Preparation method of soft magnetic ferrite material

A soft ferrite and auxiliary material technology, which is applied in the manufacture of inductors/transformers/magnets, inorganic material magnetism, electrical components, etc. Market demand, increasing the volume of Mn-Zn ferrite cores, etc., to achieve the effect of increasing the saturation magnetic flux density, increasing the density, and increasing the saturation magnetic flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

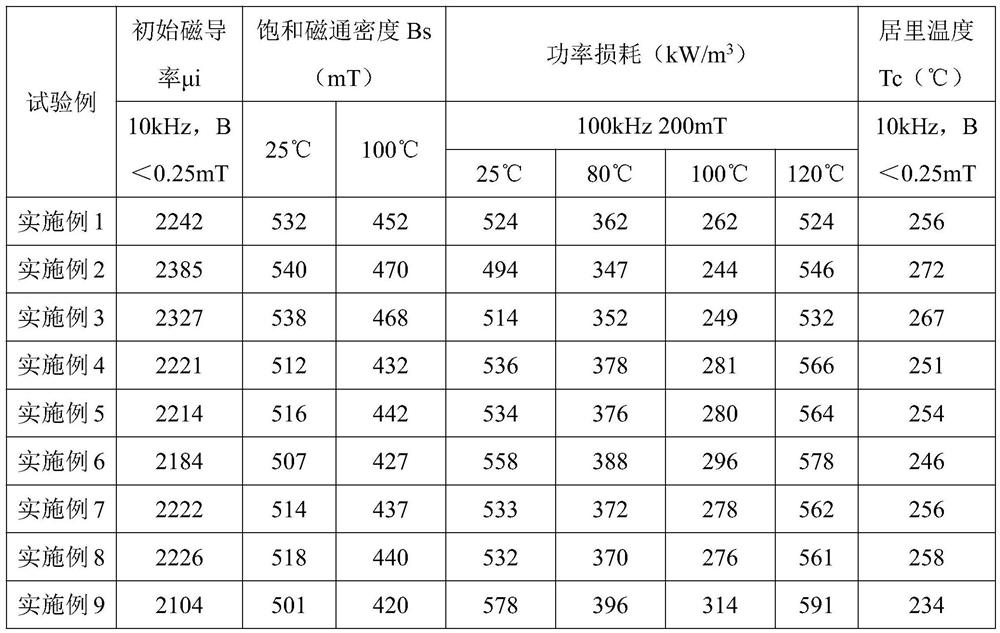

Examples

Embodiment 1

[0029] A preparation method of a soft ferrite material, comprising the following steps: the raw material includes a main material and an auxiliary material, and the main material is: Fe 2 O 3 80 parts, Mn 3 O 4 25 parts, 3 parts of ZnO, auxiliary materials: 0.1 part of CaO, Co 2 O 3 0.001 part, SiO 2 0.001 part, 2 parts superfine heavy calcium, 0.001 part chopped glass fiber;

[0030] Step S1: primary ball milling of the main material: the main material is ground in a ball mill to a particle size of 10 μm, dried and cooled to room temperature;

[0031] Step S2: Pre-sintering: the cooled main material is pre-sintered at a temperature of 600°C and a pre-sintered time of 1.5h, taken out and then cooled and blended with the auxiliary materials;

[0032] Step S3: secondary ball milling: put the mixed main material and auxiliary material into a ball mill for secondary ball milling for 2.5 hours, and obtain a pre-sintered mixture after drying;

[0033] Step S4: Mixing and grin...

Embodiment 2

[0039] A preparation method of a soft ferrite material, comprising the following steps: the raw material includes a main material and an auxiliary material, and the main material is: Fe 2 O 3 85 parts, Mn 3 O 4 40 parts, 5 parts of ZnO, auxiliary materials: 0.3 parts of CaO, Co 2 O 3 0.002 part, SiO 2 0.003 part, 5 parts of superfine heavy calcium, 0.003 part of chopped glass fiber;

[0040] Step S1: primary ball milling of the main material: the main material is ground in a ball mill to a particle size of 20 μm, dried and cooled to room temperature;

[0041] Step S2: Pre-sintering: the cooled main material is pre-sintered at a temperature of 750° C. and a pre-sintered time of 2 hours, taken out and then cooled and blended with the auxiliary materials;

[0042] Step S3: secondary ball milling: put the mixed main material and auxiliary material into a ball mill for secondary ball milling for 3 hours, and obtain a pre-sintered mixture after drying;

[0043] Step S4: Mixin...

Embodiment 3

[0049] A preparation method of a soft ferrite material, comprising the following steps: the raw material includes a main material and an auxiliary material, and the main material is: Fe 2 O 3 82 parts, Mn 3 O 4 30 parts, 4 parts of ZnO, auxiliary materials: 0.2 parts of CaO, Co 2 O 3 0.0015 part, SiO 2 0.002 part, 3 parts of superfine heavy calcium, 0.002 part of chopped glass fiber;

[0050] Step S1: primary ball milling of the main material: the main material is ground in a ball mill to a particle size of 15 μm, dried and cooled to room temperature;

[0051] Step S2: Pre-sintering: the cooled main material is pre-sintered at a temperature of 650°C and a pre-sintered time of 1.8 hours, taken out and then cooled and blended with the auxiliary materials;

[0052] Step S3: secondary ball milling: put the mixed main material and auxiliary material into a ball mill for secondary ball milling for 2.8 hours, and obtain a pre-sintered mixture after drying;

[0053] Step S4: Mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com