A generating method integrating biomass energy heat release and combustion gas

A technology of biomass energy and energy heat, applied in chemical instruments and methods, generators/motors, electrical components, etc., can solve the problem of ineffective use of gas by-products, increased gas production rate and calorific value, and difficult control of moisture, etc. problem, to achieve the effect of simple structure, improved energy utilization rate and small calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

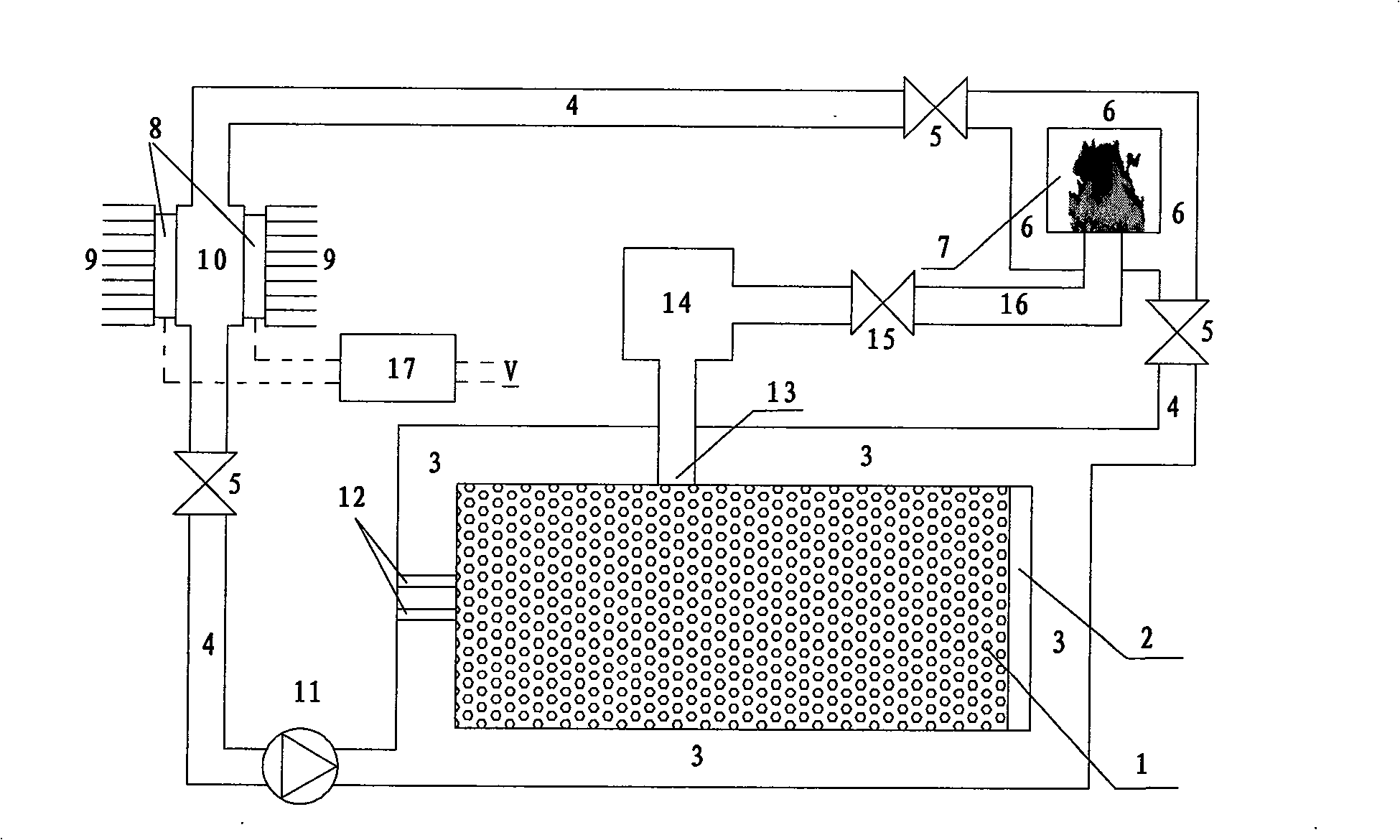

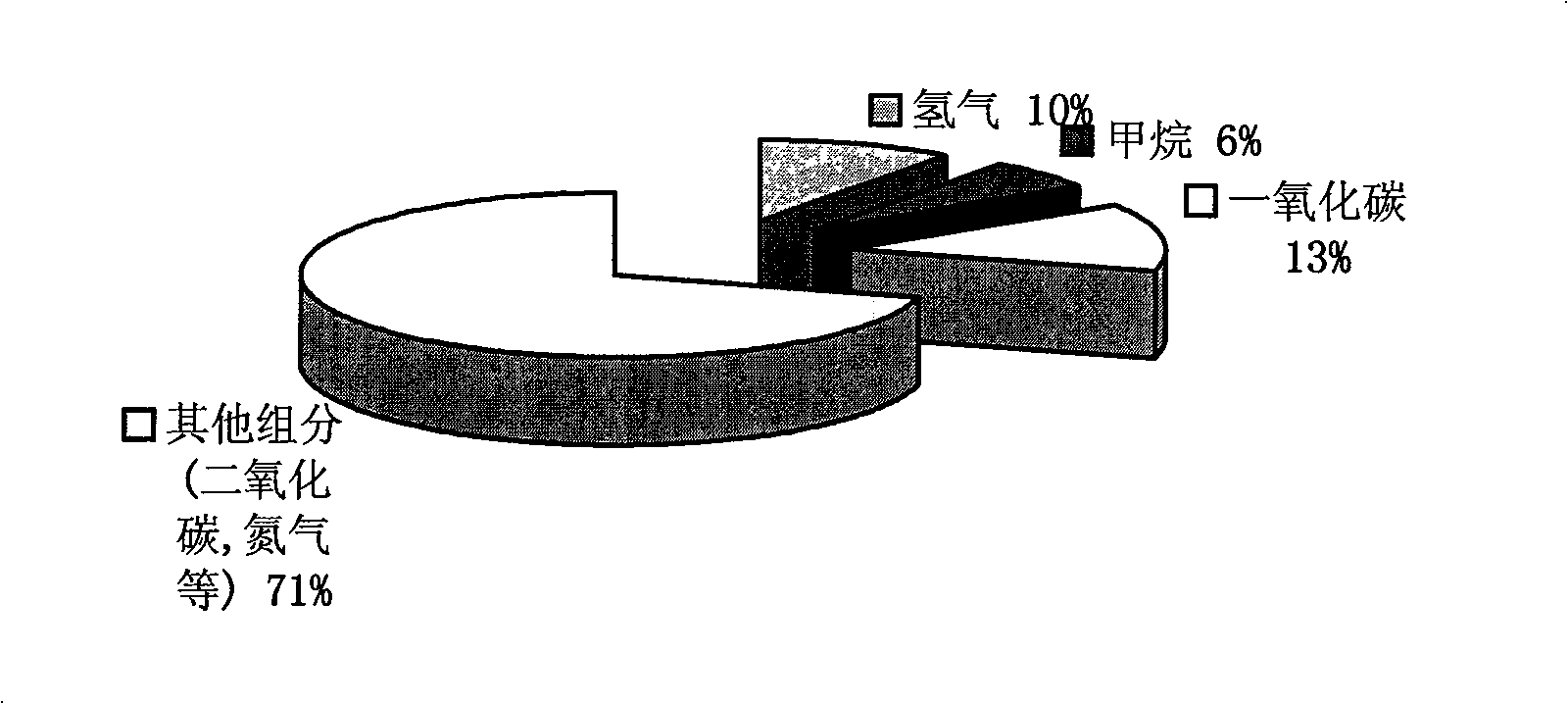

[0014] figure 1 Shown in the figure is a horizontal combustion bed, which adopts a rectangular pool structure, with an air inlet 12 left on one side, and the other side is sealed and equipped with a heating plate 2 to ignite biomass fuel 1. The air holes 13 guide combustible gases rich in H2, CO, CH4, etc. into the gas storage 14, and after the pressure is stabilized, they are transported to the burner 7 through the gas pipeline 16 for combustion and heat release, and the flow rate of the combustible gas is adjusted through the valve 15 .

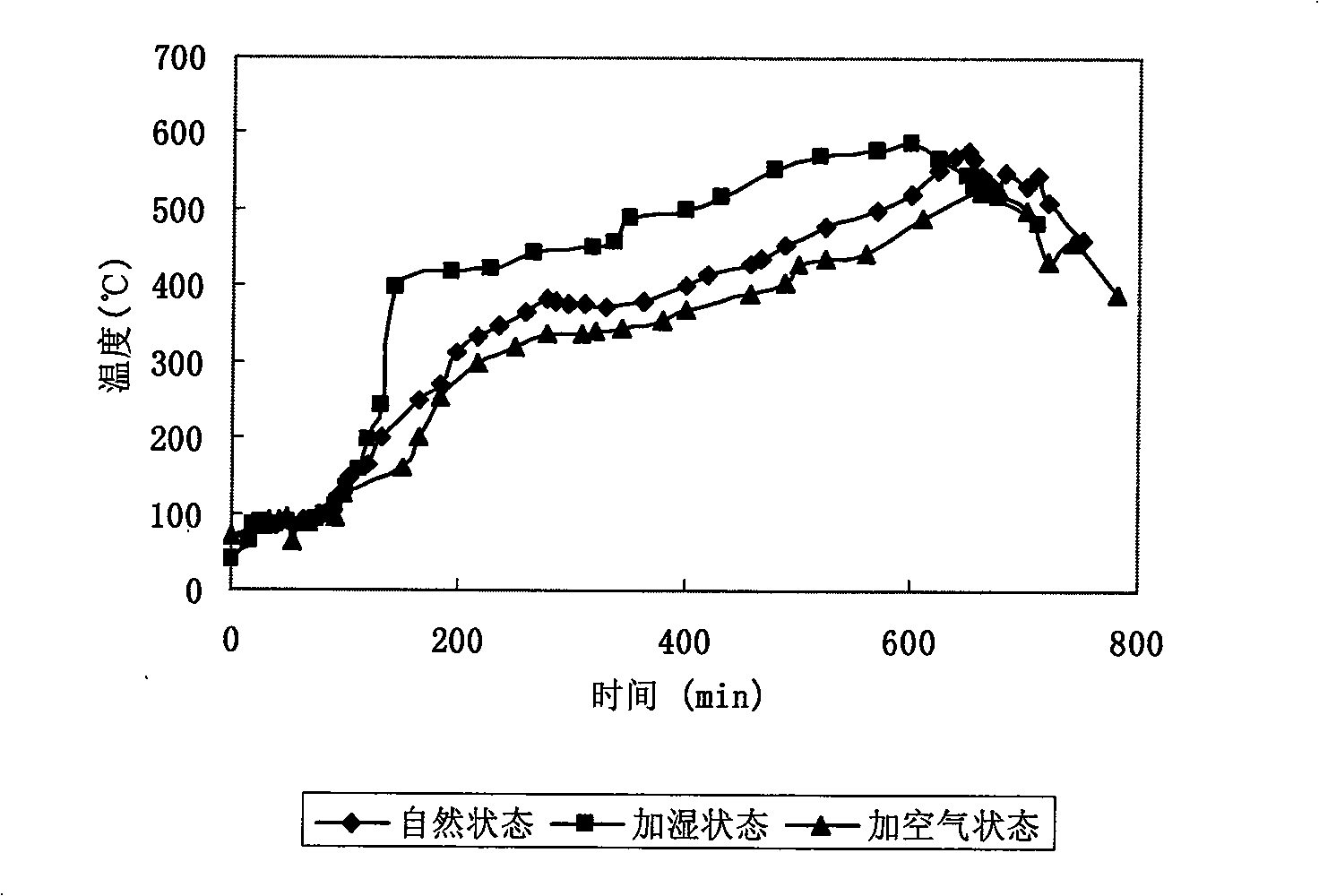

[0015] In this embodiment, sawdust (basswood) is used as biomass fuel 1, and is filled in the horizontal combustion bed in a natural fluffy state. Control the temperature of the heating plate 2 to be stable at about 650°C. After the sawdust spontaneously ignites, stop heating, and the sawdust starts to smolder and self-sustain, releasing heat and generating combustible gases such as H2, CO, CH4. The fuel bed and the burner 7 are equipped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com