Thin lithium battery and method for manufacturing same

A lithium battery, thin technology, applied in the direction of electrolyte storage battery manufacturing, electrode manufacturing, lithium storage battery, etc., can solve the problems of difficult application of electronic products, thick button battery, reduced productivity, etc., to reduce grain boundary resistance, increase productivity, The effect of increased production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

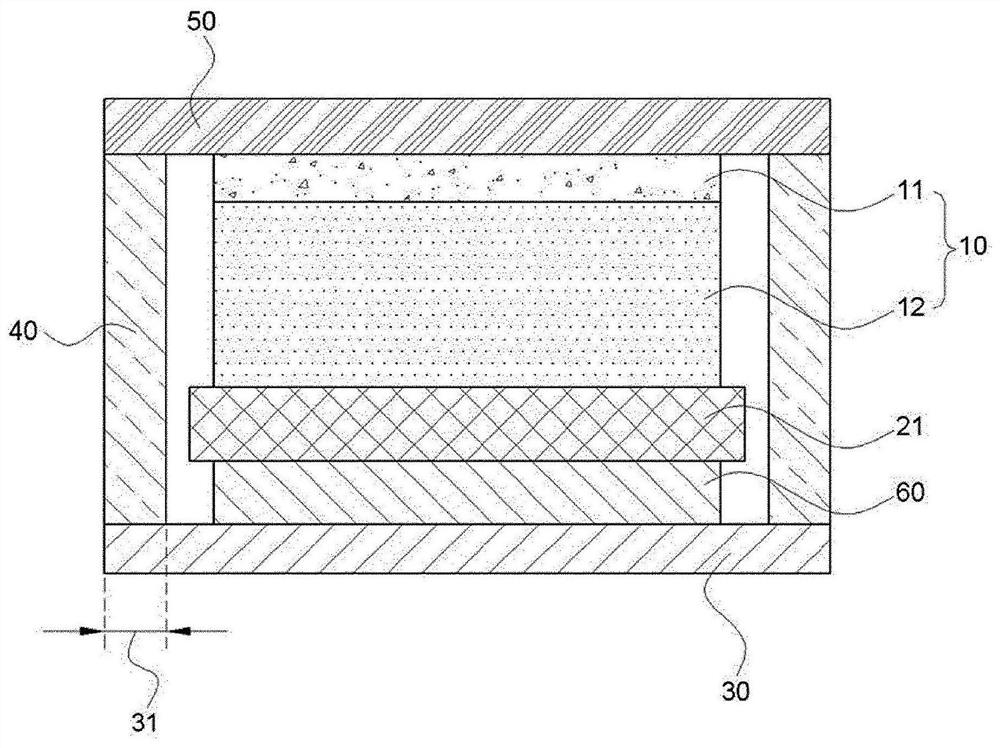

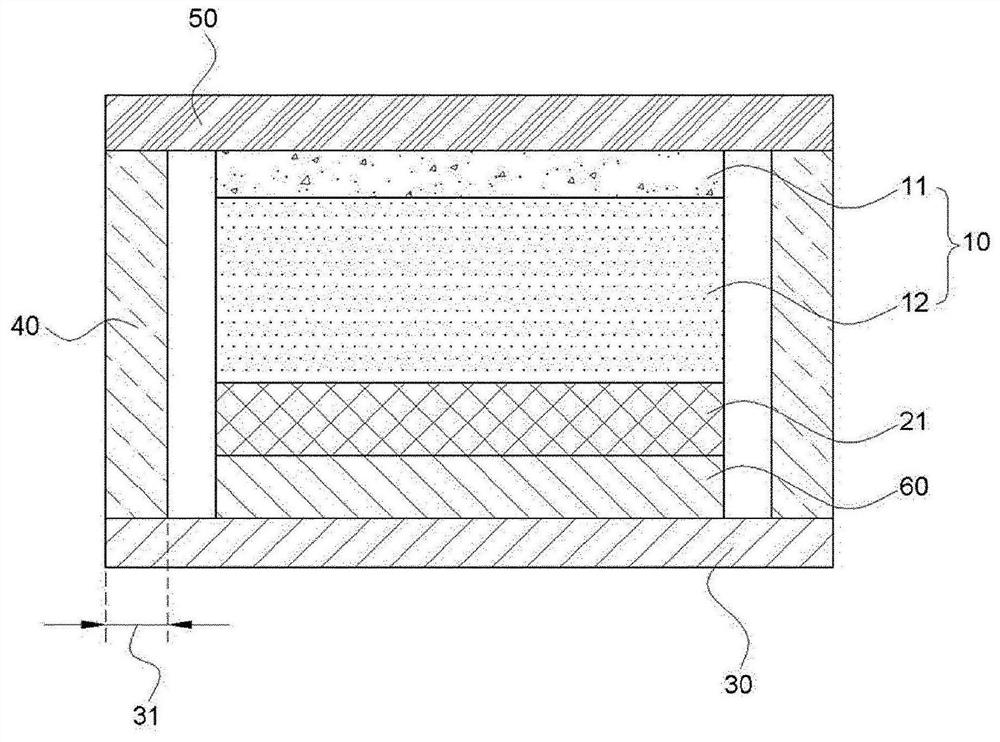

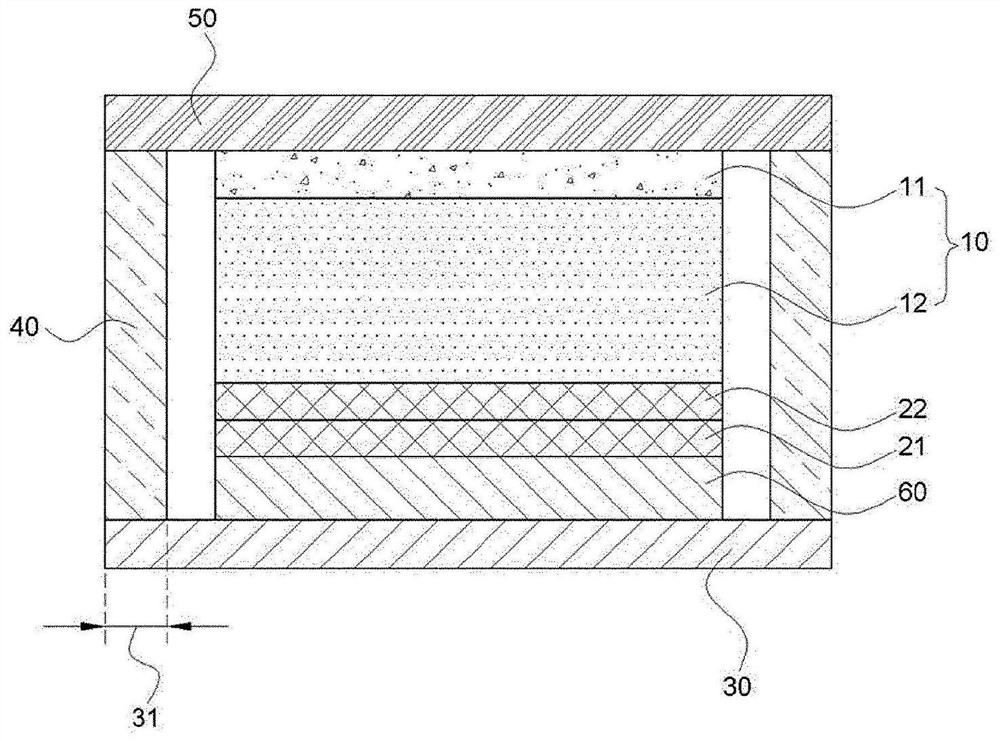

[0033] The present invention will be described in more detail below by a specific example or embodiment, including the drawings. However, the following specific examples or embodiments are intended to illustrate the reference in detail the invention, and the present invention is not limited thereto, and the present invention can be implemented in various forms.

[0034] In addition, unless otherwise defined, all technical terms and scientific terms have the same meanings as generally understood by those skilled in the art of the present invention. In the present invention, the terms used in illustration are only used to efficiently describe specific specific examples, and is not intended to limit the invention.

[0035] In addition, unless clear provisions in the context may be understood in the specification and the singular forms used in the scope of the appended claims.

[0036]In addition, when a part is mentioned "including" a constituent element, unless otherwise stated, oth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com