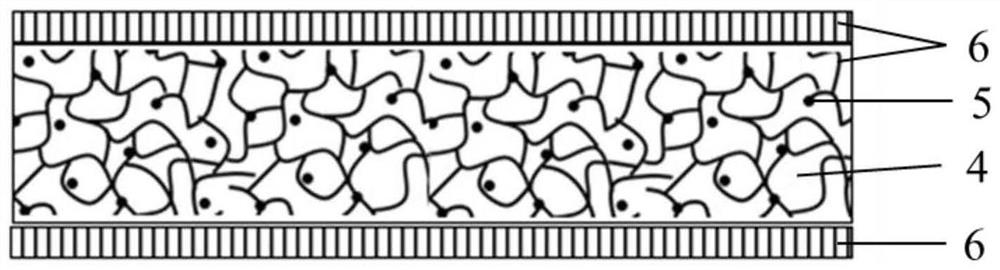

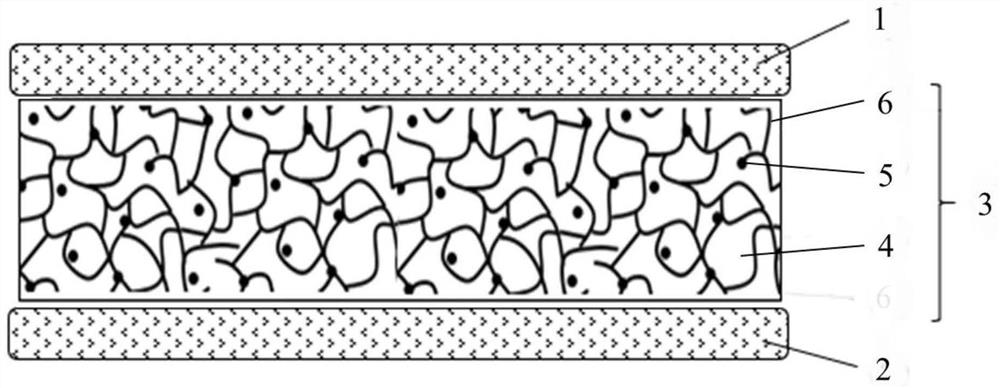

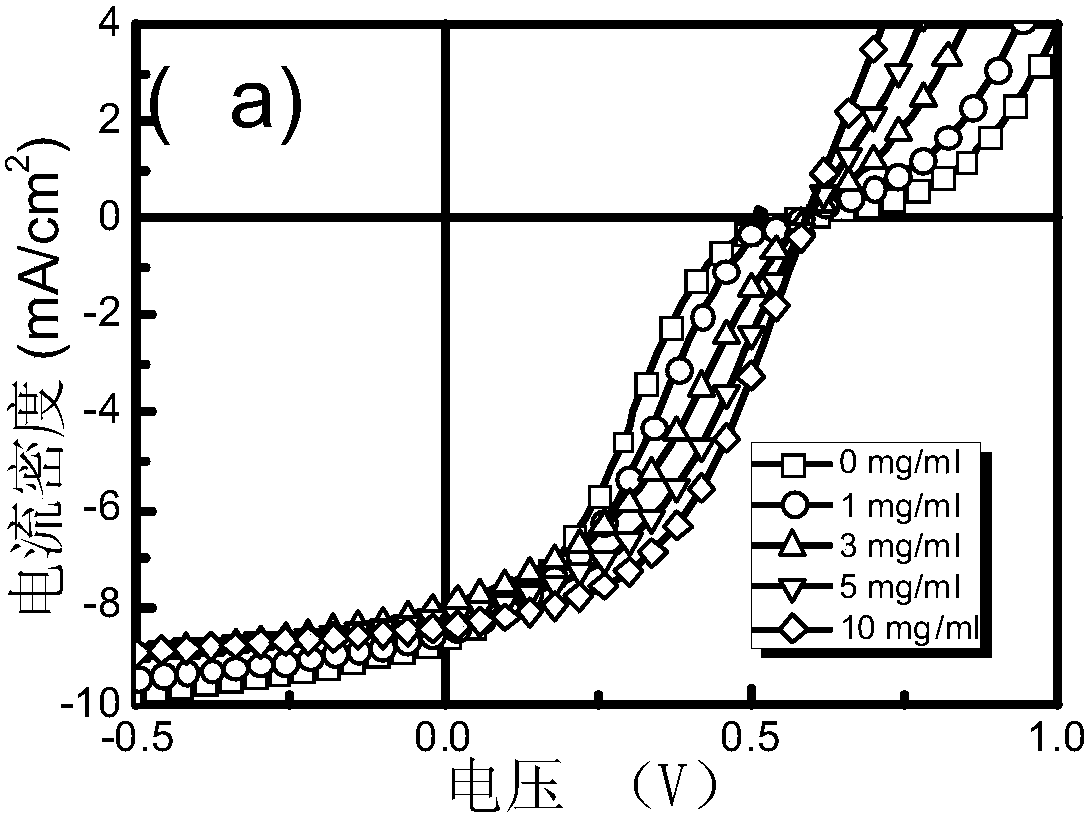

Inverted polymer solar cell of Ag nano particle compounded cavity transmission layer and fabrication method

ActiveCN102983277AUniform sizeImprove interface contact performanceFinal product manufactureSolid-state devicesSurface plasmonHole transport layer

The invention belongs to the technical field of organic photoelectric devices, and particularly relates to an inverted polymer solar cell of an Ag nano particle compounded cavity transmission layer and a fabrication method of the inverted polymer solar cell. The inverted polymer solar cell is characterized in that ITO (indium tin oxide) conducting glass serves as a cathode (1); N type TiO2 serves as a cathode buffer layer (2); a polymer serves as an active layer (3); MoO3 / Ag nano particle / MoO3 serves as a anode buffer layer (4); and Ag serves as a anode (5). The active layer (3) is mixed by a donor material namely P3HT (Poly [3-hexylthiophene-2, 5-diyl]) with an accepter material namely PCBM ([6, 6]-phenyl-C61-butyric acid methyl ester) according to a mass ratio of 1:0.8-1; and the thickness of each Ag nano particle is 1-5nm. The utilization ratio of sunlight by the active layer is increased through localized surface plasma action and backscattering enhancing action of the Ag nano particles; in addition, the interfacial contact property between the active layer and an electrode is improved; the anode-toward transmittability of current carriers is improved; the short circuit current density of the inverted polymer solar cell is increased; and the energy transformation efficiency is improved.

Owner:JILIN UNIV +1

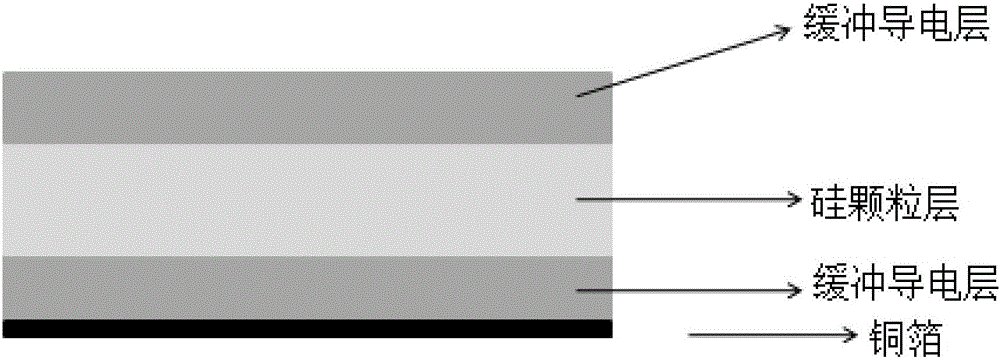

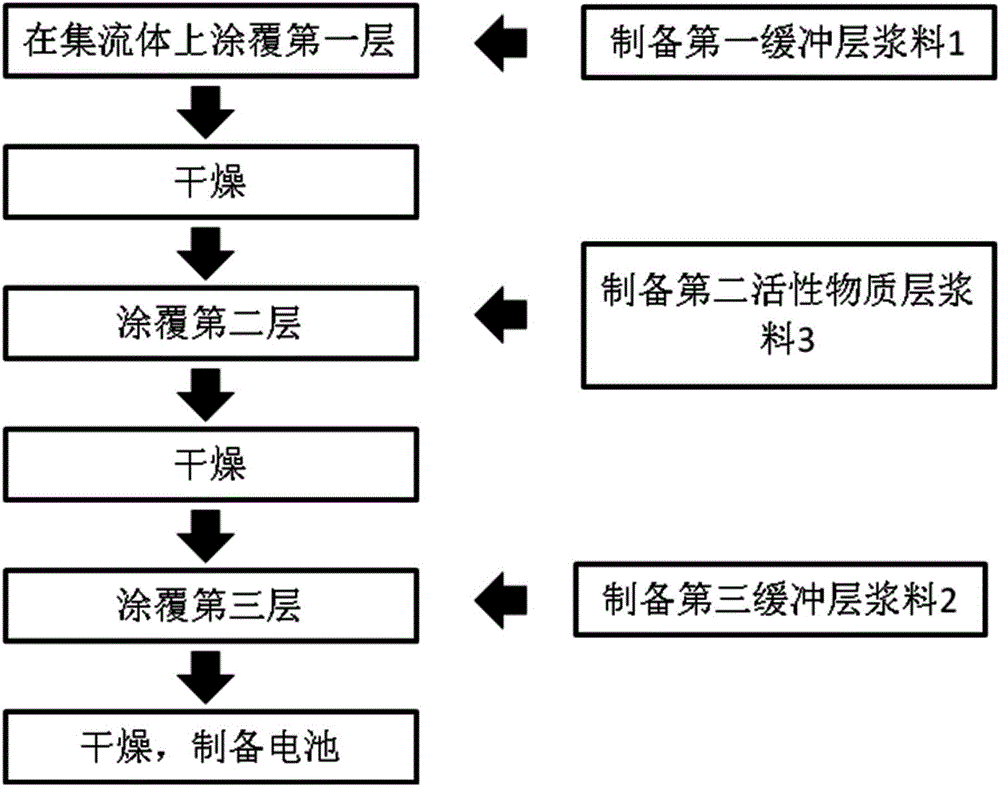

Electrode plate and lithium ion battery

InactiveCN105789556AImprove buffering effectReduce adverse effectsSecondary cellsNon-aqueous electrolyte accumulator electrodesSize changeOptoelectronics

The invention provides an electrode plate which comprises a current collector layer, a first conductive layer, an outer conductive layer and a first silicon material layer, wherein the first conductive layer is arranged on the surface of the current collector layer; the first silicon material layer is arranged on the surface of the outer conductive layer; n groups of silicon material layers and conductive layers are sequentially and alternatively arranged between the first conductive layer and the first silicon material layer. The invention further provides a lithium ion battery which comprises the electrode plate provided by the technical scheme of the invention. According to the electrode plate, the conductive layers have a relatively good buffer function on the silicon material layer, after lithium is embedded, the size of the silicon material layer is increased, then conductive layers on two sides can be compressed, in a lithium removed state, the size of the silicon material layer is reduced and the thickness is recovered, and the conductive layers on two sides are elastic and can be recovered to original thickness, so that due to the multi-layer electrode plate structure, a sufficient buffer space can be provided for the silicon material layer, and along with shrinkage of the silicon material layer, relatively good stability and interface contact property of the multi-layer structure can be maintained, and adverse influence caused by silicon material size change in the battery circulation process can be avoided.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI +1

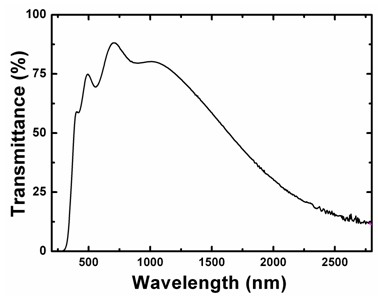

Multilayer transparent electroconductive thin film

The invention discloses a multilayer transparent electroconductive thin film which comprises a substrate, wherein n (n>=2) layers of amorphous oxide layers and electroconductive modified layers are deposited on the substrate alternately and odd layers can be either amorphous oxide layers or electroconductive modified layers. A pulsed laser deposition method or a magnetron sputtering method is used for the preparation of the thin film. The multilayer transparent electroconductive thin film has very low electrical resistivity, but has high visible light transmission and excellent comprehensive photoelectric property, as well as low surface roughness, is easy to prepare in large area evenly and etch by a process, can be applied to fields of display devices, luminescent devices, solar cells and the like, especially to the field of flexible devices.

Owner:ZHEJIANG UNIV

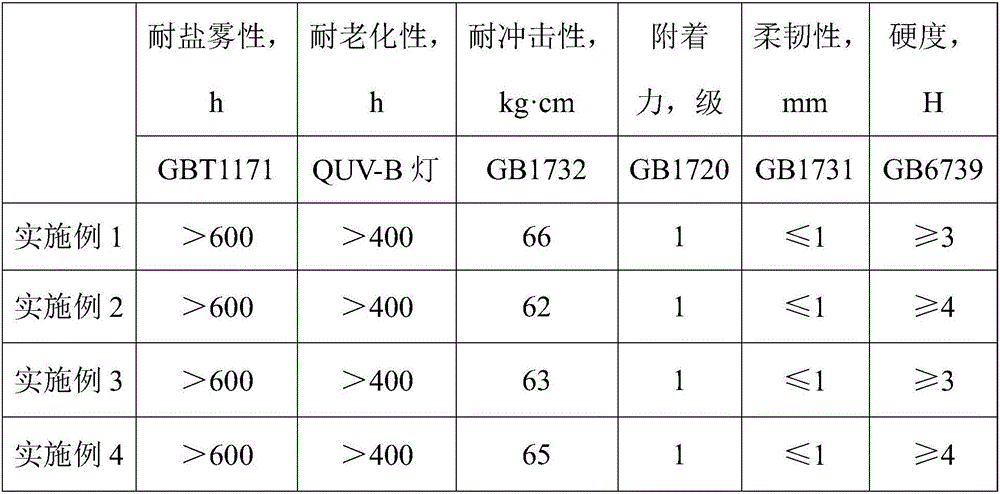

Super-weather-resistance powder coating for electrostatic spraying and preparation method thereof

ActiveCN106609098AImprove conductivityStorage Stability BalancePowdery paintsElectrically-conductive paintsCarbon nanotubeMaterials science

The invention relates to a super-weather-resistance powder coating for electrostatic spraying and a preparation method thereof. The powder coating comprises the following raw materials of, by weight, 50-80 parts of polyester resin, 15-35 parts of alkyd resin, 3-15 parts of polyester-coated carbon nanotubes, 2-6 parts of nano-titanium dioxide, 1-5 parts of nano-zinc oxide, 1-3 parts of aluminum nitride, 0.5-2 parts of phosphotungstic acid, 0.5-2 parts of quartz, 5-15 parts of bauxite, 2-6 parts of vinyltriethoxysilane, 5-10 parts of titanium dioxide, 1-2 parts of benzoin, 0.5-2 parts of leveling agents, 0.1-1 part of auxiliary agent, 1-5 parts of propylene glycol methyl ether acetate, 4-10 parts of beta-hydroxyalkylamide. According to the provided super-weather-resistance powder coating for electrostatic spraying and the preparation method thereof, on the premise that a good electrostatic spraying effect of the powder coating is ensured, the weather resistance of the coating is greatly improved.

Owner:TIANCHANG JINLING ELECTRONICS

Antibacterial polylactic acid and starch compound fully-degradable plastic film and manufacturing method thereof

InactiveCN105968743ASolve poorly described problemsHigh strengthFlexible coversWrappersPolymer scienceGlycerol

The invention discloses an antibacterial polylactic acid and starch compound fully-degradable plastic film, which is characterized by being made from the following raw materials, by weight part, 80-85 of polylactic acid, 20-25 of corn starch, a proper amount of a sodium hydroxide solution with the concentration being 1 mol / L, a proper amount of hydrochloric acid with the concentration being 1 mol / L, 25-30 of hemp fibers, 0.8-1 of a silane coupling agent kh-550, a proper amount of distilled water, 12-14 of glycerin, 1.6-2 of epichlorohydrin, 3-4 of nanometer zinc oxide, 1-1.5 of chitosan, 0.4-0.6 of OP-10, 2-3 of castor oil, and 2-3 of ultrafine zeolite powder. Components, such as nanometer zinc oxide, chitosan and castor oil, have a synergistic effect and can improve antibacterial properties of the plastic film. The plastic film has biodegradability, is good in thermostability, and is excellent in toughness, mechanical properties, and use performance. The plastic film is safe and eco-friendly, and can meet the environment-protection requirements.

Owner:ANHUI MENGNIU COLOR PRINTING&PACKAGING

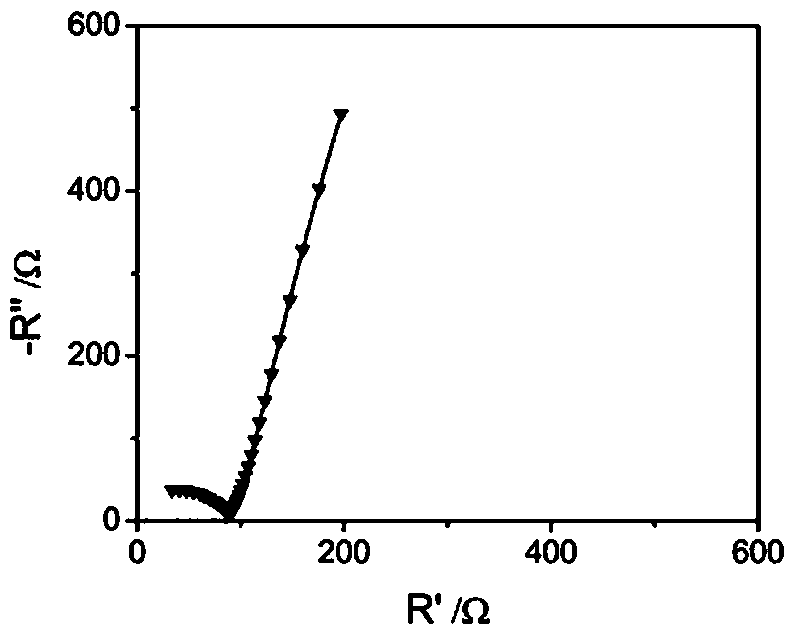

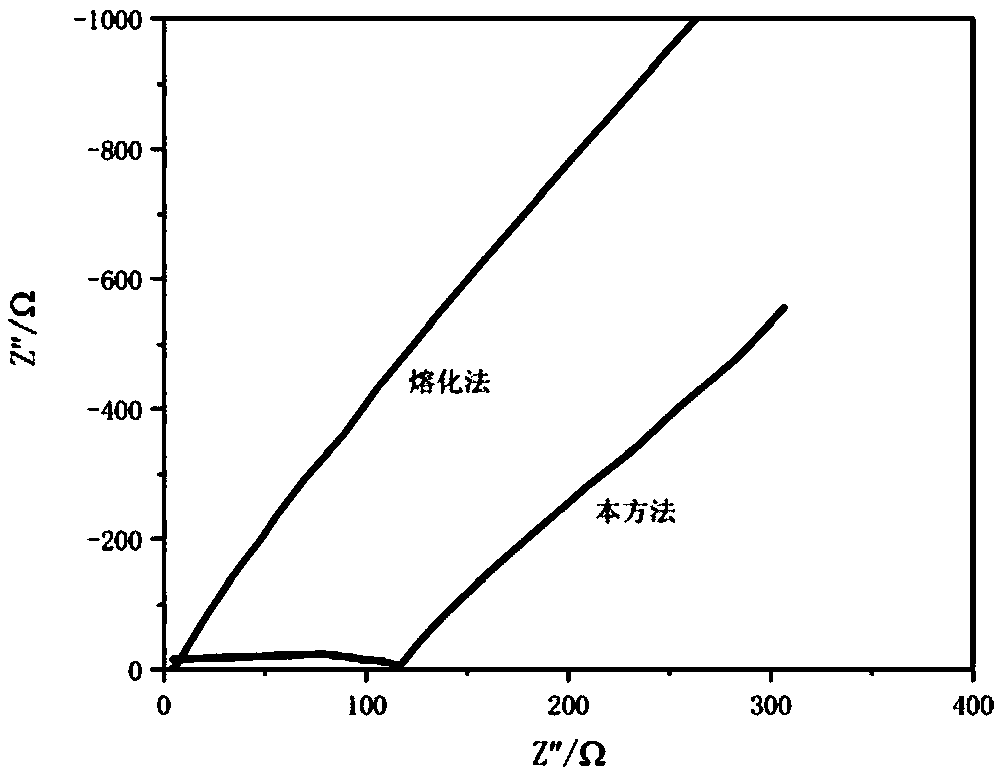

All-solid composite polymer electrolyte and preparation method thereof, and lithium ion battery

InactiveCN110429344AHigh conductivity at room temperatureImproved interface contactFinal product manufactureElectrolyte accumulators manufacturePolymer scienceSolvent

The invention discloses an all-solid composite polymer electrolyte and a preparation method thereof, and a lithium ion battery. The method comprises the following steps of: S1, preparing a polymer matrix membrane by adopting a phase inversion method, wherein the polymer matrix membrane has a plurality of closely arranged vertical through holes; S2, gradually adding inorganic powder, lithium salt,a second polymer and an appropriate amount of auxiliary agent into a solvent for uniform stirring in an argon-filled glove box to obtain a polymer electrolyte, then, performing scrap coating of the polymer electrolyte in an environment controlled in moisture and oxygen to form a film, performing standing at room temperature to perform vacuum drying to obtain a polymer electrolyte film; and S3, putting the polymer electrolyte film prepared in the S2 at the upper portion of the polymer matrix membrane in the S1, performing melting and hot-pressing of the polymer electrolyte in a vacuum oven at atemperature of 100-350 DEG C into the vertical holes of the polymer matrix membrane. The all-solid composite polymer electrolyte is high in room-temperature conductivity and good in interface contact, has a high modulus and a high voltage window and is simple to prepare and low in cost.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

Preparation method for solid-state lithium-ion battery

InactiveCN108110324AImprove interface contact performanceImprove electrochemical performanceFinal product manufactureElectrolyte accumulators manufactureSolid state electrolyteElectrolysis

Embodiments of the invention provide a preparation method for a solid-state lithium-ion battery, belonging to the technical field of battery preparation. The preparation method comprises the followingsteps: dispersing a solid electrolyte in a solvent so as to obtain a solid electrolyte solution, wherein a mass ratio of the solid electrolyte to the solvent is 1: (5-50); selecting a three-componentmaterial as a positive electrode of the solid-state lithium-ion battery and using lithium metal as a negative electrode of the solid-state lithium-ion battery; adding a film forming agent into the solid electrolyte solution, coating the surfaces of the positive electrode and the negative electrode with the solid electrolyte solution, carrying out drying, then sintering the positive electrode coated with the solid electrolyte solution at a temperature of 800 to 1000 DEG C, maintaining the positive electrode at the temperature for 2 to 10 h and then carrying out cooling, wherein the film forming agent is polyvinylidene fluoride, polytetrafluoroethylene or polyvinyl alcohol, and a mass ratio of the film forming agent to the solid electrolyte is 1: (10-20); and assembling the cooled positiveelectrode and the negative electrode coated with the solid electrolyte solution so as to obtain the solid-state lithium-ion battery. The preparation method for the solid-state lithium-ion battery is simple in process, and low in energy consumption and cost.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Carbon nanotube/zinc oxide/micro-expansion graphite composite heat-conducting silicone grease and preparation method thereof

The invention discloses carbon nanotube / zinc oxide / micro-expansion graphite composite heat-conducting silicone grease and a preparation method thereof. The preparation method comprises the following steps: uniformly mixing a carbon nanotube / micro-expansion graphite composite material with zinc oxide by virtue of a high-speed mixing machine, adding the mixture into an ethanol solution, and carryingout ultrasonic stirring until ethanol is completely evaporated, so as to obtain a heat-conducting filling; and adding the heat-conducting filling, silicone oil, a crosslinking agent, a silane surfactant and an antioxidant into an internal mixer, carrying out internal mixing, so as to obtain the composite heat-conducting silicone grease. According to the preparation method, microcrystalline graphite and crystalline flake graphite are mixed to form a micro-expansion graphite material, settling carbon nanotubes to the surface of micro-expansion graphite and into hole structures by virtue of a CVD sedimentation method, the prepared carbon nanotube / micro-expansion graphite composite material is taken as the heat-conducting filling, the heat-conducting filling is modified by virtue of a coupling agent, has good consistency with silicone oil, does not agglomerate and further has good interface contact property. The prepared heat-conducting silicone grease has excellent thermal stability, islow in oil separation value and does not crack and atomize after being used for a long time.

Owner:郴州国盛新材科技有限公司

Interface layer and lithium ion battery comprising same

PendingCN113451580AImprove interface contact performanceImprove interfacial wettabilityCell electrodesSecondary cellsMetallic lithiumSolid state electrolyte

The invention relates to the technical field of lithium ion batteries, in particular to an interface layer and a lithium ion battery comprising the interface layer. Lithium halide generated by the in-situ reaction at the interface of a solid electrolyte and a metal lithium negative electrode can optimize the interface contact property and the interface wettability and provide a rapid ion diffusion path. The metal particles generated by the in-situ reaction at the interface of the solid electrolyte and the metal lithium negative electrode can guide the uniform distribution of an electric field, regulate and control the uniform deposition of the metal lithium in the circulation process, and inhibit the formation and growth of lithium dendrites. The lithium ion battery provided by the invention can effectively stabilize the interface between the electrode and the electrolyte, reduces the chemical reaction activity of the metal lithium negative electrode, avoids the side reaction at the interface, and shows higher cycling stability and coulombic efficiency in continuous charge-discharge cycles.

Owner:ZHUHAI COSMX BATTERY CO LTD

Fully-degradable plastic film having fresh keeping function and used for packages and preparing method thereof

Fully-degradable plastic film having a fresh keeping function and used for packages is disclosed. The plastic film is characterized in that the plastic film is prepared from 80-85 parts by weight of polylactic acid, 25-30 parts by weight of China hemp fibers, 0.8-1 part by weight of a silane coupling agent kh-550, 20-25 parts by weight of corn starch, 12-14 parts by weight of glycerin, 1.6-2 parts by weight of epichlorohydrin, a proper amount of a sodium hydroxide solution having a concentration of 1 mol / L, a proper amount of hydrochloric acid having a concentration of 1 mol / L, a proper amount of distilled water, 5-6 parts by weight of porous starch, 1-2 parts by weight of magnesium stearate, 3-4 parts by weight of macroporous silica gel and 5-7 parts by weight of tourmaline powder; the plastic film is scientific and reasonable in component ratio, can be prepared into food fresh keeping film or fruit packaging bags, and the like, contains the tourmaline powder and other components, can emit far infrared light and negative ions, and keeps freshness for foods; a process is innovative and convenient in industrial control; and the plastic film is low in cost and wide in source and deserves popularization.

Owner:ANHUI MENGNIU COLOR PRINTING&PACKAGING

Method for preparing nano TiO2 (titanium dioxide) pastes

InactiveCN102231304AIncrease surface areaImprove surface roughnessLight-sensitive devicesFinal product manufactureTetraisopropyl titanateCitric acid

The invention provides a method for preparing nano TiO2 (titanium dioxide) pastes, and is characterized by comprising the following steps in percentage by weight: adding one part of tetraisopropyl titanate to 2-6 parts of ethylene glycol; heating the mixed solution to 90 DEG C; adding 2-4 parts of citric acid; stirring for 6-24 hours magnetically to form TiO2 sols; adding 2-4 parts of P25 powdersand 0.2-0.8 part of pore forming material; and mixing and grinding to prepare the pastes. The method has the advantage of low sintering temperature and is convenient to package a battery.

Owner:IRICO

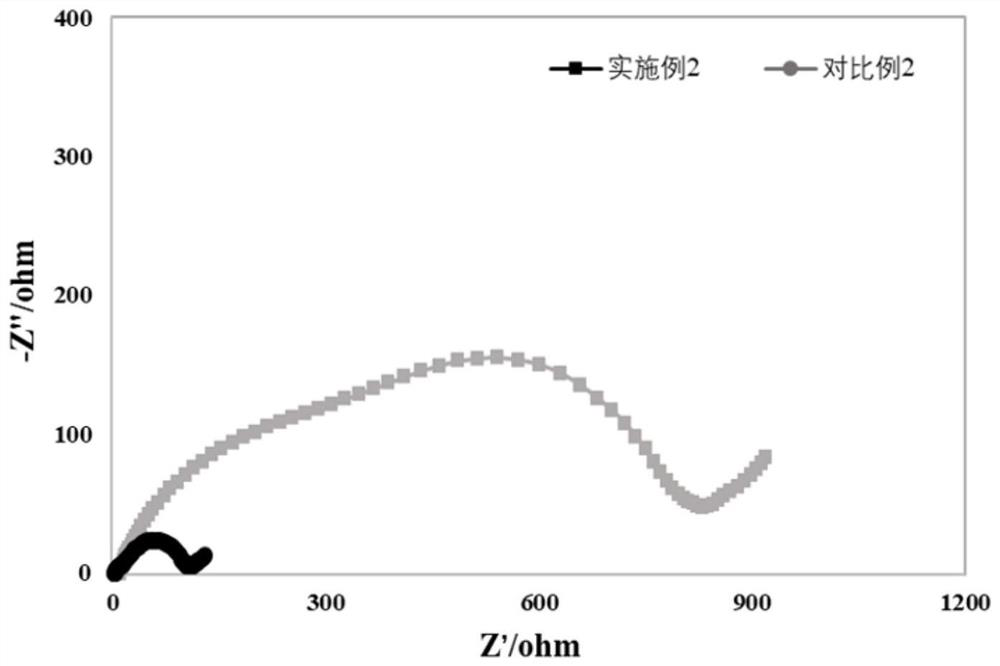

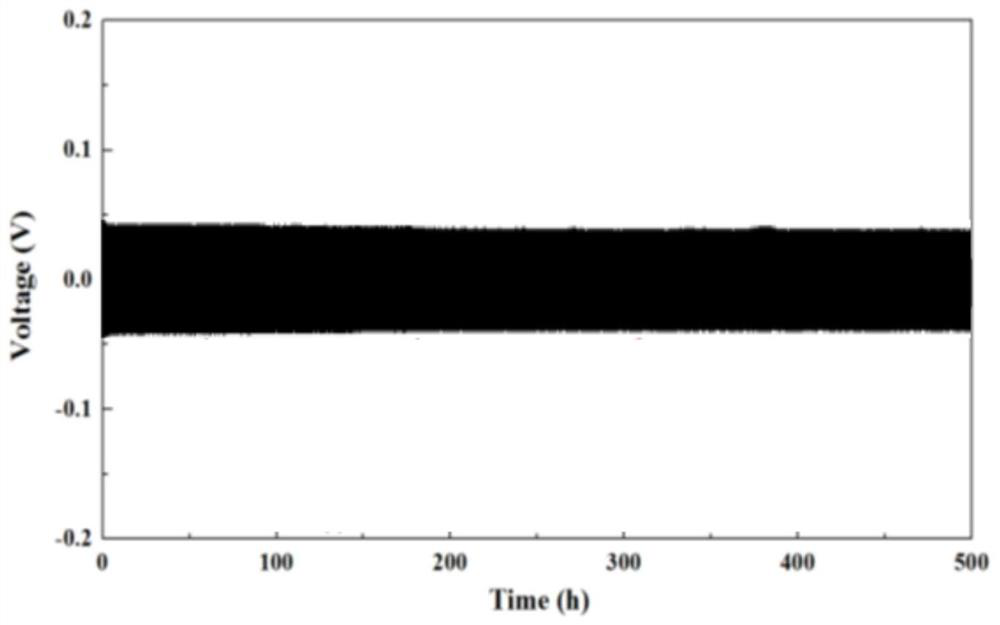

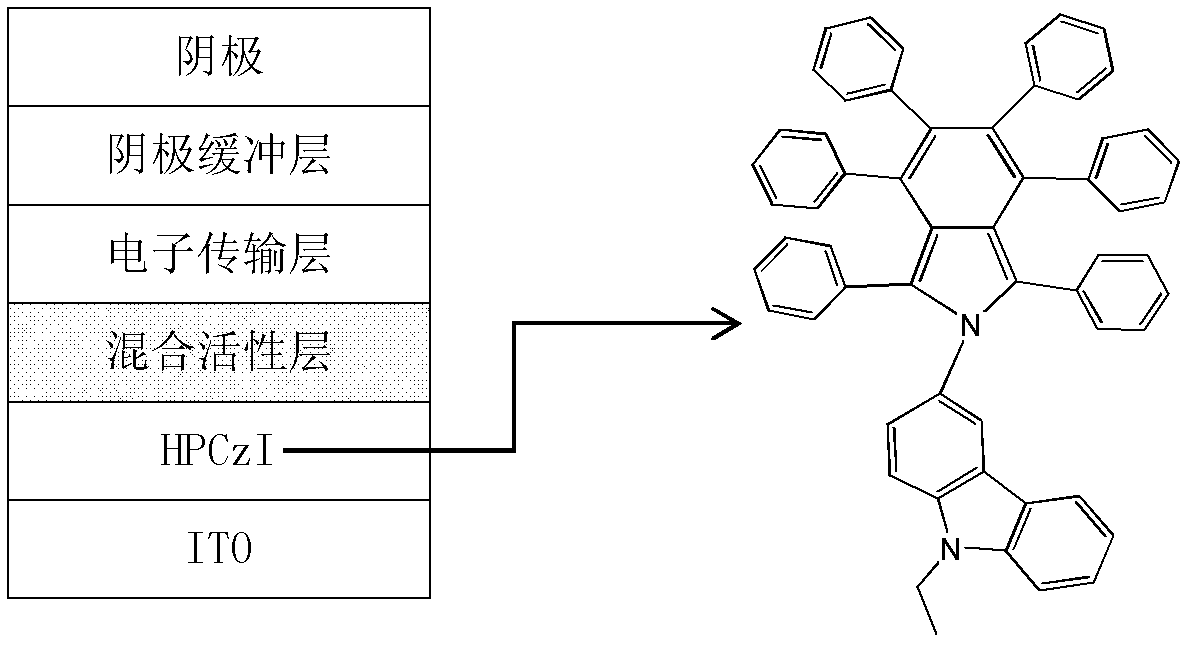

Organic solar cell

InactiveCN102593362AImprove interface contact performanceReduced series resistanceSolid-state devicesSemiconductor/solid-state device manufacturingThin membraneChemistry

The invention discloses an organic solar cell structure which is based on a 1,3,4,5,6,7-hexaphenyl-2-3'-(9'-ethylcarbazolyl)-isoindole [HPCzI] material. The structure comprises a substrate, an anode, an anode buffering layer, a hole transport layer, a mixed photoactivity layer, an electronic transport layer, a cathode buffering layer and a cathode in sequence from down to up, wherein the substrate is made of transparent materials such as quartz plates, glass sheets, polystyrene or polyethylene and the like, the anode is made of metal, metallic oxide, carbon black or conducting polymer and the like, whose work functions are all more than that of the cathode, the anode buffering layer and the hole transport layer are made of the HPCzl, the mixed photoactivity layer is made of an organic donor material and an organic receptor material which are mixed, such as CuPc or AnPc which is mixed with C60 or PCBM (fullerene derivatives), the electronic transport layer is made of organic electronic transport materials such as C60 and the like, the cathode buffering layer is made of TPBi, BCP, BPhen, LiF and the like, and the cathode is made of metal or metal alloy, whose work function is relatively lower than that of the anode. Except the anode, all the layers are prepared in a way that organic films are deposited by vacuum vapour plating, spraying, printing and the like. The organic solar cell structure is beneficial for improving power converting efficiency of an organic solar cell.

Owner:NANJING UNIV OF POSTS & TELECOMM

Fully-degradable plastic film with excellent thermal stability for color printing packaging and manufacturing method of fully-degradable plastic film

InactiveCN105968749ASolve poorly described problemsHigh strengthFlexible coversWrappersColor printingSilicon oxide

The invention discloses a fully-degradable plastic film with excellent thermal stability for color printing packaging. The fully-degradable plastic film is characterized by being made from the following raw materials, by weight part, 80-85 of polylactic acid, 20-25 of corn starch, 12-14 of glycerin, 1.6-2 of epichlorohydrin, a proper amount of a sodium hydroxide solution with the concentration being 1 mol / L, a proper amount of hydrochloric acid with the concentration being 1 mol / L, a proper amount of distilled water, 25-30 of hemp fibers, 0.8-1 of a silane coupling agent kh-550, 3-4 of peach gum powder, 2-3 of castor oil, 3-4 of zirconia powder and 3-4 of silicon oxide. Zirconia powder and silicon oxide are modified and added in polylactic acid for inner mixing, so that modified zirconia powder and silicon oxide can be uniformly dispersed and the thermal stability and strength of the plastic film are improved. According to the formula and the technical innovation, the plastic film is good in thermal stability and toughness and is high in strength. Through addition of corn starch, the cost is reduced. The plastic film is safe and non-toxic and can be used for color printing packaging.

Owner:ANHUI MENGNIU COLOR PRINTING&PACKAGING

Carbon nanotube/micro-expansion graphite composite heat-conducting silicone grease and preparation method thereof

The invention discloses carbon nanotube / micro-expansion graphite composite heat-conducting silicone grease and a preparation method thereof. The preparation comprises the following steps: firstly preparing a carbon nanotube / micro-expansion graphite composite material, adding to an ethanol solution, and carrying out ultrasonic stirring until ethanol is completely evaporated, so as to obtain a modified compound heat-conducting filling; and adding the heat-conducting filling, methyl phenyl silicone oil, a crosslinking agent, a structure improver and an antioxidant into an internal mixer, carryingout internal mixing, so as to obtain the composite heat-conducting silicone grease. The prepared heat-conducting silicone grease has excellent thermal stability, is low in oil separation value and does not crack and atomize after being used for a long time. Meanwhile, a preparation process is simple and short in cycle and has important significance to the improvement of the quality in industry products.

Owner:郴州国盛新材科技有限公司

Carbon-coated foamed aluminium compound and preparation method thereof, current collector and filtering material

InactiveCN109786757AAvoid formingImprove stabilityElectrode carriers/collectorsFiltration separationCarbon layerCarbon coated

The invention provides a carbon-coated porous aluminum compound. The compound is of a coated core-shell structure, the core body is foamed aluminium formed by an aluminum wire skeleton and a three-dimensional communication hole, the shell layer is a carbon layer having a plurality of micropores, the carbon layer is uniformly coated on the surface of the aluminum wire skeleton, and the carbon layerhas a thickness of 0.34 nm to 5 um. In the carbon-coated porous aluminum compound provided by the invention, the foamed aluminium is formed by the aluminum wire skeleton and the three-dimensional communication hole, the surface of the aluminum wire skeleton is uniformly and densely coated with a thin carbon layer having a thickness of nanometer to several micrometers to avoid formation of an oxide film, and compared with the conventional porous aluminum material, the mechanical strength is effectively improved; when being used as an electrochemical energy storage current collector, the contact resistance with an electrode material can be reduced; and the microporous structure carbon layer can not only function to improve the conductivity and improve interface contact effect, but also hasenergy storage and active substance fixation functions, thereby improving the stability of an electrochemical energy storage device.

Owner:ZHONGTIAN ENERGY STORAGE TECH +2

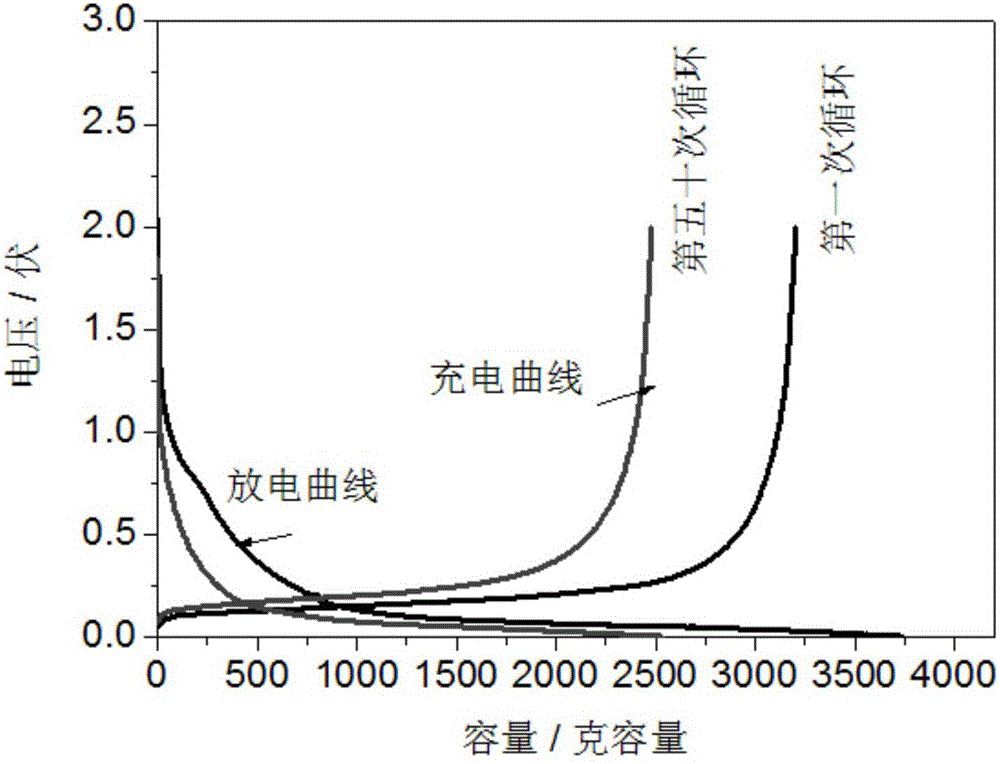

Negative electrode material for lithium battery and preparation method of negative electrode material

The invention provides a negative electrode material for a lithium battery and a preparation method of the negative electrode material. The negative electrode material for the lithium battery has the structure as follows: the inner layer is nanometer porous silicon; the outer layer is nano graphene; and the middle layer is graphite. The lithium battery manufactured by the negative electrode material for the lithium battery has the advantages of good rate capability and stable cycle performance; the method provided by the invention is simple to operate; and industrial production is easy to achieve.

Owner:周志才

Composite solid electrolyte, preparation method thereof and all-solid-state lithium ion battery

PendingCN112635818ALower grain boundary resistanceImprove interface performanceSecondary cells servicing/maintenanceSolid state electrolyteAll solid state

The invention provides a composite solid electrolyte, a preparation method thereof and an all-solid-state lithium ion battery. The composite solid electrolyte comprises an oxide electrolyte, and a sintering aid, a plasticizer, a polymer and a lithium salt which are filled in the oxide electrolyte, wherein the mass ratio of the oxide electrolyte to the sintering aid to the polymer to the lithium salt to the plasticizer is (50-95):(1-10):(0.1-40):(0.1-40):(0.1-40). The composite solid electrolyte provided by the invention can effectively reduce the interface impedance between electrolyte grains, and improve the cycle efficiency, the cycle stability and other qualities of the lithium ion battery.

Owner:ZHUHAI COSMX BATTERY CO LTD

Flame-retardant polylactic acid and starch compound fully-degradable plastic film and manufacturing method thereof

The invention discloses a flame-retardant polylactic acid and starch compound fully-degradable plastic film, which is characterized by being made from the following raw materials, by weight part, 80-85 of polylactic acid, 20-25 of corn starch, 12-14 of glycerin, 1.6-2 of epichlorohydrin, a proper amount of a sodium hydroxide solution with the concentration being 1 mol / L, a proper amount of hydrochloric acid with the concentration being 1 mol / L, a proper amount of distilled water, 25-30 of hemp fibers, 0.8-1 of a silane coupling agent kh-550, 1-2 of stearic acid, 5-6 of red phosphorus, 2-3 of attapulgite, 2-3 of zinc borate, 1-2 of rosin pentaerythrityl ester and a proper amount of absolute alcohol. In a process of internal mixing of polylactic acid, the added red phosphorus, attapulgite and zinc borate has a compound effect and a high-temperature-resistant and flame-retardant effect, and the whole cost of the plastic film is greatly reduced. The plastic film is good in flame retardance, toughness and mechanical properties, and is sturdy and durable. The method is innovative in technology and convenient for industrial control. The plastic film has a high degradation speed and can be widely applied.

Owner:ANHUI MENGNIU COLOR PRINTING&PACKAGING

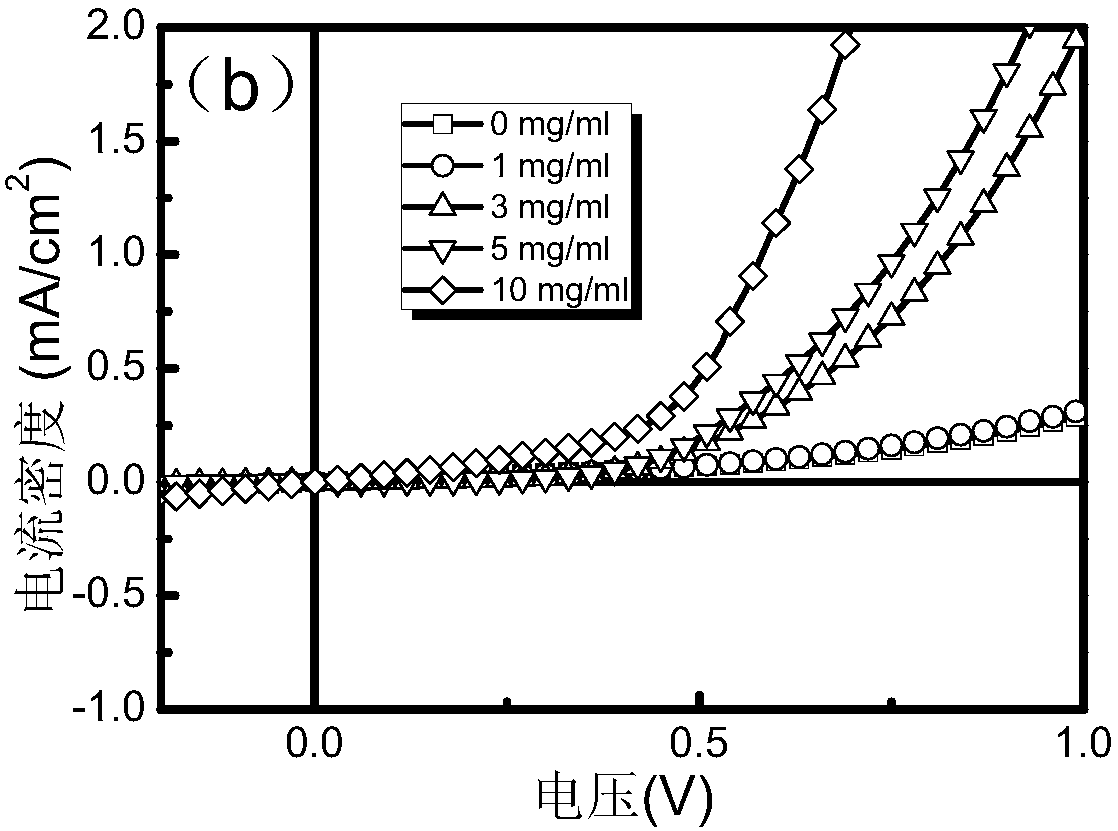

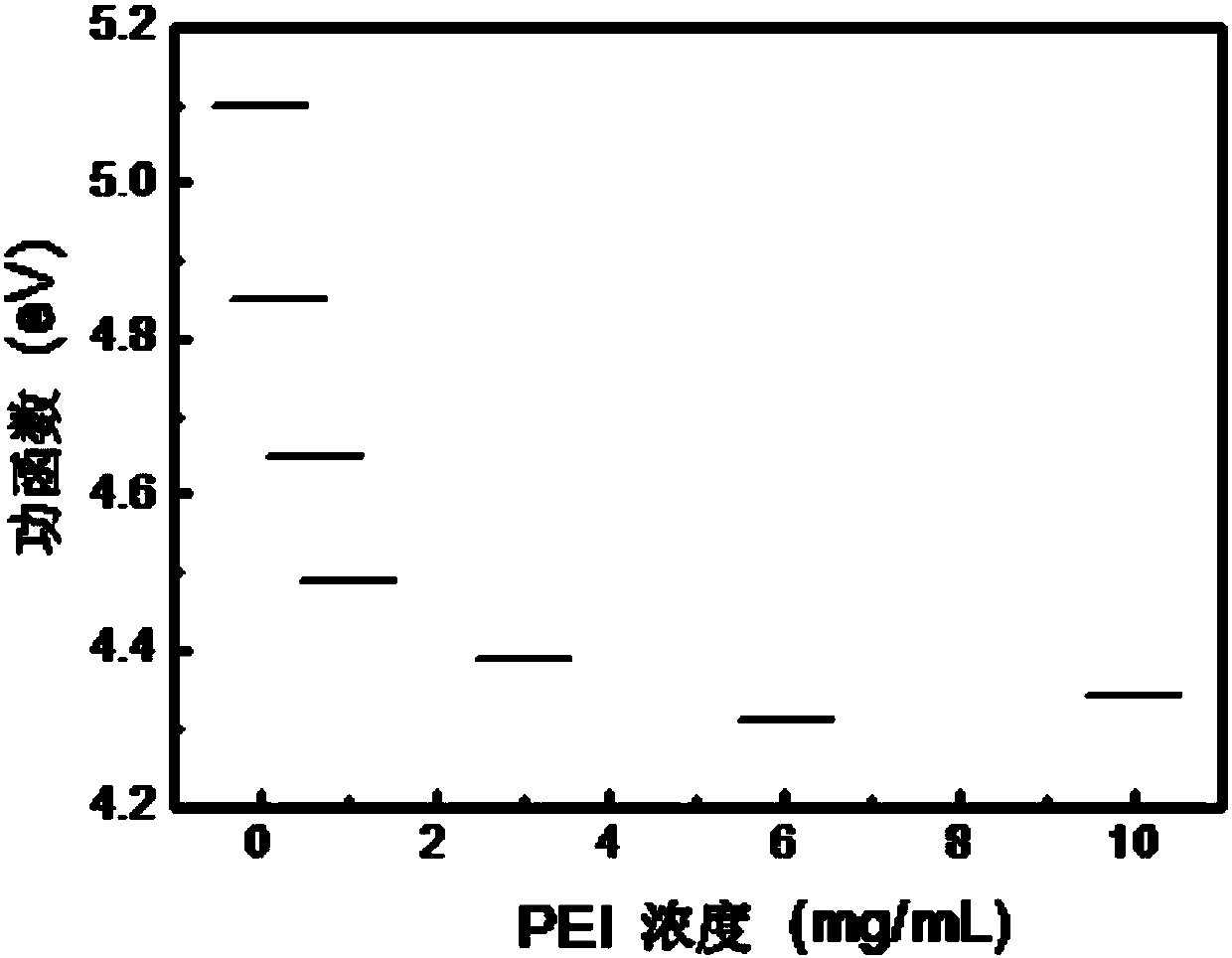

Polymer composite material with adjustable work function, and preparation method and application thereof

ActiveCN107629642AImprove interface contact performanceEasy to processFinal product manufactureSolid-state devicesComposite filmConductive polymer

The invention discloses a polymer composite material with an adjustable work function, and a preparation method and application thereof. The polymer composite material comprises at least one conductive polymer, at least one doping agent and at least one solvent which is used for cooperation with the other components of the composite material to form a uniform mixed system. The invention also discloses composite ink and a composite film based on the composite material, and preparation methods thereof. The polymer composite material, the composite ink and the composite film can be used for semiconductor devices with a photoelectric device as a representative. With the polymer composite material provided by the invention, the conductive composite film with a work function adjustable in a range of 4.0 to 5.2 eV can be formed, so the conductive composite film can be used as a modification layer for a positive electrode and a negative electrode, improves interfacial contact performance between electrodes and a photoactive layer and allows a formed device to present lower dependence on film thickness; and thus, requirements on preparation processes for devices can be lowered, and the yield of devices can be increased.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

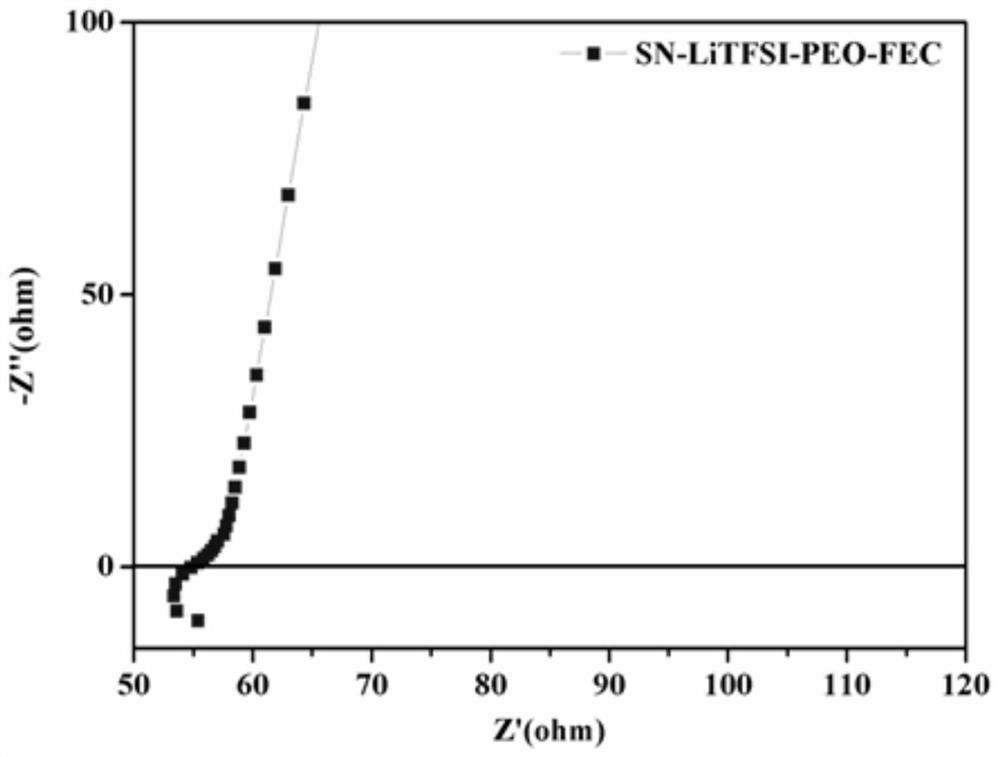

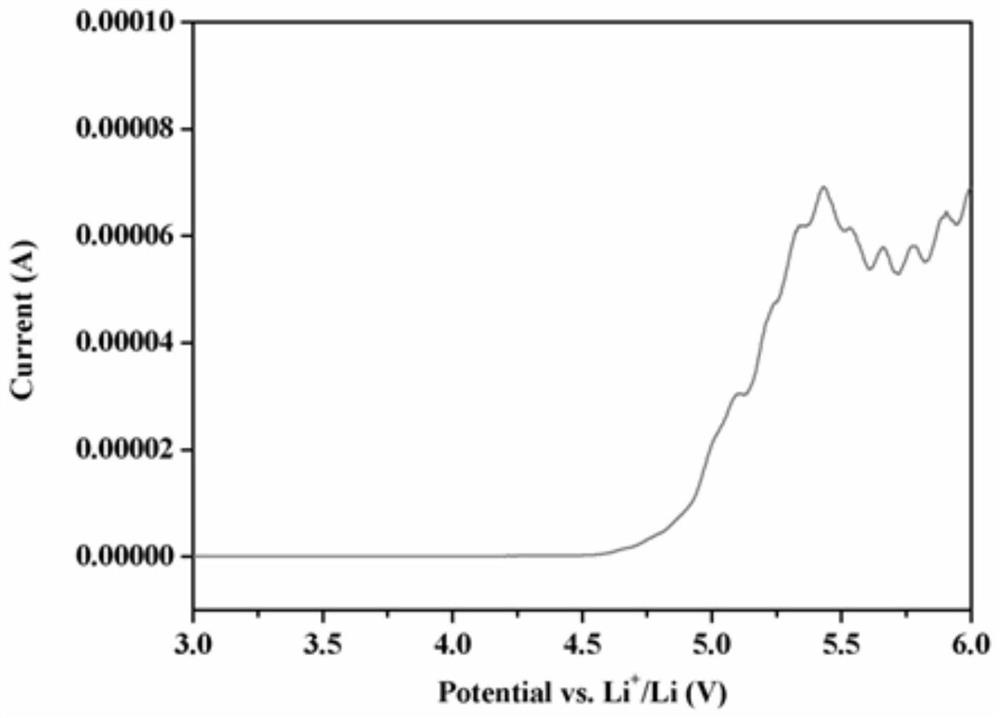

Gel-state electrode and preparation method thereof

ActiveCN113421995AAvoid pollutionFacilitates ion transportNon-aqueous electrolyte accumulator electrodesElectrolyte layer coatingPlastic crystalSolid-state battery

The invention discloses a gel-state electrode and a preparation method thereof. The electrode comprises an electrode active material, a conductive agent, SN, a lithium salt, a polymer and an additive. The preparation method comprises the following steps of dissolving the lithium salt and the additive in SN at 60-80 DEG C, adding the polymer, and fully stirring and dissolving to form a gel-state substance, and then, mixing the prepared gel-state substance, an electrode active material and a conductive agent, stirring or uniformly grinding, and coating one side of a solid electrolyte with the mixture to serve as the gel-state electrode of the solid-state battery. According to the type of the added polymer, whether cross-linking treatment is carried out or not is determined. The lithium salt can be completely dissolved in SN to form a plastic crystal electrolyte, and the selected polymer can also be dissolved in the plastic crystal electrolyte. According to the gel-state electrode provided by the invention, the contact performance between the electrode and the solid electrolyte can be improved, the ion transmission in the electrode can be improved, and the negative effect on the battery performance caused by the volume change generated in the charging and discharging process of the electrode active material can also be inhibited.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

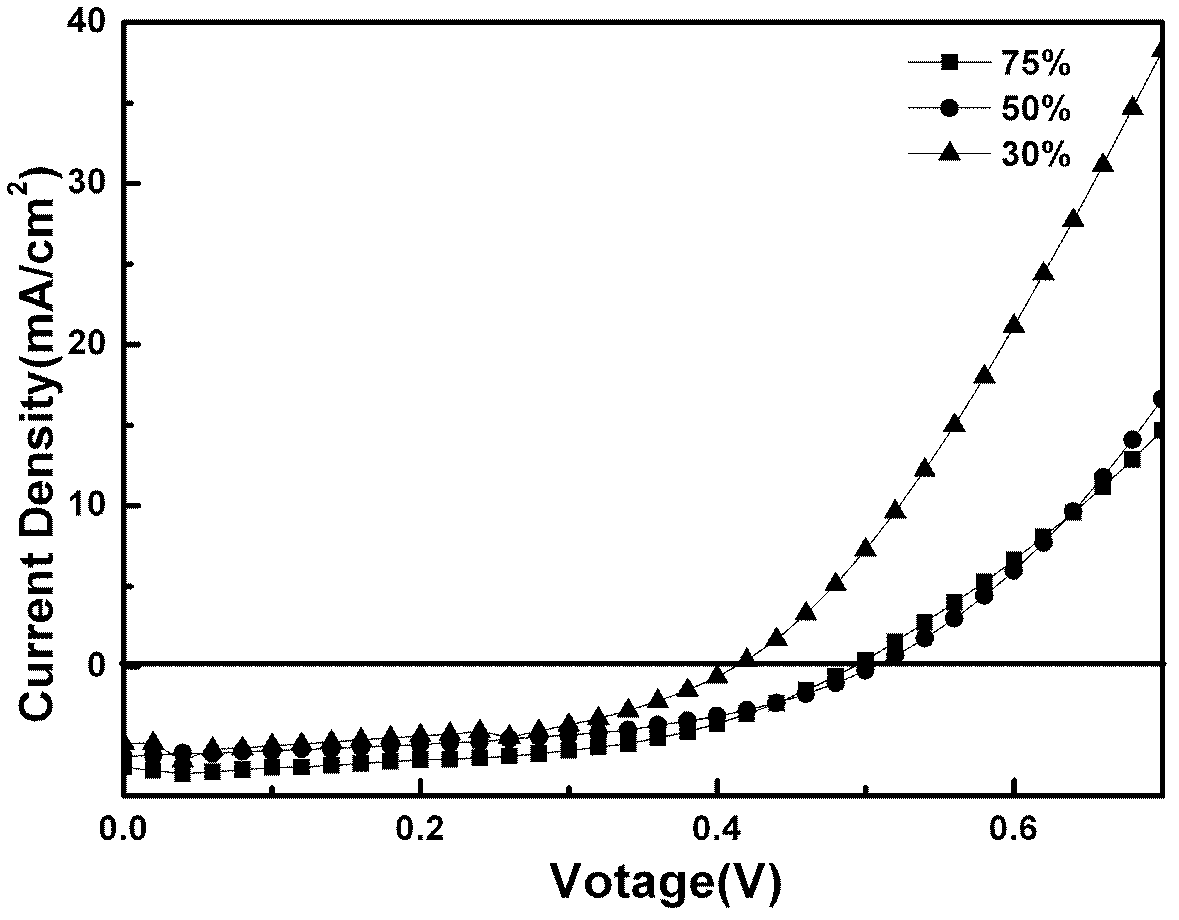

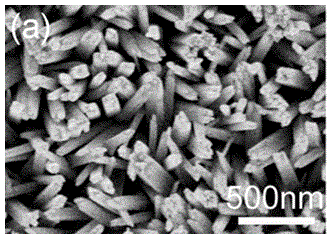

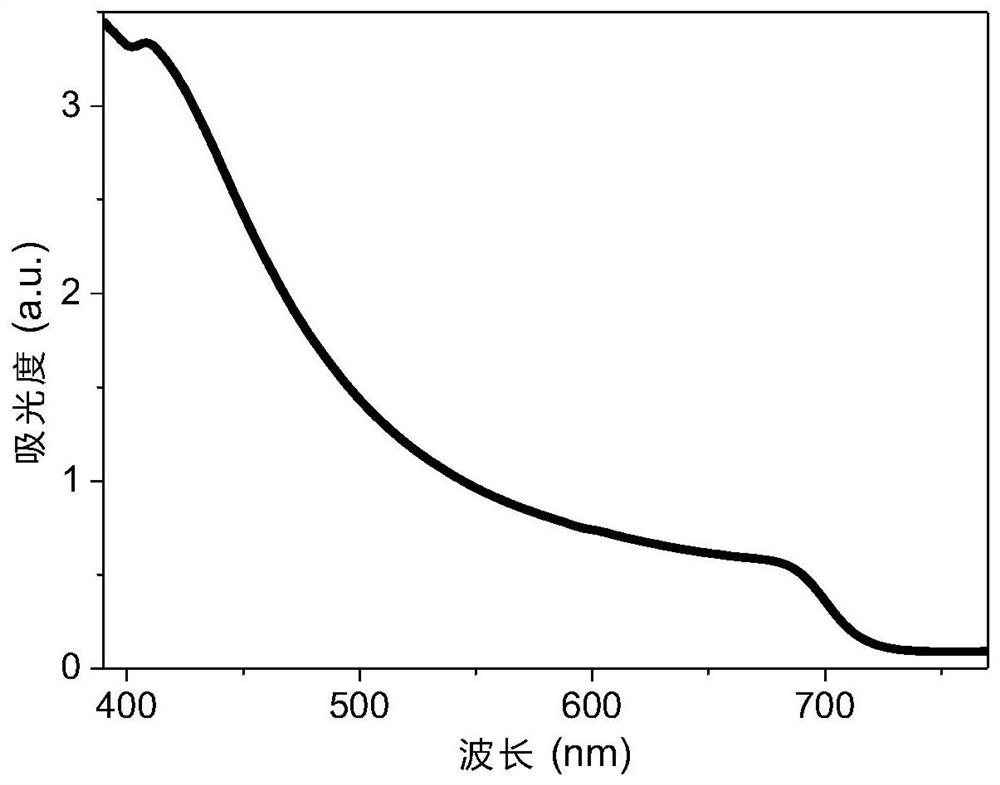

Organic-inorganic hybrid solar cell and preparation method thereof

InactiveCN104617221AEasy to makeEnhanced fluorescence quenchingFinal product manufactureSolid-state devicesHole transport layerOrganic polymer

The invention discloses an organic-inorganic hybrid solar cell and a preparation method thereof. The organic-inorganic hybrid solar cell includes a piece of FTO (Fluorine-doped Tin Oxide) conducting glass, a TiO2 nano rod array growing on the FTO conducting glass, a hole transmission layer and metal Au, wherein the hole transmission layer covers on the surface of the TiO2 nano rod array and is formed by a PEDOT:PSS film; metal Au is evaporated on the PEDOT:PSS film. Triphenylamine dyestuff is adsorbed on the surface of the TiO2 nano rod array, p-type organic polymer poly-3- hexylthiophene is coated on the surface of the TiO2 nano rod array in a spinning mode. By providing interface modification, the organic-inorganic hybrid solar cell can improve contact of inorganic semiconductor TiO2 and organic polymer P3HT as well as the separation efficiency of excitons in the interface, restrain charge recombination and reduce dark currents, and has high photoelectric conversion efficiency. The preparation method of the organic-inorganic hybrid solar cell is simple and easy to operate, obviously improves the photoelectric property and shows a potential application prospect.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

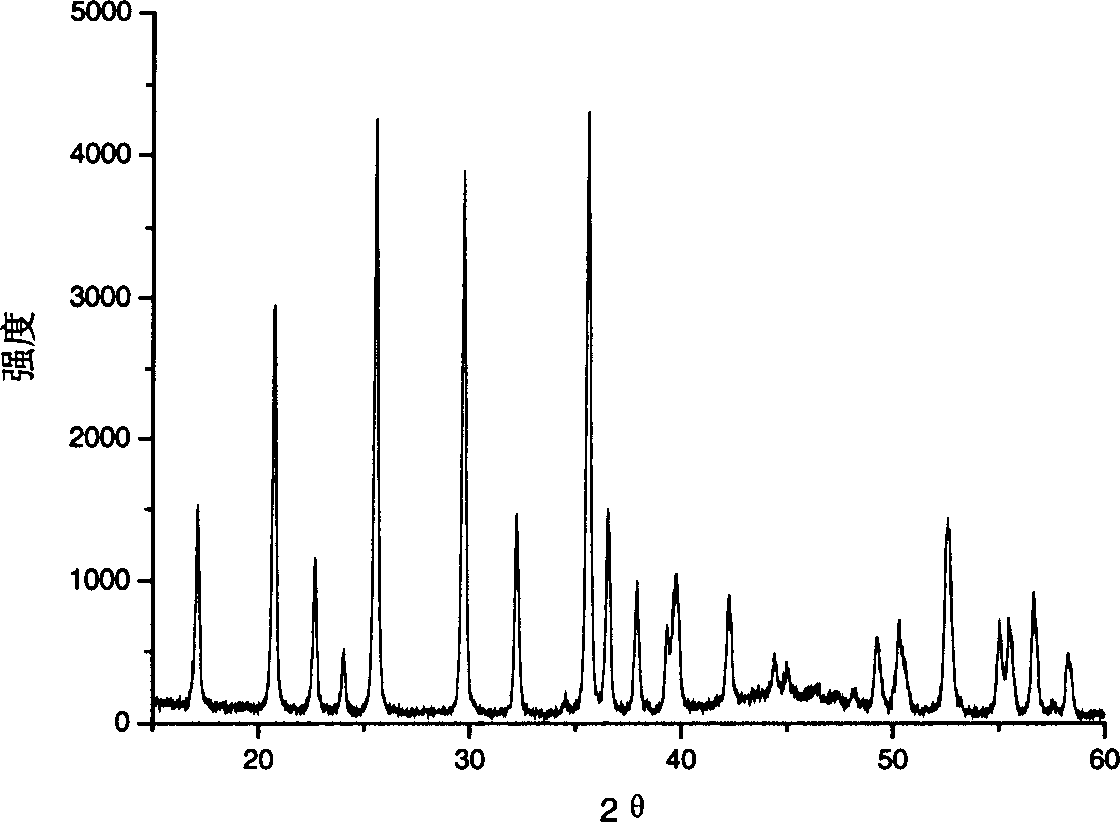

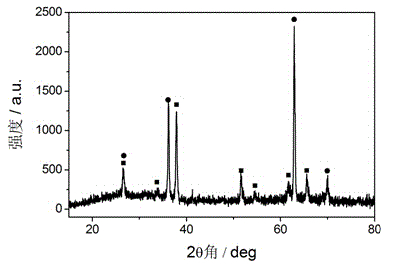

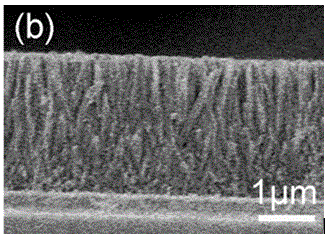

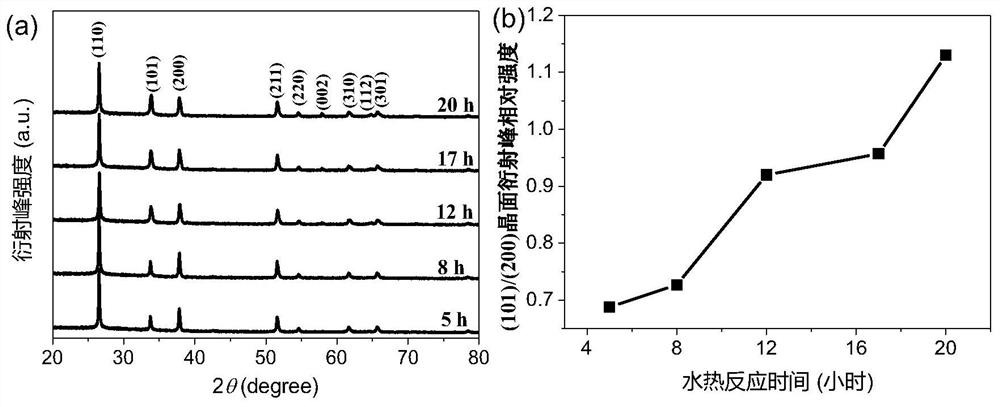

Inorganic perovskite solar cell based on ordered SnO2 nanorod array and preparation method of inorganic perovskite solar cell

ActiveCN111739961AImprove collection efficiencyImprove light absorption efficiencyMaterial nanotechnologyFinal product manufactureFast chargingSolar battery

The invention relates to the field of solar cells, specifically, relates to an inorganic perovskite solar cell based on an ordered SnO2 nanorod array and a preparation method of inorganic perovskite solar cell. The inorganic perovskite solar cell comprises a conductive substrate, a SnO2 seed crystal layer deposited on the surface of the conductive substrate, a SnO2 seed crystal layer, a SnO2 nanorod array growing on the surface of the SnO2 seed crystal layer, an inorganic perovskite layer deposited in gaps of SnO2 nanorods and on the surfaces of the SnO2 nanorods, a hole transport layer deposited on the surface of the inorganic perovskite layer, and an Au electrode layer deposited on the surface of the hole transport layer. The inorganic perovskite solar cell provided by the invention hasthe advantages of fast charge transmission, high charge extraction efficiency, high photoelectric conversion efficiency, good device stability and the like. The preparation method is simple and convenient to operate, is low in cost and wide in application range, and the prepared solar cell is stable and efficient.

Owner:HUBEI UNIV OF ARTS & SCI

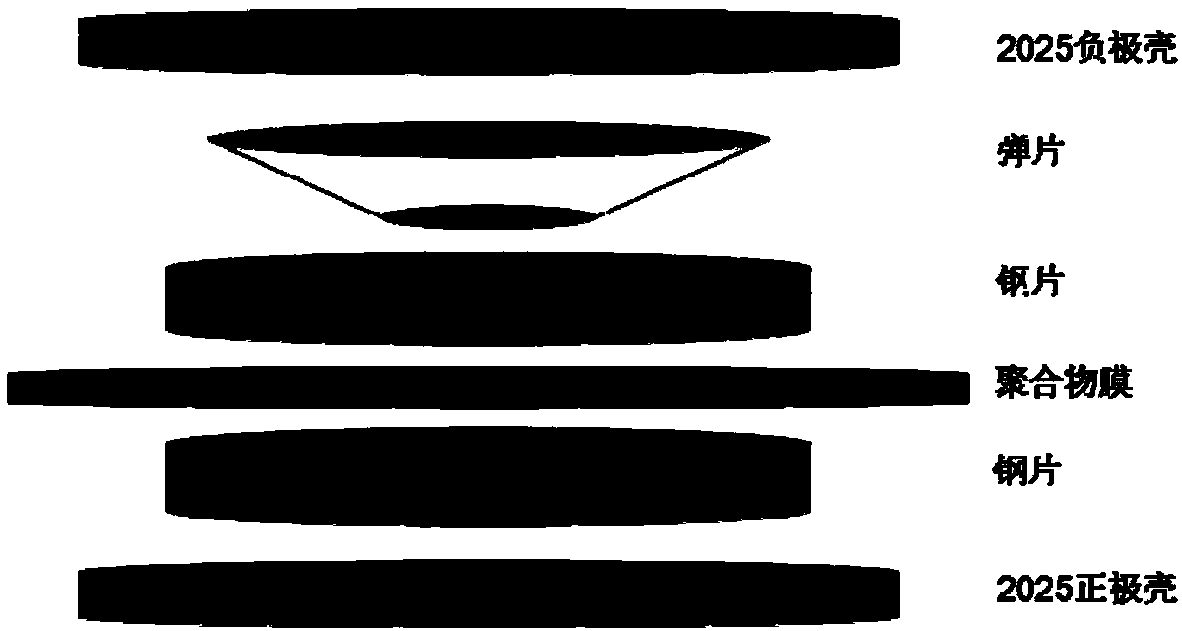

A method for assemble a blocking cell to improve that interface contact of the blocking cell

ActiveCN108987815AImprove interface contact performanceImprove fitFinal product manufactureElectrolyte accumulators manufacturePolymer electrolytesNon destructive

The invention discloses a blocking battery assembly method for improving the contact property of the blocking battery interface, which comprises the following steps: (1) treating the front and back sides of a polymer electrolyte membrane with a polar solvent; (2) placing two stainless steel sheets or gold sheets on two sides of the polymer electrolyte membrane treated in the step (1) to form a blocking battery precursor; 3) fully dry that blocking battery precursor and encapsulate the blocking battery by a mold to obtain a blocking battery. The blocking battery assembly method provided by theinvention can improve the contact property of the blocking battery interface, In order to avoid the contradiction that the traditional polymer can not improve the contact property of the interface byhot melting due to the poor thermal stability, the polymer film and blocking electrode can be bonded well when the polymer film is not heated at high temperature, and the non-destructive characterization of the room temperature ionic conductivity of the polycarbonate-based solid electrolyte can be realized.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

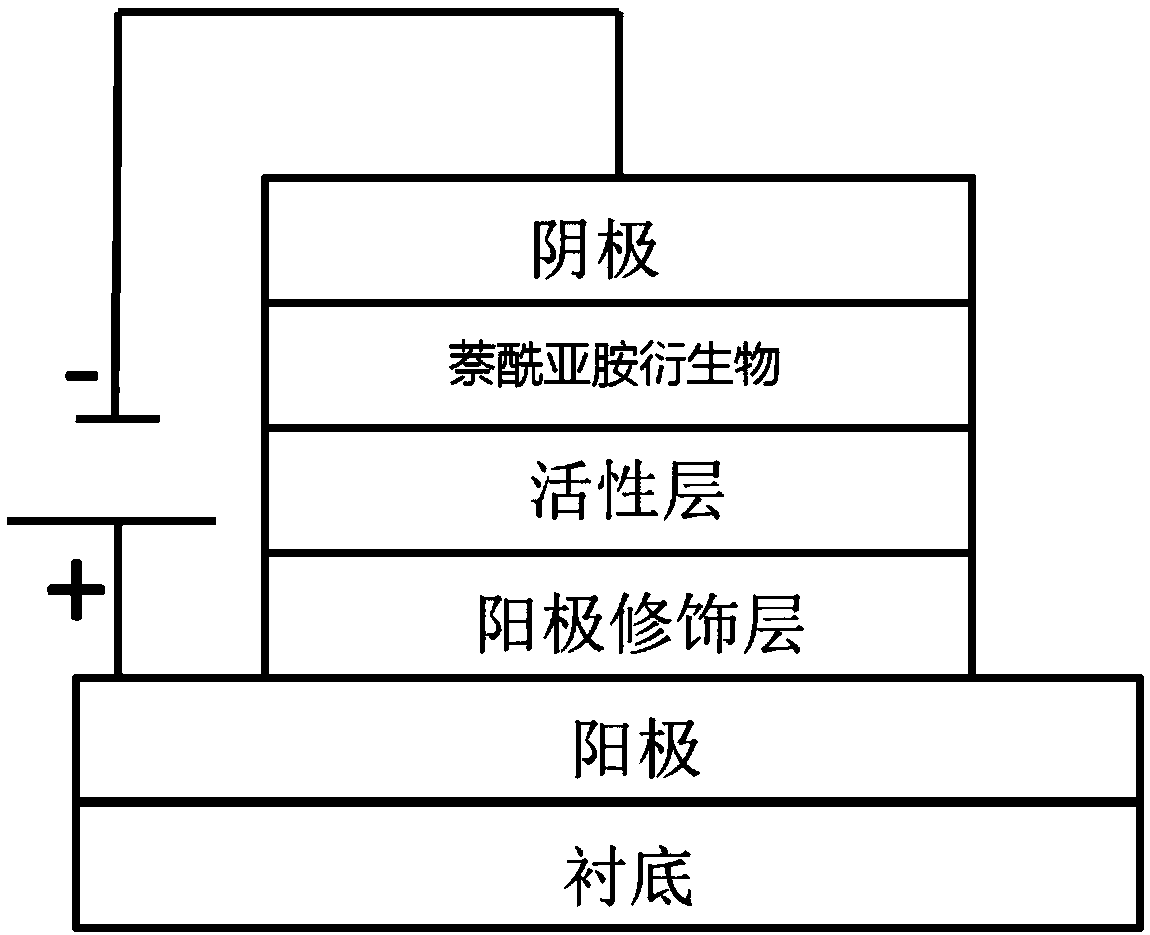

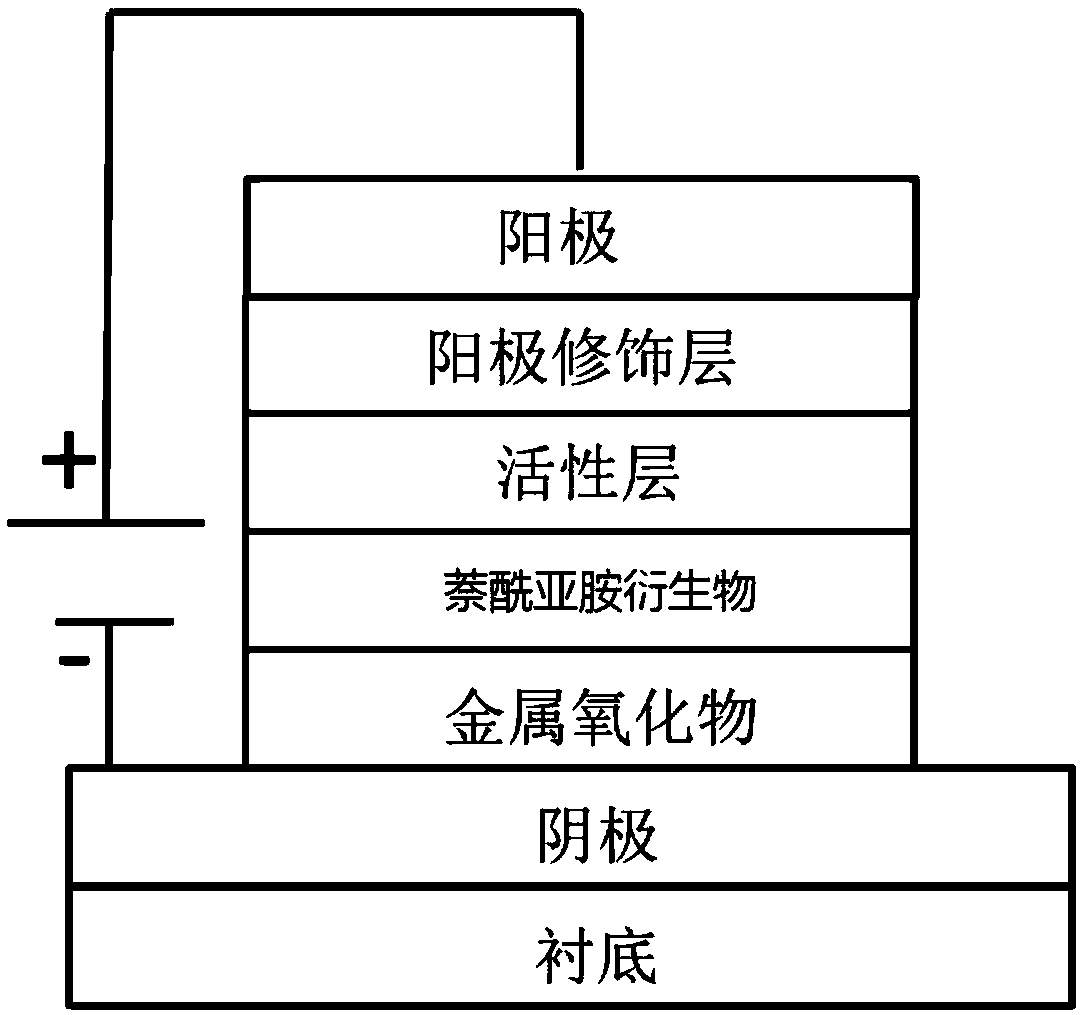

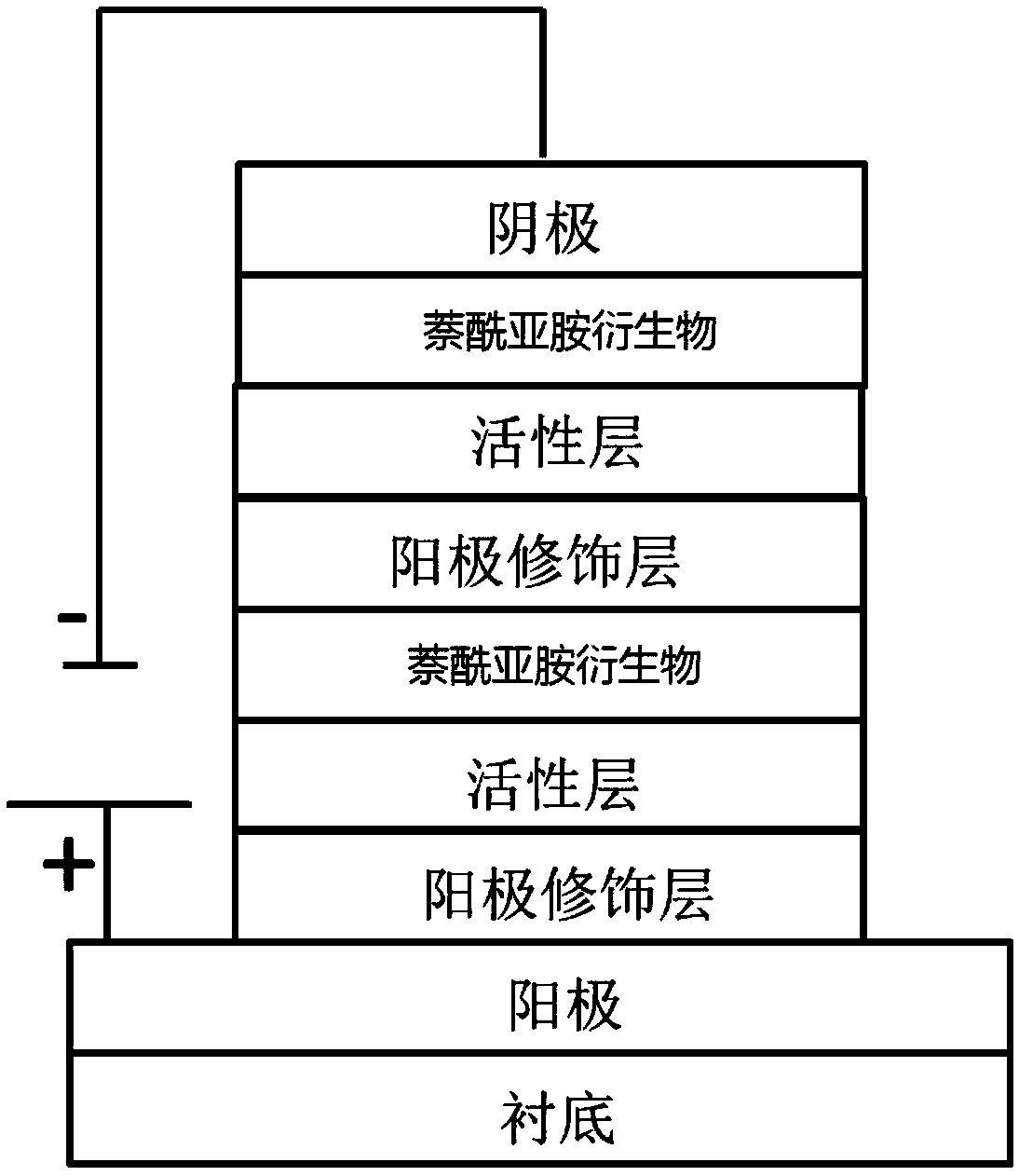

Naphthalimides derivatives and solar cell

InactiveCN109535078AImprove transmission performanceImprove transmission efficiencyOrganic chemistrySolid-state devicesElectronic transmissionAlcohol

The invention discloses naphthalimides derivatives and a solar cell, and provides the series of naphthalimides derivatives. The naphthalimides derivatives take n-type naphthalimides as basic units; the naphthalimides is connected through ethylene bonds, acetylene bonds or aromatic compounds; the tail ends of naphthalimides contain strong polarity water / alcohol-soluble groups; and the naphthalimides derivatives are water / alcohol-soluble conjugated small molecules. The molecules have excellent dissolution performance in environment-friendly solvents (such as water and alcohol), and meanwhile canfurther improve the electronic transmission performance; in addition, freely moving counter-anions can conduct n-type doping on active layer materials, the interface contact performance is improved,the electronic transmission loss is reduced, and the electronic transmission efficiency is improved; and therefore, the naphthalimides derivatives, serving as cathode interface materials, will have great application potential in the aspect of the novel solar cells.

Owner:SHENZHEN UNIV

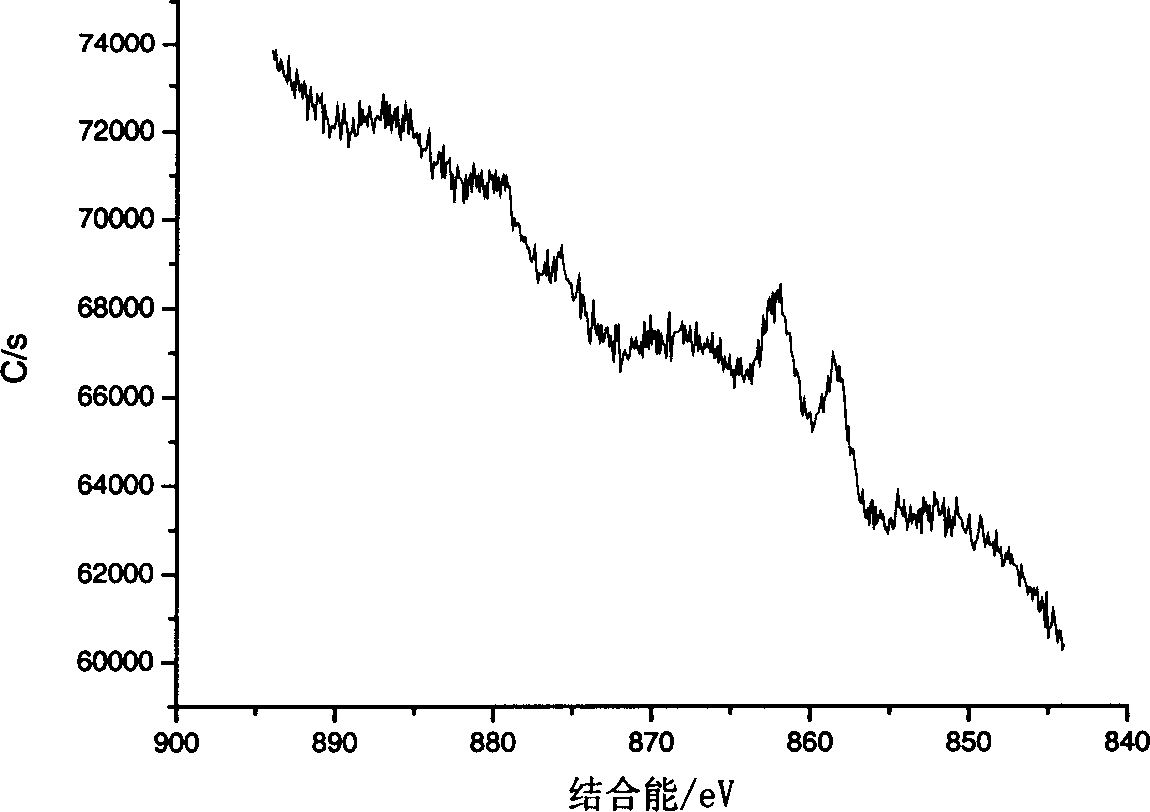

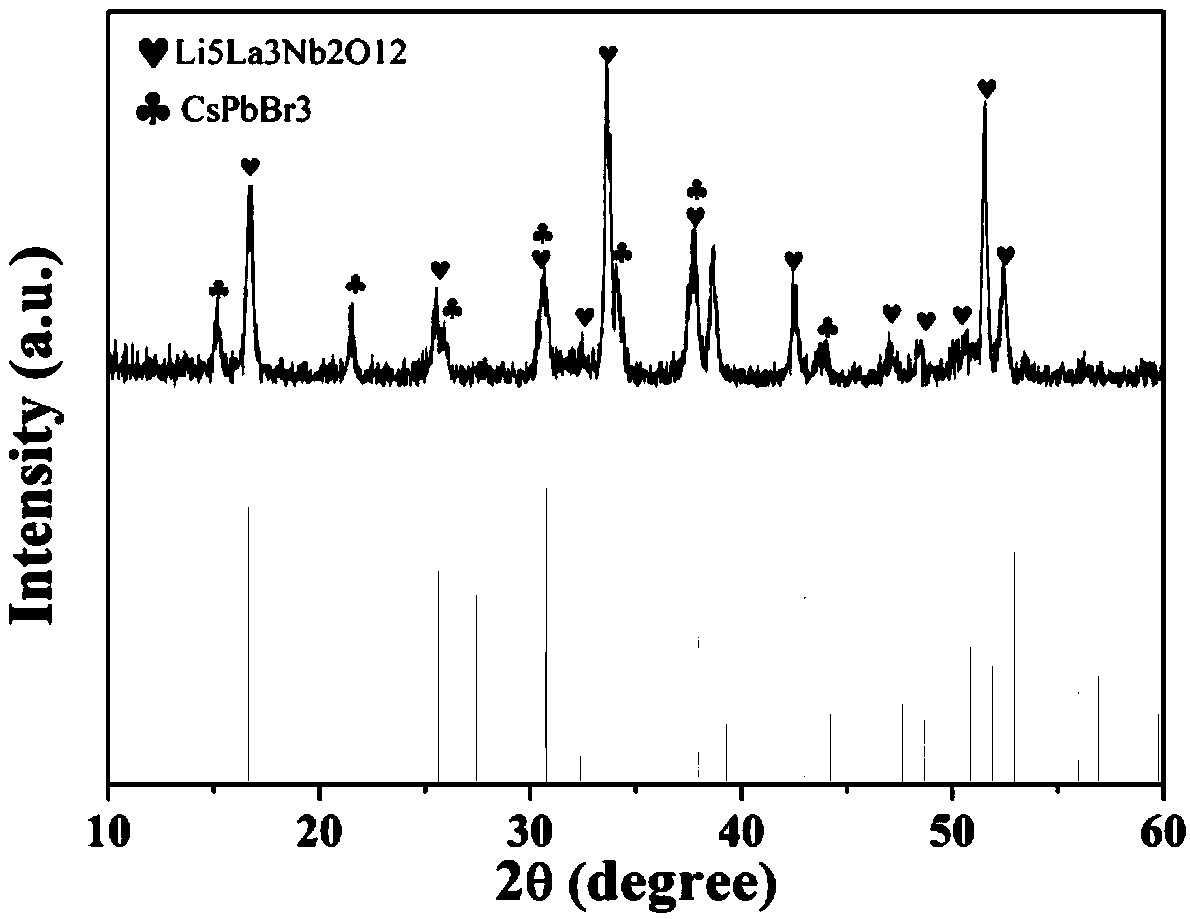

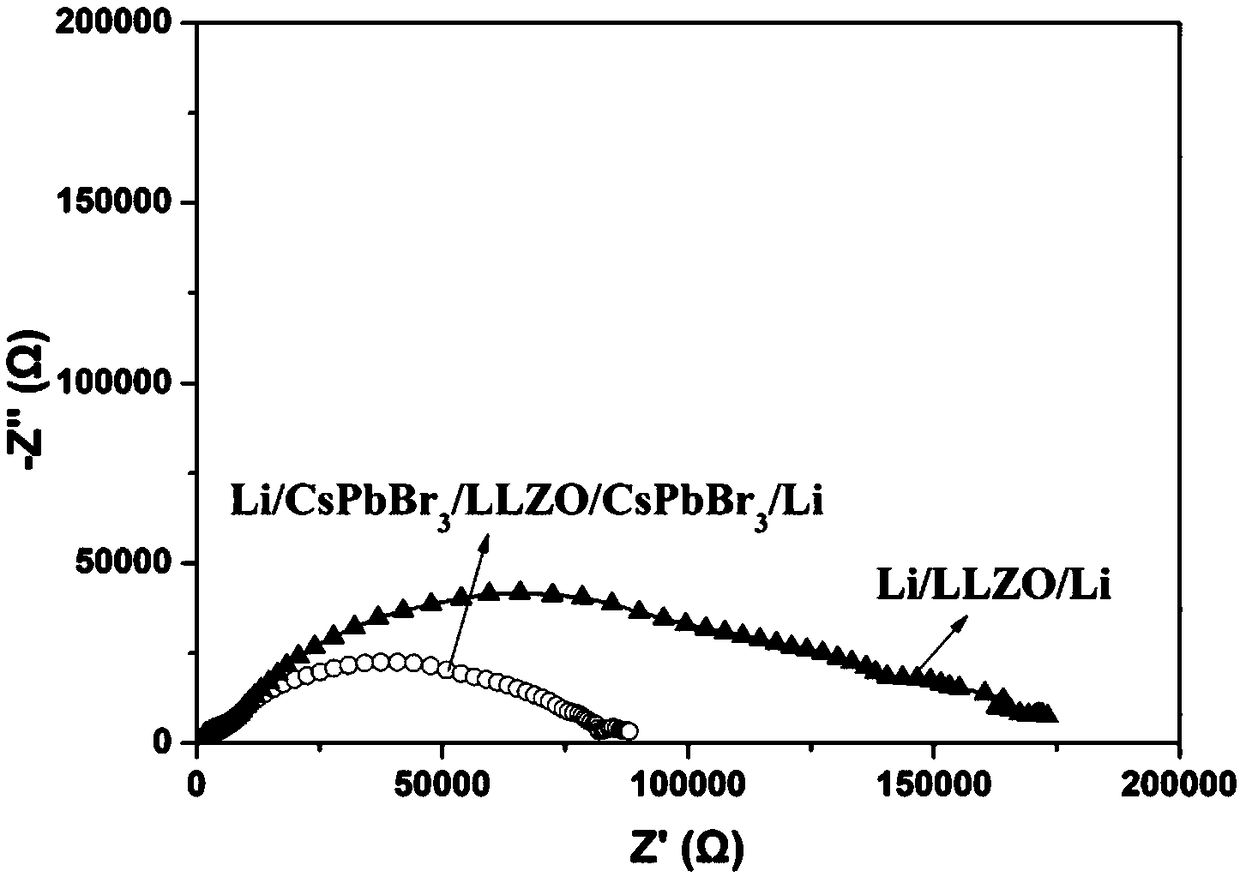

Lithium secondary battery, solid electrolyte composite material for same and method for preparing solid electrolyte composite material

ActiveCN109361014AImprove ionic conductivityWide electrochemical windowSolid electrolytesFinal product manufactureLithiumInter layer

The invention relates to a lithium secondary battery, a solid electrolyte composite material for the same and a method for preparing the solid electrolyte composite material, and belongs to the fieldof material chemistry. The solid electrolyte composite material is of a double-layer or three-layer structure. The solid electrolyte composite material comprises a layer of Li<7>La<3>Zr<2>O<12> and alayer of CsPbBr<3> when the solid electrolyte composite material is of the double-layer structure. The solid electrolyte composite material comprises an intermediate layer of Li<7>La<3>Zr<2>O<12> whenthe solid electrolyte composite material is of the three-layer structure, and two layers of CsPbBr<3> are arranged on the upper side and the lower side of the intermediate layer. The solid electrolyte composite material is prepared by the aid of spin-coating processes. The lithium secondary battery, the solid electrolyte composite material and the method have the advantages that the solid electrolyte composite material can be used as a solid electrolyte to be applied to the lithium secondary battery, accordingly, interface contact of the solid electrolyte and metal lithium negative electrodescan be improved, interface resistance can be lowered, the capacity of the battery can be enhanced, and the cycle performance of the battery can be improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Silicon dioxide/micro-swelling graphite/graphite composite heat conduction silicone grease and preparation method thereof

InactiveCN107746576AImprove insulation performanceImprove thermal conductivityHeat-exchange elementsAlcoholAntioxidant

The invention discloses silicon dioxide / micro-swelling graphite / graphite composite heat conduction silicone grease and a preparation method thereof. The preparation method comprises the following steps of uniformly mixing micro-swelling graphite and graphite by a high-speed mixing machine, so as to obtain heat conduction filler for further use; adding the heat conduction filler into an ethyl alcohol solution, stirring by ultrasonic waves, then adding a coupling agent into a reaction kettle, stirring, then adding silicon dioxide, and enabling the ethyl alcohol to completely evaporate, so as toobtain modified compound heat conduction filler; finally, adding the obtained modified compound heat conduction filler, silicone oil, a crosslinking agent, a surfactant and an antioxidant into an internal mixer to perform banburying, so as to obtain the composite heat conduction silicone grease. The silicon dioxide / micro-swelling graphite / graphite composite heat conduction silicone grease has theadvantages that the surfaces of the micro-swelling graphite and graphite are coated with the surfactant, and the insulation property, heat conduction property, softness, rebound resilience and plasticity are improved at the premises of sufficient utilization of heat conduction property; the heat conduction rate of the silicon dioxide is high, and the sources are wide; by compounding with grapheneand the graphite, the heat conduction silicone grease with high heat conduction coefficient, excellent insulation property, high price-to-performance ratio and wide application range can be prepared.

Owner:郴州国盛新材科技有限公司

Novel polylactic acid and starch compound fully-degradable plastic film and manufacturing method thereof

The invention discloses a novel polylactic acid and starch compound fully-degradable plastic film, which is characterized by being made from the following raw materials, by weight part, 80-85 of polylactic acid, 20-25 of corn starch, 12-14 of glycerin, 1.6-2 of epichlorohydrin, a proper amount of a sodium hydroxide solution with the concentration being 1 mol / L, a proper amount of hydrochloric acid with the concentration being 1 mol / L, a proper amount of distilled water, 25-30 of hemp fibers, 0.8-1 of a silane coupling agent kh-550 and 2-3 of talcum powder. The fully-degradable plastic film is excellent in toughness and mechanical properties, is easy to degrade under a natural condition and is safe and eco-friendly. The method is innovative in technology and convenient for industrial control. The film can be used as food package bags, preservative films, and the like.

Owner:ANHUI MENGNIU COLOR PRINTING&PACKAGING

Dry thermal interface material

InactiveCN1697870APositive coefficient of thermal expansionAvoid pollutionSemiconductor/solid-state device detailsSolid-state devicesPolymer scienceActive agent

Owner:AOS THERMAL COMPOUNDS

Fully-degradable plastic film with enhanced mechanical property and manufacturing method of fully-degradable plastic film

InactiveCN105968744ASolve poorly described problemsHigh strengthEnvironmental resistanceMechanical property

The invention discloses a fully-degradable plastic film with enhanced mechanical property. The plastic film is characterized by being made from the following raw materials, by weight part, 80-85 of polylactic acid, 25-30 of hemp fibers, 0.8-1 of a silane coupling agent kh-550, 20-25 of corn starch, 12-14 of glycerin, 1.6-2 of epichlorohydrin, a proper amount of a sodium hydroxide solution with the concentration being 1 mol / L, a proper amount of hydrochloric acid with the concentration being 1 mol / L, a proper amount of distilled water, 1-1.5 of epoxidized soybean oil, 5-7 of natural latex, 2-3 of butyl lactate and 3-5 of bamboo fibers. The manufactured fully-degradable plastic film is good in toughness and mechanical property, is easy to degrade in a natural condition, and is safe and eco-friendly. The manufacturing method is innovative in process and convenient for industrial control. The fully-degradable plastic film can be widely applied to packages for food and daily necessities. The plastic film is safe and eco-friendly, can be fully degraded, and is high in degradation speed.

Owner:ANHUI MENGNIU COLOR PRINTING&PACKAGING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com