Composite solid electrolyte, preparation method thereof and all-solid-state lithium ion battery

A solid-state electrolyte, lithium-ion battery technology, applied in secondary batteries, secondary battery repair/maintenance, circuits, etc., can solve the problems of poor physical contact and limited improvement effect, achieve low room temperature impedance and dense surface macroscopic morphology The effect of leveling and avoiding lithium loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] Another aspect of the present invention provides a method for preparing a composite solid electrolyte, comprising:

[0041] The mixed powder containing oxide electrolyte, sintering aid and pore-forming agent is sequentially subjected to tableting and sintering treatment to obtain a composite solid electrolyte precursor;

[0042] After infiltrating the composite solid electrolyte precursor with a slurry containing polymer monomers, lithium salts, initiators and plasticizers, and then undergoing thermal initiation treatment, the composite solid electrolyte is obtained.

[0043] The above-mentioned oxide electrolytes, sintering aids, polymerized monomers, initiators, lithium salts and plasticizers are used as raw materials for composite solid electrolytes. Reasonable adjustment of the ratio / dosage of each raw material can further improve the ionic conductivity of composite solid electrolytes, etc. Performance, in specific implementation, in the above raw materials, the mas...

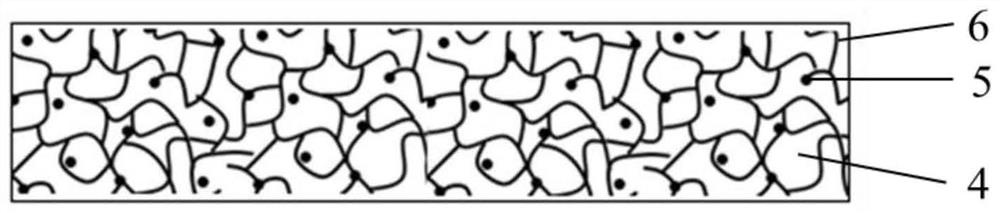

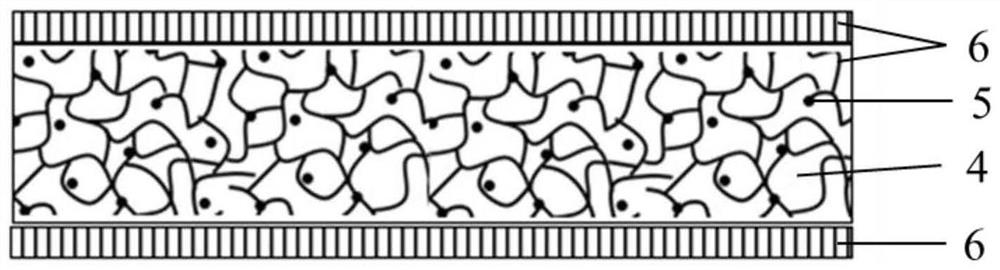

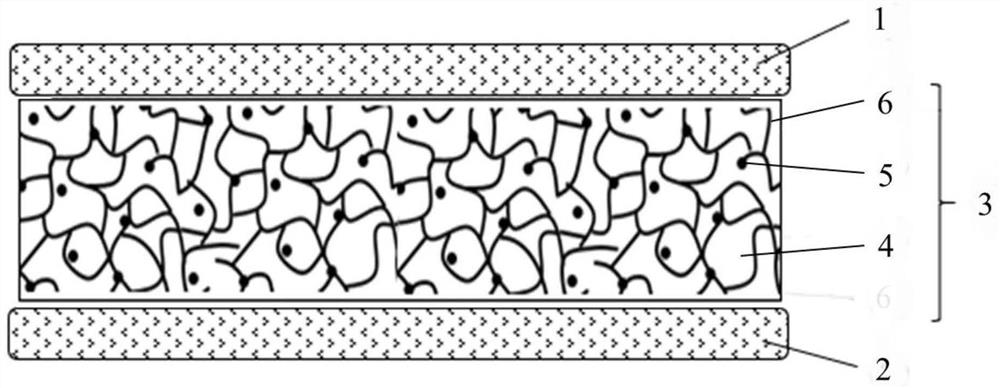

Embodiment 1

[0062] The composite solid electrolyte and lithium-ion battery provided by this embodiment are as follows: Figure 4 As shown, the lithium ion battery includes a positive electrode sheet 1, a negative electrode sheet 2 and a composite solid electrolyte 3, wherein the composite solid electrolyte 3 includes a core layer and a first surface positioned at the core layer and a second surface opposite to the first surface Polymer electrolyte layer 6 (polymer electrolyte 6 is composed of plasticizer, polymer and lithium salt), the core layer includes oxide electrolyte 4 and sintering aid 5 filled in oxide electrolyte 4 and filled in oxide electrolyte Plasticizer, polymer and lithium salt in 4 (plasticizer, polymer and lithium salt form polymer electrolyte 6); Wherein, positive electrode sheet 1 comprises current collector and the positive electrode function layer that is coated on collector, this The surface density of the positive electrode functional layer is 10mg / cm 2 , its raw m...

Embodiment 2

[0078] The composite solid electrolyte and lithium-ion battery provided by this embodiment are as follows: Figure 4 As shown, the lithium ion battery includes a positive electrode sheet 1, a negative electrode sheet 2 and a composite solid electrolyte 3, wherein the composite solid electrolyte 3 includes a core layer and a first surface positioned at the core layer and a second surface opposite to the first surface Polymer electrolyte layer 6 (polymer electrolyte 6 is composed of plasticizer, polymer and lithium salt), the core layer includes oxide electrolyte 4 and sintering aid 5 filled in oxide electrolyte 4 and filled in oxide electrolyte Plasticizer, polymer and lithium salt in 4 (plasticizer, polymer and lithium salt form polymer electrolyte 6); Wherein, positive electrode sheet 1 comprises current collector and the positive electrode function layer that is coated on collector, this The surface density of the positive electrode functional layer is 12mg / cm 2 , whose raw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com