Carbon nanotube/zinc oxide/micro-expansion graphite composite heat-conducting silicone grease and preparation method thereof

A technology of micro-expanded graphite and thermally conductive silicone grease, which is applied in the field of carbon nanotube/zinc oxide/micro-expanded graphite composite thermally conductive silicone grease and its preparation, and achieves the effects of good compatibility, excellent thermal stability and good interface contact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

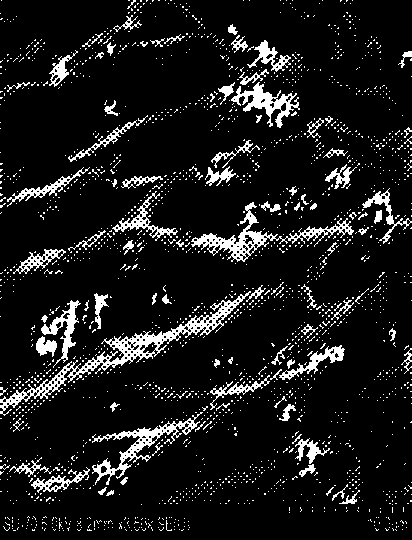

Image

Examples

Embodiment 1

[0037] The present embodiment provides a kind of preparation method of micro-expanded graphite material, comprises the following steps::

[0038] S11. Get the microcrystalline graphite raw material with carbon content of 70% and the flake graphite raw material with carbon content of 85%, the mass ratio of flake graphite and microcrystalline graphite is 2:1, crushing and grinding, until particle size is 300 purpose mixed graphite powder;

[0039] S12. Place the mixture obtained in S11 in a muffle furnace, slowly heat up to 350° C. under a nitrogen atmosphere, keep it warm for 30 minutes, and air-cool to room temperature for use;

[0040] S13. Perform chemical intercalation treatment on the mixture after S12 heat treatment to obtain expandable mixed graphite, wherein the specific steps of chemical intercalation treatment are as follows: S131. Mix perchloric acid and microcrystalline graphite powder at a liquid-solid ratio of 10:1L / Kg mix and stir evenly; S132. Add strong oxidan...

Embodiment 2

[0043] This embodiment provides a method for preparing a carbon nanotube / micro-expanded graphite composite material, comprising the following steps:

[0044]Using the micro-expanded graphite prepared in Example 1 as a raw material, immerse the micro-expanded graphite in a 0.1mol / L ferric nitrate aqueous solution, filter after ultrasonic vibration for 2 hours, then vacuum-dry at 90°C for 10 hours, and place the dried material in In a tube furnace, the temperature was raised to 700°C under a nitrogen atmosphere, and then C2H2 gas was introduced, kept for 40 minutes, and then cooled to room temperature under a nitrogen atmosphere to obtain a carbon nanotube / micro-expanded graphite composite material.

Embodiment 3

[0046] This embodiment provides a method for preparing a carbon nanotube / zinc oxide / micro-expanded graphite composite heat-conducting silicone grease, using the carbon nanotube / micro-expanded graphite composite material in Example 2, and the specific steps are as follows:

[0047] S1. Accurately weigh 35 parts of carbon nanotube / micro-expanded graphite composite material and 5 parts of zinc oxide of 0.5~2um, then mix evenly by high-speed mixer at 1800r / min for 10min, and set aside;

[0048] S2. Take 400 parts of absolute ethanol and put it into the reaction kettle, take 3% coupling agent of thermally conductive filler and add it into the reaction kettle, and stir at a constant temperature of 60°C and 100r / min for 10min to obtain an ethanol solution;

[0049] S3. Add the heat-conducting filler in step S1 into the ethanol solution, stir ultrasonically for 2 hours, and wait until the ethanol is completely evaporated to obtain a modified compound heat-conducting filler;

[0050] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com