Mineral concentration new technique for weak-magnetic iron ore

An iron ore and weak magnetic technology, applied in the field of iron ore beneficiation, can solve the problems of weak magnetic iron ore not being able to be utilized, poor benefit, high investment, etc., achieve good economic value and practicability, good energy saving effect, Good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

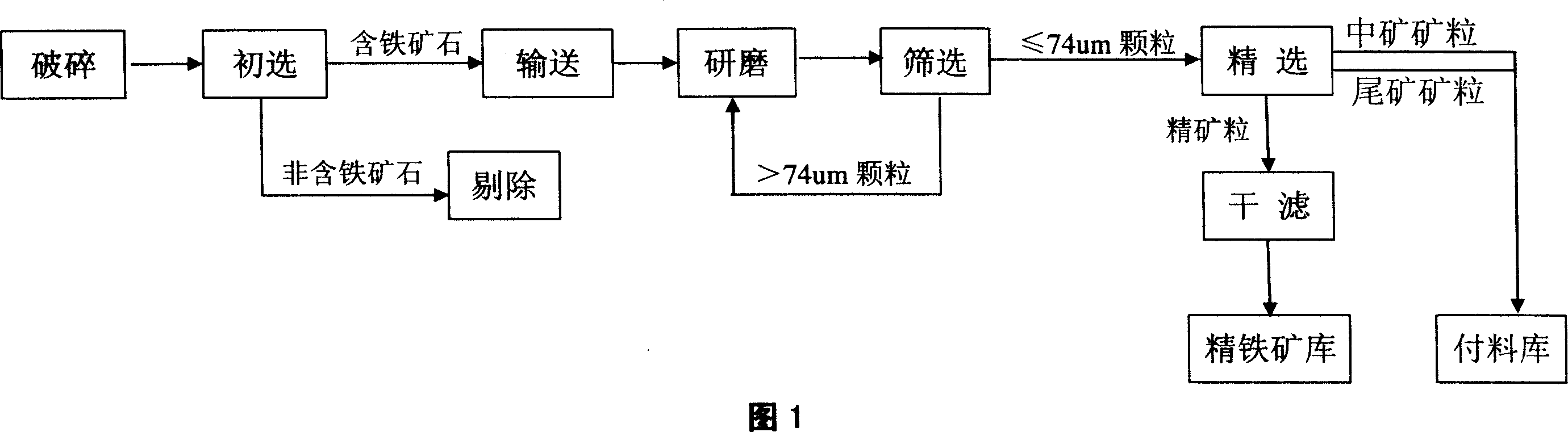

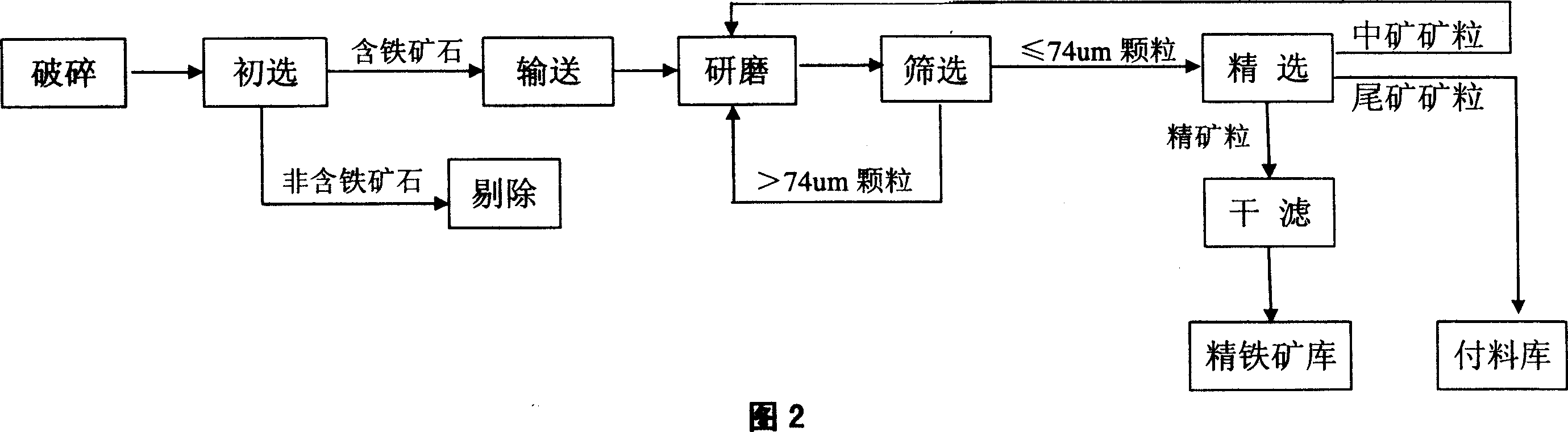

[0019] Fig. 1 is the new beneficiation process of a kind of weak magnetic iron ore of the present invention, and its concrete steps have been described in the summary of the invention, Fig. 2 is embodiment 1 of the present invention, in order to increase benefit, make the fine iron ore product When the iron content reaches ≥55%, the medium ore powder obtained in the beneficiation can be increased and sent back to the additional step of the wet ball mill, so that it can be ground, screened and beneficiated again.

[0020] According to new technology of the present invention, the inventor has carried out industrial test in the hematite producing area of Hebei Province, China, and obtained good effect, and its specific implementation scheme is:

[0021] 1. First use the jaw crusher to crush the raw ore until the particles are less than 20mm, and then enter the impact hammer crusher for crushing, and crush the iron ore particles into particles and powders less than 8mm;

[0022]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com